Vertical double-hanging clamp

A technology of double elevators and fixtures, applied in the direction of overhead line/cable equipment, etc., can solve the problems of increased risk factor, deformation of tower materials, and uneven force on tower materials on both sides, so as to reduce risks, reduce operating time, reduce The effect of risk of personal injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

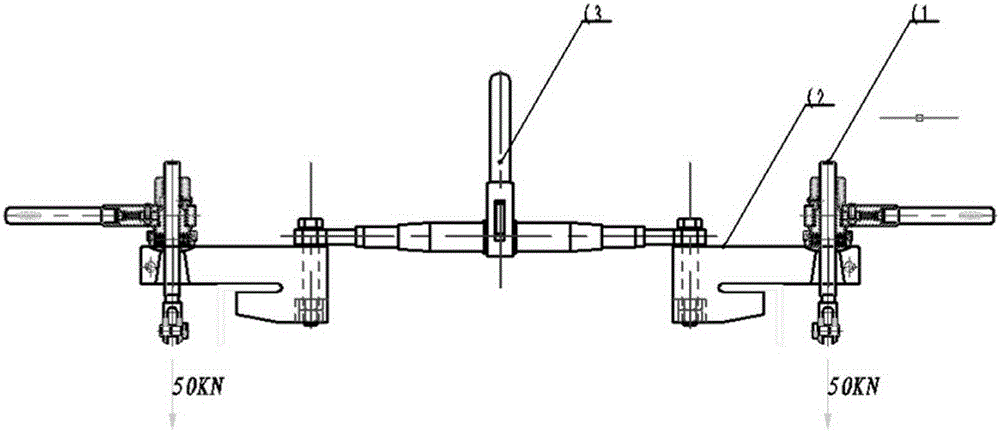

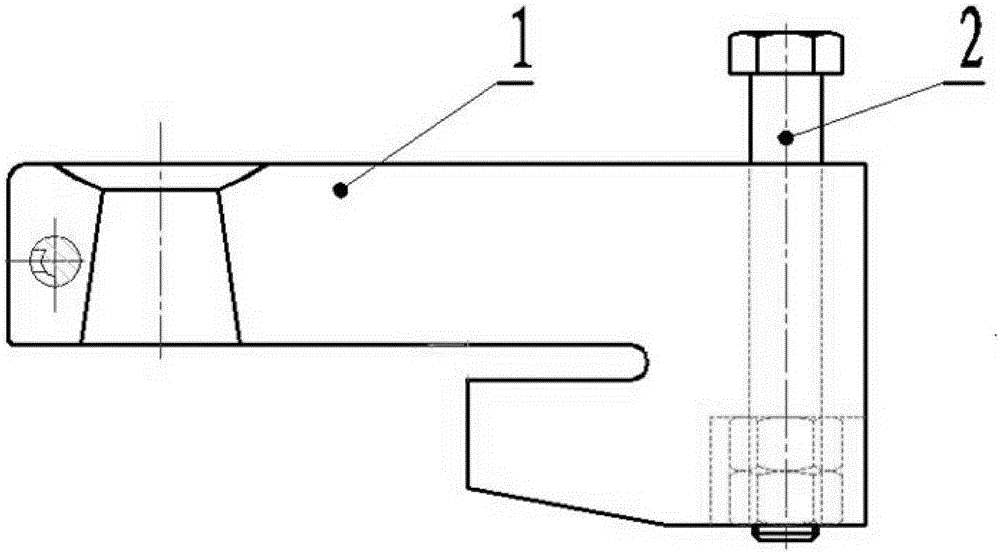

[0019] See figure 1 , Fig. 2, vertical double elevators, the present invention is characterized in that it includes two cross-arm angle steel clamps 2, two sets of screw rods 1 connected to the cross-arm angle steel clamps 2 respectively, and two sets of cross-arm angle steel clamps 2 in the middle The balance rod 3 connected with it; wherein, the screw 1 is screwed in through the screw threaded hole 2.1 on the cross-arm angle steel clamp 2; the balance rod 3 includes a vertical rod 3.1 located in the center and a fixed connection with the vertical rod 3.1 The crossbar 3.2 has bolt connection holes 3.3 on both sides of the crossbar 3.2, and the bolts 4 are respectively inserted into the bolt connection holes 3.3 and the bolt holes 2.2 opened on the crossarm angle steel fixture 2 to balance the two ends of the tie rod 3 crossbar 3.2 Connect with cross-arm angle steel fixture 2.

[0020] The cross-arm angle steel fixture 2 of the present invention includes a rectangular clamp b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com