Hard nanometer layered ZrO2/TiN coating

A nano-multilayer and coating technology is applied to the surface of cutting tool materials with ceramic coating, ceramic coating, which can solve the problem that the shear modulus difference is not large enough, fails to meet the necessary conditions of nano-multilayer and coating, Can not form superhard effect coherent interface and other problems, to achieve the effect of large application value and excellent high temperature oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

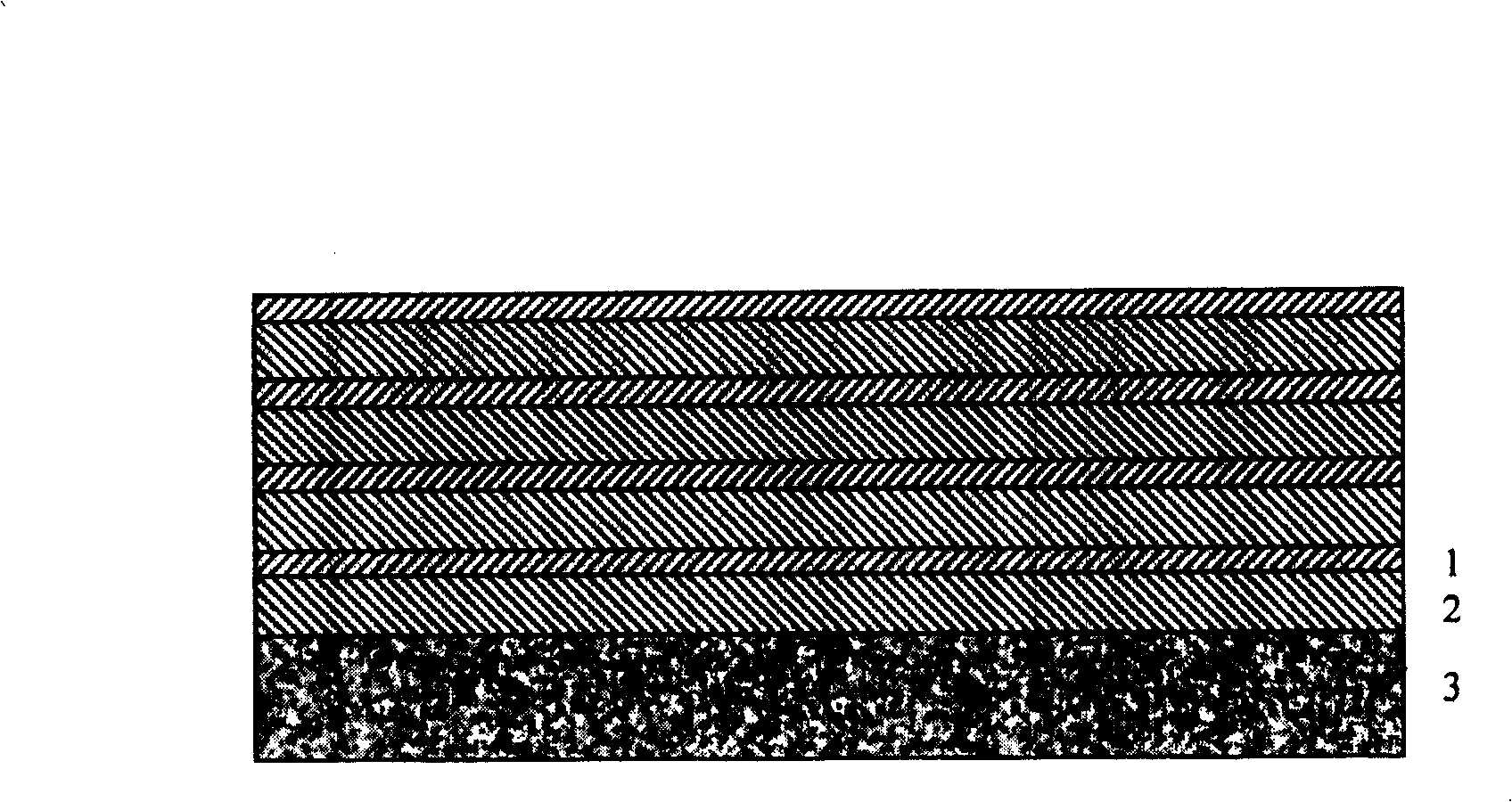

Image

Examples

example 1

[0017] The present invention ZrO 2 The specific process parameters of the preparation method of the / TiN multilayer coating are: the partial pressure of Ar gas is 3.2×10 -1 Pa, ZrO 2 The sputtering power of the target is 150W, the deposition time is 9 seconds, the power of the TiN target is 50W, the deposition time is 1 second, the total sputtering time is 2h, and the substrate temperature is 2 / ZrO in TiN multilayer coating 2 The layer thickness is 4.4 nm, the TiN layer thickness is 0.4 nm, and the total thickness is 2 μm. The hardness of the coating was 19.6 GPa.

example 2

[0019] The present invention ZrO 2 The specific process parameters of the preparation method of the / TiN multilayer coating are: the partial pressure of Ar gas is 3.2×10 -1 Pa, ZrO 2 The sputtering power of the target is 150W, the deposition time is 9 seconds, the power of the TiN target is 50W, the deposition time is 2 seconds, the total sputtering time is 2h, and the substrate temperature is 2 / ZrO in TiN multilayer coating 2 The layer thickness is 4.4 nm, the TiN layer thickness is 0.8 nm, and the total thickness is 2 μm. The hardness of the coating was 23 GPa.

example 3

[0021] The present invention ZrO 2 The specific process parameters of the preparation method of the / TiN multilayer coating are: the partial pressure of Ar gas is 3.2×10 -1 Pa, ZrO 2 The sputtering power of the target is 150W, the deposition time is 9 seconds, the power of the TiN target is 50W, the deposition time is 1 second, the total sputtering time is 3.5h, and the substrate temperature is 2 The thickness of the ZrO2 layer in the / TiN multilayer coating is 4.4nm, the thickness of the TiN layer is 1.2nm, and the total thickness is 3.5μm. The hardness of the coating was 21 GPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com