Preparation method of substituted diaryl phosphate

A technology of aryl phosphate and diaryl, which is applied in the field of preparation of substituted diaryl phosphate salts, and achieves the effects of favorable equipment utilization, friendly operation environment, and easy and convenient recovery of solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

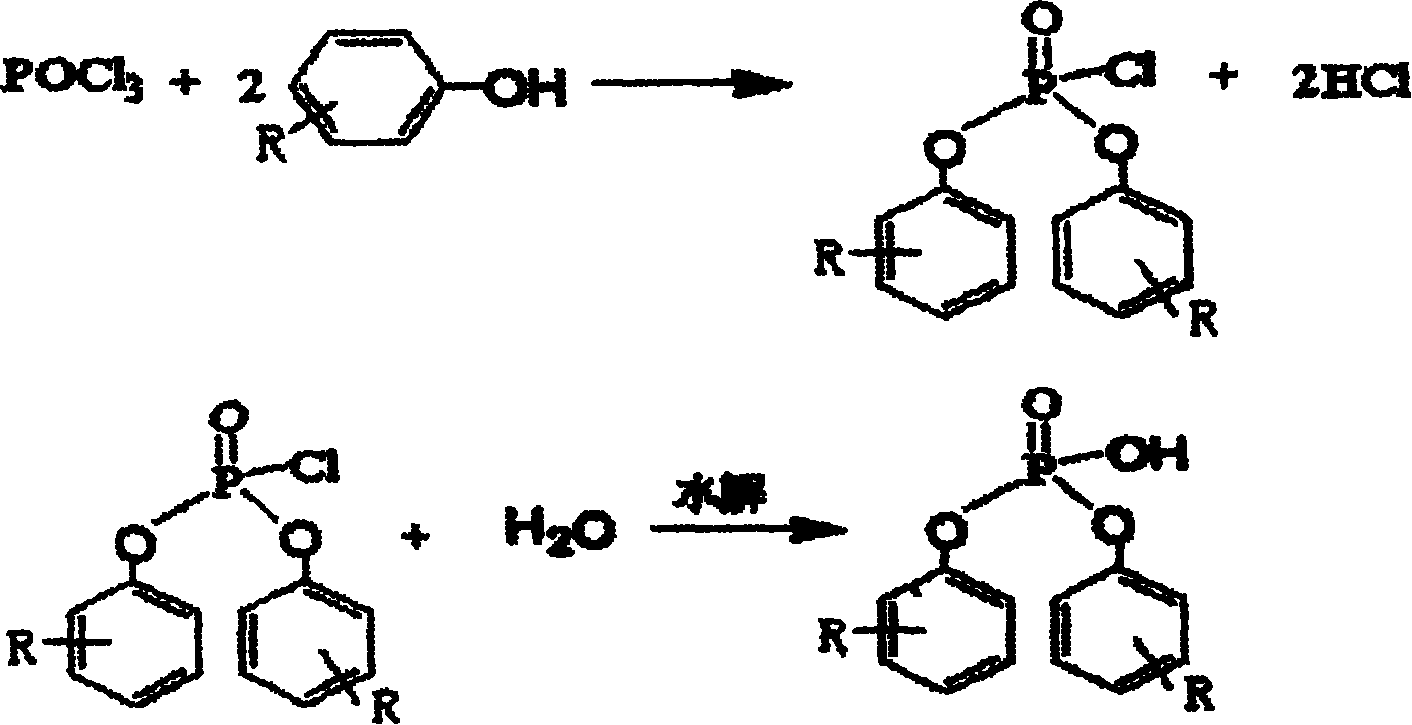

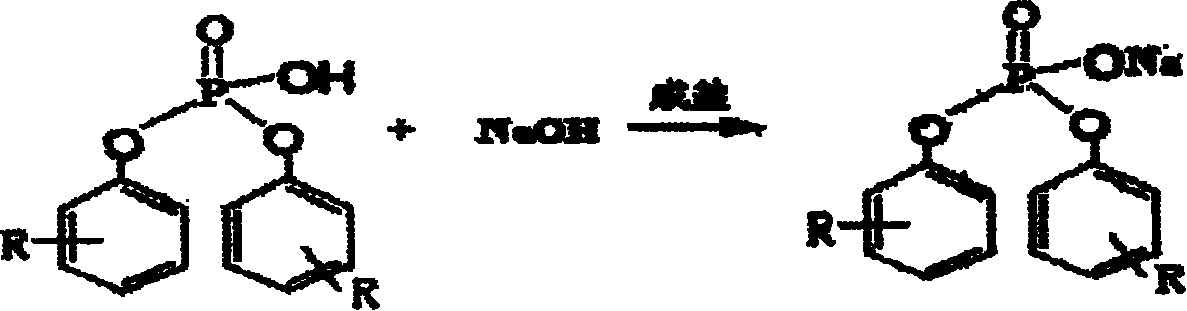

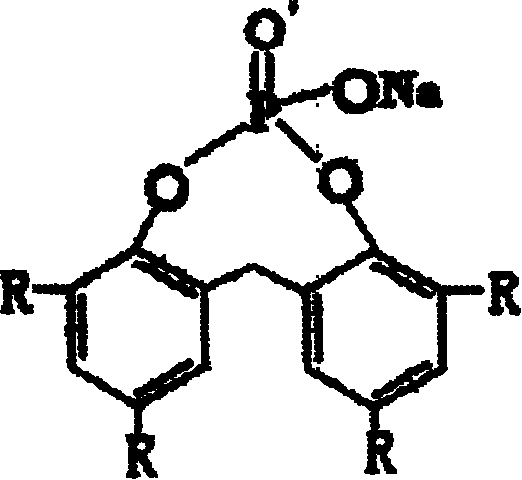

Method used

Image

Examples

Embodiment 1

[0030] Add 15 grams of p-tert-butylphenol (0.1mol), 4 grams of sodium hydroxide, and 100 mL of cyclohexane into a four-necked flask with a stirrer, water separator and condenser, and reflux at 80°C for 2 hours . Cool to normal temperature, add 9.2ml of phosphorus oxychloride slowly dropwise with constant pressure dropping funnel, and finish dropping in about 30 minutes. Then the temperature was raised to 80° C. under a silicone oil bath and heated to reflux and stirred for 3 hours. Then lower the temperature to 75° C. and maintain this temperature, add 30% by mass of sodium hydroxide aqueous solution, adjust the pH to 12, and stir for 4 hours. The system becomes a white extrudate mixed material. The purification operation is to drain the product with Buchner funnel, wash with water and then with cyclohexane. After vacuum drying, a white solid fine powder of di-p-tert-butyl phosphate sodium salt was obtained, which was weighed. The melting point of the product was greater th...

Embodiment 2

[0032] Add 20.6 g (0.1 mol) of 2,4-di-tert-butylphenol, 4 g of sodium hydroxide, and 100 mL of cyclohexane into a four-necked flask with a stirrer, a water separator, and a condenser. Condensate at reflux for 2 hours. Cool to normal temperature, add 9.2ml of phosphorus oxychloride with constant pressure dropping funnel, slowly add dropwise, about more than 25 minutes to finish dropping. Then the temperature was raised and stirred under reflux under 80° C. silicone oil bath for 3 hours. Then, an aqueous solution of 30% by mass of sodium hydroxide was added dropwise at 75° C. to adjust the pH value to about 12, and stirred under reflux for about 4 hours. The purification operation is to drain the product with Buchner funnel, wash with water and then with cyclohexane. After vacuum drying, a white solid fine powder of di-2,4-di-tert-butylphenyl phosphate sodium salt was obtained, which was weighed. The melting point of the product was greater than 300°C, and the yield was 86% ba...

Embodiment 3

[0034] Add 21.2g (0.05mol) of 2,2'-methylene bis(4,6-di-tert-butylphenol) in a four-necked flask with a stirrer, a water separator and a condenser tube, and 2 grams of hydroxide Sodium, 2mL triphenyl phosphite, add 100mL petroleum ether and heat to reflux temperature (about 80°C), reflux for 3 hours; cool to normal temperature, add 4.8ml phosphorus oxychloride with constant pressure dropping funnel, slowly drop, About more than 30 minutes to drop. Maintain the temperature in the reaction bottle, and react for 5 hours; add dropwise an aqueous solution of 30% by mass of sodium hydroxide, adjust the pH value to about 12, and stir for about 3 hours under reflux. The resulting solution was suction filtered to remove the solvent, then washed with water and petroleum ether several times, and dried in vacuo to obtain a white powder, sodium salt of 2,2-methylenebis(4,6-di-tert-butylphenyl)phosphate, with a melting point of Greater than 300°C. Based on phenol, the yield is 82%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com