Foamed aluminum carried titanium dioxide catalyst, its preparation method and uses

A technology of titanium dioxide and aluminum foam, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of inability to decompose organic compounds, little adsorption capacity, harmful to human body, etc., and achieve reliable preparation methods , Simple recycling and convenient source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] About the preparation of catalyst, be to carry out as follows:

[0037] a. Preparation of nano-TiO 2 Dispersion solution, or doped nano TiO 2 dispersion solution, or TiO 2 Colloidal solution, or doped TiO 2 Colloidal solution;

[0038] b. Select a foamed aluminum matrix, the porosity of the foamed aluminum matrix is 10%-95%, and the pore diameter is 10nm-5mm;

[0039] c. Using the solution soaking method, soak the foamed aluminum in the dispersion solution or colloid solution described in step a, take it out after 1 hour, and dry it naturally in the air to obtain nano-TiO 2 , or doped nano-TiO 2 , or TiO 2 colloid, or doped TiO 2 Colloidal aluminum foam;

[0040] D, aftertreatment, the loaded nano-TiO that step c makes 2 , or doped nano-TiO 2 , or TiO 2 colloid, or doped TiO 2 The colloidal aluminum foam is annealed at 100-1000°C for 1-2 hours under the protection of inert gas.

[0041] About the application of the catalyst in the present embodiment in the ...

example 1

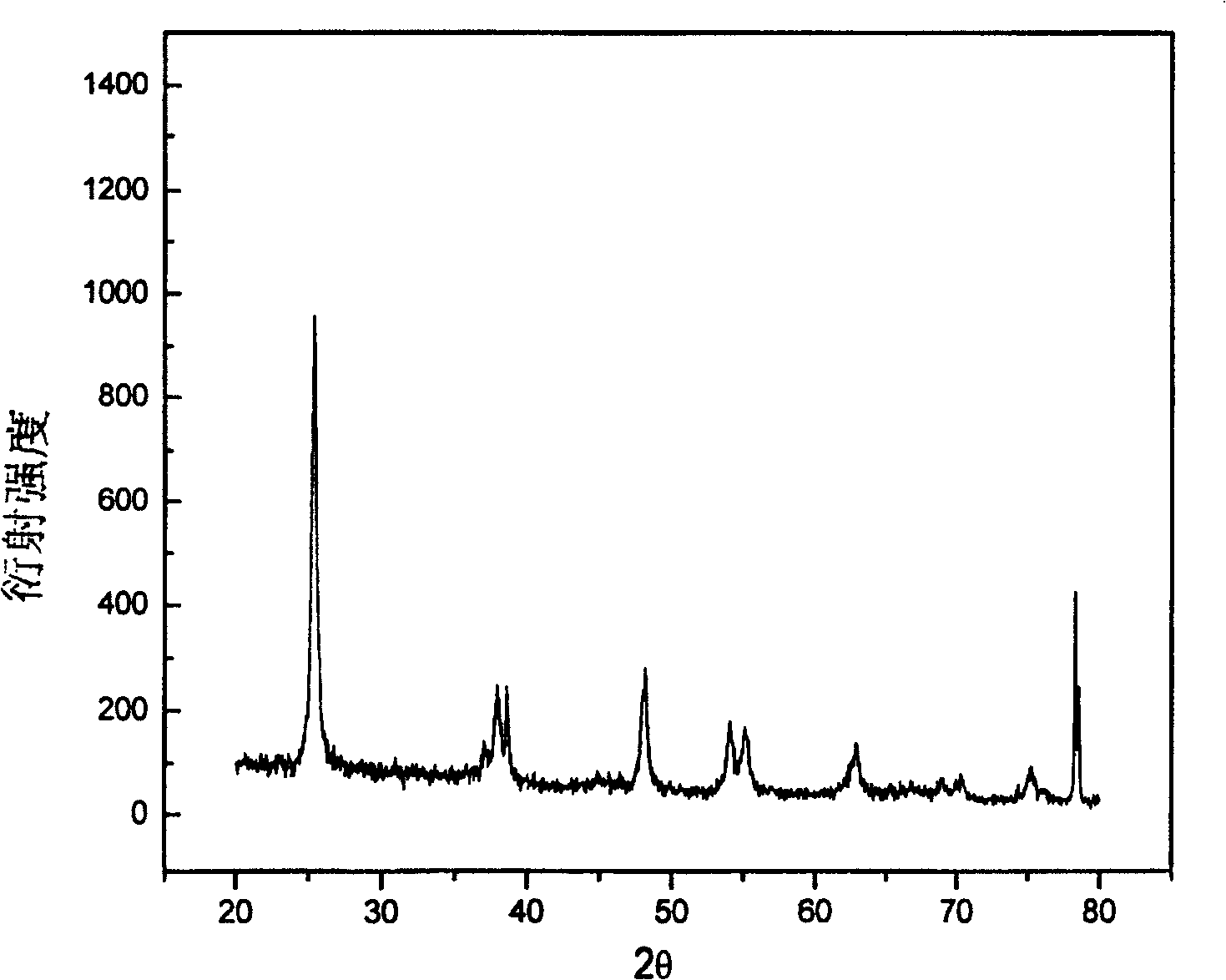

[0050] Example 1: TiO 2 Preparation of nanoparticles:

[0051] Take 20ml of tetrabutyl titanate and dissolve it in ethanol solvent; add a few drops of hydrochloric acid after mixing 30mL of distilled water and 30ml of ethanol to make the pH value 1-5, and add 0.2% by weight of surfactant polyethylene glycol to it. Alcohol, heated to 60°C; then slowly drop the ethanol solution of tetrabutyl titanate into the ethanol aqueous solution, and vigorously stir, and cool naturally after the dropwise addition. TiO formed by hydrolysis 2 Precipitation and filtration, drying at 80°C to obtain TiO 2 powder, and then annealed at 200-700°C to obtain TiO 2 nanoparticles.

example 2

[0052] Example 2: Fe 3+ Compound doped nano TiO 2 Preparation of granules:

[0053] Take 20ml of tetrabutyl titanate and dissolve it in an ethanol solvent, add an appropriate amount of trimethoxyiron to it, the molar ratio of trimethoxyiron to tetrabutyl titanate is 0.5%; another take after mixing 30ml of distilled water and 30ml of ethanol Add a few drops of hydrochloric acid to make the pH value 8-13, and add 0.2% by weight surfactant polyethylene glycol to the solution, and heat to 60°C; then slowly drop the ethanol solution of tetrabutyl titanate and heat the ethanol aqueous solution in, and vigorously stirred, and cooled naturally after the dropwise addition. TiO formed by hydrolysis 2 Precipitation and filtration, drying at 80°C to obtain TiO 2 Powder, then annealed at 200-700°C to obtain Fe 3+ compound doped TiO 2 nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com