Production of magnesium-based hydrogen-storage material under equalized strong magnetic field and its producer

A technology of hydrogen storage material and strong magnetic field, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as restricting practical application and making little breakthrough in low-temperature hydrogen storage and release performance of magnesium-based alloys, saving energy and time, Easy to operate, safe and simple effect of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] According to hydrogen storage alloy Mg 2 Weigh the metal powders in the amount determined by the Ni chemical composition, mix them and place them in ethanol, perform ultrasonic vibration to disperse them to make them fully mixed, and then dry them naturally; press the above mixture into a shape, maintain the pressure for 10-20 minutes, and then It is mechanically broken into granules smaller than 2mm; the above-mentioned granules are placed in a high-temperature and high-pressure reactor, and the vacuum reaches 2.00×10 -3 After Pa, inert gas or hydrogen with a purity of ≥99.9% is introduced, and the pressure is maintained at 1.0 MPa for 10 minutes. The reaction kettle is placed in a constant-strength magnetic field of 2-14T, slowly heated at a heating rate of 5-20°C / min, heated to 500°C, kept for 180min, and then cooled to room temperature to obtain a hydrogen storage alloy. Mg is prepared under different intensities of applied uniform and constant magnetic fields 2 Ni. Mea...

Embodiment 2

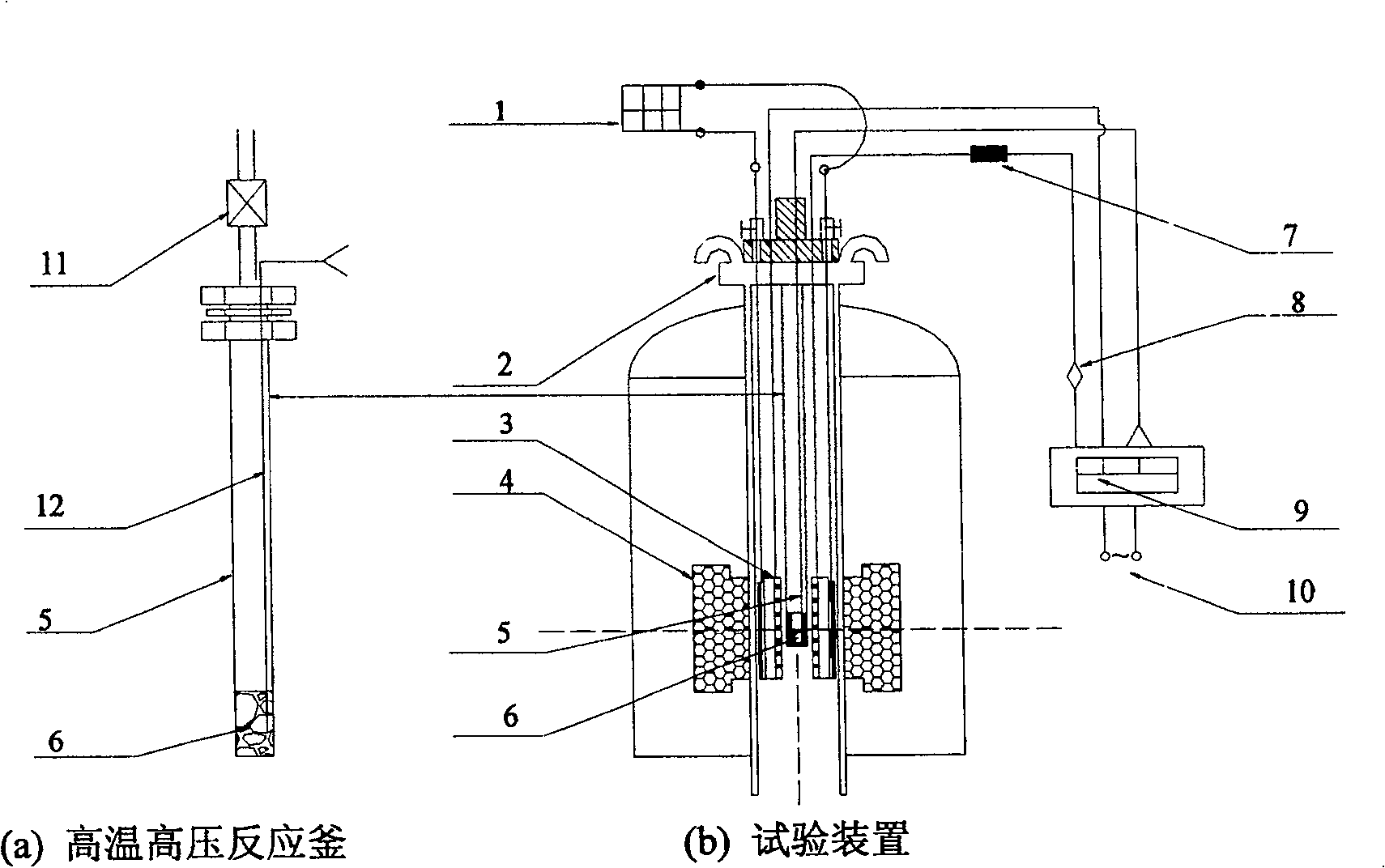

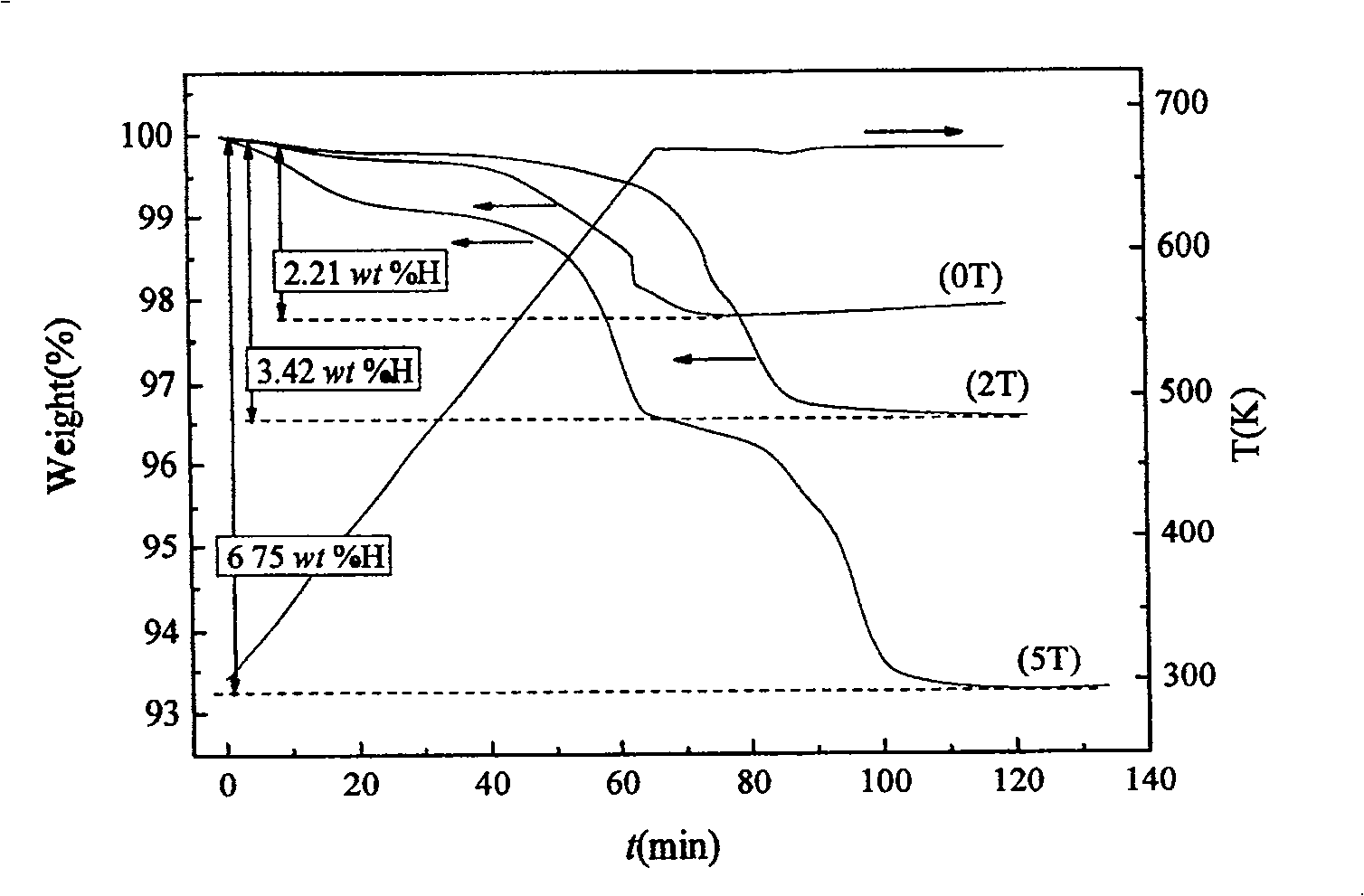

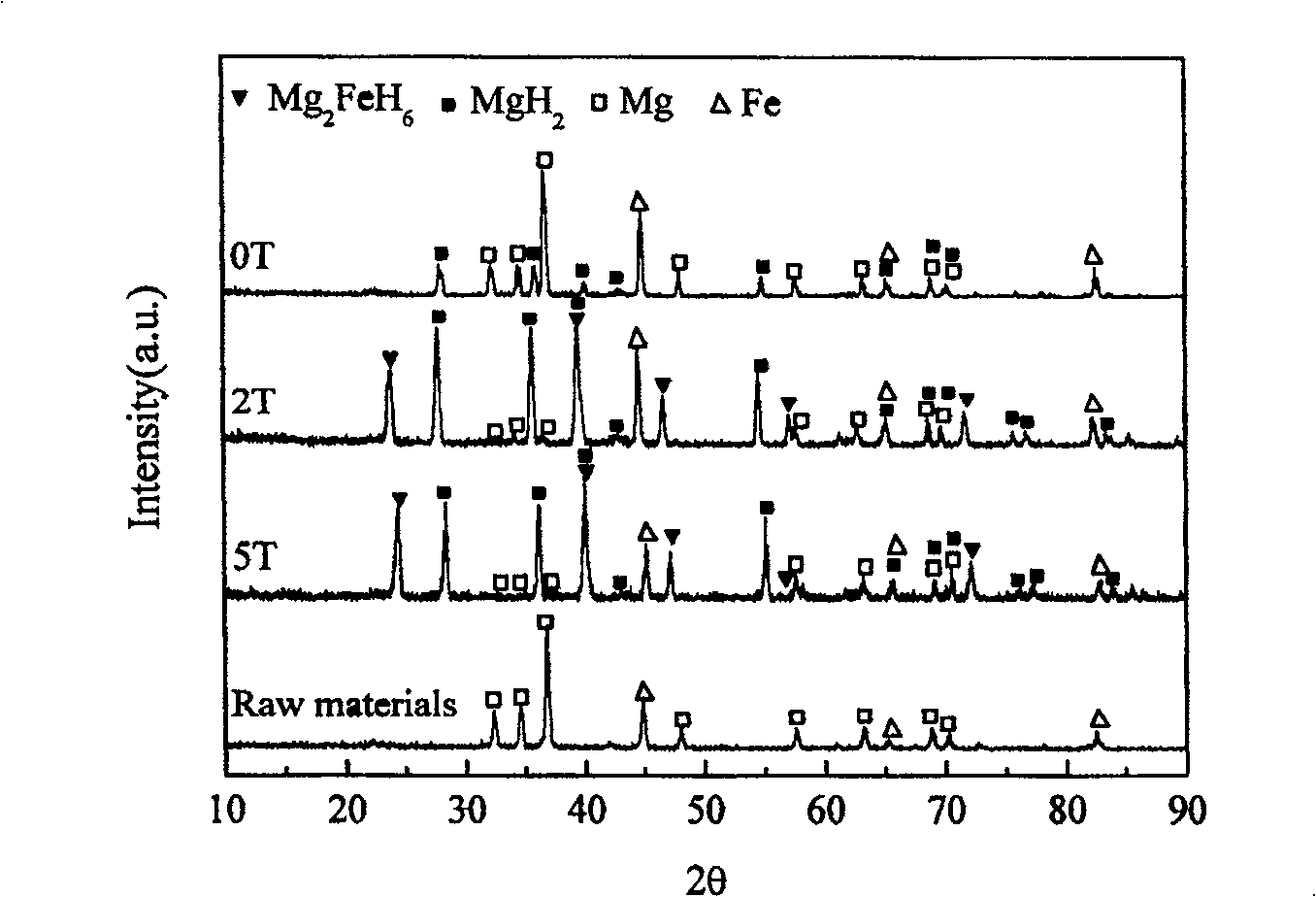

[0031] According to chemical composition Mg 2 Weigh each metal powder with the amount determined by Fe, mix it and place it in acetone, perform high-frequency ultrasonic vibration and dispersion to make it fully mixed, and then dry it naturally; press the above mixture into a shape, hold the pressure for 20 minutes, and then mechanically crush it Into small particles smaller than 2mm; put the above-mentioned crushed particles in an autoclave and vacuum up to 2.00×10 -3 After Pa, inert gas or hydrogen with a purity of ≥99.9% is introduced, and the pressure is maintained at 7.0MPa for 20 minutes. The reaction kettle is placed in a constant-strength magnetic field of 2-5T, slowly heated at a heating rate of 5-20℃ / min, heated to 650℃, kept for 240min, and then cooled to room temperature to obtain a hydrogen storage alloy. Mg can be prepared by adopting the present invention 2 FeH 6 Hydrogen storage materials. figure 2 It is the TG diagram of Mg-Fe-H ternary system materials prepared ...

Embodiment 3

[0035] First, LaNi is made by electric arc furnace smelting 25 Binary alloy, crushed to 400 mesh under the protection of argon, vacuum sealed and packaged. Then follow Mg-4mol% LaNi 25 The stoichiometric ingredients are mixed and placed in isoacetone. The mixture is fully mixed by high-frequency ultrasonic vibration and dispersion, and then dried naturally; the above-mentioned mixture is pressed into a shape with a pressure holding time of 60min, and then it is mechanically broken into a size less than 2mm Crumbs; put the above crumbs in an autoclave, and vacuum up to 2.00×10 -5 After Pa, inert gas or hydrogen with a purity of ≥99.99% is introduced, and the pressure is maintained at 5.0MPa for 30 minutes. The reaction kettle is placed in a 10T uniformly strong magnetic field, slowly heated at a temperature increase rate of 5-20°C / min, heated to 600°C, held for 300 minutes, and then cooled to room temperature to obtain a magnesium-based composite hydrogen storage alloy. Test its PC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com