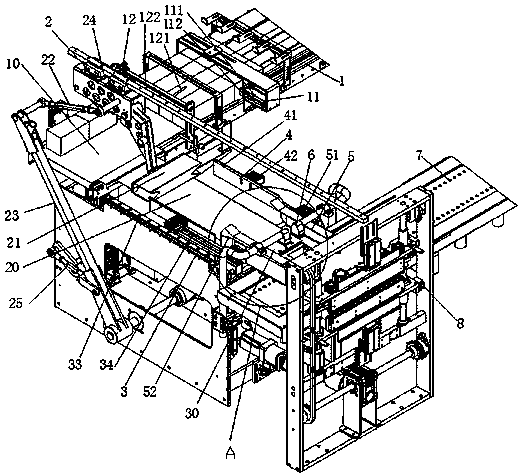

Material holding and conveying method of prefabricated bag packaging machine

A pre-made bag and packaging machine technology, applied in packaging and other directions, can solve the problems of long stroke and low efficiency of subsequent packaging, and achieve the effect of improving efficiency, improving material conveying efficiency, and short conveying and packaging stroke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0109] The material holding and conveying method of the prefabricated bag packaging machine includes the following steps:

[0110] a. The material is sent into the holding mechanism 9;

[0111] b. Hold and convey the material to the station to be pushed, and the prefabricated bag is opened by the bag opening mechanism 5;

[0112] c. The material is pushed by the pushing mechanism 2, and at the same time, the prefabricated bag moves towards the material under the drive of the bag stretching mechanism 5.

[0113] The material is sent into the holding mechanism 9. Specifically, the material can be put into the funnel, and the material is put into the holding mechanism 9 through the funnel; a conveyor belt can also be used to set the height of the conveyor belt higher than the holding mechanism 9. The conveyor belt and the holding mechanism 9 form a height difference, and the materials are transported into the holding mechanism 9 through the conveyor belt.

[0114] The material ...

Embodiment 2

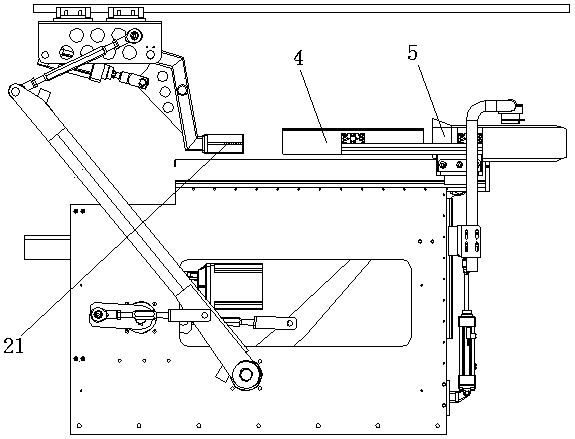

[0116] The material holding and conveying method of the prefabricated bag packaging machine specifically includes the following steps:

[0117] a. The material is sent to the top of the holding mechanism 9 by the feeding mechanism 1, and the material falls into the holding mechanism 9;

[0118] b. The holding mechanism 9 holds the material to the station to be pushed under the action of the translation mechanism 3;

[0119] c. The material is pushed into the prefabricated bag opened by the bag stretching mechanism 5 by the pushing head 21, and the holding mechanism 9 returns to the initial position.

[0120] The material is sent to the top of the holding mechanism by the feeding mechanism, and the material falls into the holding mechanism; the holding mechanism holds the material to the position to be pushed under the action of the translation mechanism; the material is pushed to the bag opening mechanism by the pushing head to open In the prefabricated bag, the holding mecha...

Embodiment 3

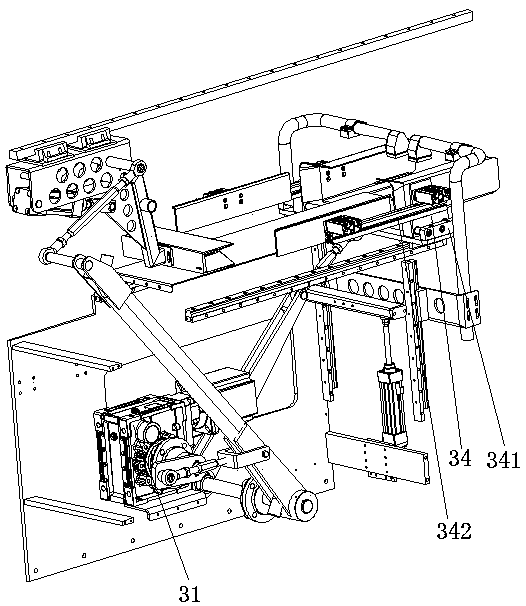

[0122] The material holding and conveying method of the prefabricated bag packaging machine specifically includes the following steps:

[0123] a. The material is sent to the top of the holding mechanism 9 by the feeding mechanism 1, and the material falls into the holding mechanism 9;

[0124] b. The holding mechanism 9 holds the material to the station to be pushed under the action of the translation mechanism 3;

[0125] c. The material is pushed into the prefabricated bag opened by the bag stretching mechanism 5 by the pushing head 21, and the holding mechanism 9 returns to the initial position;

[0126] In the step a, the material is a bulk material, and the material falling into the holding mechanism 9 means that the holding mechanism 9 moves to the bottom of the feeding mechanism 1 under the action of the translation mechanism 3, and the feeding mechanism 1 puts the material into the holding mechanism 9 Inside.

[0127] In step a, the material is a bulk material, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com