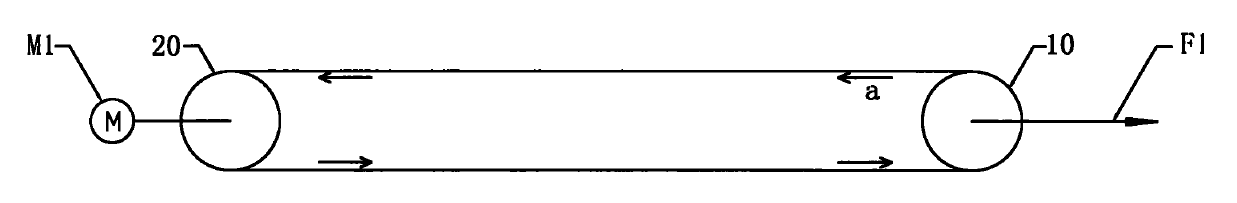

Pipe chain machine tensioner

A technology of tensioning device and pipe chain machine, which is applied in the field of pipe chain machine, can solve the problems of unable to provide constant force, limited tension force, inconstant tension force, etc., and achieves reliable structural strength, constant tension force, The effect of large displacement space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

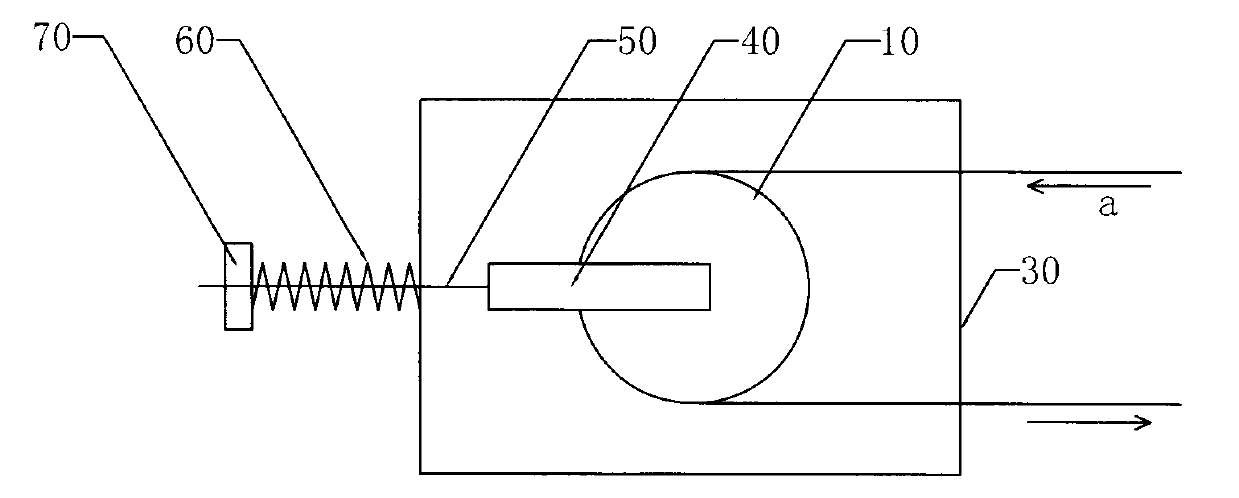

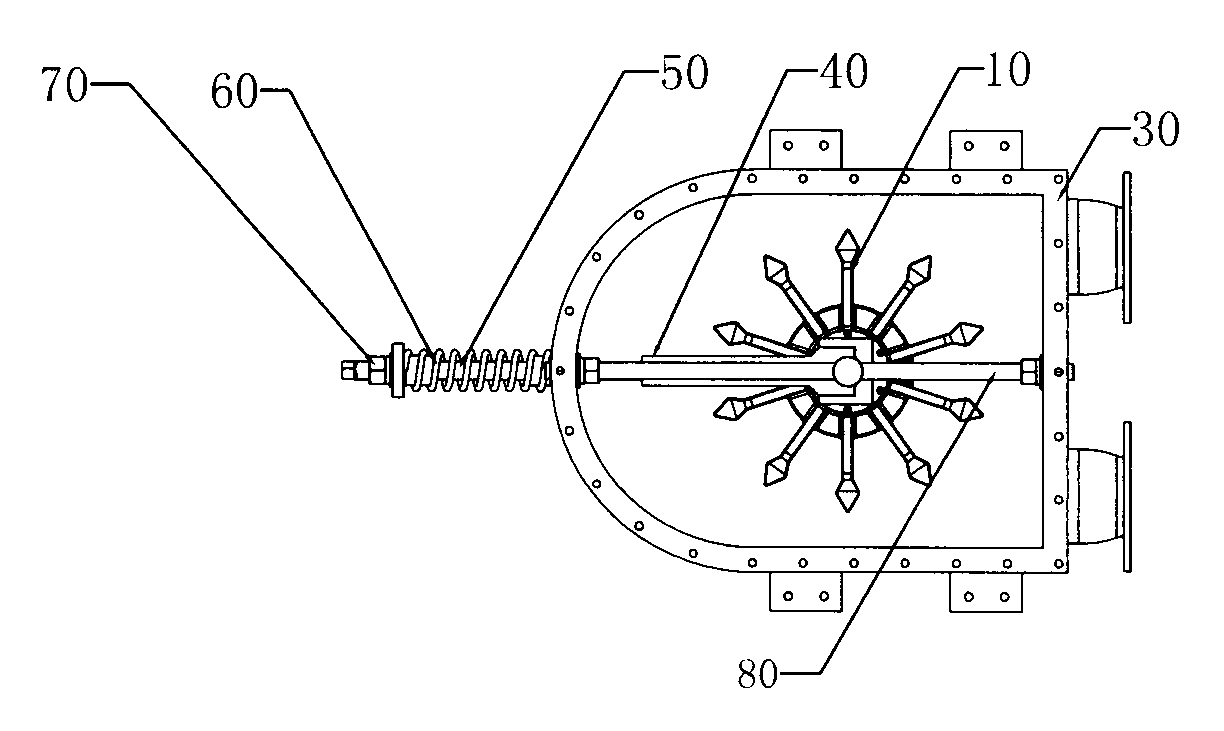

[0033] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and several preferred embodiments.

[0034] The pipe chain machine tensioning device of the present invention comprises:

[0035] tensioning sprocket mechanism,

[0036] And, a tension drive mechanism for providing constant tension to the tension sprocket mechanism. Specifically, the aforementioned tensioning sprocket mechanism includes a tensioning sprocket 1, the tensioning sprocket cooperates with a main shaft, the two ends of the main shaft are fixed on a frame structure, and at least part of the frame structure has a slide plate or Slider structure, driven by the aforementioned tension force, the tensioning sprocket mechanism can move freely along at least one fixed slideway or slide rail through the aforementioned slide plate or slider structure, so that the structure of the tensioning sprocket mechanism can Strength is more reliable.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com