Prefabricated bag packaging method of prefabricated bag packaging machine

A packaging method and prefabricated bag technology, which is applied in the field of packaging machine packaging technology, can solve the problems of long pushing stroke, low packaging efficiency, and complicated process, and achieve the effects of shortening the pushing distance, improving packaging efficiency, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

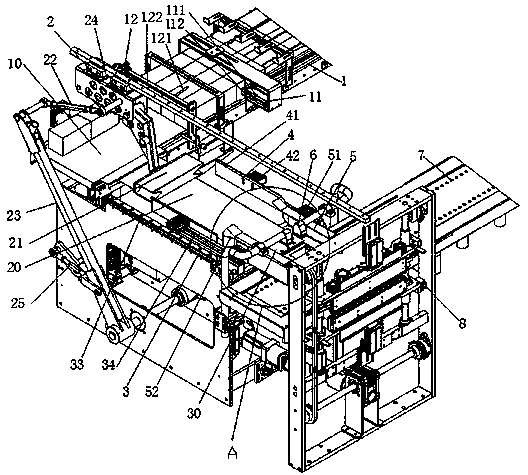

[0094] This embodiment discloses the packaging method of the prefabricated bag of the prefabricated bag packaging machine,

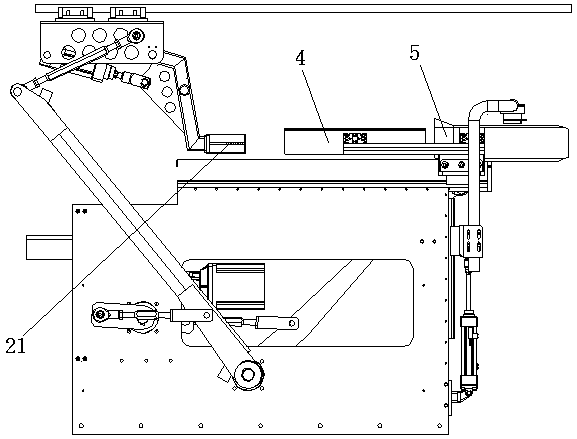

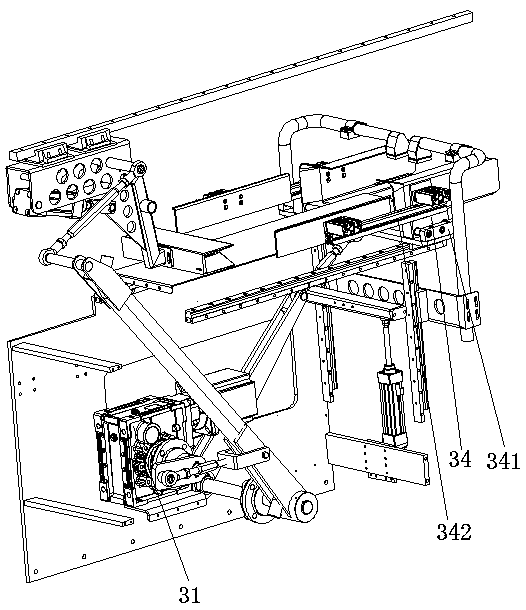

[0095] The prefabricated bag is transported to the bag opening station 30, where the prefabricated bag is opened and placed on the bag opening mechanism 5 of the prefabricated packaging machine at the bag opening station 30;

[0096] The prefabricated bag moves towards the material along with the opening mechanism 5 of the prefabricated bag packaging machine;

[0097] During the movement of the prefabricated bag and the material, under the action of the pushing mechanism 2 of the prefabricated bag packaging machine, the prefabricated bag wraps the material pushed by the pushing mechanism 2, and under the action of the pushing mechanism 2, wraps the material After the pre-made bags are rolled out.

[0098] The packaging method of the prefabricated bag of this embodiment is to let the prefabricated bag and the material form a relative movement, and when t...

Embodiment 2

[0100] This embodiment discloses the packaging method of the prefabricated bag of the prefabricated bag packaging machine,

[0101] The prefabricated bag is transported to the bag opening station 30, where the prefabricated bag is opened and placed on the bag opening mechanism 5 of the prefabricated packaging machine at the bag opening station 30;

[0102] The prefabricated bag moves towards the material along with the opening mechanism 5 of the prefabricated bag packaging machine;

[0103] During the movement of the prefabricated bag and the material, under the action of the pushing mechanism 2 of the prefabricated bag packaging machine, the prefabricated bag wraps the material pushed by the pushing mechanism 2, and under the action of the pushing mechanism 2, wraps the material After the prefabricated bag is launched;

[0104] The opening of the prefabricated bag at the bag opening station 30 specifically refers to: the bag opening mechanism 6 of the prefabricated bag packa...

Embodiment 3

[0109] This embodiment discloses the packaging method of the prefabricated bag of the prefabricated bag packaging machine,

[0110] The prefabricated bag is transported to the bag opening station 30, where the prefabricated bag is opened and placed on the bag opening mechanism 5 of the prefabricated packaging machine at the bag opening station 30;

[0111] The prefabricated bag moves towards the material along with the opening mechanism 5 of the prefabricated bag packaging machine;

[0112] During the movement of the prefabricated bag and the material, under the action of the pushing mechanism 2 of the prefabricated bag packaging machine, the prefabricated bag wraps the material pushed by the pushing mechanism 2, and under the action of the pushing mechanism 2, wraps the material After the prefabricated bag is launched;

[0113] The opening of the prefabricated bag at the bag opening station 30 specifically refers to: the bag opening mechanism 6 of the prefabricated bag packa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com