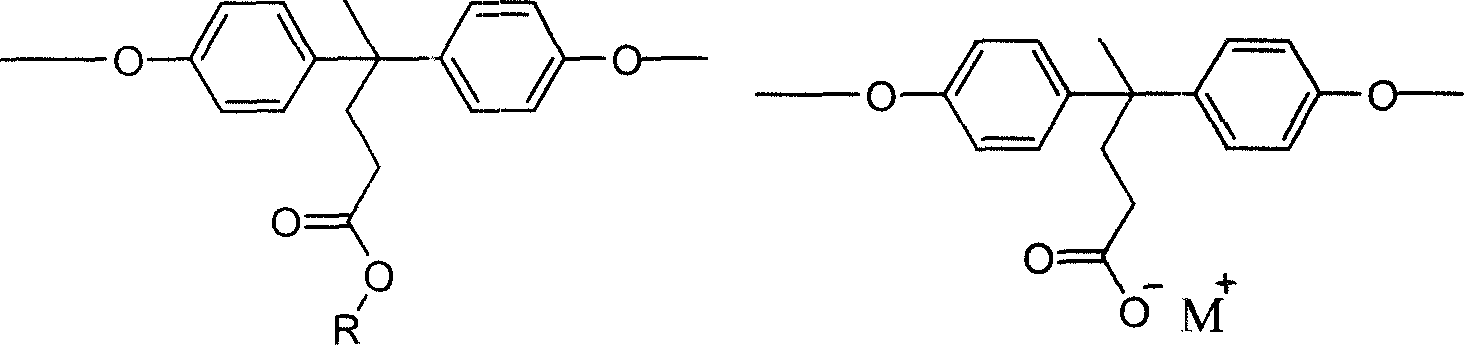

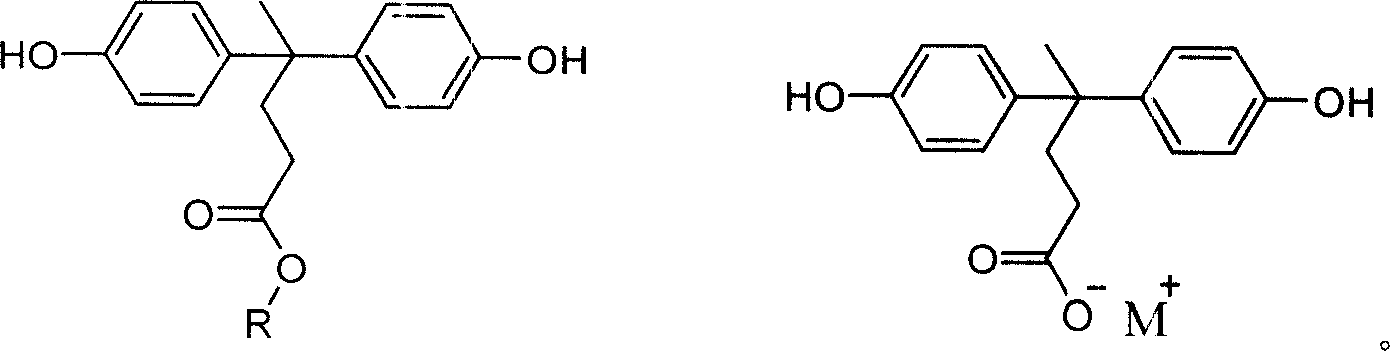

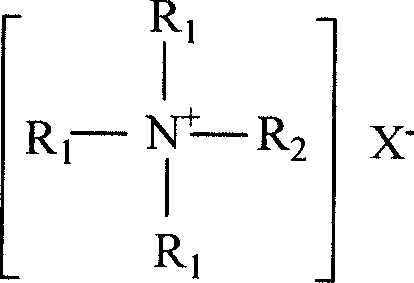

Copoaromatic ether and preparation thereof

A technology of copolyarylate and bisphenolic acid ester, which is applied in the field of copolyarylate and its preparation, copolyarylate of bisphenolic acid or its derivative structural unit and its preparation, can solve the problems of heat resistance reduction, etc., and achieve The effect of short polymerization time, fast polymerization rate, and expanded application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] In the preparation method of copolyarylate provided by the present invention, the reaction time is short under the normal temperature of the polymerization, and the copolyarylate with pendant carboxyl, carboxylate or carboxylate functional group can be obtained within 2 hours. The yield can reach more than 90%.

[0031] The intrinsic viscosity of the polymer is measured by Ubbelohde viscometer at a concentration of 0.5g / dl at 30°C, and the solvent is H 2 SO 4 4.76% by volume phenol / tetrachloroethane (3:2, w / w).

Embodiment 1

[0040] In the three-port reactor, bisphenolic acid (DPA, 0.01mol, 2.863g), NaOH (0.03mol, 1.2g), 90ml deionized water, stirred to completely dissolve the bisphenolic acid, constant temperature at 25°C, quickly add m-benzene Diformyl chloride / terephthaloyl chloride (IPC / TPC=3:7, 0.01mol, 2.03g) in 50ml of dichloromethane was stirred at 400rpm and reacted for 1 hour. After the reaction, add dilute HCl solution to adjust the pH of the solution to about 3, then wash with deionized water and acetone, filter, and dry under vacuum at 100° C. for 12 hours. The yield of the obtained copolyarylate was 56.7%, and the reduced viscosity was 0.558dl / g.

Embodiment 2

[0042] In the three-port reactor, bisphenolic acid (DPA, 0.01mol, 2.863g), NaOH (0.03mol, 1.2g), deionized water 90ml, phase transfer catalyst tetrabutylammonium chloride (TBAC, 0.117g, 4mol%) / [DPA]), stirring, to completely dissolve the bisphenolic acid, at a constant temperature of 25°C, quickly add 50ml of isophthaloyl chloride / terephthaloyl chloride (IPC / TPC=3:7, 0.01mol, 2.03g) The methyl chloride solution was stirred at a speed of 400 rpm, and reacted for 1 hour. After the reaction, dilute HCl solution was added to adjust the pH of the solution to about 3, then washed with deionized water and acetone, filtered and dried in vacuum at 100° C. for 12 hours. The yield of the obtained copolyarylate was 89.8%, and the reduced viscosity was 0.827dl / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com