Chemic homogeneous coprecipitation method for preparing precursor body of permanent magnetic material of terrae rare cobalt

A technology of permanent magnet materials and precursors, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problem of small particle size of rare earth permanent magnet powder, and achieve complete grain structure, precise chemical ratio, and excellent magnetic properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

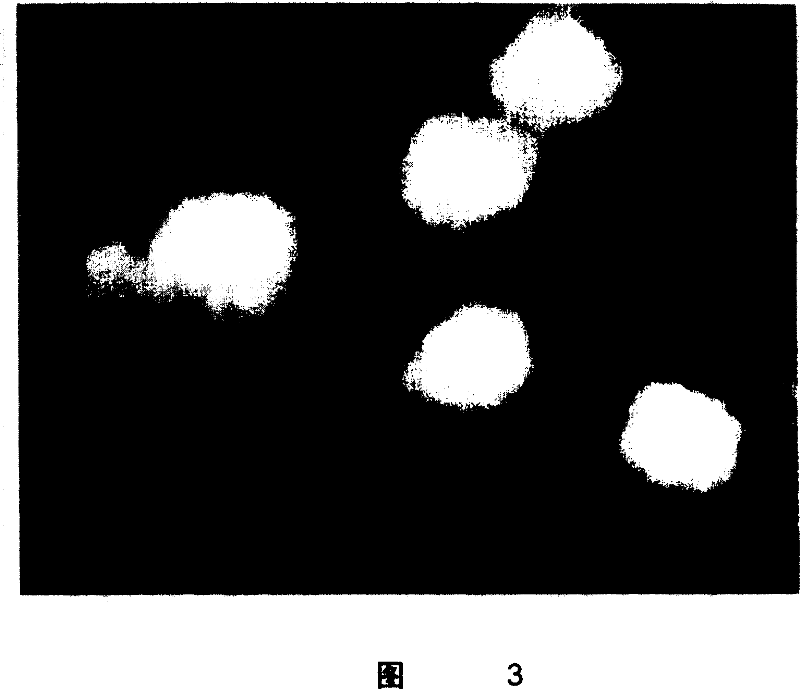

[0031] Take 1.0mol / L CoCl 2 solution and 0.2mol / L SmCl 3 Each solution is 500ml, mixed at room temperature, heated to 28-32°C to adjust pH=2.0; then take 1.0mol / L NH 4 HCO 3 Solution 1.0L, heated to 28-32°C to adjust pH = 9.5; fast feed in parallel flow, feed speed control is based on pH adjustment between 6.5-7.0. After the feeding is completed, the temperature is raised to about 60° C. and aged for 1.5 hours. During the aging process, NaOH and HCl are used to adjust the pH range to 6.5-7.0, and the stirring speed is controlled at 200 rpm during the feeding and aging process. After aging, filter and wash the powder with hot water until the anions cannot be detected. After drying, samarium-cobalt basic carbonate precursor powder was obtained, the weight was 16.5g, the cobalt-samarium molar ratio was 5:1, X-Ray showed that it was amorphous, the powder particle size was between 0.2-20 μm, and the average particle size was 5 μm Left and right, the shape is spherical or spher...

Embodiment 2

[0034] Take 0.1mol / L CoCl 2 solution and 0.02mol / L SmCl 3 Each solution is 500ml, mixed at room temperature, heated to 28-32°C, adjusted to pH=20; then take 0.1mol / L NH 4 HCO 3 Solution 1.0L, heated to 28-32°C, and adjusted to pH = 9.5; quickly fed in parallel flow, and the feeding speed was controlled so that the pH of the reaction mixture was between 6.5 and 7.0. After the feeding is completed, the temperature is raised to about 60°C for aging for 1.5 hours, and the stirring speed is controlled to 300 rpm. During the aging process, the pH is controlled to be 6.5-7.0, and the pH value is adjusted with NaOH and HCl, and the stirring speed is controlled at 200 rpm during the feeding and aging process. After aging, filter and wash the powder with hot water until the anions cannot be detected. After drying, 1.55 g of samarium cobalt basic carbonate precursor powder was obtained.

[0035] The obtained samarium cobalt basic carbonate precursor powder was heated in CO 2 Atmosp...

Embodiment 3

[0037] Take lmol / L of CoCl 2 solution and 0.2mol / L of PrCl 3 Each solution is 500ml, mixed at room temperature, heated to 28~32°C to adjust pH=2.0; then take 1mol / L NH 4 HCO 3 Solution 1L, heated to 28~32°C to adjust pH=9.5, fast feeding in parallel flow, feeding speed control is based on pH adjustment between 6.5~7.0. After the feeding is completed, the temperature is raised to about 60° C. and aged for 1.5 hours. During the aging process, the pH is controlled at 6.5~7.0, and the pH value is adjusted with NaOH and HCl. After completion, filter and wash the powder with hot water until the anions cannot be detected. After drying, 17.3 g of praseodymium cobalt basic carbonate precursor powder was obtained. The obtained praseodymium cobalt basic carbonate precursor powder was calcined at 700°C for 5 hours in an Ar atmosphere to obtain 12.7g of oxide powder (a mixture of praseodymium oxide and cobalt oxide) for reduction and diffusion in a vacuum or protective atmosphere tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com