Method for preparing RE-Mg-Ni-M series hydrogen storage alloy

A hydrogen storage alloy and alloy technology are applied in the field of preparation of RE-Mg-Ni-M hydrogen storage alloys, which can solve the problems of uneven alloy composition and structure, difficulty in realizing large-scale production, and difficulty in controlling composition uniformity. Achieve the effect of uniform Mg composition, easy control of volatilization, and convenient and fast smelting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

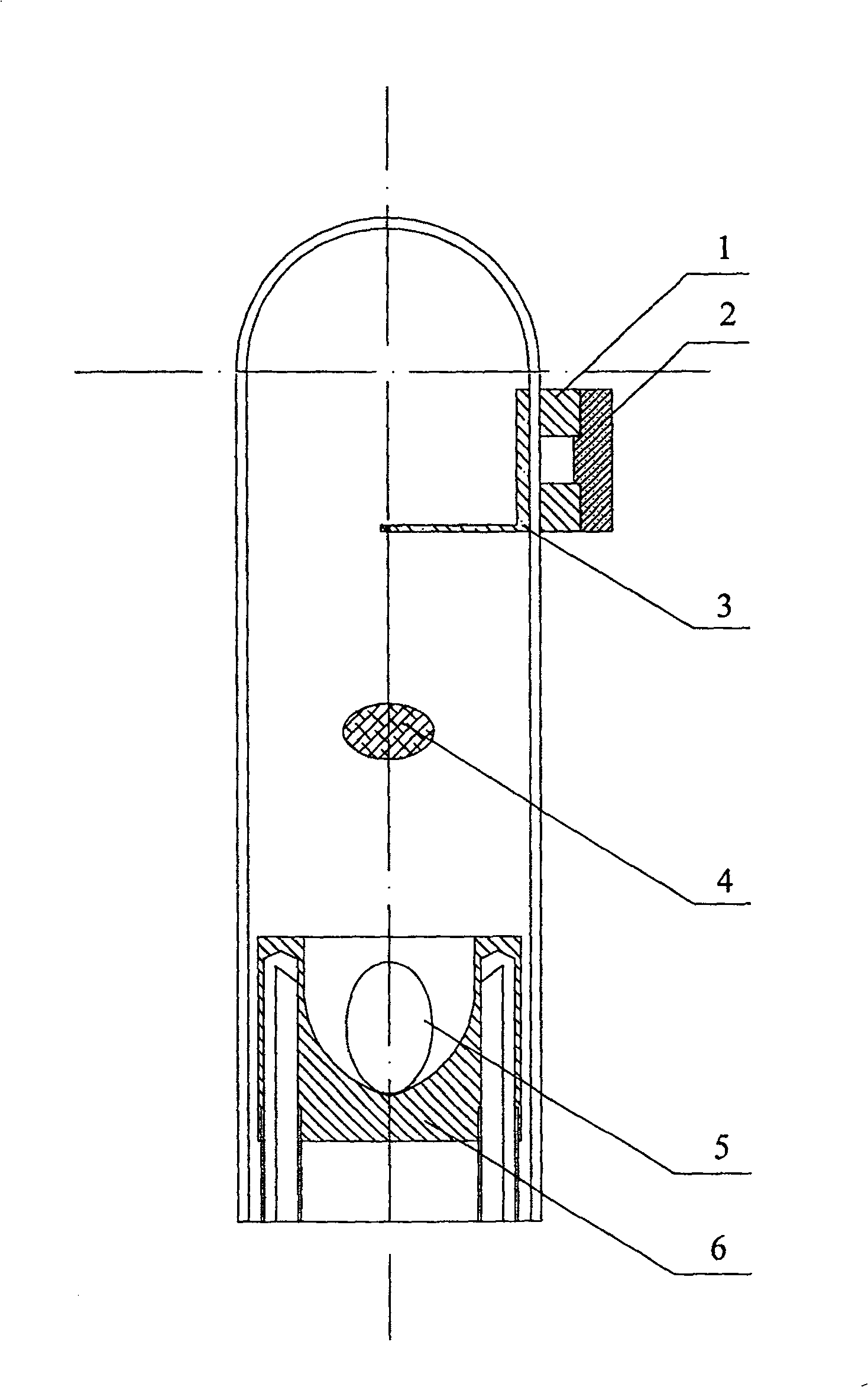

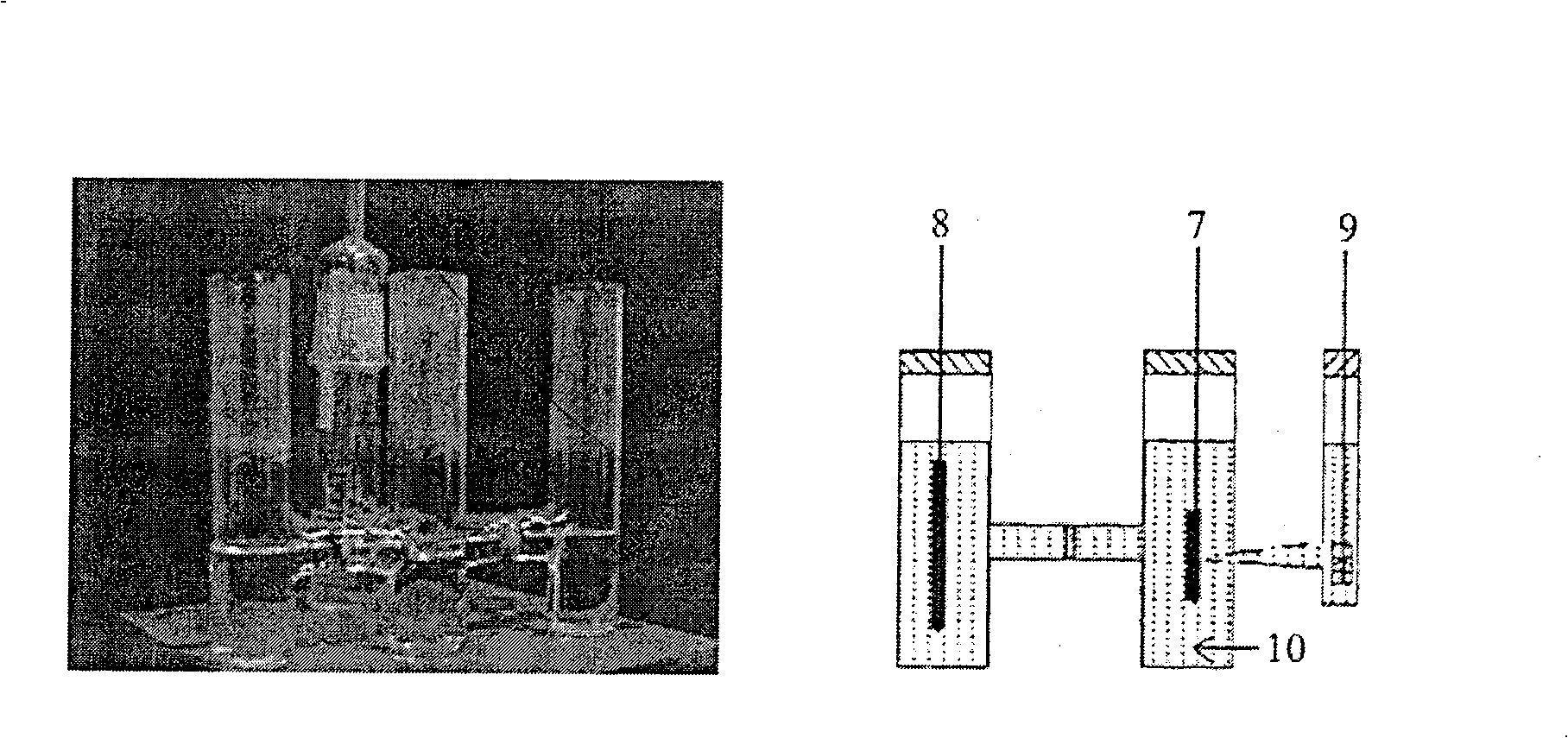

Method used

Image

Examples

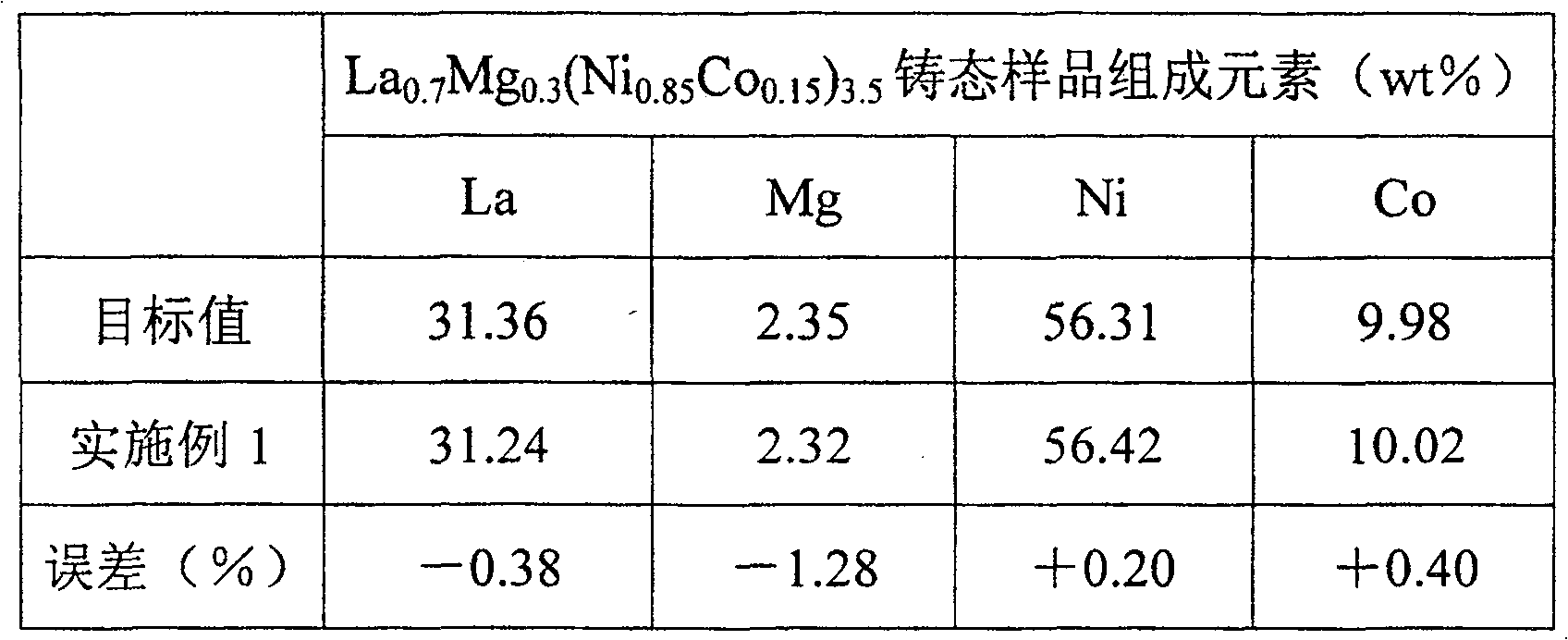

Embodiment 1

[0056] According to the designed composition La 0.7 Mg 0.3 (Ni 0.85 co 0.15 ) 3.5 , prepare La (purity>99.5%), nickel-magnesium master alloy (Mg content 10~20%, Ni+Mg total content>99%), Ni (purity>99.5%), Co (purity>99.5%) altogether 70 grams , where the Mg content is designed to be over 20%. First put Ni and Co into the crucible, vacuumize to 0.1-1Pa, fill with high-purity argon (purity is 99.999%), repeat this 2-3 times, adjust the power of the equipment to 26.1KW for heating, and refine for 1 minute , fully cool down and take out the nickel-cobalt alloy ingot; then put the rare earth metal La into the crucible, evacuate to 0.1-1Pa, fill with high-purity argon, repeat this 2-3 times, and adjust the power of the equipment to 19.2KW Heating, refining for 1 minute, fully cooling and taking out the La ingot; then put the above two ingots together into the crucible, wherein the nickel-cobalt alloy ingot is placed at the bottom of the crucible, vacuumize to 0.1-1Pa, and fill...

Embodiment 2

[0060] According to the designed composition La 0.7 Mg 0.3 (Ni 0.79 co 0.15 Al 0.06 ) 3.4 , prepare La (purity > 99.5%), nickel-magnesium master alloy (Mg content 10-20%, Ni+Mg total content > 99%), Ni (purity > 99.5%), Co (purity > 99.5%), Al ( Purity > 99.5%) totals 70 grams, wherein the Mg content is designed to exceed 20%. The smelting and preparation process was the same as in Example 1, and an as-cast La-Mg-Ni-Co-Al hydrogen storage alloy sample was obtained. Using the ICP-AES method to measure the content of each component element in the alloy (as shown in Table 2), the error is within ±4.0%, and the error of the Mg content is -3.67%, which can meet the requirements of the electrochemical performance test for the alloy composition. Electrochemical performance tests show that the maximum discharge capacity of the as-cast alloy sample reaches 367.9mAh / g, which is higher than that of the traditional RE-Ni system AB 5 Type hydrogen storage alloys are 10-20% higher. ...

Embodiment 3

[0064] The design components are the same as in Example 1, wherein the Mg content is designed to be in excess of 30%. The as-cast sample preparation process is the same as in Example 1. Take part of the as-cast alloy sample, wrap it with nickel tape and put it in an alumina ceramic crucible (60mm×20 / 30mm×15mm), put it into a muffle furnace together, and spread a layer of RE-Ni powder around it As an oxygen-absorbing agent, under the protection of an industrial-grade argon (purity of 99.99%, slightly positive pressure) atmosphere, heat treatment at 900 ° C for 8 hours, and then cool down with the furnace to obtain a heat-treated sample of La-Mg-Ni-Co hydrogen storage alloy. The Mg element content in the sample was determined by ICP-AES method (as shown in Table 3), and the error was -2.13%, which can meet the requirements of the electrochemical performance test on the alloy composition. The electrochemical performance test shows that the maximum discharge capacity of the heat-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com