Tantalum titanate cadmium sulphide platinum-carried laminated composite catalyst and its preparation method

A platinum catalyst, cadmium sulfide technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc. Improved photocorrosion ability, improved crystallinity, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

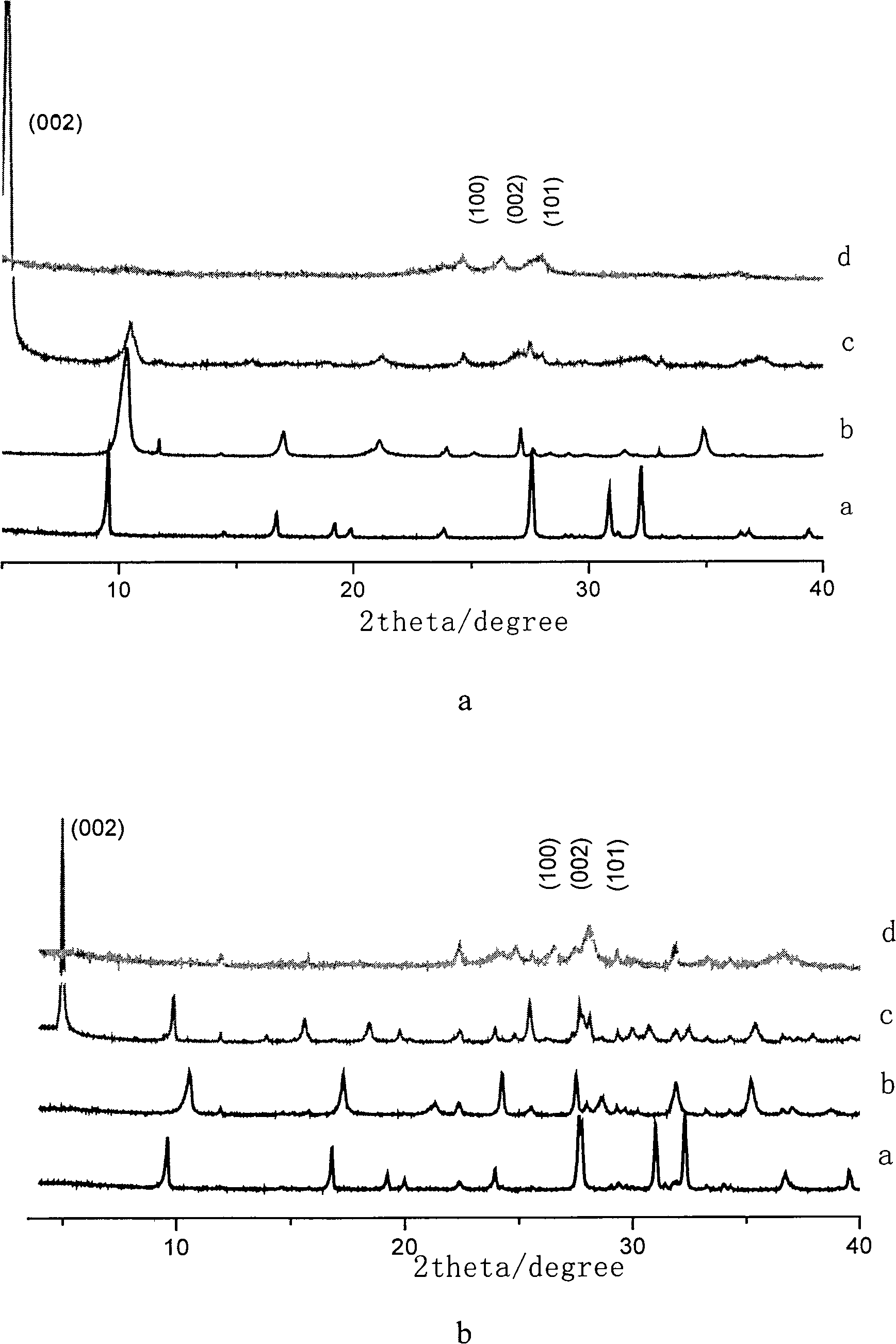

[0049] 1) Potassium carbonate K 2 CO 3 , titanium dioxide TiO 2 and Tantalum Oxide 2 o 5 Mixed according to the stoichiometric ratio, wherein an excess of K is added 2 CO 3 , whose molar weight is 10%, calcined at 700°C for 1 hour, ground for 1-2 hours and then calcined at 1000°C for 12 hours to obtain potassium titanium tantalate KTiTaO 5 ;

[0050] 2) 10g potassium titanium tantalate KTiTaO 5 Place in 250ml of nitric acid with a concentration of 2mol / L, stir at room temperature for 2 days, wash the product with deionized water after ion exchange, until the pH of the washing residue is 5, and dry it at 80°C to obtain a layered matrix tantalum titanium Acid HTiTaO 5 ;

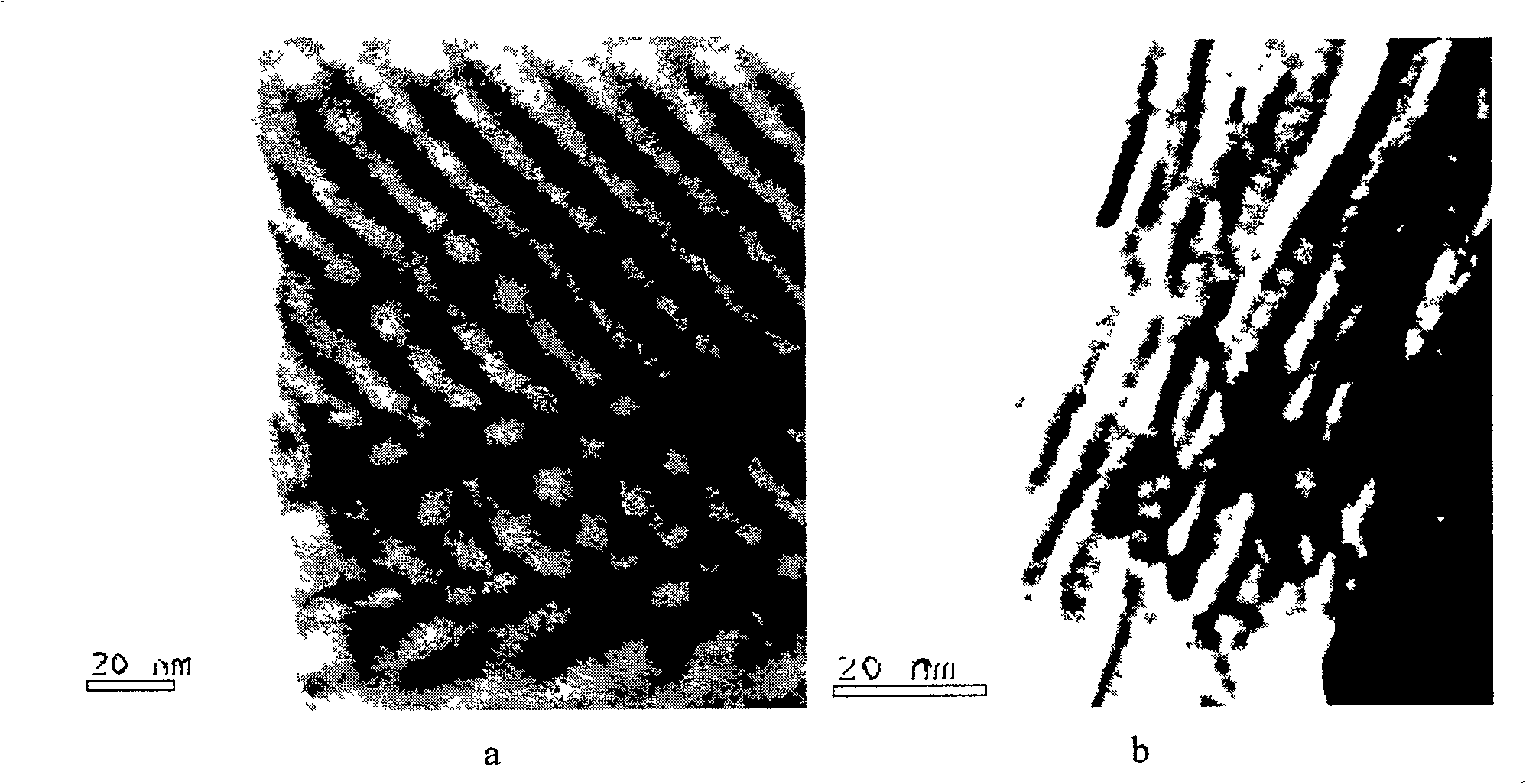

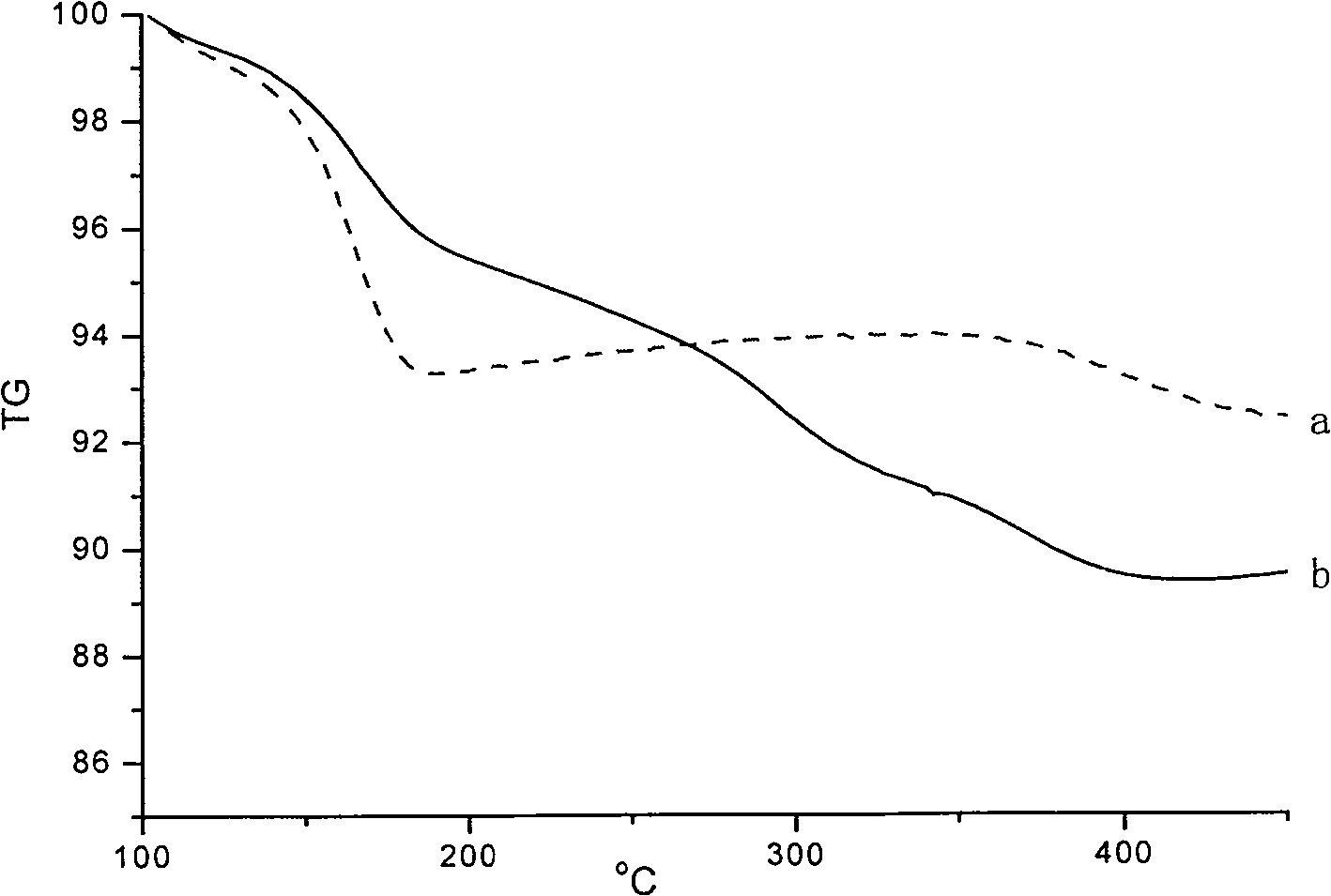

[0051] 3) 5g tantalum titanate HTiTaO 5 Place in 250ml of propylamine aqueous solution, volume ratio 1:1, reflux and stir at 40°C for 2 days to obtain propylamine pillars of layered matrix; place 5g of propylamine pillars of layered matrix in 250ml saturated cadmium acetate solution, 50°C Reflux and ...

Embodiment 2

[0055] 1) Potassium carbonate K 2 CO 3 , titanium dioxide TiO 2 and Tantalum Oxide 2 o 5 Mix according to the stoichiometric ratio, wherein an excess of potassium carbonate K is added 2 CO 3 , whose molar weight is 15%, calcined at 800°C for 1 hour, ground for 1 hour and then calcined at 1100°C for 24 hours to obtain potassium titanium tantalate KTiTaO 5 ;

[0056] 2) 10g potassium titanium tantalate KTiTaO 5 Place in 250ml of nitric acid with a concentration of 4mol / L, stir at room temperature for 2 days, wash the obtained product with deionized water after ion exchange, until the pH of the washing residue is 6, and dry at 90°C to obtain a layered matrix tantalum titanium Acid HTiTaO 5 ;

[0057] 3) 5g tantalum titanate HTiTaO 5 Place in 250ml of propylamine aqueous solution, volume ratio 1:1, reflux and stir at 50°C for 2 days to obtain propylamine pillars of layered matrix; place 5g of propylamine pillars of layered matrix in 250ml saturated cadmium acetate soluti...

Embodiment 3

[0061] 1) Potassium carbonate K 2 CO 3 , titanium dioxide TiO 2 and Tantalum Oxide 2 o 5 Mixed according to the stoichiometric ratio, wherein an excess of K is added 2 CO 3 , whose molar weight is 25%, calcined at 900°C for 2 hours, ground for 2 hours and then calcined at 1150°C for 24 hours to obtain potassium titanium tantalate KTiTaO 5 ;

[0062] 2) 10g potassium titanium tantalate KTiTaO 5 Place in 250ml of nitric acid with a concentration of 5mol / L, stir at room temperature for 3 days, wash the product with deionized water after ion exchange, until the pH of the washing residue is 7, and dry at 100°C to obtain a layered matrix tantalum titanium Acid HTiTaO 5 ;

[0063] 3) 5g tantalum titanate HTiTaO 5 Place in 250ml propylamine aqueous solution, volume ratio 1: 1, reflux and stir at 60°C for 3 days to obtain the propylamine pillars of the layered matrix; place 5g of the propylamine pillars of the layered matrix in 250ml saturated cadmium acetate solution, 70°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quantum efficiency | aaaaa | aaaaa |

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com