Multi-color shuttle weft satin double brocade woven label and its weaving method

A weft satin and color shuttle technology, which is applied in the field of multi-color shuttle weft satin double brocade weaving labels and its weaving field, can solve the problems that are difficult to achieve compact structure, stable shape, etc., and achieve the reduction of color penetration and color performance Good, the effect of the tight structure of the woven label

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The woven label in this embodiment is woven with 8 pieces of 5-ply ground structure + 8 pieces of 5-ply reinforced satin lining structure + 16 pieces of 5-ply net shuttle structure for weaving. The weaving label process parameters are: woven label warp density 146 Roots / inch, weft density 146 / inch; woven label warp yarn is 75D white, woven label weft yarn is: the first color shuttle is the woven label ground tissue layer__polyester yarn 100D white, the second color shuttle is the woven label ground weave Layer __ polyester yarn 100D gray, the third color shuttle is woven label net shuttle organization layer __ polyester yarn 100D black.

[0049] The weaving method of the woven label of the present embodiment specifically comprises the following steps:

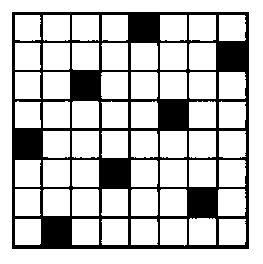

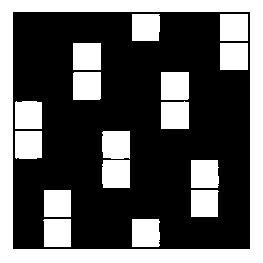

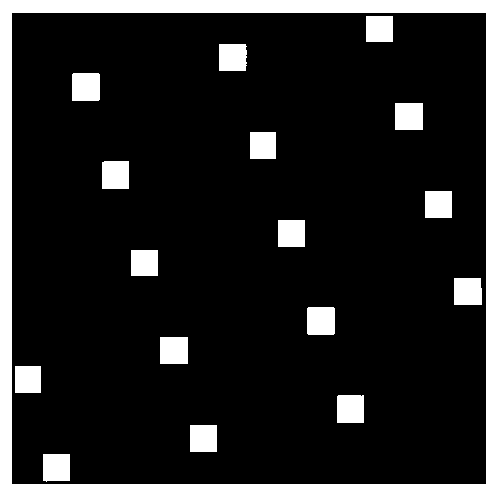

[0050] (1), woven label writing design: first make or determine the fabric structure, the woven label structure layer is 8 pieces of 5 flying weft surface structure ( figure 1 ), the woven label lining layer is 8 pieces...

Embodiment 2

[0055] The woven label in this embodiment is woven with 5 2-fly ground weaves + 10 7-fly reinforced satin lining weaves + 20 7-fly net shuttle weaves. The weaving label process parameters are: woven label warp density 146 Roots / inch, weft density 146 / inch; woven label warp yarn is 75D black, woven label weft yarn is: the first color shuttle is the woven label ground tissue layer__polyester yarn 75D black, the second color shuttle is the woven label lining weave Layer__polyester yarn 75D dark blue, the third color shuttle is the woven label mesh shuttle organization layer, the first mesh shuttle__polyester yarn 75D gray, the fourth color shuttle is the woven label mesh shuttle organization layer, the second mesh shuttle__polyester yarn 75D red.

[0056] The weaving method of the woven label of the present embodiment specifically comprises the following steps:

[0057] (1), woven label writing design: first make or determine the fabric structure, the weave layer of the woven la...

Embodiment 3

[0062] The woven label in this embodiment adopts 8 pieces of 3 enclave weave + 8 pieces of 3 fly reinforced satin liner weave + 16 pieces of 11 fly first mesh shuttle organization + 32 pieces of 27 fly second mesh shuttle organization for weaving, weaving The process parameters of the label are: the warp density of the woven label is 146 pieces / inch, and the weft density is 146 pieces / inch; the warp yarn of the woven label is 75D white, and the weft yarn of the woven label is: the first color shuttle is the ground tissue layer of the woven label__polyester yarn 100D light blue , the second color shuttle is the weaving label lining layer__polyester yarn 100D blue, the third color shuttle is the weaving label mesh shuttle weave layer, the first mesh shuttle__polyester yarn 100D green, the fourth color shuttle is the weaving label mesh shuttle Organization layer 2nd mesh shuttle __ polyester yarn 100D black.

[0063] The weaving method of the woven label of the present embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com