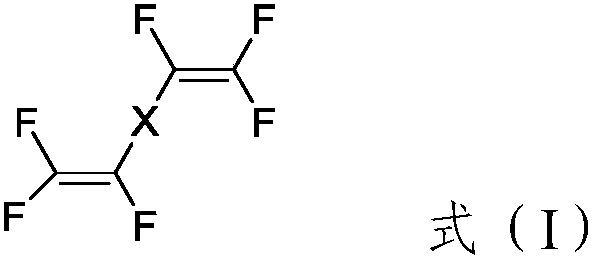

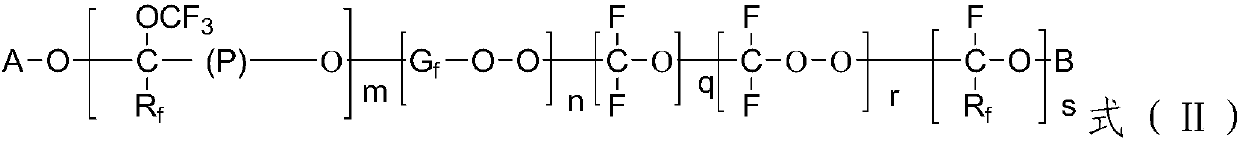

Aqueous fluorine-containing dispersion solution as well as preparation method and application thereof

A dispersion liquid, water-based technology, applied in the field of water-based fluorine-containing dispersion liquid and its preparation, can solve the problems of inability to form firmness, slow reaction, direct termination of reaction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] A preparation method of an aqueous fluorine-containing dispersion liquid, comprising the steps of:

[0090] (1) In the 10L stainless steel reactor with agitator, add 5.0kg deionized water, 100g mass concentration is the aqueous solution of 10% perfluorocarboxylate polyether ammonium salt, extract the air in the reactor with vacuum pump, then Replace with nitrogen, repeat nitrogen filling and evacuation and degassing until the oxygen content reaches below 30ppm, and then replace with the reaction monomer until the oxygen content in the reactor drops below 30ppm. Then start stirring, raise the temperature to 80° C., and add VDF / TFE / HFP (75 / 10 / 15 mol%) mixed monomers into the reactor through a compressor until the pressure of the reactor reaches 2.0 MPa. After the temperature and pressure are stabilized, add 30g of perfluorobutadiene and 100g of K with a mass concentration of 10% through a metering pump 2 S 2 o 8 aqueous solution to start the reaction. The reacted mono...

Embodiment 2

[0095]According to the method of embodiment 1, change step (1) fluorine-containing monomer to be VDF / TFE / CTFE (80 / 10 / 10, mol%), the reaction time is 2.2h, the solid content that obtains fluorine-containing seed polymer emulsion is 47.1%, the particle size is 122nm, and the calculated latex particle concentration is 2.75×1014 (piece / 1g emulsion).

[0096] Step (2) According to the method of Example 1, an aqueous fluorine-containing dispersion liquid with a solid content of 44.9%, an average particle diameter of 151 nm, and a mechanical stability of 352 s was obtained.

[0097] Using the same performance measurement method as in Example 1, it was detected that the light transmittance of the paint film prepared from the dispersion was 93.8%, the tensile strength was 12.3 MPa, and the elongation at break was 510%.

Embodiment 3

[0099] According to the method of embodiment 1, change step (1) perfluorobutadiene to 50g perfluoroethylene propylene ether, other unchanged, reaction time is 2.6h, the solid content that obtains fluorine-containing seed polymer emulsion is 46.3%, grain The diameter is 102nm, calculated to be 4.63×1014 (unit / 1g emulsion).

[0100] Step (2) According to the method of Example 1, an aqueous fluorine-containing dispersion liquid with a solid content of 43.9%, an average particle diameter of 121 nm and a mechanical stability of 392 s was obtained.

[0101] Using the same performance measurement method as in Example 1, it was detected that the light transmittance of the paint film prepared from the dispersion was 95.4%, the tensile strength was 10.3 MPa, and the elongation at break was 580%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com