Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Will not cause uneven force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

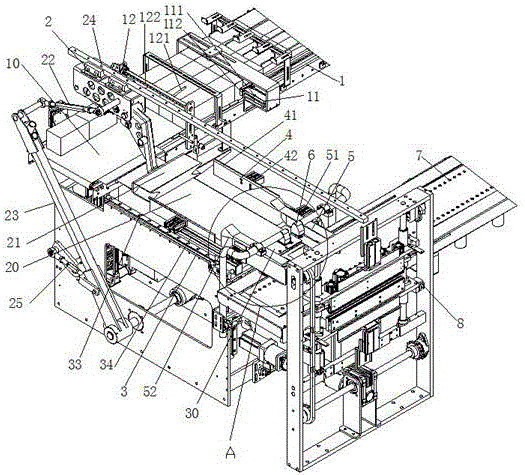

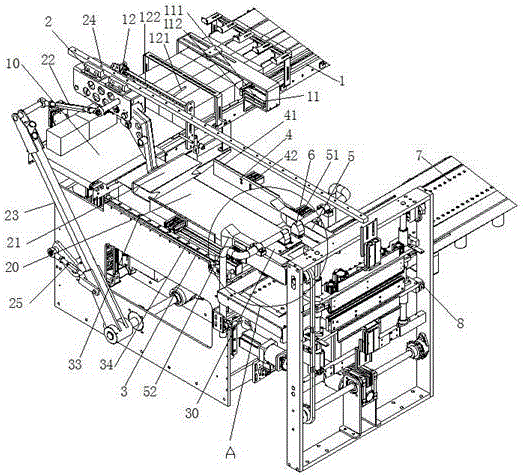

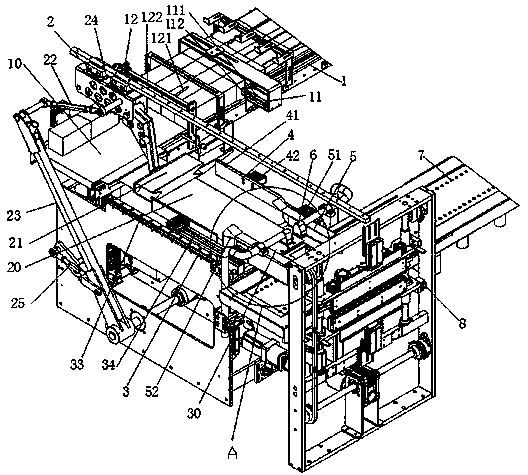

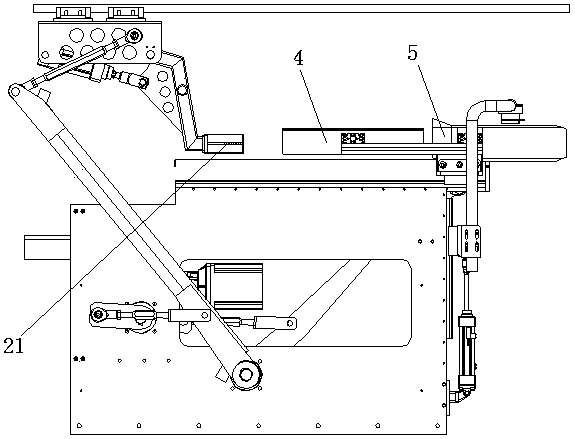

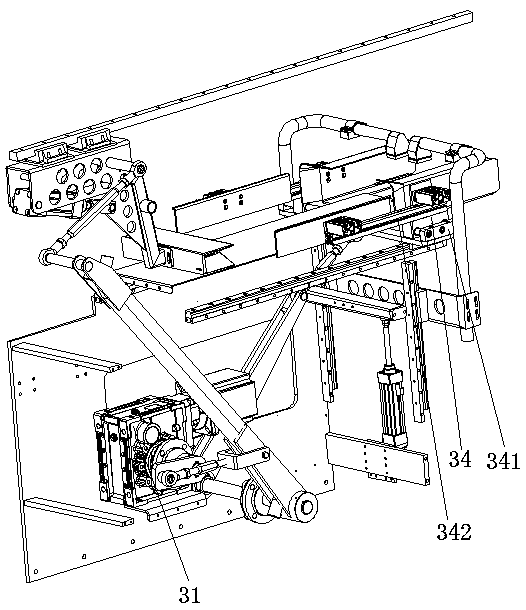

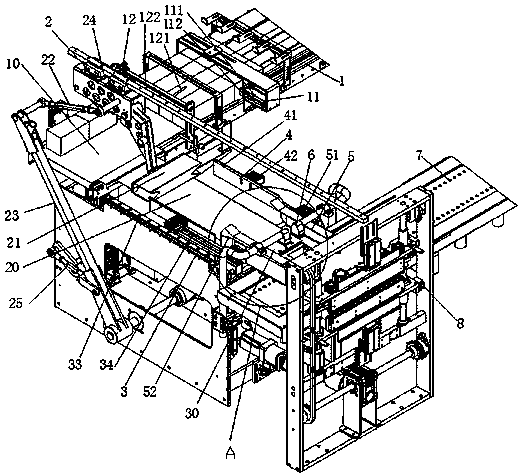

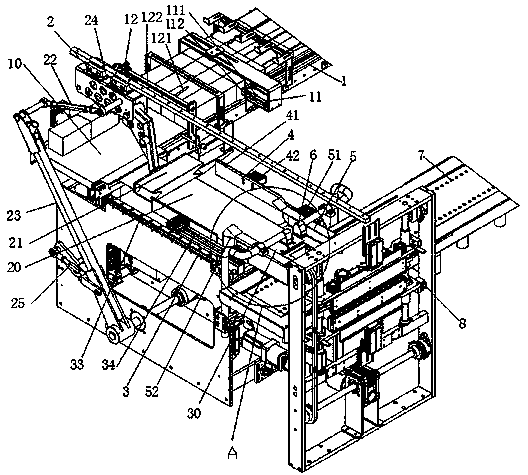

Control system of prefabricated bag packing machine

ActiveCN105857649AShort tripPrevent the situation of dumpingSolid materialRolling paperControl system

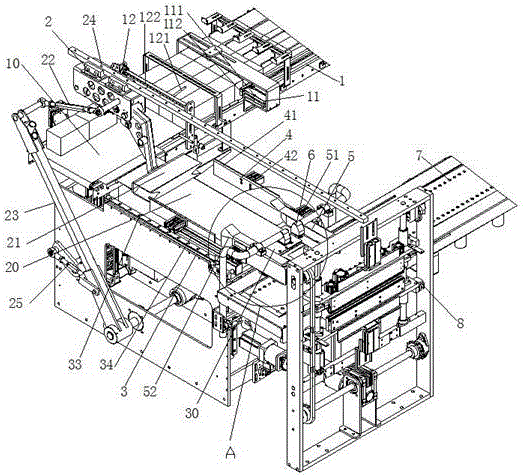

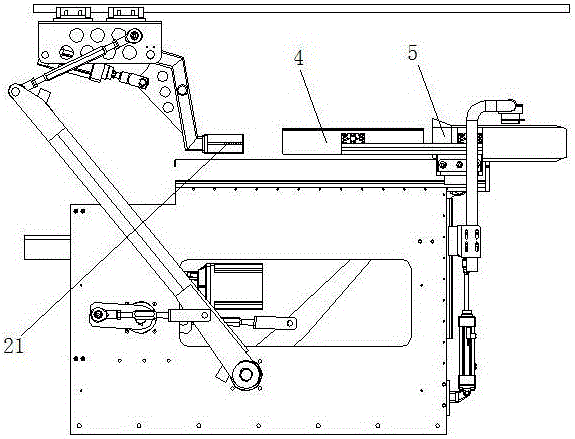

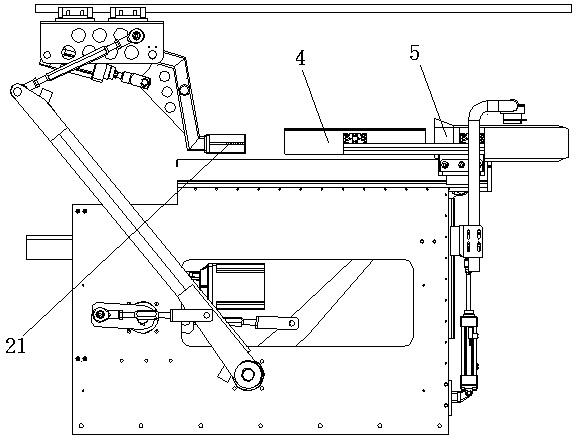

The invention discloses a control system of a prefabricated bag packing machine and relates to the technical field of mechanical control of packing machines. The control system of the prefabricated bag packing machine comprises a feeding mechanism, a pushing mechanism, a bag stretching mechanism, a bag opening mechanism and a bag conveying mechanism and is characterized by further comprising a clamping mechanism and a translation mechanism. The control system of the prefabricated bag packing machine is applicable to packing machines for packing via prefabricated bags such as small packing machines, medium packing machines and large packing machines and the like; meanwhile, the control system of the prefabricated bag packing machine is also suitable for packing materials such as facial tissues, flat paper, paper towels, blocky foods, drugs, roll paper, unpackaged foods and the like. Through the control system of the prefabricated bag packing machine, the problems that processes in single station of the prefabricated bag packing machine are complex, various packing actions are needed, the travel distance among the stations is long, the equipment occupied area is large, the material is irregular and is easy to pour, the prefabricated bags are easy to break, the material-pushing travel distance is long, the packing effect is poor, and the packaging efficiency is low in the prior art can be solved.

Owner:上海松川峰冠包装自动化有限公司

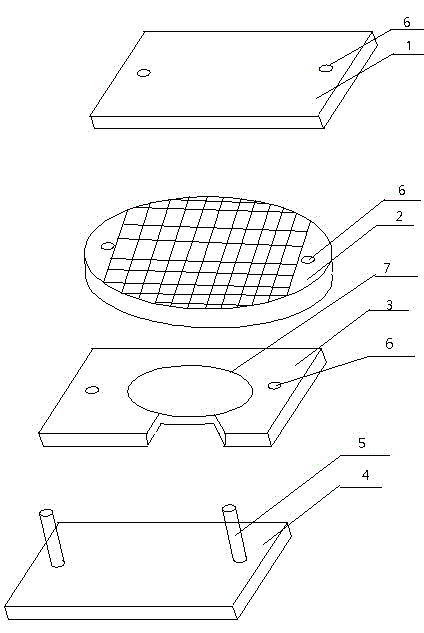

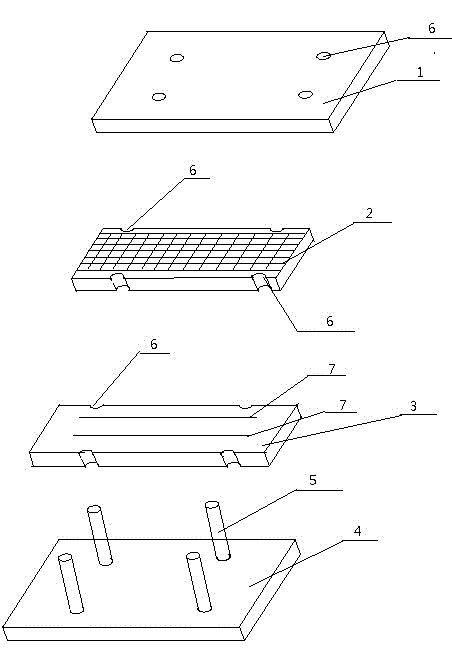

Device and method for detecting microbending loss of optical fiber

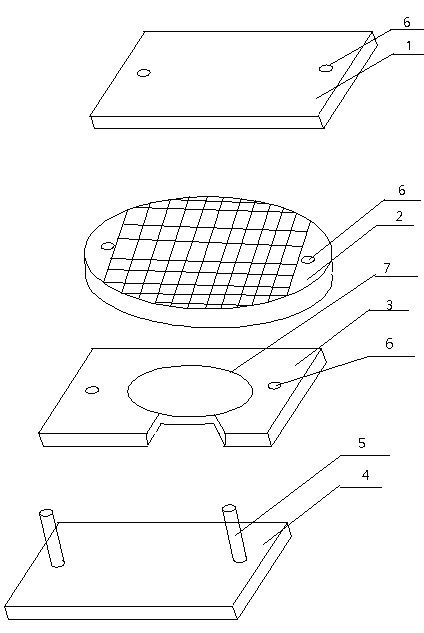

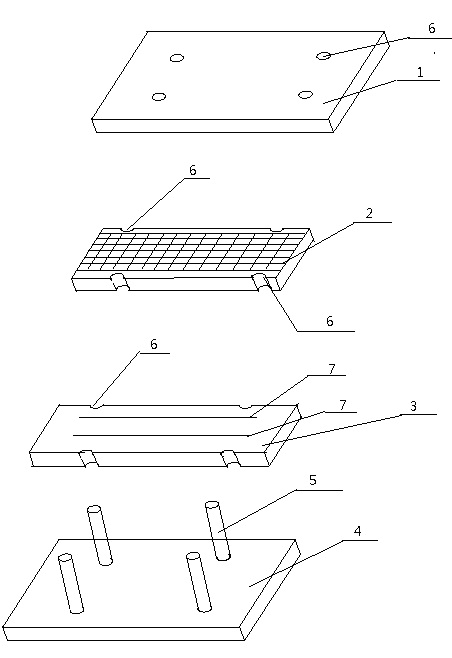

ActiveCN102692315AEasy to operateWill not cause uneven forceTesting optical propertiesMetal meshMesh grid

The invention provides a device and method for detecting the microbending loss of an optical fiber, relating to the field of detection of optical fibers. The device comprises a metal cover plate, a metal mesh, a rubber plate and a metal base, wherein two marked lines with the spacing distance of 20-30 mm and the length of 145-155 mm are arranged on the rubber plate, and the length of the metal mesh is the same as that of the marked lines. The method for detecting the microbending loss of the optical fiber, provided by the invention, comprises the following steps of: reserving a free end from the optical fiber, connecting the free end with an optical power meter, fixing the optical fiber on one marked line, making a circle around posts by using the optical fiber, fixing the optical fiber on the other marked line, reserving another free end, and connecting the another free end with the optical power meter; sleeving the metal mesh on the metal base, sleeving the metal cover plate on the metal base, and recording a numerical value displayed by the optical power meter; adding a weight on the metal cover plate, and recording a numerical value displayed by the optical power meter; and obtaining a difference value of the two numerical values, thereby obtaining the microbending loss of the optical fiber. The device for detecting the microbending loss of the optical fiber, provided by the invention, is simple and convenient in operation; and the method is simple and accurate.

Owner:NANJING WASIN FUJIKURA OPTICAL COMM LTD

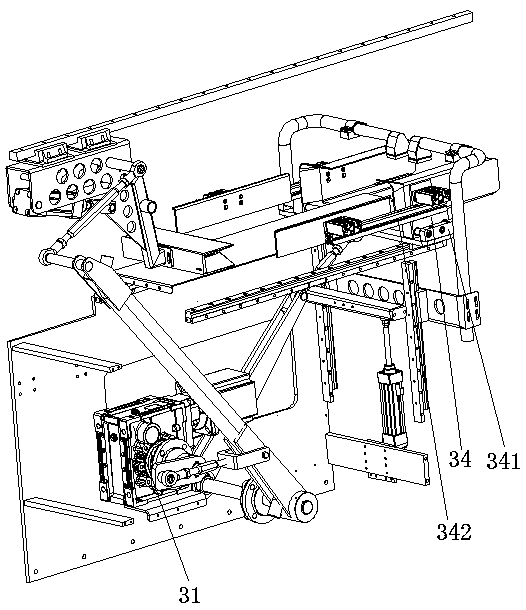

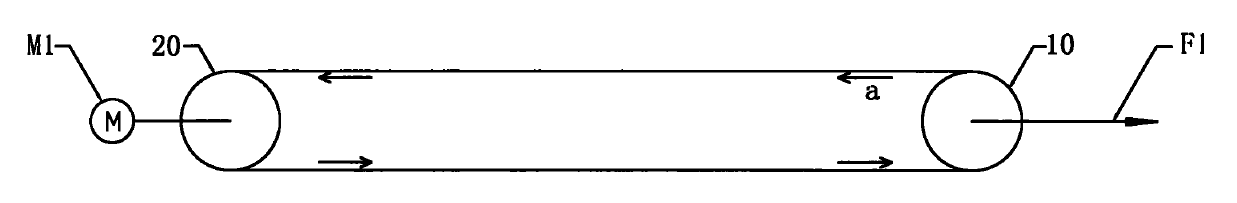

Material conveying and pushing method for prefabricated bag packaging machine

ActiveCN105691676ARealize the action of opening and opening bagsReduce processIndividual articlesRisk strokeSingle station

The invention discloses a material conveying and pushing method for a prefabricated bag packaging machine and relates to the technical field of packaging machine packaging processes. The material conveying and pushing method includes the steps that materials are conveyed to a to-be-clamped station; the materials conveyed to the to-be-clamped station are conveyed to a to-be-pushed station in a clamped manner; in the process of conveying the materials to the to-be-clamped station or the to-be-pushed station, prefabricated bags are conveyed to a bag opening station and opened on the bag opening station; the prefabricated bags are opened while the materials on the to-be-clamped station are conveyed to the to-be-pushed station in the clamped manner; in the material pushing process, the prefabricated bags and the materials move in the opposite directions; and the materials are pushed into the prefabricated bags moving in the direction opposite to the material pushing direction, and the prefabricated bags containing the materials in a wrapping manner are pushed to the assigned positions in the original material pushing direction. The material conveying and pushing method for the prefabricated bag packaging machine can solve the problems that by means of a prefabricated bag packaging machine in the prior art, the working procedures of a single station are complex, the number of the packaging actions is large, the stroke among different stations is long, the area occupied by equipment is large, material dumping occurs easily and the prefabricated bags are broken easily due to the fact that materials are irregular, the material pushing stroke is long, the packaging effect is poor, and the packaging efficiency is low.

Owner:上海松川峰冠包装自动化有限公司

Material clamping and conveying method for prefabricated bag packaging machine

The invention discloses a material clamping and conveying method for a prefabricated bag packaging machine, and belongs to the field of material packaging. The material clamping and conveying method is characterized by comprising the following steps: a, a material is fed by a material feeding mechanism to a to-be-clamped station, and clamped by the two sides in the horizontal material conveying direction of a clamping mechanism; b, the clamped material is conveyed to a to-be-pushed station, and a prefabricated bag is expanded by a bag expanding mechanism; and c, the material conveyed to the to-be-pushed station is pushed by a material pushing mechanism, and meanwhile the prefabricated bag is driven by the bag expanding mechanism to move opposite to the pushed material. By adoption of the material clamping and conveying method, the material can be pushed by the material pushing mechanism into the prefabricated bag continuously, and the continuous degree of material conveying and pushing is high. Besides, the material clamping and conveying method has the characteristics that the conveying and packaging stroke is short, and the packaging efficiency is high.

Owner:上海松川峰冠包装自动化有限公司

Material packaging method for prefabricated bag packaging machine

ActiveCN105691677AHigh degree of continuityImprove packaging efficiencyIndividual articlesEngineeringPacking method

The invention discloses a material packaging method for a prefabricated bag packaging machine, and belongs to the technical field of material packaging. The material packaging method comprises the following steps: material clamping or holding, prefabricated bag expanding, material pushing and prefabricated bag removing, wherein in the material clamping or holding process, a material is clamped or held under the action of a clamping mechanism or a holding mechanism, and conveyed to a to-be-pushed station; in the prefabricated bag expanding process; the left and right sides of the bag mouth of the prefabricated bag are expanded under the action of a bag expanding mechanism; in the material pushing process, the material moves under the action of a material pushing mechanism in the direction of the bag mouth of the prefabricated bag to the bottom of the prefabricated bag, and continues being pushed along with the prefabricated bag; and in the prefabricated bag removing process, after moving to the bottom of the prefabricated bag, the material continues being pushed by the material pushing mechanism, and then is removed from the bag expanding mechanism. By adoption of the material packaging method, the material can be pushed by a material pushing head into the prefabricated bag continuously, and the continuous degree of material conveying and pushing is high. Compared with a conventional packaging method, the material packaging method provided by the invention has the advantages that the conveying and packaging stroke is shorter, and the packaging efficiency is higher.

Owner:上海松川峰冠包装自动化有限公司

Material conveying method for prefabricated bag packing machine

The invention discloses a material conveying method for a prefabricated bag packing machine, and belongs to the technical field of material packing. The material conveying method is characterized by comprising the following steps that (a), material after being held or clamped is conveyed to a station to be pushed in the opening direction of a prefabricated bag; (b), the left side and the right side of the prefabricated bag are opened; (c), the material is pushed on the station to be pushed, the precast bag is moved, the material and the prefabricated bag perform opposite motion, and the material is pushed into the prefabricated bag; (d), the material is pushed to the bottom of the prefabricated bag, and the material continues moves along with the prefabricated bag in the pushed direction; (e), next material is cyclically conveyed according to the steps. The material conveying method disclosed by the invention has the characteristics that the material pushing serialization degree is high, the conveying and packing distance is short, the materials cannot fall, and the conveying and packing efficiency is high.

Owner:上海松川峰冠包装自动化有限公司

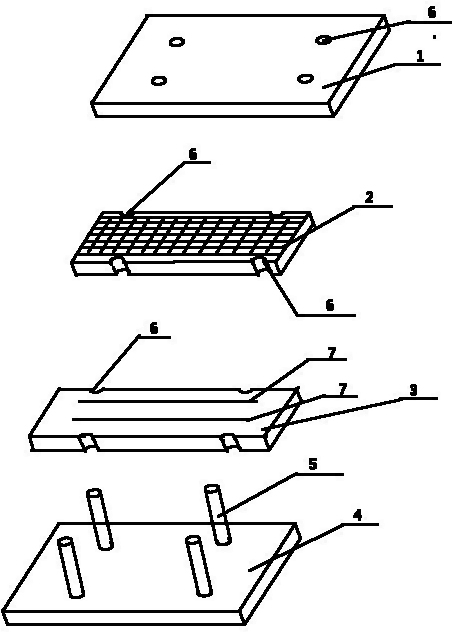

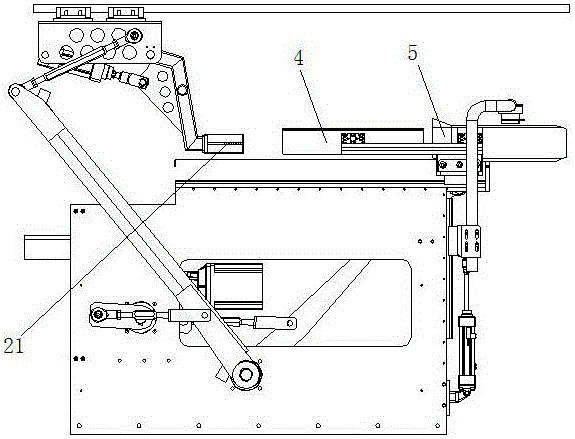

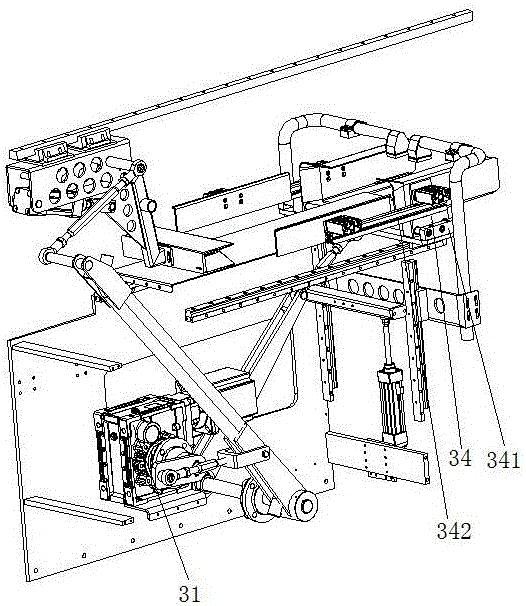

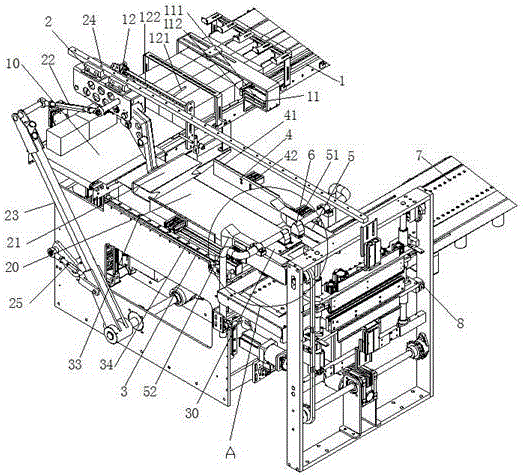

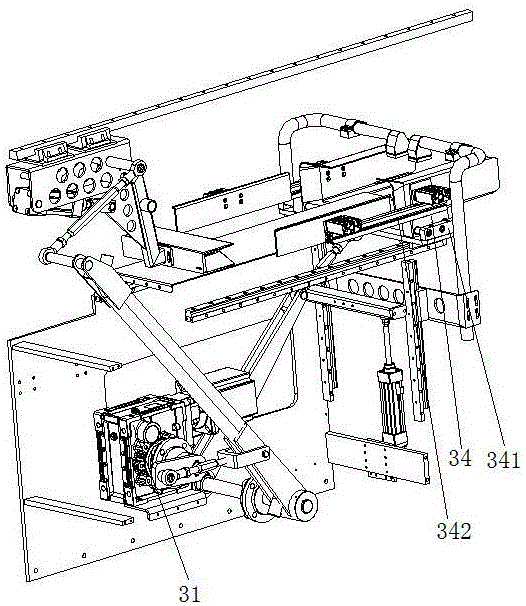

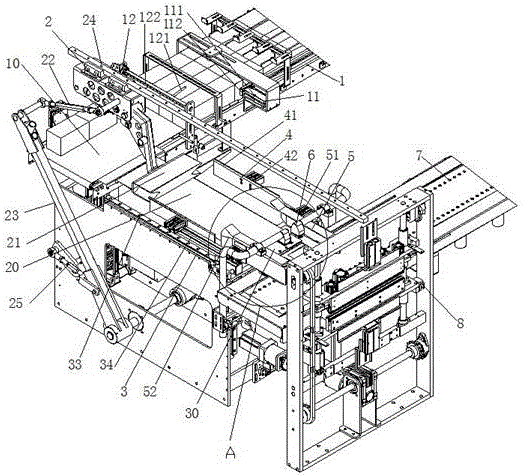

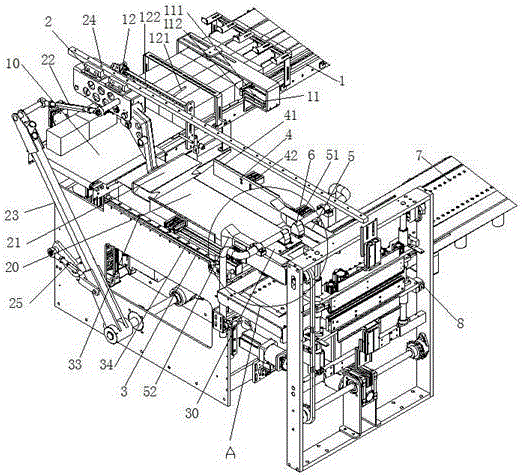

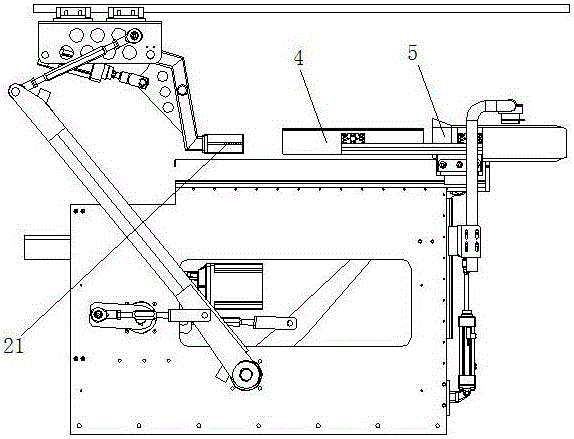

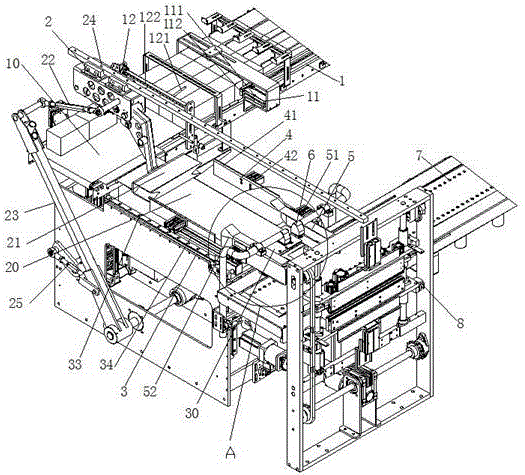

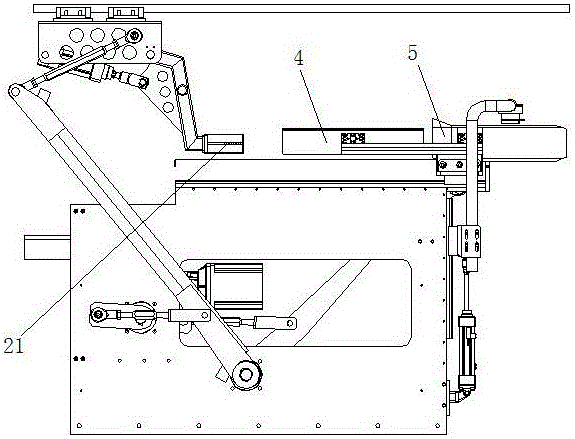

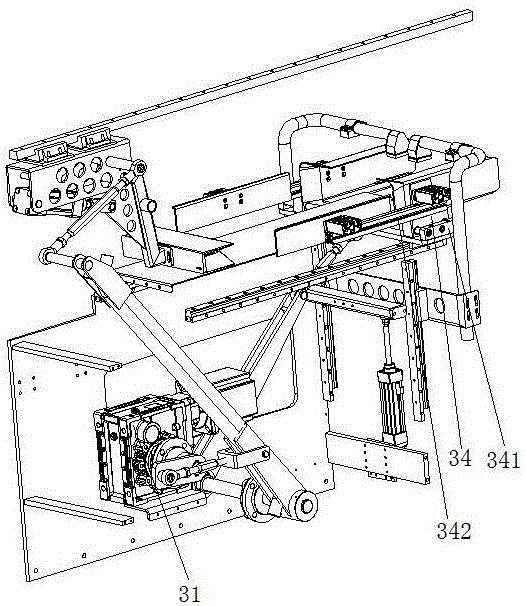

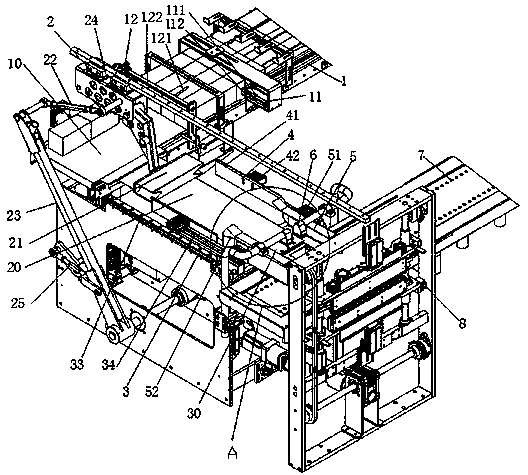

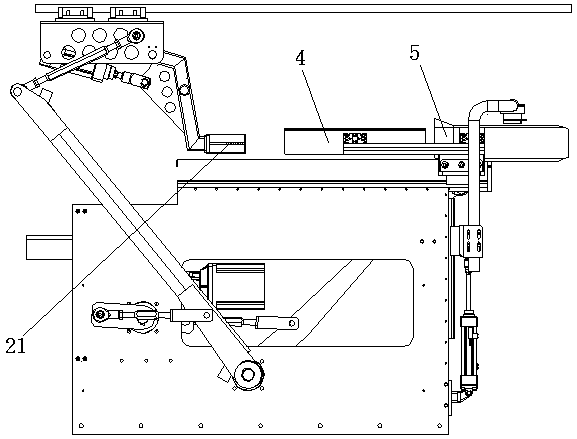

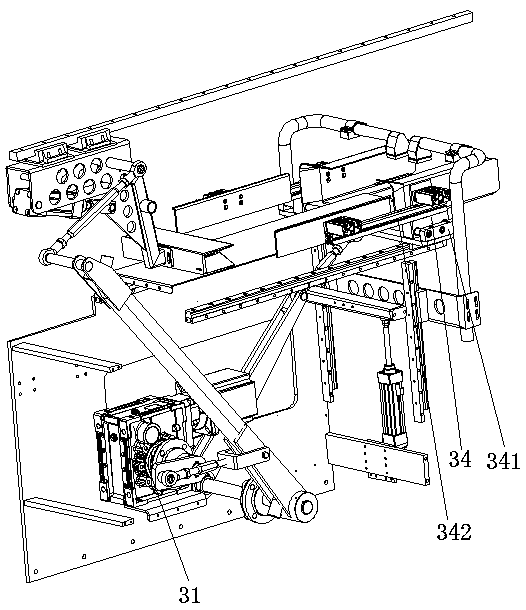

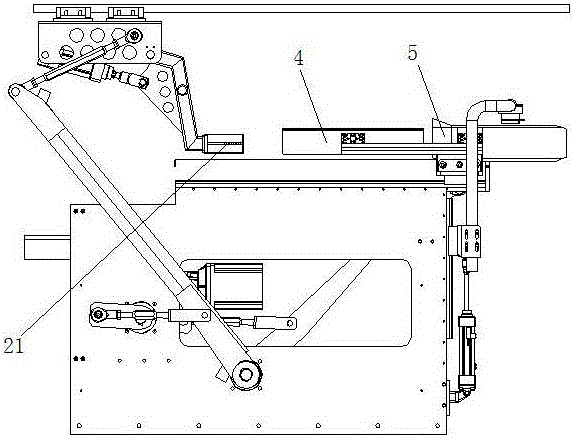

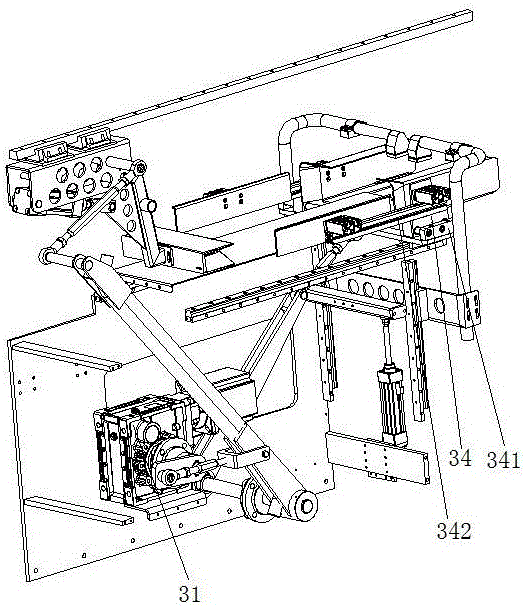

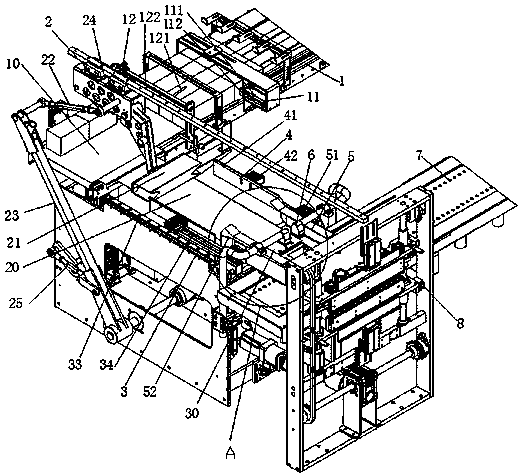

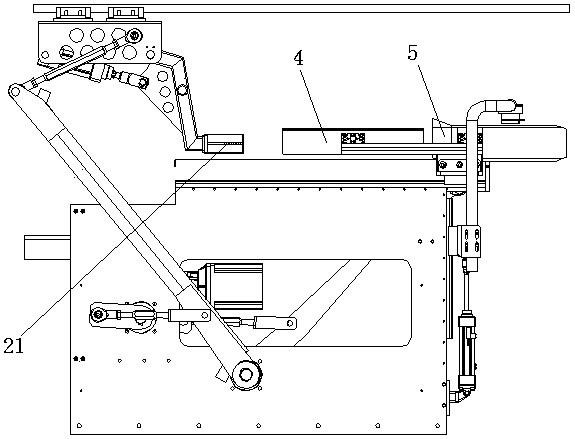

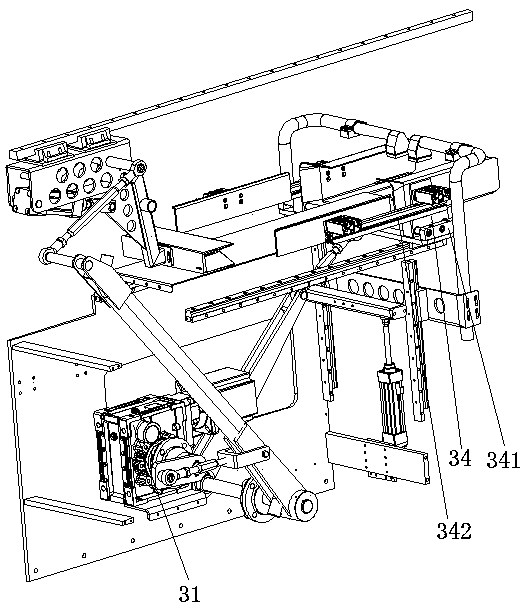

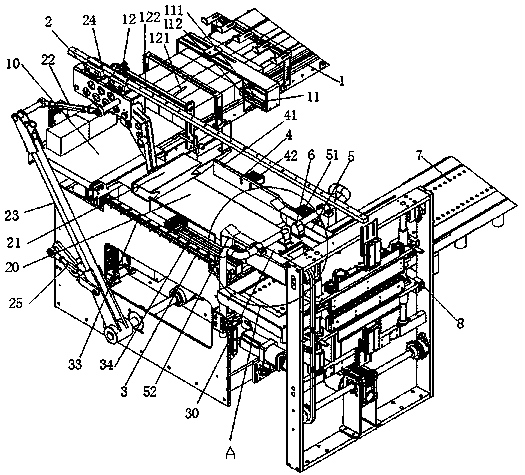

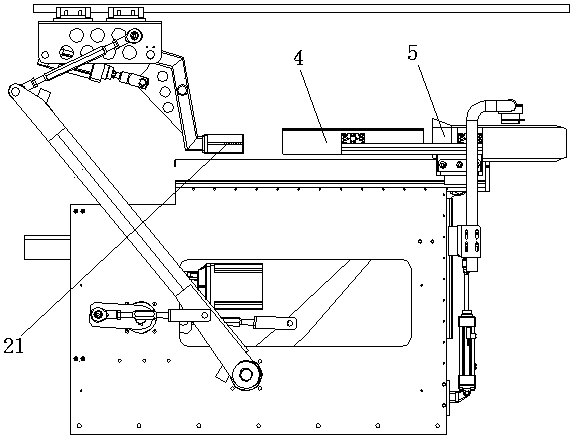

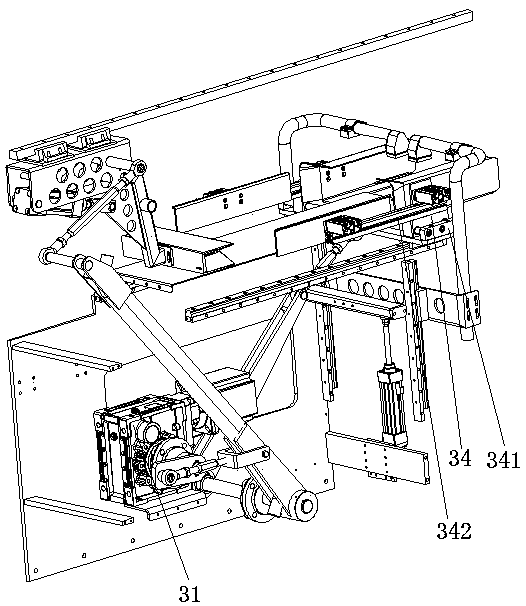

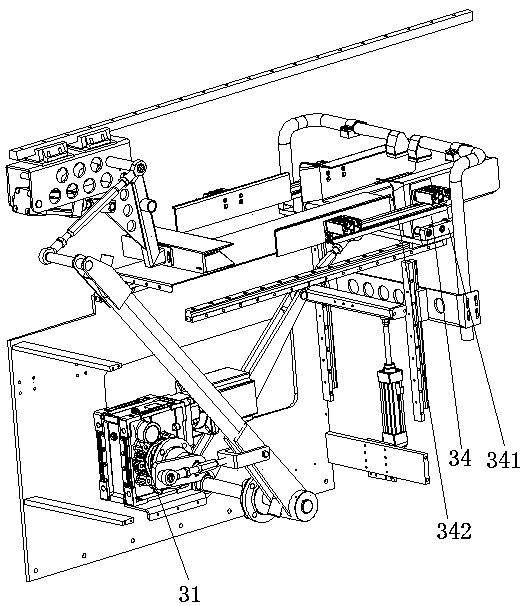

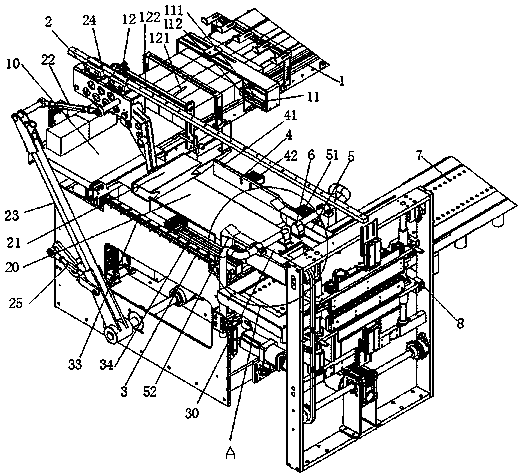

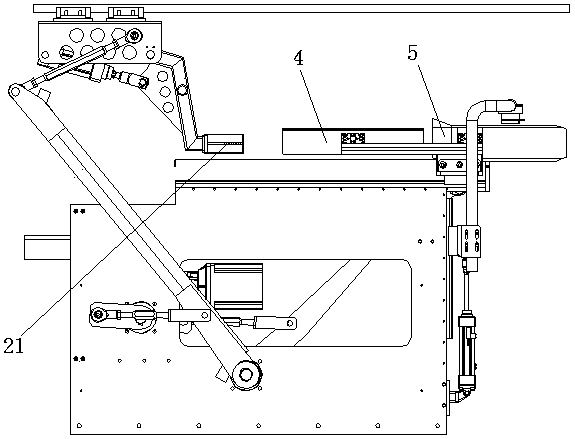

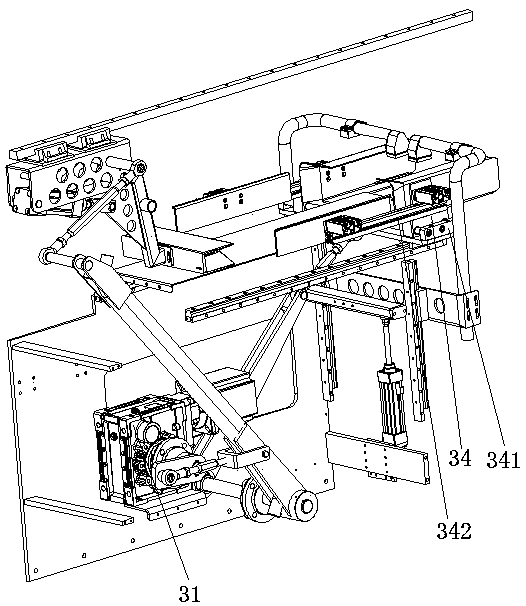

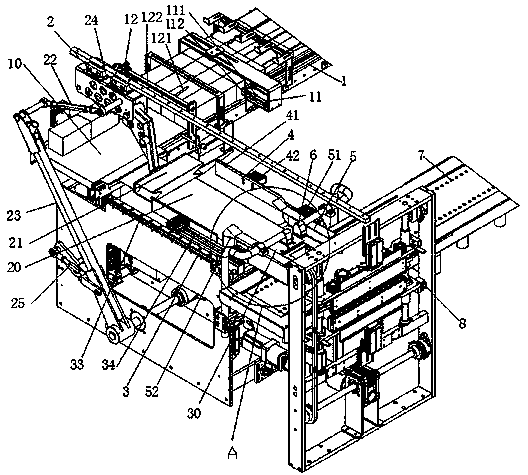

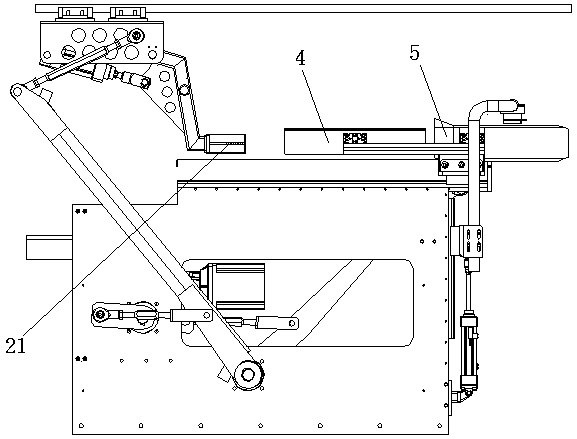

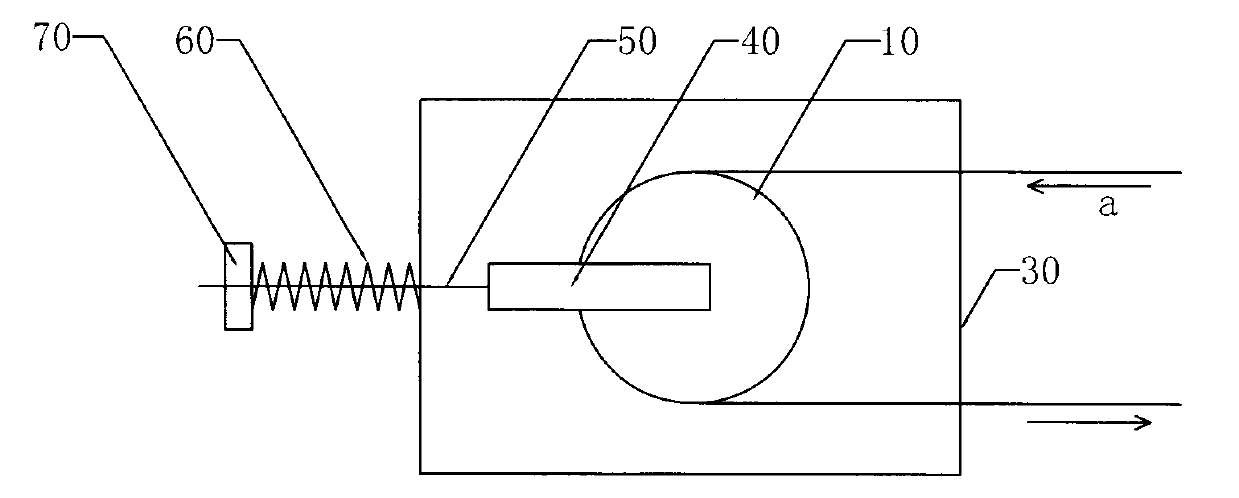

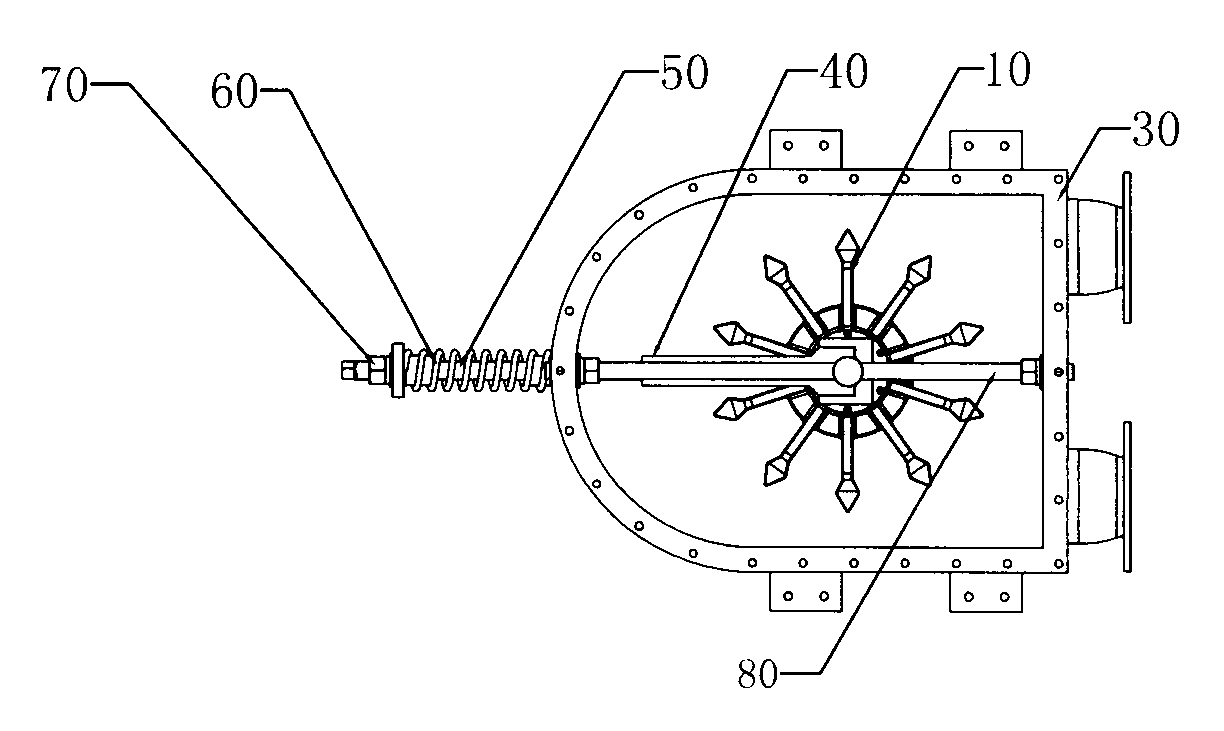

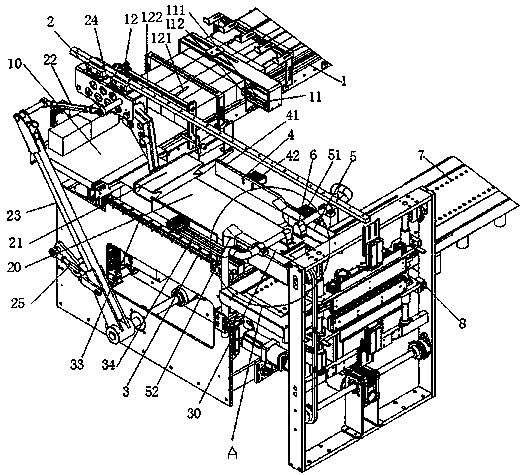

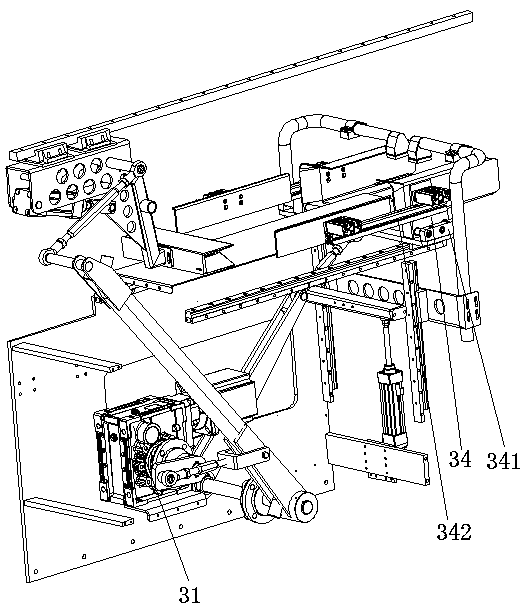

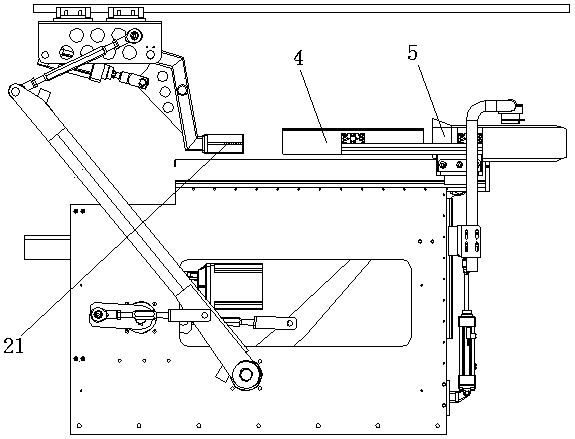

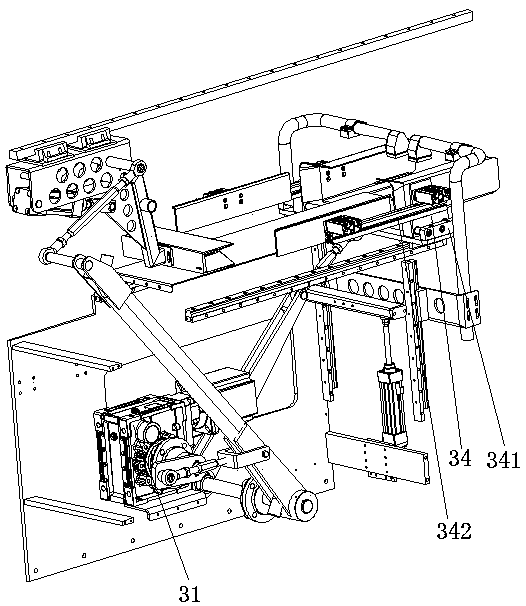

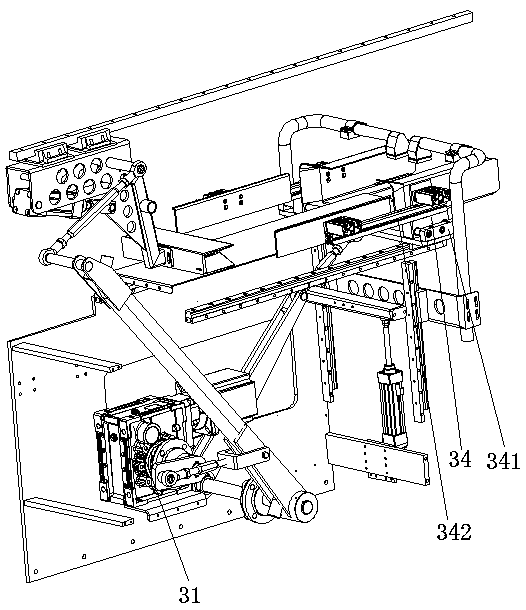

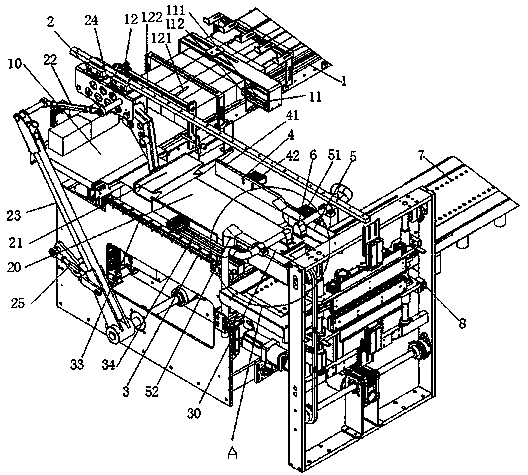

Prefabricated bag packaging machine

ActiveCN105691713ASolve complexitySolve problems with more motionPackagingReciprocating motionEngineering

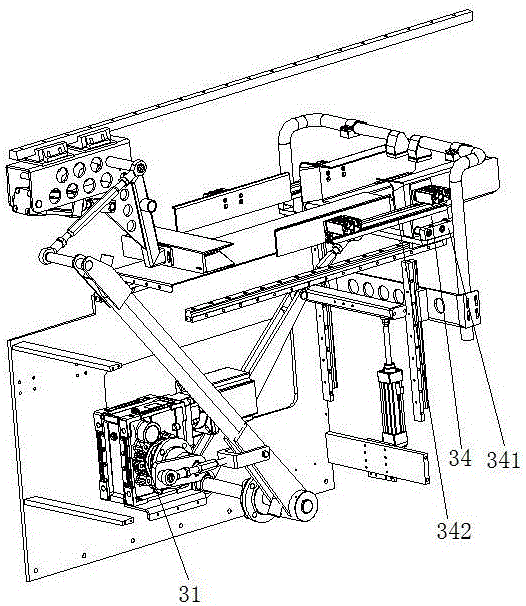

The invention discloses a prefabricated bag packaging machine, and relates to the technical field of packaging machinery. The prefabricated bag packaging machine adopts the structure that a clamping and conveying device is arranged between a to-be-clamped station and a bag opening station; the clamping and conveying device comprises a clamping mechanism and a translation mechanism; and the translation mechanism drives the clamping mechanism to perform reciprocating motion in the material clamping and conveying direction. The prefabricated bag packaging machine provided by the invention solves a plurality of problems in the prior art, for example, the working procedure at a single station of a conventional prefabricated bag packaging machine is complex; the quantity of packaging actions is large; the strokes among various stations are relatively long; the equipment occupied area is large; materials are irregular, and the possibility of material overturning is high; a prefabricated bag is liable to broken; the material pushing stroke is long; the packaging effect is poor; and the packaging efficiency is low.

Owner:上海松川峰冠包装自动化有限公司

Prefabricated bag packaging method of prefabricated bag packaging machine

ActiveCN105691736BReduce processRealize the action of opening and opening bagsPackagingEngineeringSingle station

The invention discloses a prefabricated bag packaging method for a prefabricated bag packaging machine and relates to the technical field of packaging machine packaging processes. The prefabricated bag packaging method includes the steps that prefabricated bags are conveyed to a bag opening station, opened on the bag opening station and arranged on a bag expanding mechanism of the prefabricated bag packaging machine in a sleeving manner; the prefabricated bags move in the direction opposite to the material movement direction along with the bag expanding mechanism of the prefabricated bag packaging machine; and in the process of opposite movement of the prefabricated bags and the materials, under the action of a material pushing mechanism of the prefabricated bag packaging machine, the materials pushed by the material pushing mechanism are contained in the prefabricated bags in a wrapping manner, and the prefabricated bags containing the materials in the wrapping manner are pushed out under the action of the material pushing mechanism. The prefabricated bag packaging method for the prefabricated bag packaging machine can solve the problems that by means of a prefabricated bag packaging machine in the prior art, the working procedures of a single station are complex, the number of the packaging actions is large, the stroke among different stations is long, the area occupied by equipment is large, material dumping occurs easily and the prefabricated bags are broken easily due to the fact that materials are irregular, the material pushing stroke is long, the packaging effect is poor, and the packaging efficiency is low.

Owner:上海松川峰冠包装自动化有限公司

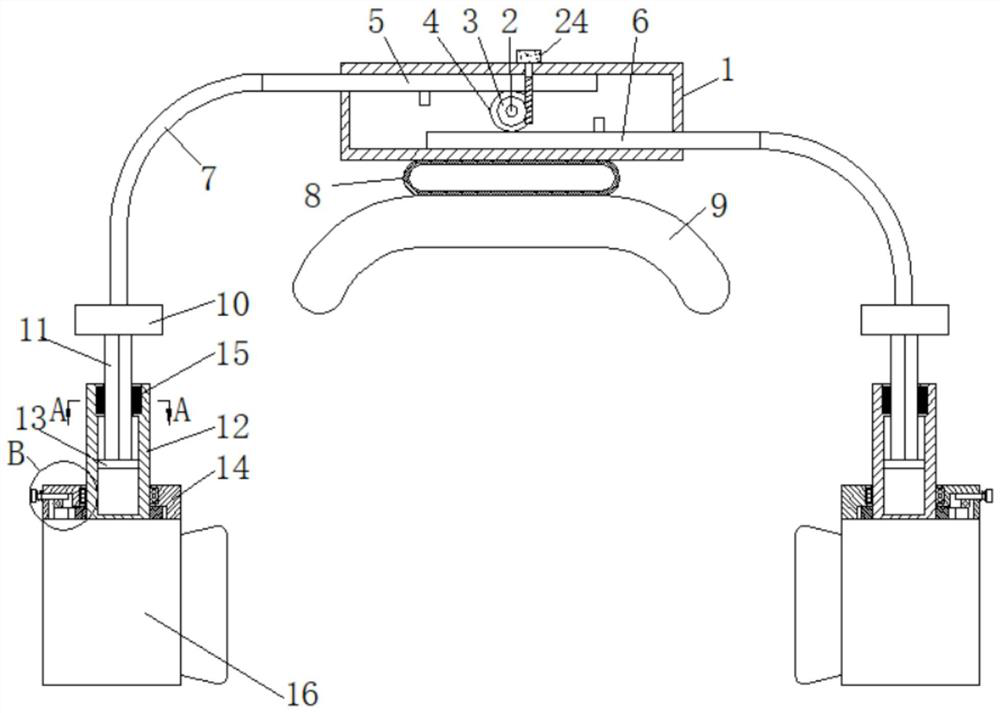

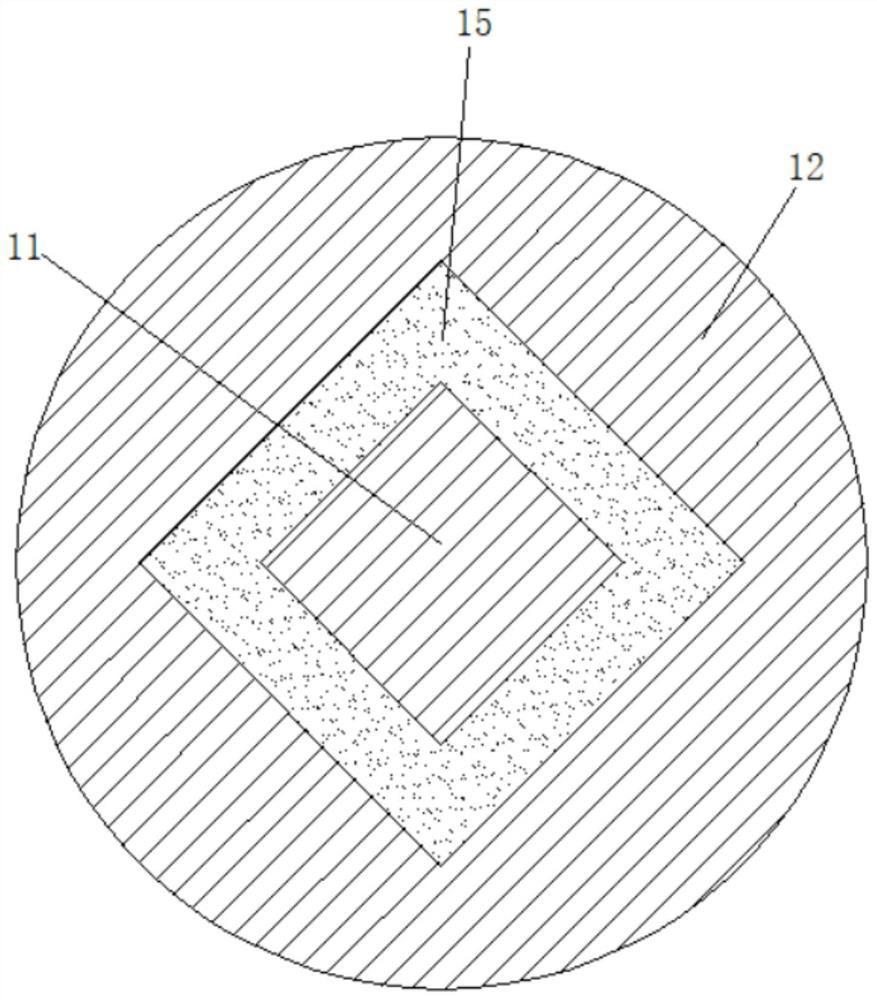

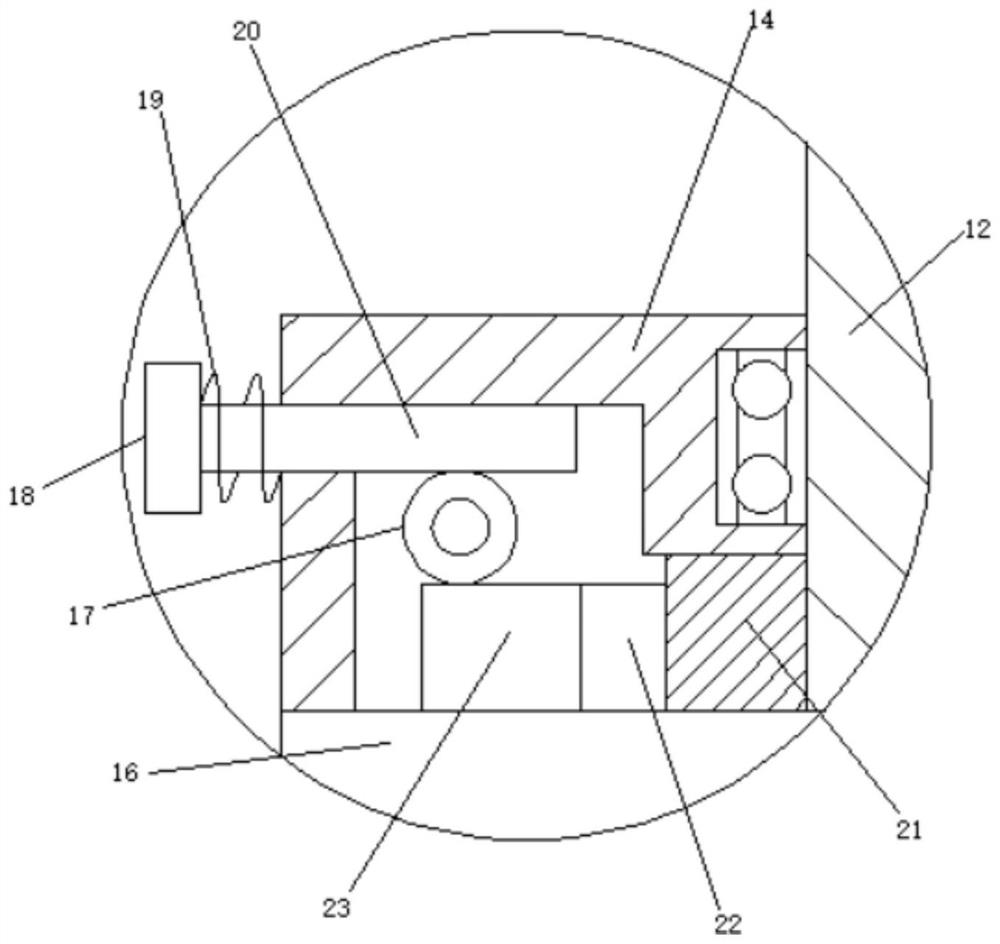

Auxiliary device for English listening training

InactiveCN111818417AWill not cause uneven forceFit tightlyEarpiece/earphone attachmentsElectrical appliancesEngineeringEarmuffs

The invention relates to the field of English learning tools, particularly relates to an auxiliary device for English listening training. The auxiliary device comprises an adjusting frame and two earmuffs, a first rack and a second rack which are arranged in parallel are slidably connected into the adjusting frame. The ends, located on the outer side of the adjusting frame, of the first rack and the second rack are fixedly connected with arc-shaped frames respectively, telescopic mechanisms are arranged at the lower ends of the two arc-shaped frames, the two earmuffs correspond to the telescopic mechanisms, adjusting boxes are fixed to the upper ends of the earmuffs, and the lower ends of the telescopic mechanisms are arranged in the corresponding adjusting boxes. The auxiliary device forEnglish listening training is suitable for people with different head circumference sizes; when the two earmuffs move, the shapes of the earmuffs are kept unchanged; the adjustable earmuff is simple and convenient to operate, the angle between the earmuff body and the plane where the ears are located is adjusted through the adjusting box, the earmuff body can be parallel to the plane where the ears are located, the earmuff body can be tightly attached to the ears, external noise transmission is reduced, and the hearing training level can be improved.

Owner:HUNAN UNIV OF HUMANITIES SCI & TECH

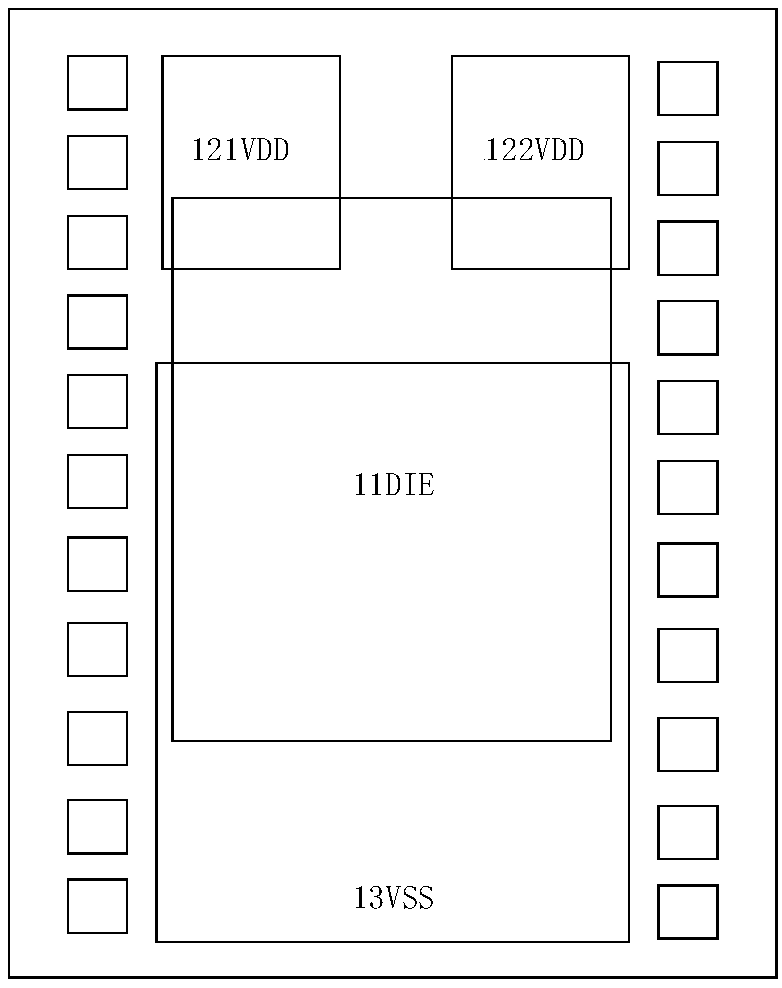

Chip structure and packaging method thereof, and electronic equipment

PendingCN108735708AWill not cause uneven forceNo lossSemiconductor/solid-state device detailsSolid-state devicesElectric equipmentElectron

The embodiment of the invention discloses a chip structure and a packaging method thereof, and electronic equipment. the chip comprises a wafer (DIE) and a circuit substrate, wherein the circuit substrate comprises a first bonding pad (VSS), a second bonding pad (VDDS) and a third bonding pad (VDDM); the wafer (DIE) is arranged on the first bonding pad (VSS), the mapping plane of the wafer (DIE) on the first bonding pad (VSS) is within the frame of the first bonding pad (VSS). Compared with the prior art, in the embodiment of the invention, the wafer (DIE) is arranged on the first bonding pad(VSS), the mapping plane of the wafer (DIE) on the first bonding pad (VSS) is within the frame of the first bonding pad (VSS), the wafer (DIE) does not stretch across two or more pads, the wafer (DIE)is prevented from being subjected to non-uniform stress during a packaging process, and thus loss caused by cracking of the chip is avoided, and the production yield of the chip is ensured.

Owner:BEIJING BITMAIN TECH LTD

Prefabricated bag packaging method for prefabricated bag packaging machine

ActiveCN105691736AReduce processRealize the action of opening and opening bagsPackagingEngineeringRisk stroke

The invention discloses a prefabricated bag packaging method for a prefabricated bag packaging machine and relates to the technical field of packaging machine packaging processes. The prefabricated bag packaging method includes the steps that prefabricated bags are conveyed to a bag opening station, opened on the bag opening station and arranged on a bag expanding mechanism of the prefabricated bag packaging machine in a sleeving manner; the prefabricated bags move in the direction opposite to the material movement direction along with the bag expanding mechanism of the prefabricated bag packaging machine; and in the process of opposite movement of the prefabricated bags and the materials, under the action of a material pushing mechanism of the prefabricated bag packaging machine, the materials pushed by the material pushing mechanism are contained in the prefabricated bags in a wrapping manner, and the prefabricated bags containing the materials in the wrapping manner are pushed out under the action of the material pushing mechanism. The prefabricated bag packaging method for the prefabricated bag packaging machine can solve the problems that by means of a prefabricated bag packaging machine in the prior art, the working procedures of a single station are complex, the number of the packaging actions is large, the stroke among different stations is long, the area occupied by equipment is large, material dumping occurs easily and the prefabricated bags are broken easily due to the fact that materials are irregular, the material pushing stroke is long, the packaging effect is poor, and the packaging efficiency is low.

Owner:上海松川峰冠包装自动化有限公司

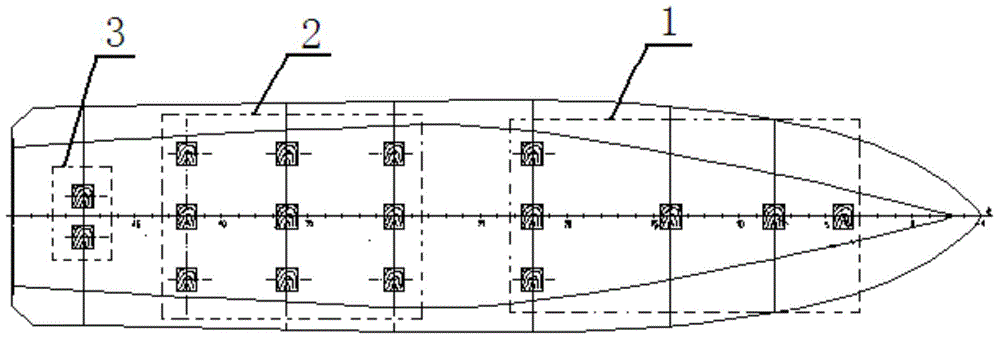

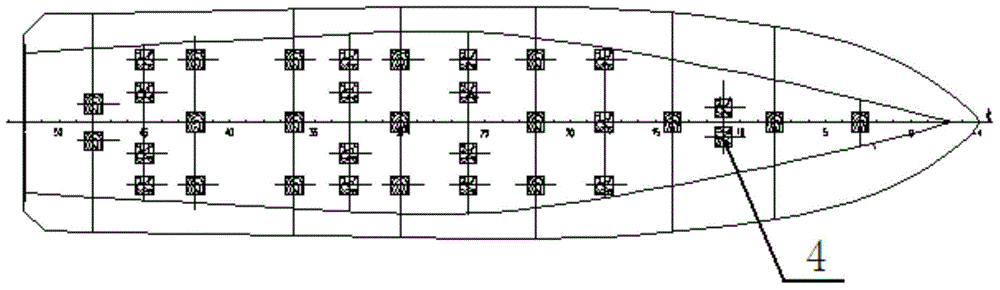

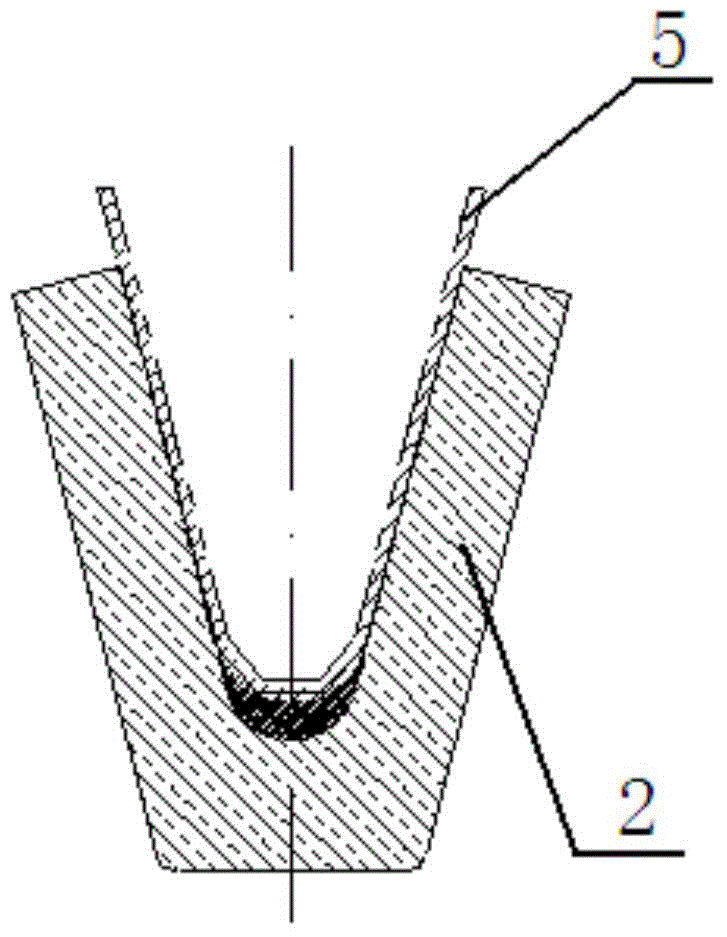

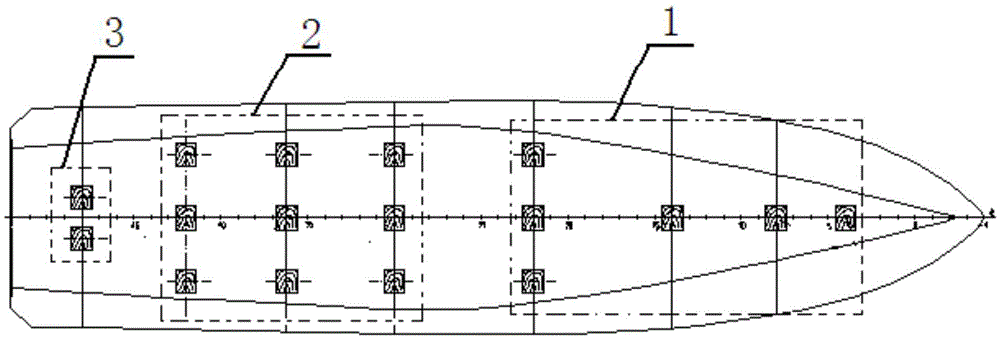

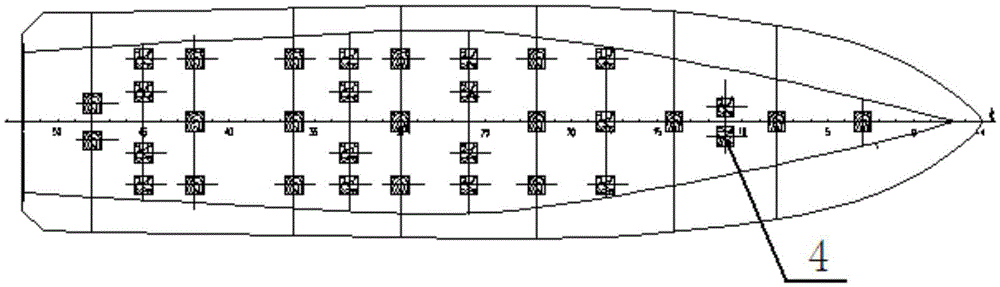

Block docking method for water surface boat with outer surface paved with flexible materials

Owner:CHINA SHIP DEV & DESIGN CENT

Material holding type conveying method for preformed-bag packer

ActiveCN105752402ADoes not pinch and squeezeImprove delivery efficiencyPackagingEngineeringMechanical engineering

The invention discloses a material holding type conveying method for a preformed-bag packer and belongs to the technical field of material packing. The material holding type conveying method is characterized by including the steps of firstly, conveying materials into a holding mechanism; secondly, conveying the materials by a holding way to a to-be-pushed work station and opening preformed bags by a bag opening mechanism; thirdly, pushing the materials by a pushing mechanism while driving the preformed bags to move opposite the materials by the bag opening mechanism. The material holding type conveying method is adaptable to both regular materials in bulk and irregular materials in bulk; the material holding type conveying way is stabler than the material clamping type conveying way and squeezing of the materials is avoided; thus, material conveying efficiency is improved, and efficiency of preformed bag packing is improved.

Owner:上海松川峰冠包装自动化有限公司

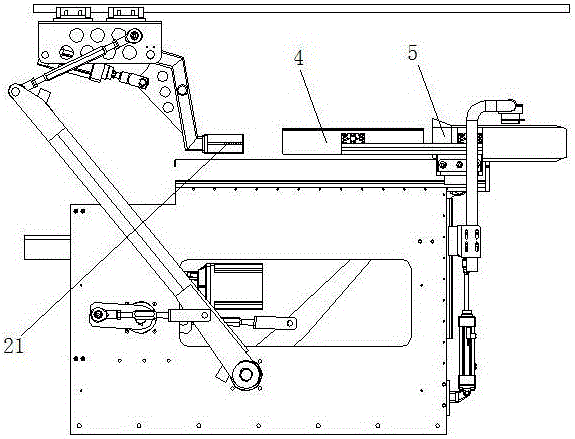

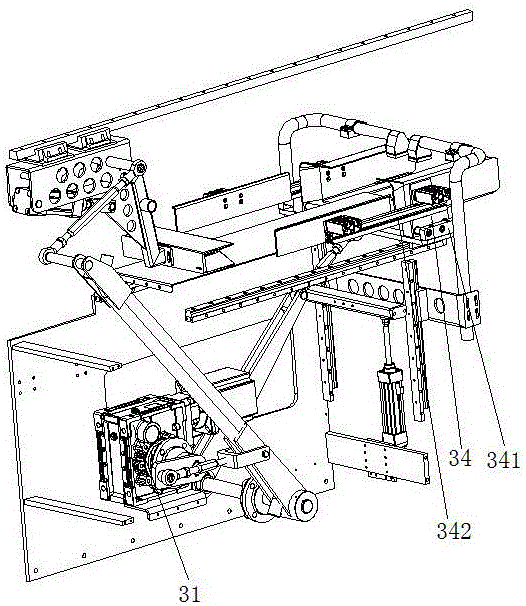

Premade Bag Packaging Machine

ActiveCN105691713BShorten the timePrevent the situation of dumpingPackagingReciprocating motionSingle station

A prefabricated bag packaging machine. A clamping and conveying device is disposed between a to-be-clamped station (10) and a bag opening station (30); the clamping and conveying device comprises a clamping mechanism (4) and a translation mechanism (3); and the translation mechanism (3) drives the clamping mechanism (4) to perform reciprocating motion in the material clamping and conveying direction. The prefabricated bag packaging machine resolves the problems in the prior art of complex working procedures of a single station, the great quantity of packaging actions, long travel distance among stations, large area occupied by the devices; easy overturning of materials due to the irregular materials, easy breaking of prefabricated bags, long travel distance of material pushing, poor packaging effect and low packaging efficiency of the existing prefabricated bag packaging machine.

Owner:上海松川峰冠包装自动化有限公司

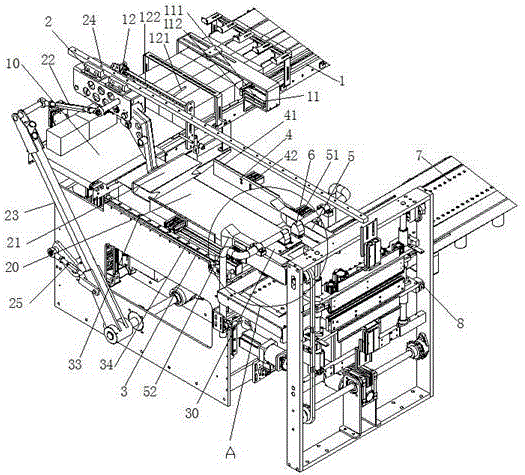

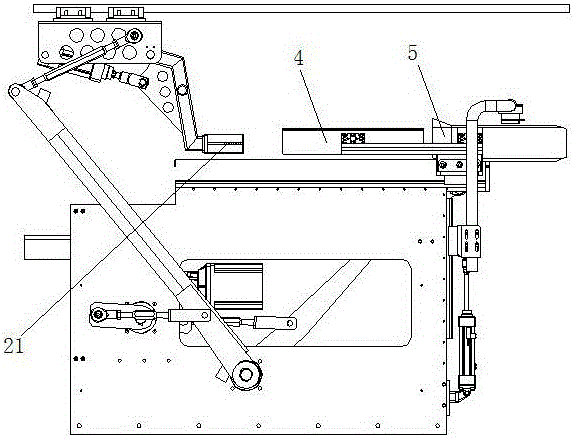

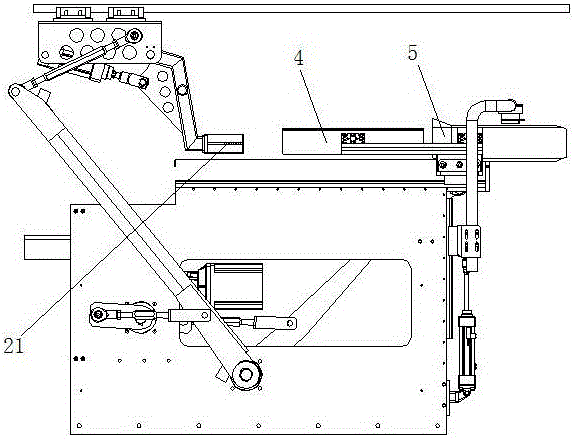

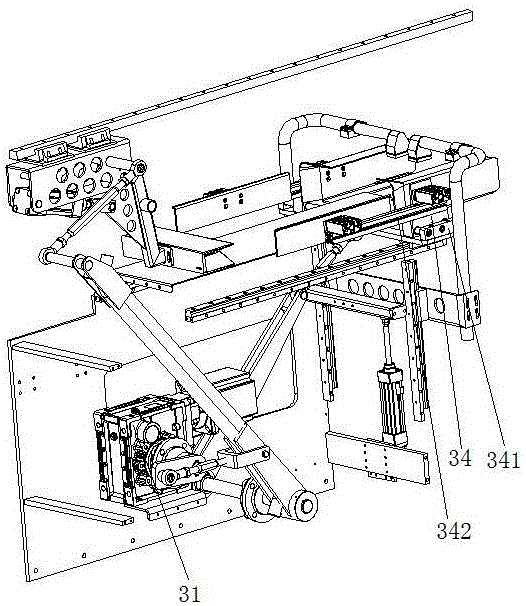

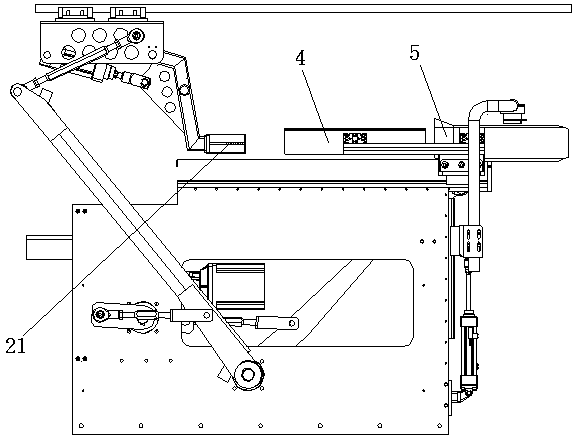

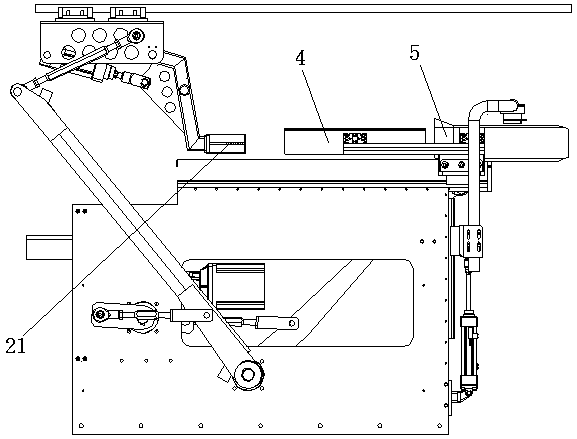

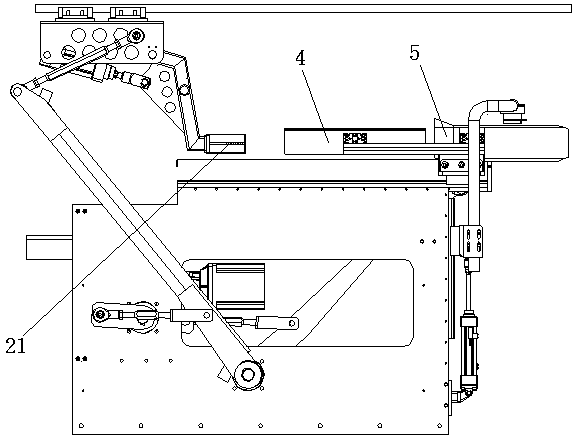

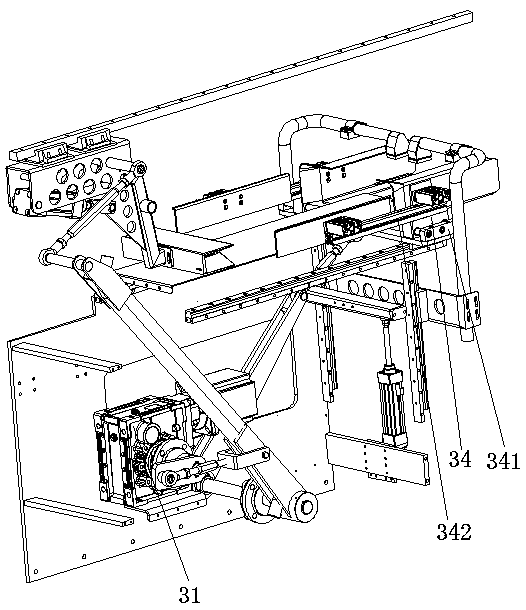

Bag opening device for prefabricated bag packaging machine

The invention discloses a bag opening device of a prefabricated bag packaging machine, and belongs to the technical field of packaging machines. The bag opening device is characterized by comprising a translation mechanism and a bag opening mechanism connected to the translation mechanism, wherein the bag opening mechanism is driven by the translation mechanism to move back and forth in a material operation direction. According to the bag opening device, prefabricated bags are moved in a material conveying direction by virtue of the bag opening mechanism, so that the stroke is shortened, and the packaging efficiency is improved; moreover, the bag opening mechanism is driven by the translation mechanism to stably operate without shaking, so that the bags are prevented from being damaged; and the bag opening device has the characteristics of being high in material conveying continuous degree, short in conveying and packaging stroke, and high in material conveying and packaging efficiency.

Owner:上海松川峰冠包装自动化有限公司

Material conveying and pushing method of prefabricated bag packaging machine

ActiveCN105691676BRealize the action of opening and opening bagsReduce processIndividual articlesEngineeringSingle station

A material conveying and pushing method for a prefabricated bag packaging machine. The method comprises: convey materials to a to-be-clamped station (10); conveying the materials conveyed to the to-be-clamped station (10), to a to-be-pushed station (20) in a clamped manner; in the process of conveying the materials to the to-be-clamped station (10) or the to-be-pushed station (20),convey prefabricated bags to a bag opening station (30) and open the prefabricated bags on the bag opening station (30); when the materials on the to-be-clamped station (10) are conveyed to the to-be-pushed station (20) in the clamped manner, open the prefabricated bags; in the material pushing process, the prefabricated bags and the materials move in the opposite directions; and push the materials into the prefabricated bags moving in the opposite direction, and push the prefabricated bags containing the materials in a wrapping manner to specified positions in the original material pushing direction. The method can resolve the problems in the prior art of complex working procedures of a single station, long travel distance among different stations, large area occupied by devices, easy overturning of materials and low packaging efficiency of the existing prefabricated bag packaging machine.

Owner:上海松川峰冠包装自动化有限公司

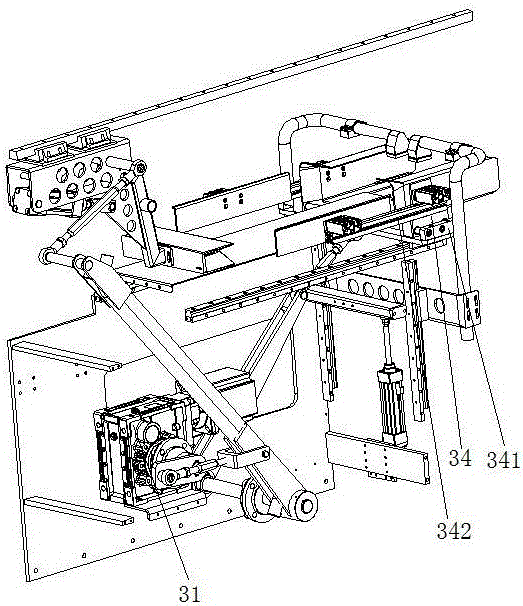

Material conveying equipment for pre-made pouch packaging machines

ActiveCN105667881BShort strokes for conveying packagesImprove the efficiency of conveying and packagingPackagingReciprocating motionPackaging machine

The invention discloses a material conveying device of a prefabricated bag packaging machine, and belongs to the technical field of packaging machines. The material conveying device comprises a bag opening mechanism and further comprises a clamping mechanism and horizontal moving mechanisms; the clamping mechanism is located behind the bag opening mechanism; and the clamping mechanism does the reciprocating motion in the material running direction under the effect of one horizontal moving mechanism. One horizontal moving mechanism drives the clamping mechanism to oppositely move in the material pushing direction, the material conveying stroke is shortened, and the material conveying and packaging efficiency is improved; the horizontal moving mechanisms and the clamping mechanism are standard parts, and the replacement cost is low; and the beneficial effects that the material pushing continuation degree is high, the conveying and packaging stroke is short, materials are not poured, and the conveying and packaging efficiency is high are achieved.

Owner:上海松川峰冠包装自动化有限公司

Device and method for detecting microbending loss of optical fiber

ActiveCN102692315BEasy to operateWill not cause uneven forceTesting optical propertiesOptical power meterEngineering

The invention provides a device and method for detecting the microbending loss of an optical fiber, relating to the field of detection of optical fibers. The device comprises a metal cover plate, a metal mesh, a rubber plate and a metal base, wherein two marked lines with the spacing distance of 20-30 mm and the length of 145-155 mm are arranged on the rubber plate, and the length of the metal mesh is the same as that of the marked lines. The method for detecting the microbending loss of the optical fiber, provided by the invention, comprises the following steps of: reserving a free end from the optical fiber, connecting the free end with an optical power meter, fixing the optical fiber on one marked line, making a circle around posts by using the optical fiber, fixing the optical fiber on the other marked line, reserving another free end, and connecting the another free end with the optical power meter; sleeving the metal mesh on the metal base, sleeving the metal cover plate on the metal base, and recording a numerical value displayed by the optical power meter; adding a weight on the metal cover plate, and recording a numerical value displayed by the optical power meter; and obtaining a difference value of the two numerical values, thereby obtaining the microbending loss of the optical fiber. The device for detecting the microbending loss of the optical fiber, provided by the invention, is simple and convenient in operation; and the method is simple and accurate.

Owner:NANJING WASIN FUJIKURA OPTICAL COMM LTD

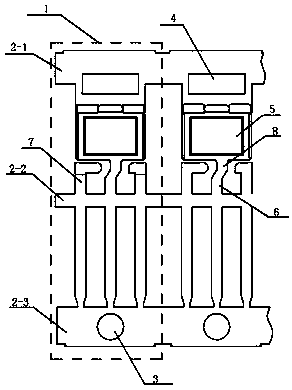

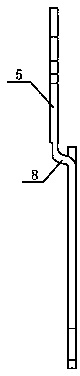

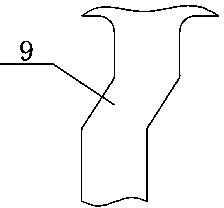

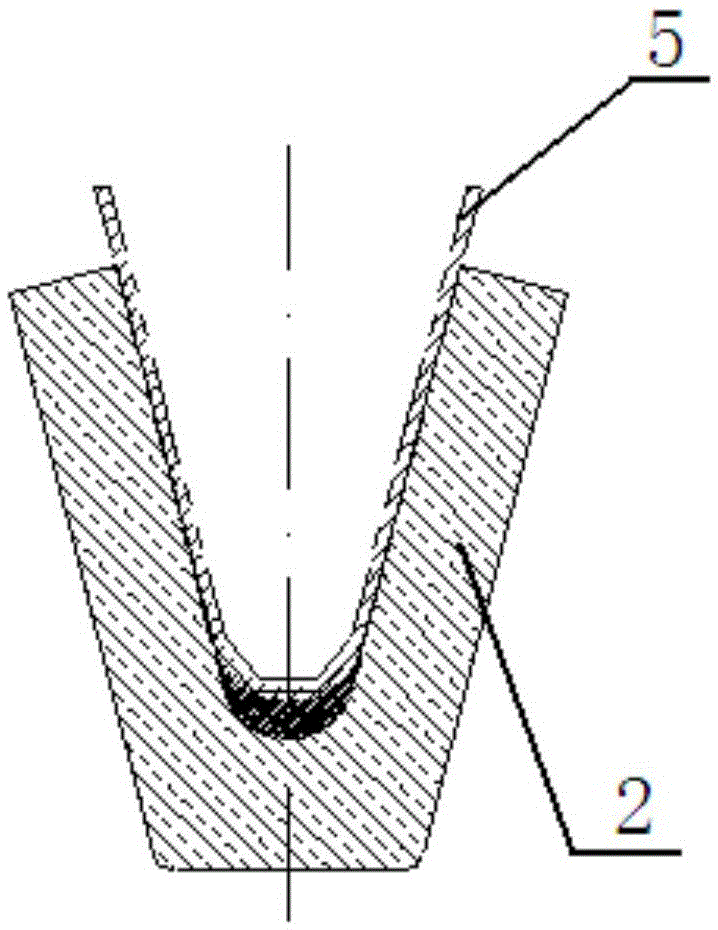

Lead frame with inclined bending portion

InactiveCN103560123AWill not cause uneven forceWon't cause skewSemiconductor/solid-state device detailsSolid-state devicesEngineeringLead frame

The invention discloses a lead frame with an inclined bending portion. The lead frame is formed through connection of thirty lead frame units in a single row. The lead frame units are fixedly connected with one another through connecting pieces. Each lead frame unit comprises a positioning hole (3), a cooling fin (4), a substrate (5) and a lead pin, the positioning holes are formed in the connecting piece (2-3), the cooling fins (4) are arranged on the connecting piece, each lead pin comprises a middle lead pin body (6) and a side lead pin body (7), each middle lead pin body (6) is provided with a bonding portion (8), each bonding portion (8) is provided with an inclined section (9), the middle lead pin bodies (6) and the substrates (5) are fixedly connected through the bonding portions (8), the bonding portions (8) are bent, and the middle lead pin bodies (6) and the side lead pin bodies (7) are fixedly connected through the connecting piece (2-2). According to the lead frame, defective products are not prone to being produced in the production process, and product quality meets standards.

Owner:沈健

Material conveying method of prefabricated bag packaging machine

The invention discloses a material conveying method for a prefabricated bag packing machine, and belongs to the technical field of material packing. The material conveying method is characterized by comprising the following steps that (a), material after being held or clamped is conveyed to a station to be pushed in the opening direction of a prefabricated bag; (b), the left side and the right side of the prefabricated bag are opened; (c), the material is pushed on the station to be pushed, the precast bag is moved, the material and the prefabricated bag perform opposite motion, and the material is pushed into the prefabricated bag; (d), the material is pushed to the bottom of the prefabricated bag, and the material continues moves along with the prefabricated bag in the pushed direction; (e), next material is cyclically conveyed according to the steps. The material conveying method disclosed by the invention has the characteristics that the material pushing serialization degree is high, the conveying and packing distance is short, the materials cannot fall, and the conveying and packing efficiency is high.

Owner:上海松川峰冠包装自动化有限公司

Material clamping and conveying method of prefabricated bag packaging machine

Owner:上海松川峰冠包装自动化有限公司

Pipe chain machine tensioner

The invention discloses a tensioning device of a tube chain machine. The tensioning device comprises a tension sprocket mechanism, and a tension driving mechanism used for providing tensioning force for the tension sprocket mechanism, wherein the tension sprocket mechanism comprises a tension sprocket which is matched with a main shaft, two ends of the main shaft are fixed on a frame structure, at least a local part of the frame structure is provided with a sliding plate or sliding block structure, and under the driving of the tensioning force, the tension sprocket mechanism can be moved freely by the sliding plate or sliding block structure along at least one fixed slideway or slide rail. The tension driving mechanism is preferably selected from a cylinder driving mechanism and / or a counter weight driving mechanism. Preferably, the tensioning device also comprises an alarm device used for monitoring and warning chain fracture. The tensioning device has a firm and reliable structure, the displacement of the tension sprocket is completely along a straight line, chain falling and ununiform stress of a chain and the sprocket can not be caused, the displacement space of the tension sprocket is larger, the applicability is stronger, and the damage on other components of a conveying device when the chain is fractured can also be effectively avoided.

Owner:苏州麦科威化工设备有限公司

Nursing chair device and operating method

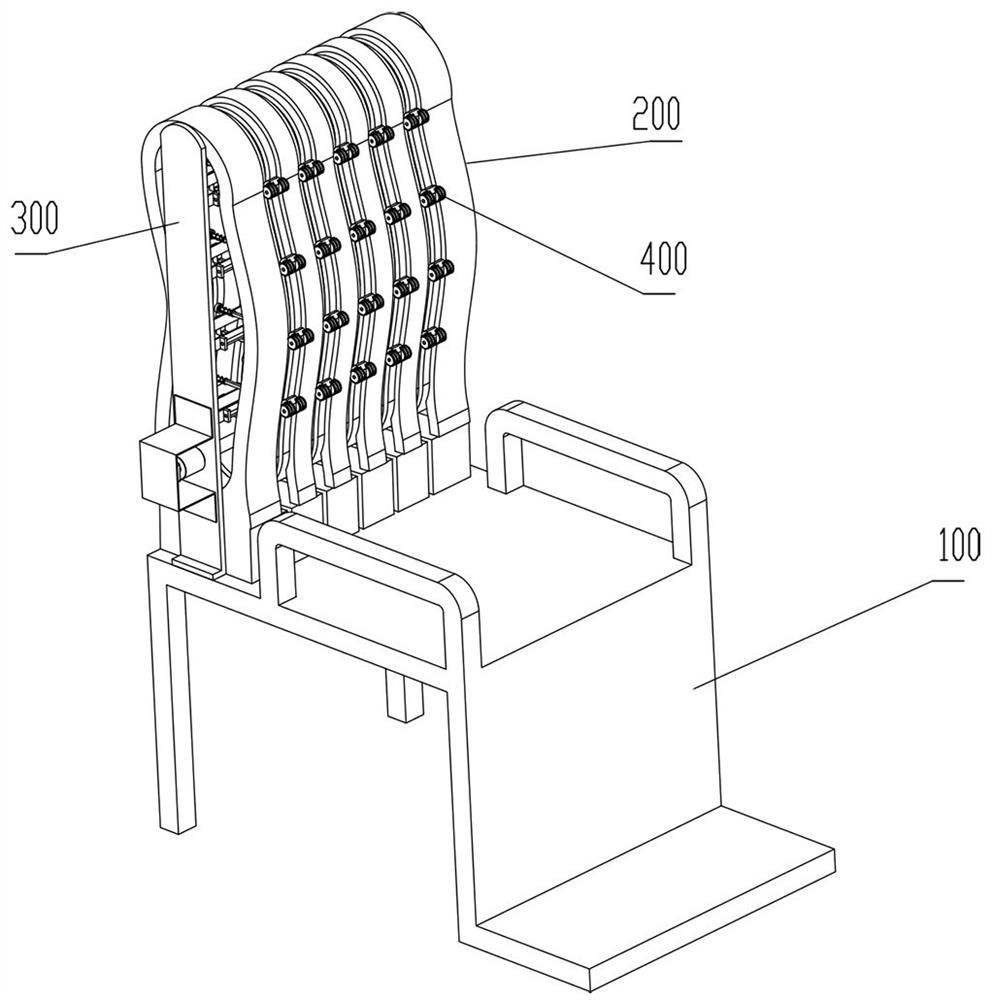

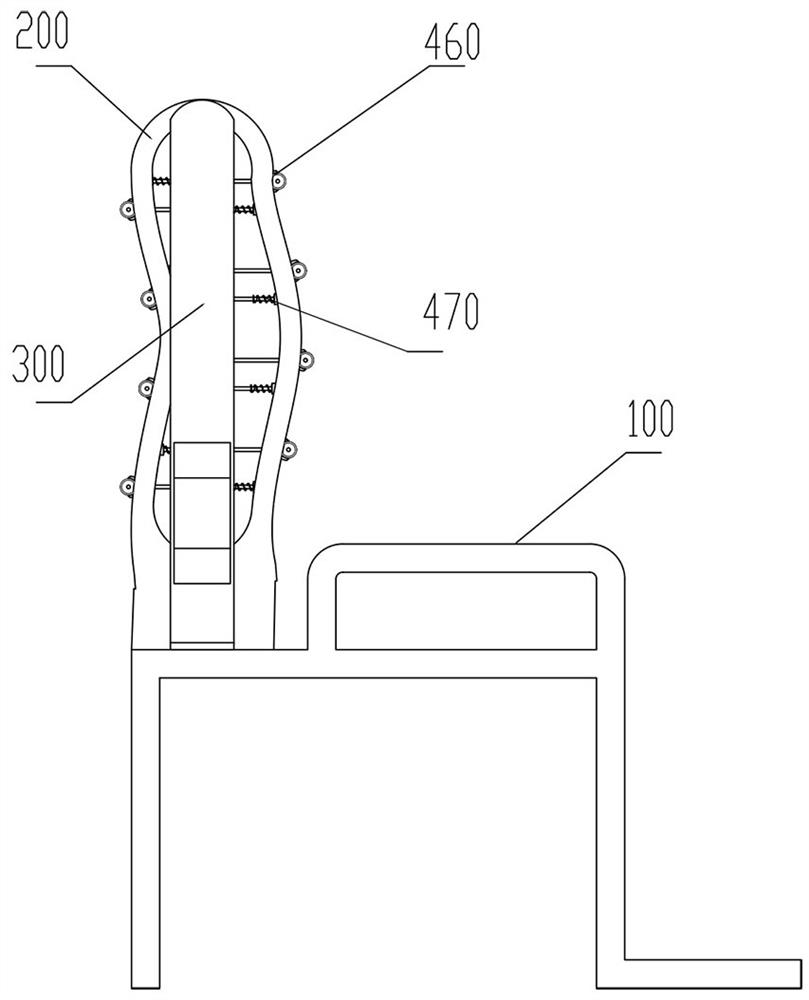

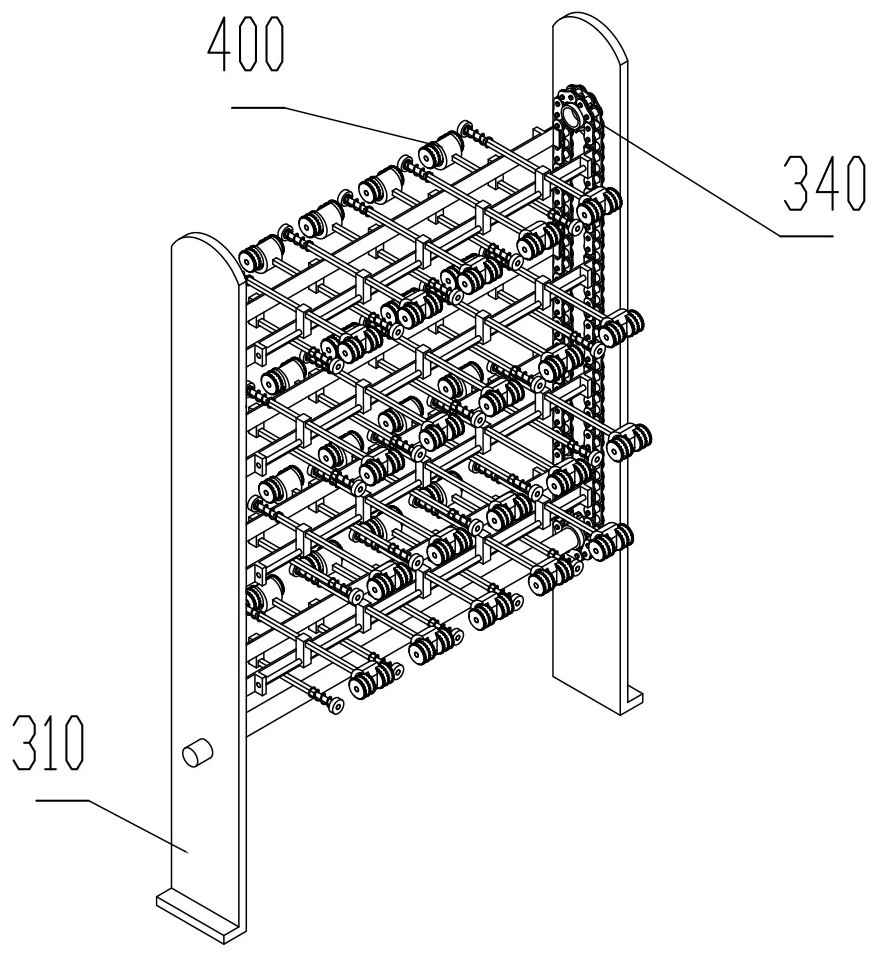

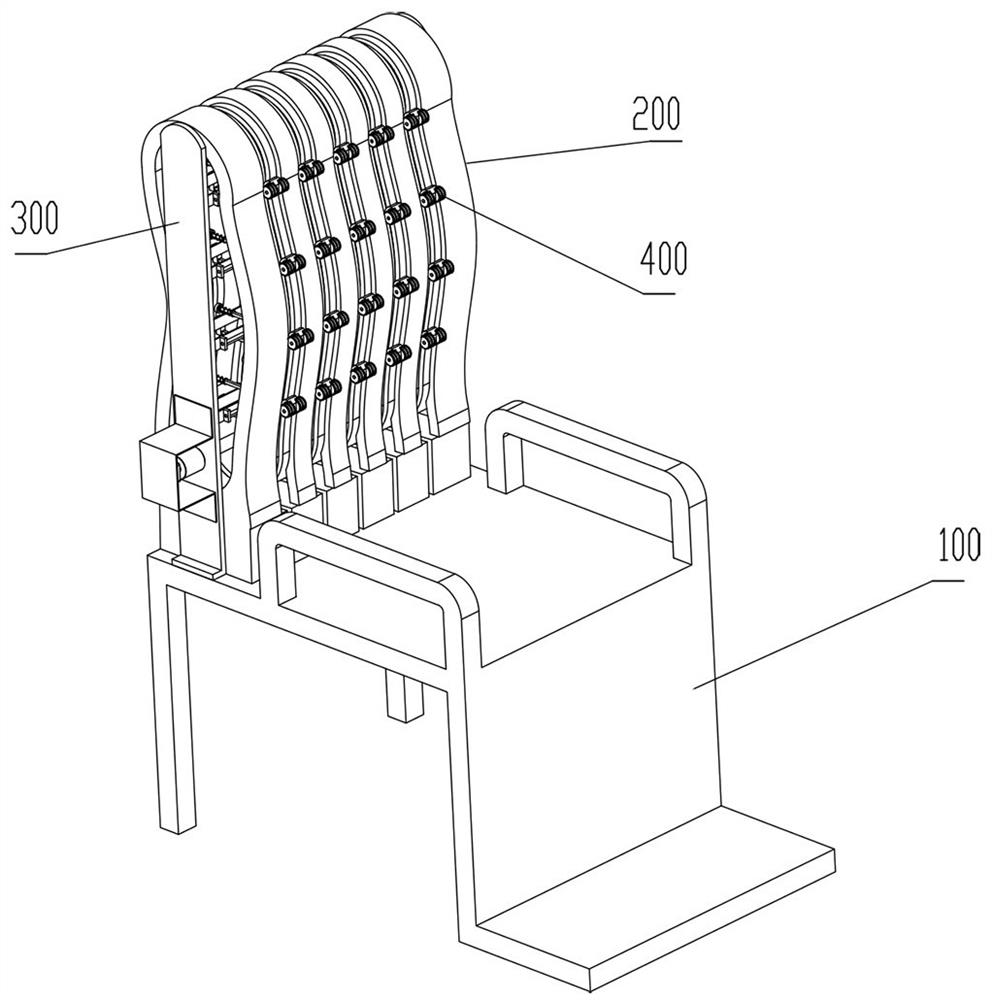

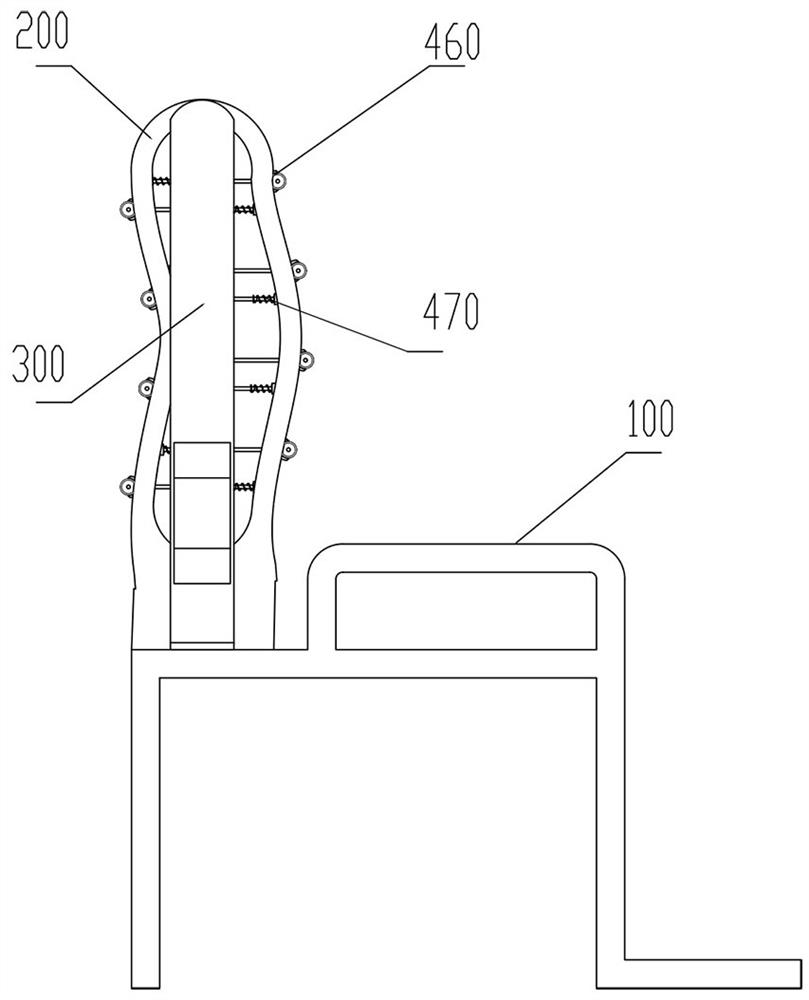

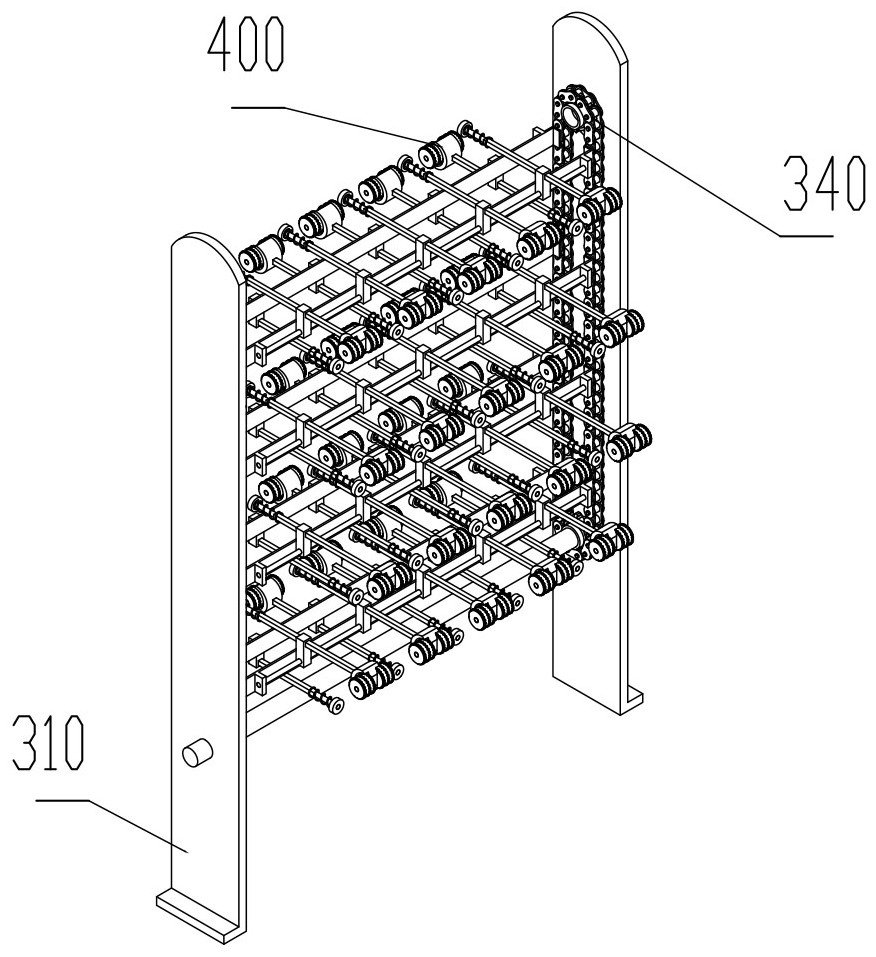

ActiveCN113057806BImprove comfortImprove fitDevices for pressing relfex pointsWheelchairs/patient conveyancePhysical medicine and rehabilitationDrive shaft

A nursing chair device and operation method, including a seat, a chair back assembly, a transmission device, and a roller assembly. The chair back assembly includes a left back, a middle back, and a right back, and the transmission device includes a support frame, a transmission shaft, a sprocket, Chain, motor, motor seat, the roller assembly includes a roller frame, a roller frame shaft, a positioning ring, a positioning block, a square shaft, a massage roller, the lower part of the seat has legs, both sides of the seat have armrests, and the front of the seat has Pedals, upper left back has left back, left back right has left back cam face, left back middle has left middle chamber, middle back upper has middle back, middle back has middle back cams on both sides There is a middle dorsal cavity in the middle of the middle back, a right dorsal cavity in the upper part of the right back, a right dorsal cam surface on the left side of the right back, and a right dorsal cavity in the middle of the right back.

Owner:JIAMUSI UNIVERSITY

Nursing chair device and operation method thereof

ActiveCN113057806AImprove comfortImprove fitDevices for pressing relfex pointsWheelchairs/patient conveyanceMedicineNursing care

The invention discloses a nursing chair device and an operation method thereof, the nursing chair device comprises a chair seat, a chair back assembly, a transmission device and a roller assembly, the chair back assembly comprises a left side back, a middle back and a right side back, the transmission device comprises a support frame, a transmission shaft, a chain wheel, a chain, a motor and a motor seat, and the roller assembly comprises a roller frame, a roller frame shaft, a positioning ring, a positioning block, a square shaft and a massage roller. The lower part of the chair seat has legs, both sides of the chair seat have armrests, and the front of the seat has footrests. The upper part of the left back is provided with a left back surface; the right side of the left back surface is provided with a left back cam surface, the middle of the left back surface is provided with a left middle cavity, the upper part of the middle back is provided with a middle back surface, both sides of the middle back surface are provided with middle back cam surfaces, the middle of the middle back is provided with a middle back middle cavity, and the upper right back has a right back surface, a right back cam face is arranged on the left side of the right back face, and a right back middle cavity is formed in the middle of the right back face.

Owner:JIAMUSI UNIVERSITY

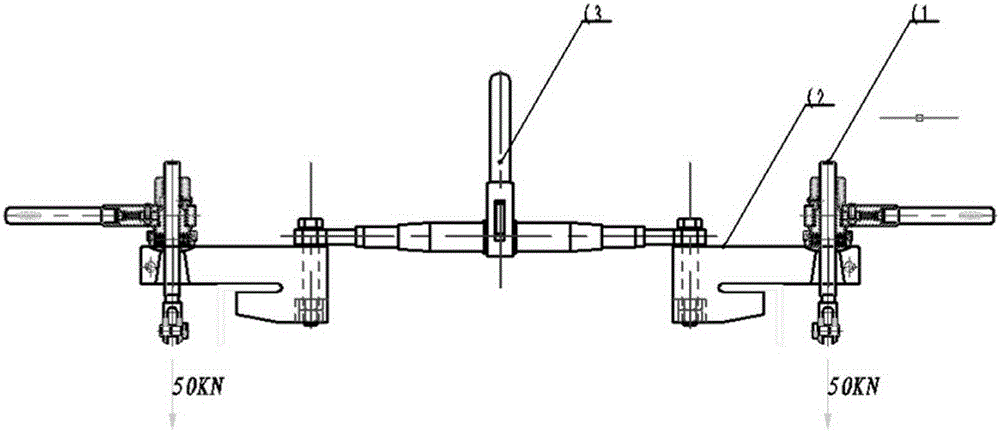

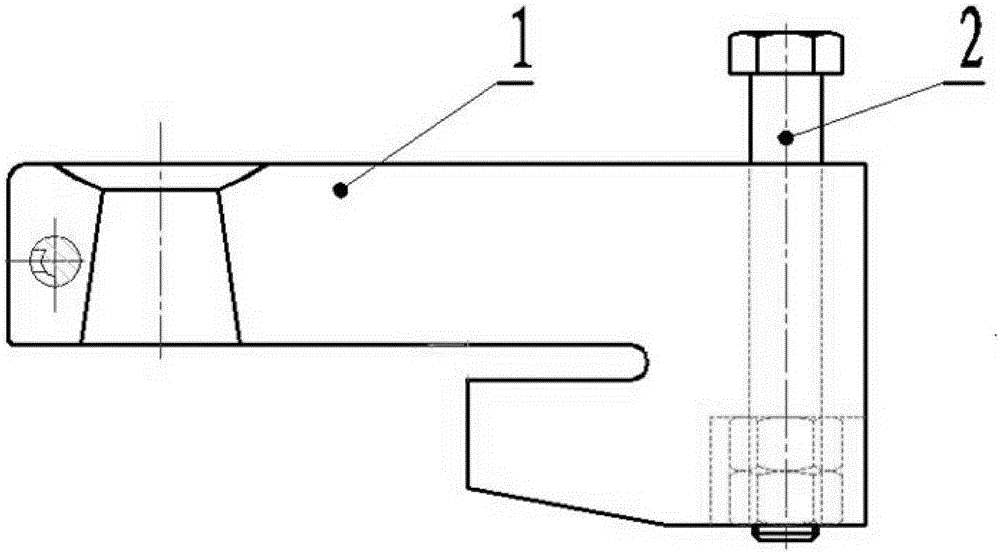

Vertical double-hanging clamp

InactiveCN105186366AShorten working timeReduce harmApparatus for overhead lines/cablesStructural engineeringTower

A vertical double-hanging clamp is characterized by comprising two symmetrically arranged cross arm angle steel clamping apparatuses (2), two sets of lead screws (1) connected with the cross arm angle steel clamping apparatuses (2) respectively, and a balancing pull rod (3) located in the middle of the two cross arm angle steel clamping apparatuses (2) and connected with the two cross arm angle steel clamping apparatuses (2). The beneficial effects of the invention are that: the vertical double-hanging clamp enables the whole work to be operated conveniently, effectively balances the tensile forces generated by tightening the lead screws to thereby not enable the tower materials to deform, enables the personal injury risk during the tightening process to be reduced effectively, does not need the help of other tools when being installed, can be installed rapidly during the installation process, and enables the working risk to be reduced.

Owner:YUNNAN POWER GRID CO LTD PUER POWER SUPPLY BUREAU

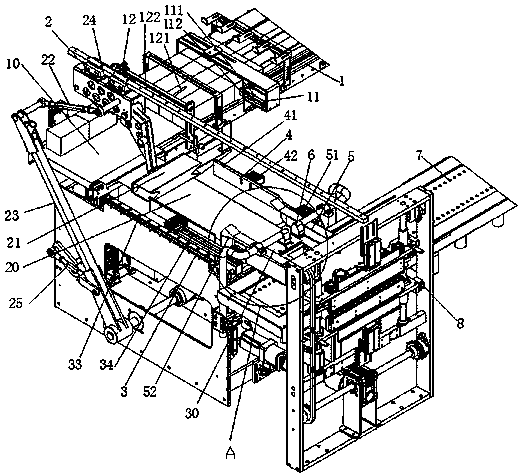

Control System of Prefabricated Bag Packaging Machine

ActiveCN105857649BShort tripPrevent the situation of dumpingSolid materialRolling paperControl system

The invention discloses a control system of a prefabricated bag packing machine and relates to the technical field of mechanical control of packing machines. The control system of the prefabricated bag packing machine comprises a feeding mechanism, a pushing mechanism, a bag stretching mechanism, a bag opening mechanism and a bag conveying mechanism and is characterized by further comprising a clamping mechanism and a translation mechanism. The control system of the prefabricated bag packing machine is applicable to packing machines for packing via prefabricated bags such as small packing machines, medium packing machines and large packing machines and the like; meanwhile, the control system of the prefabricated bag packing machine is also suitable for packing materials such as facial tissues, flat paper, paper towels, blocky foods, drugs, roll paper, unpackaged foods and the like. Through the control system of the prefabricated bag packing machine, the problems that processes in single station of the prefabricated bag packing machine are complex, various packing actions are needed, the travel distance among the stations is long, the equipment occupied area is large, the material is irregular and is easy to pour, the prefabricated bags are easy to break, the material-pushing travel distance is long, the packing effect is poor, and the packaging efficiency is low in the prior art can be solved.

Owner:上海松川峰冠包装自动化有限公司

Material holding and conveying method of prefabricated bag packaging machine

The invention discloses a material holding type conveying method for a preformed-bag packer and belongs to the technical field of material packing. The material holding type conveying method is characterized by including the steps of firstly, conveying materials into a holding mechanism; secondly, conveying the materials by a holding way to a to-be-pushed work station and opening preformed bags by a bag opening mechanism; thirdly, pushing the materials by a pushing mechanism while driving the preformed bags to move opposite the materials by the bag opening mechanism. The material holding type conveying method is adaptable to both regular materials in bulk and irregular materials in bulk; the material holding type conveying way is stabler than the material clamping type conveying way and squeezing of the materials is avoided; thus, material conveying efficiency is improved, and efficiency of preformed bag packing is improved.

Owner:上海松川峰冠包装自动化有限公司

Packing machine with pre-made bags

The invention discloses a packaging machine for packaging by adopting prefabricated bags, and relates to the technical field of packaging machinery. The packaging machine comprises a bag opening mechanism and further comprises a translation mechanism and a conveying device for moving in a material clamping or holding-conveying direction, wherein the conveying device is arranged behind the bag opening mechanism; the conveying device is connected to the translation mechanism, and is driven by the translation mechanism to move back and forth in the material clamping or holding-conveying direction. The packaging machine can solve the problems such as complex processes, many packaging actions, relatively long stroke between stations, great equipment floor space, easy material pouring due to irregular materials, easy prefabricated bag breaking, a long material pushing stroke, poor packaging effect, low packaging efficiency and the like on single station of prefabricated bag packaging machinery in the prior art.

Owner:上海松川峰冠包装自动化有限公司

A kind of water surface ship pier method with flexible material laid on the outer surface

Owner:CHINA SHIP DEV & DESIGN CENT

Material packaging method of prefabricated bag packaging machine

ActiveCN105691677BRealize deliveryRealize the continuous effectIndividual articlesEngineeringPacking method

Owner:上海松川峰冠包装自动化有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com