Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Reduce jet noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

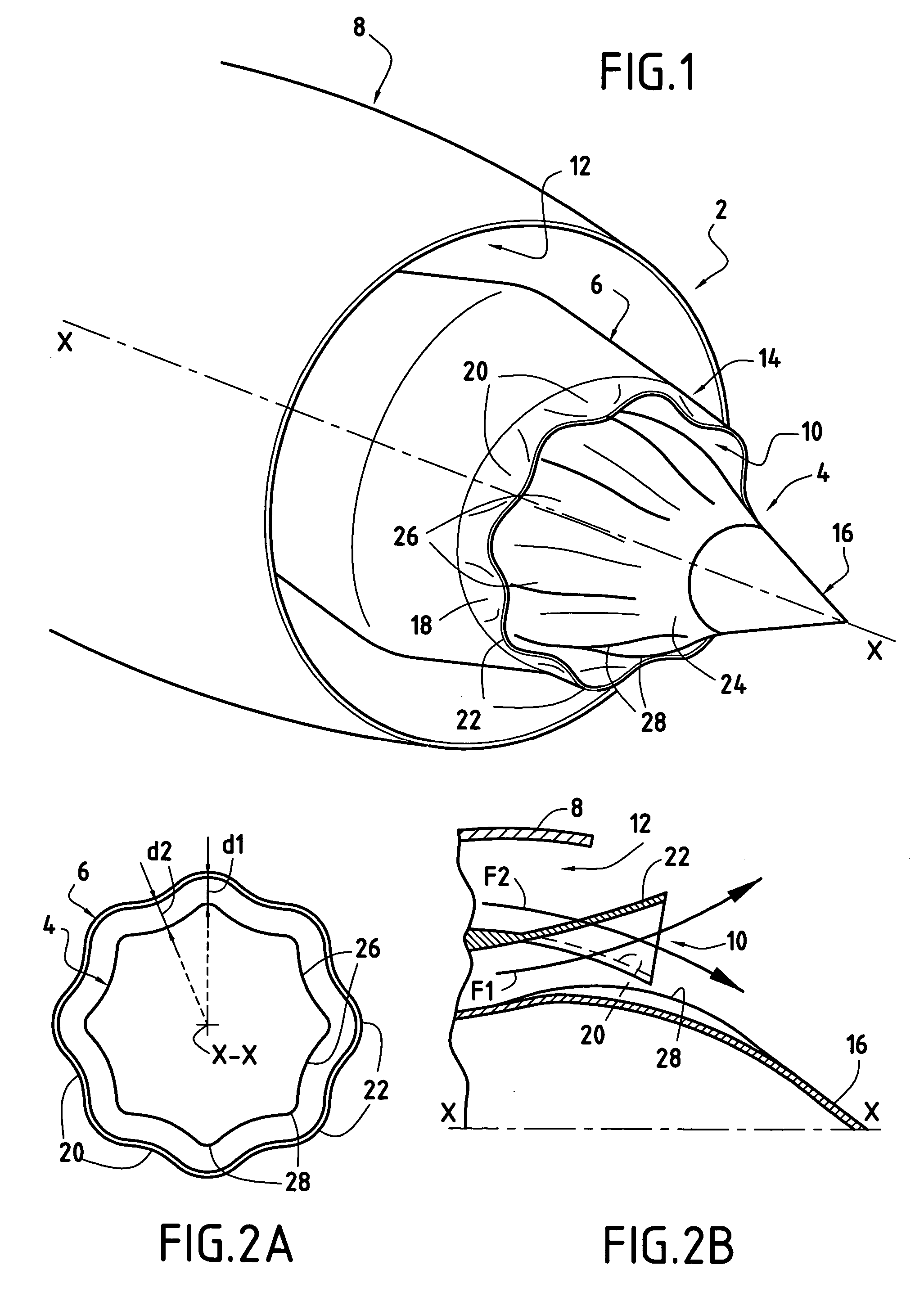

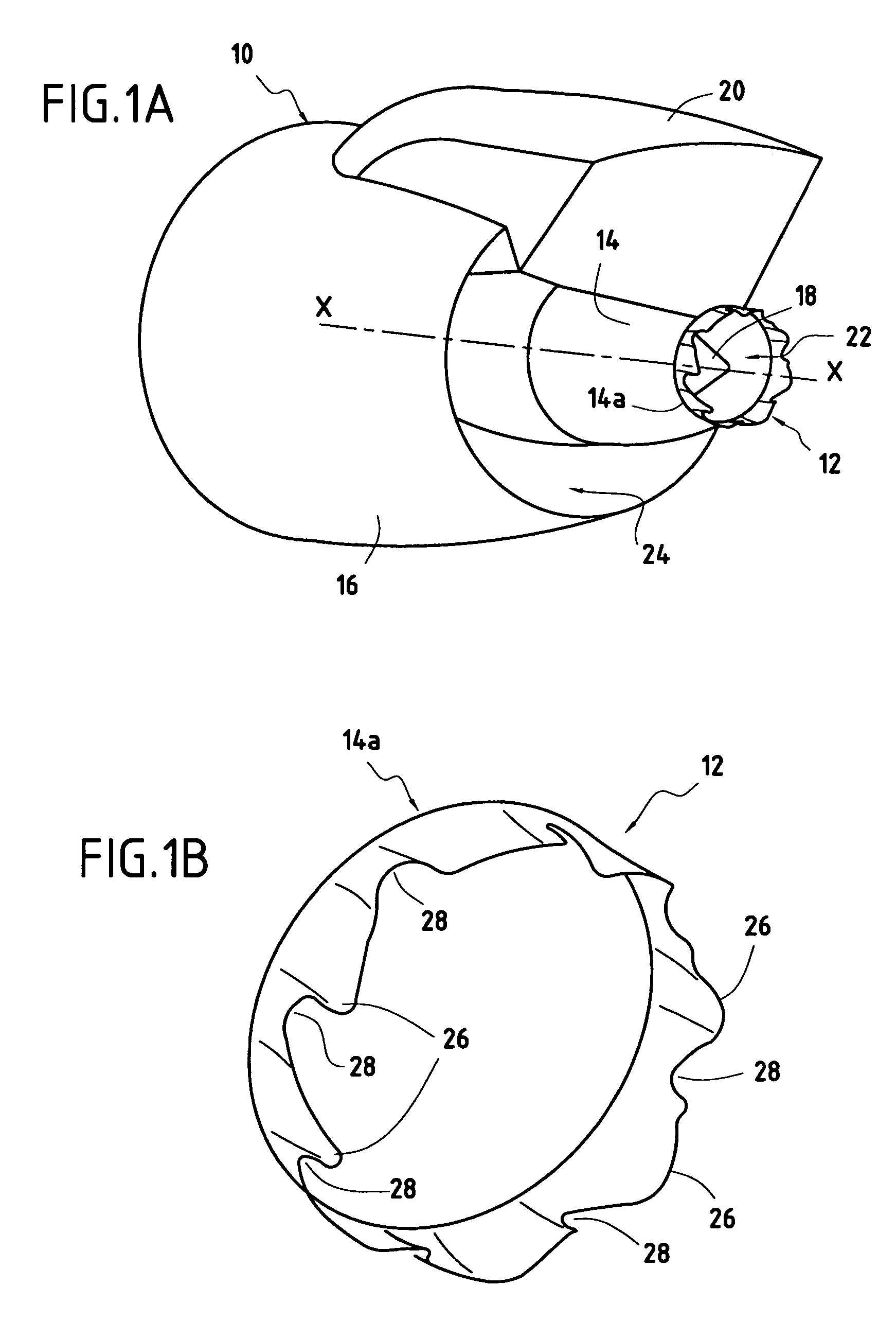

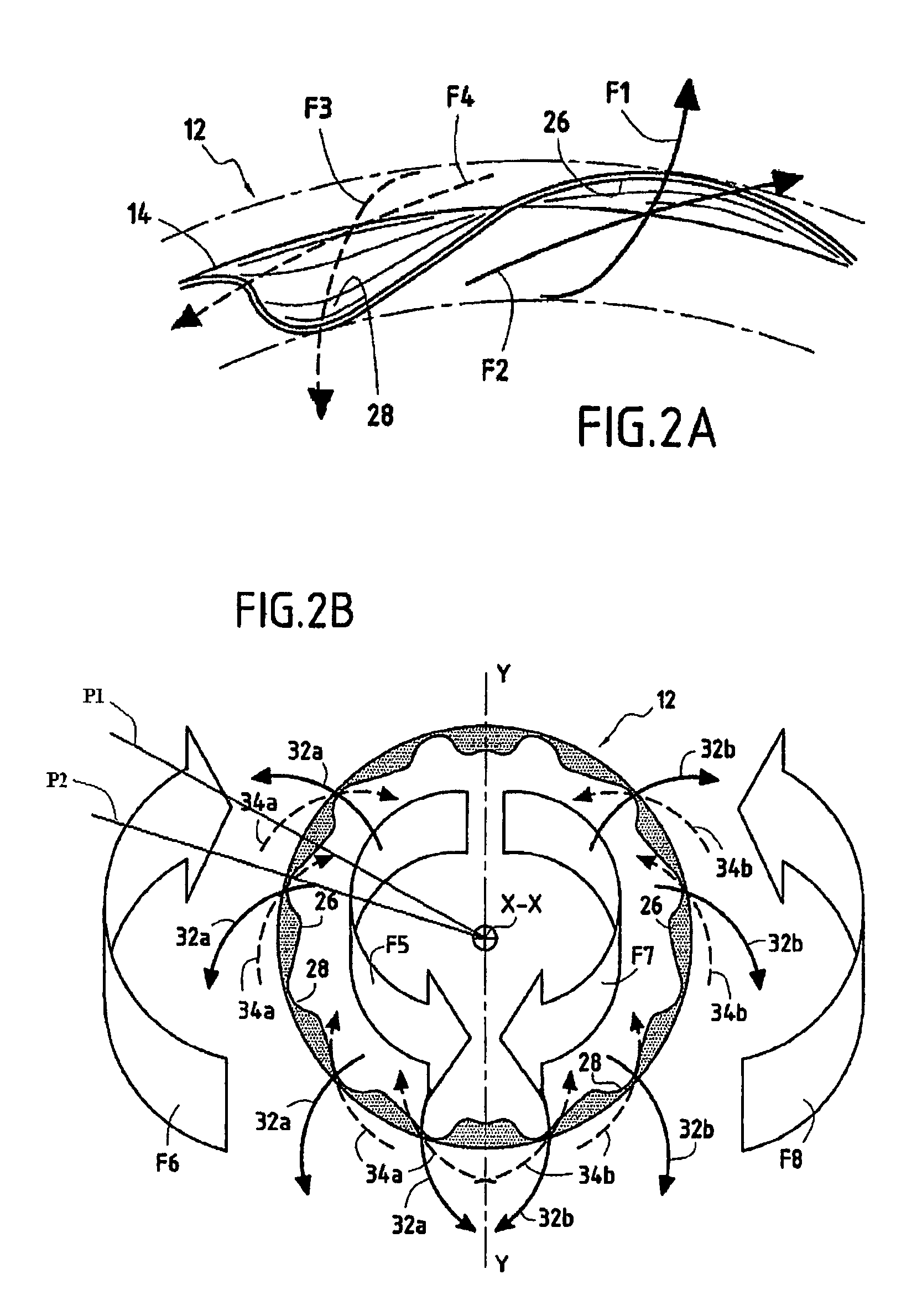

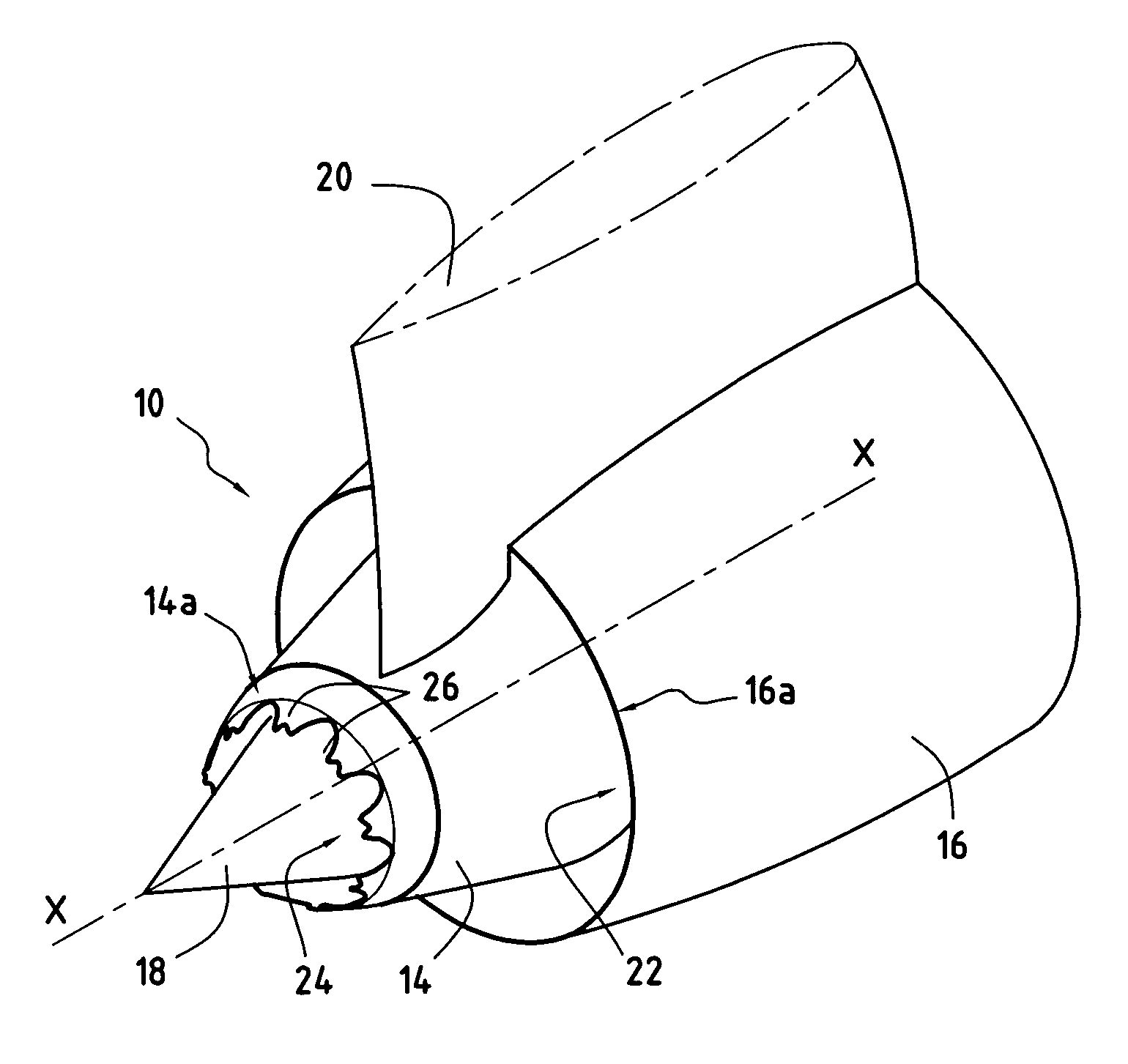

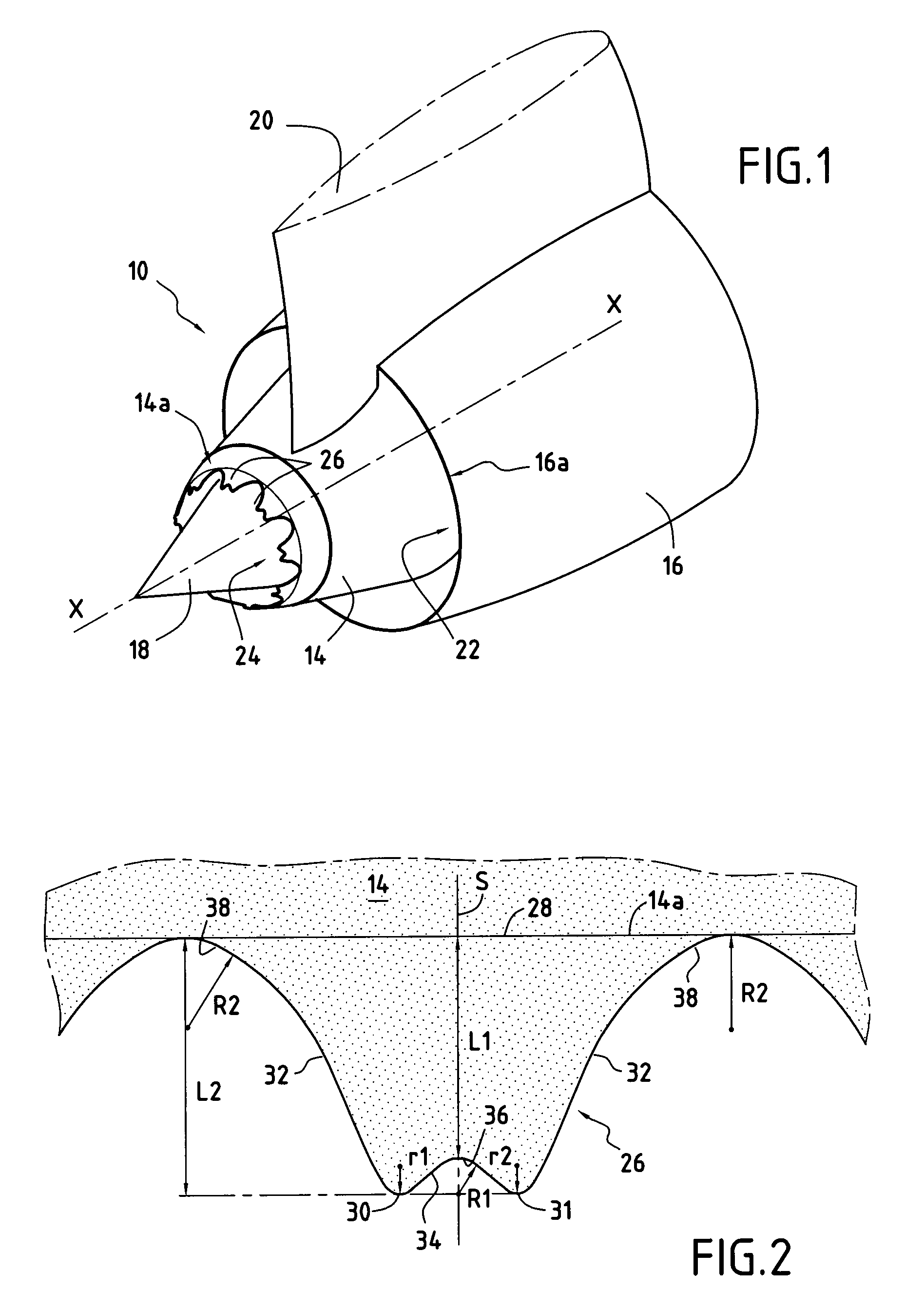

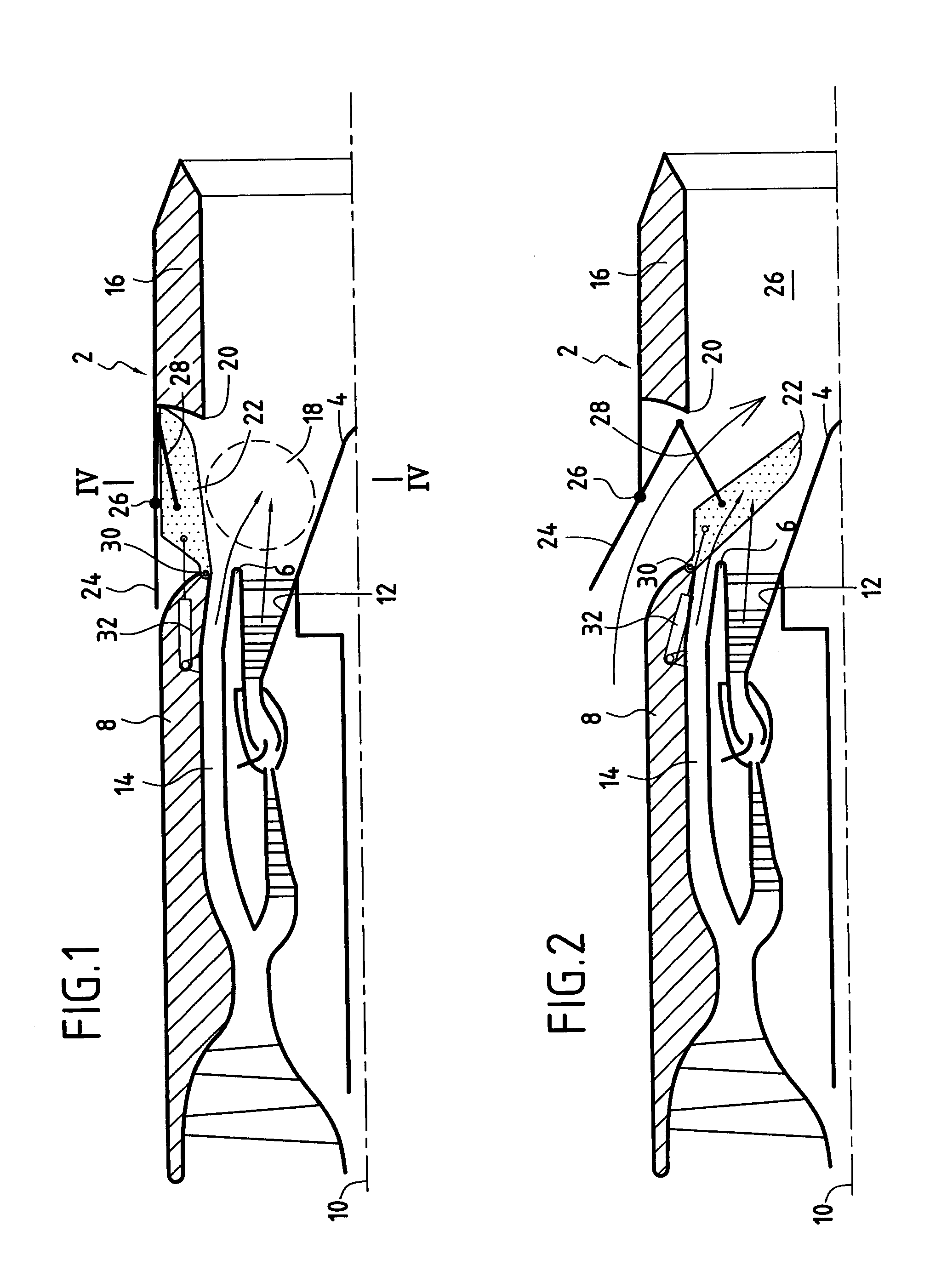

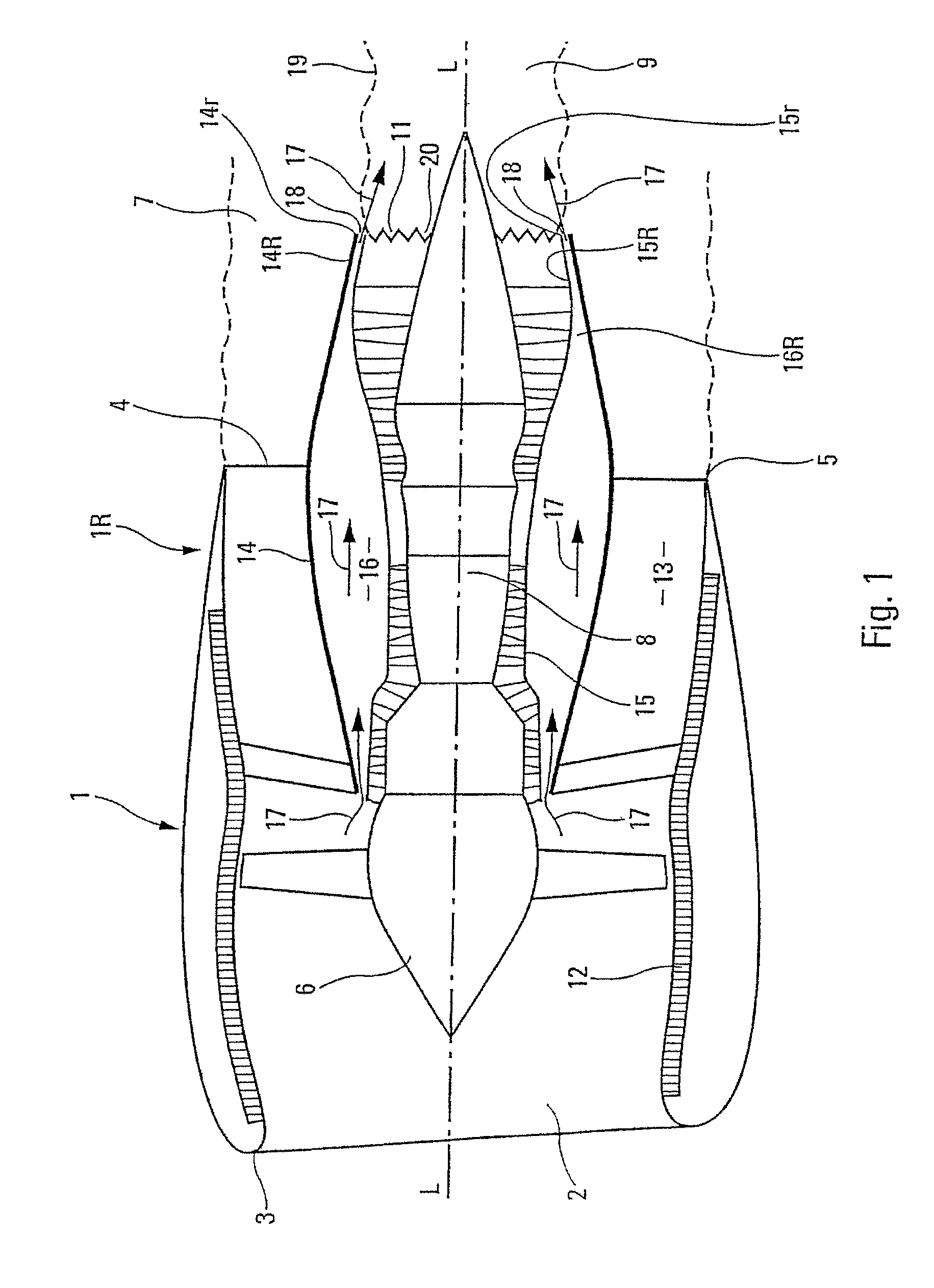

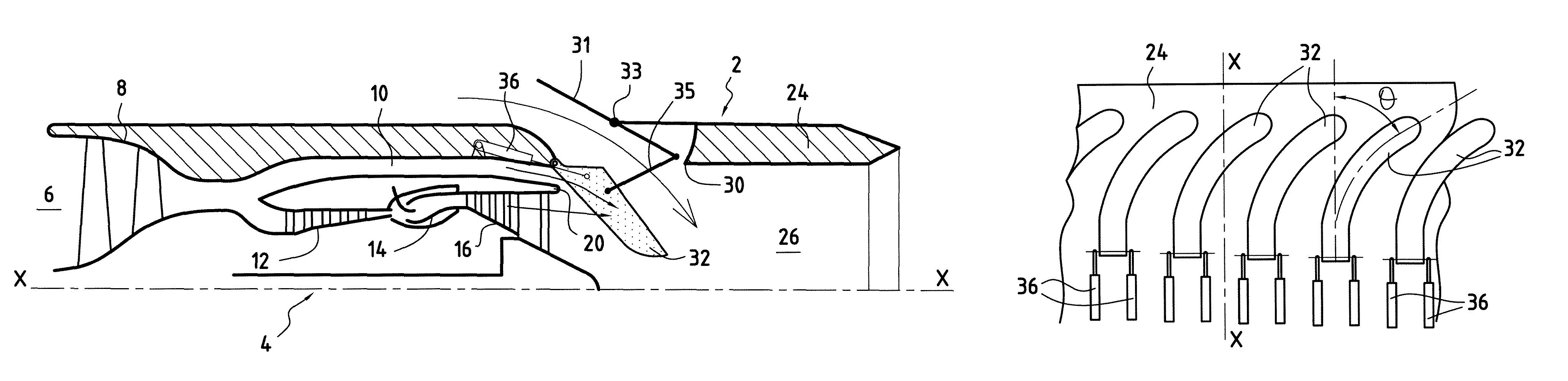

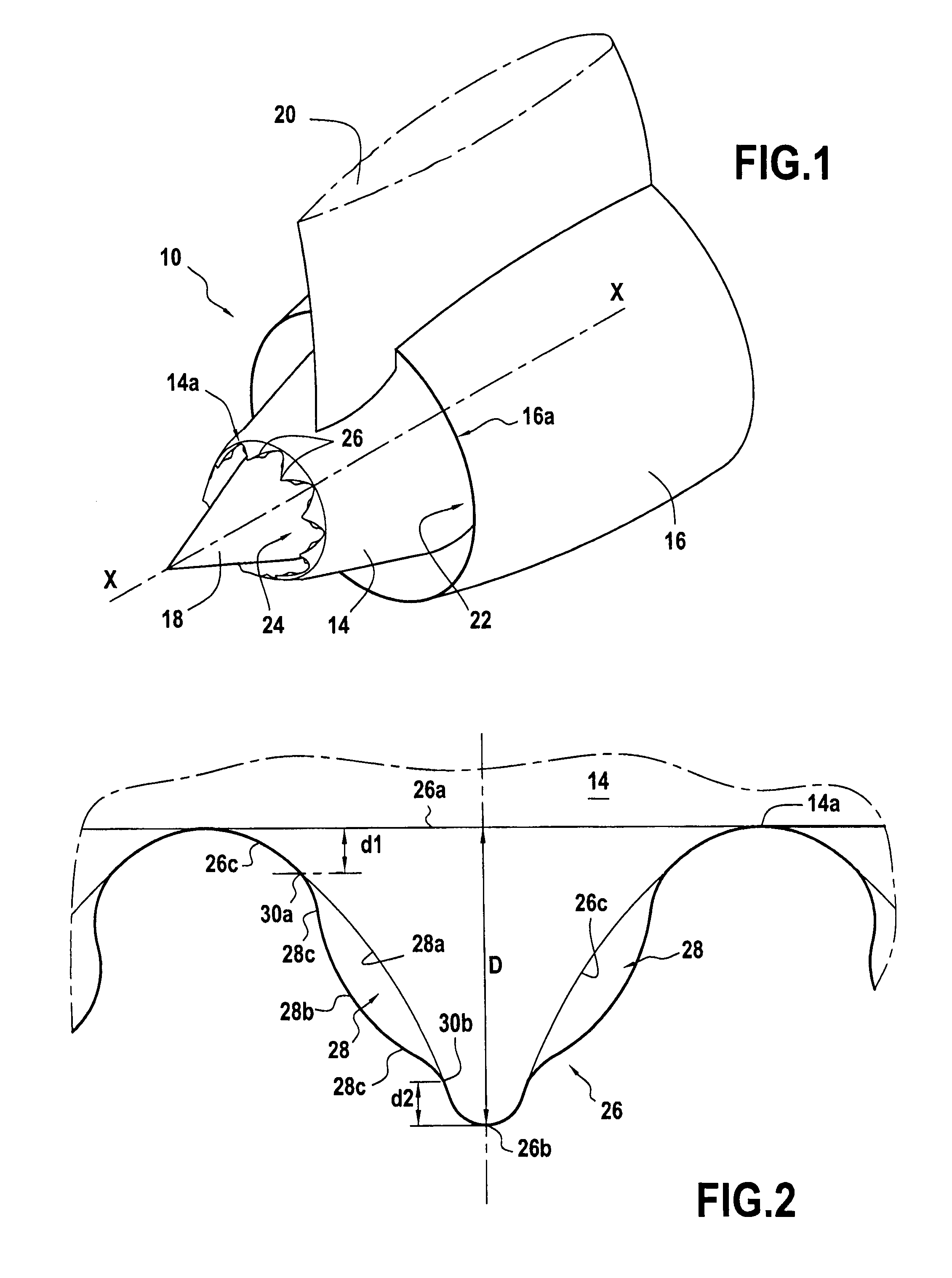

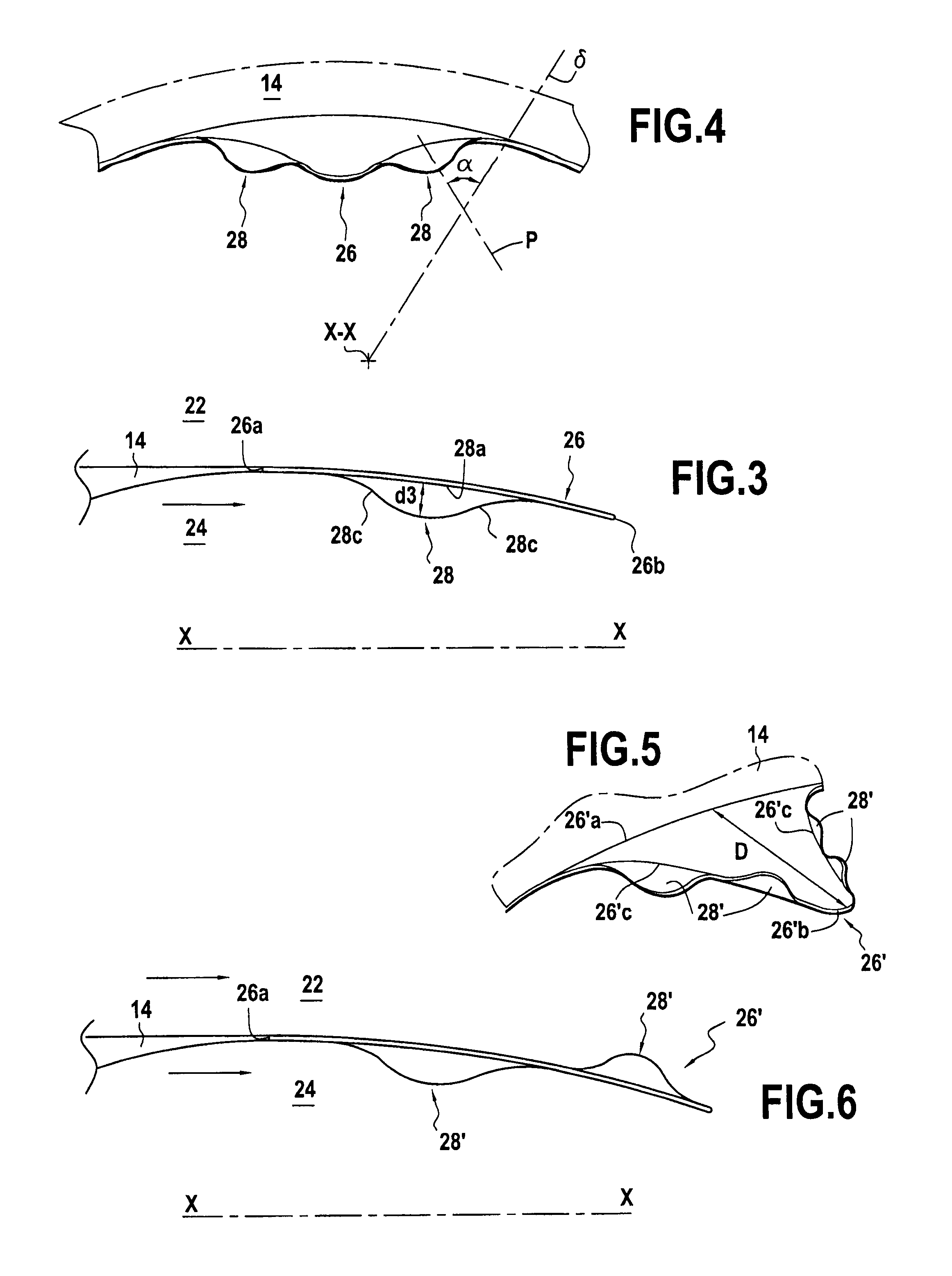

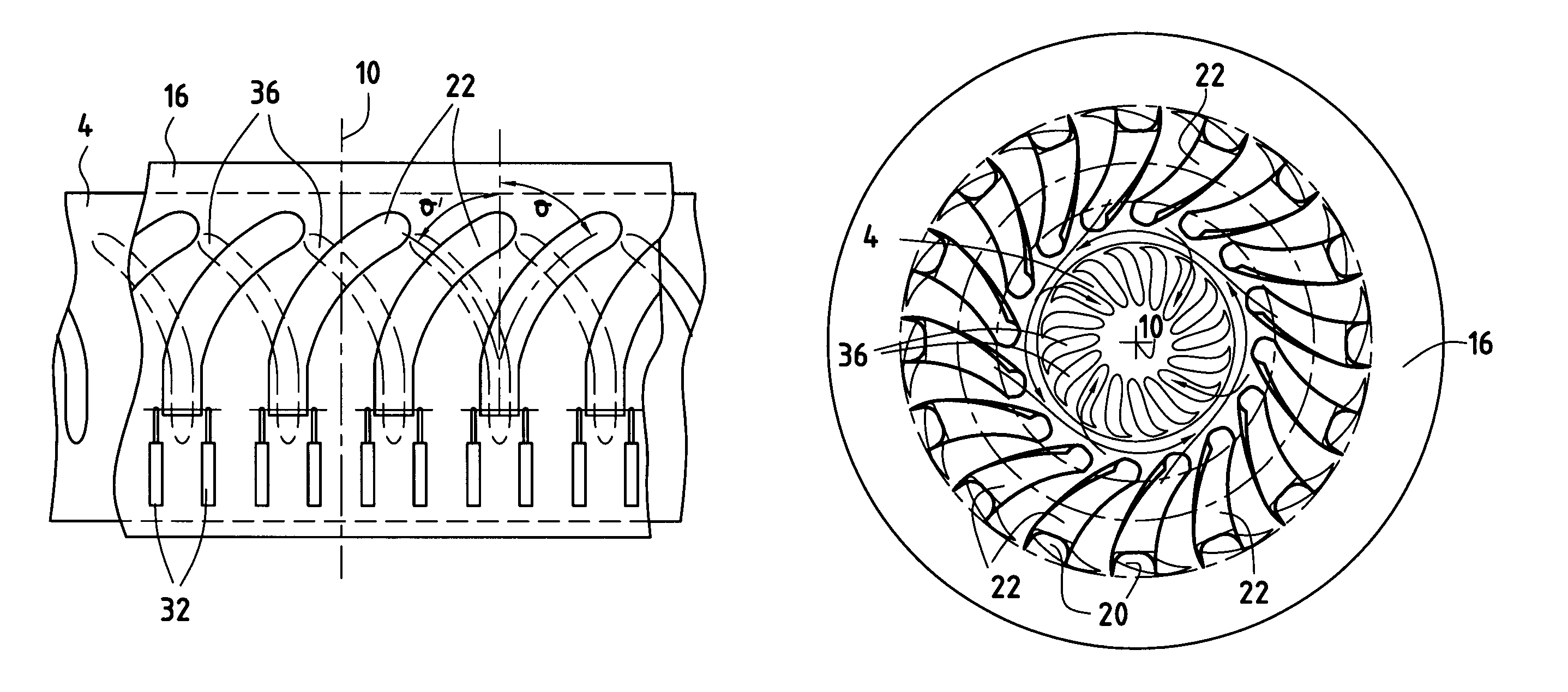

Turbomachine nozzle with noise reduction

ActiveUS6935098B2Reduce jet noiseReduce noisePower plant exhaust arrangementsJet propulsion plantsEngineeringNoise reduction

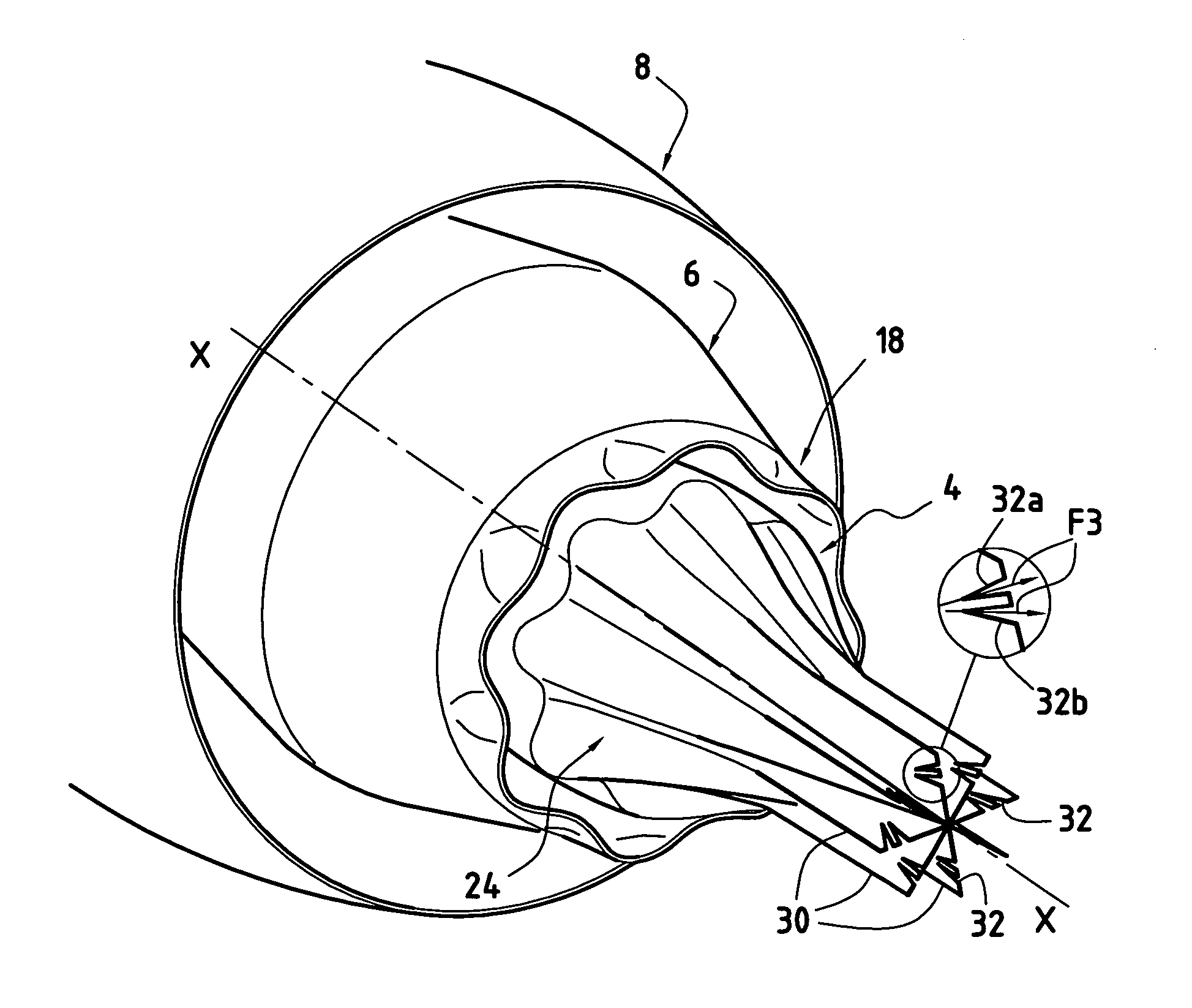

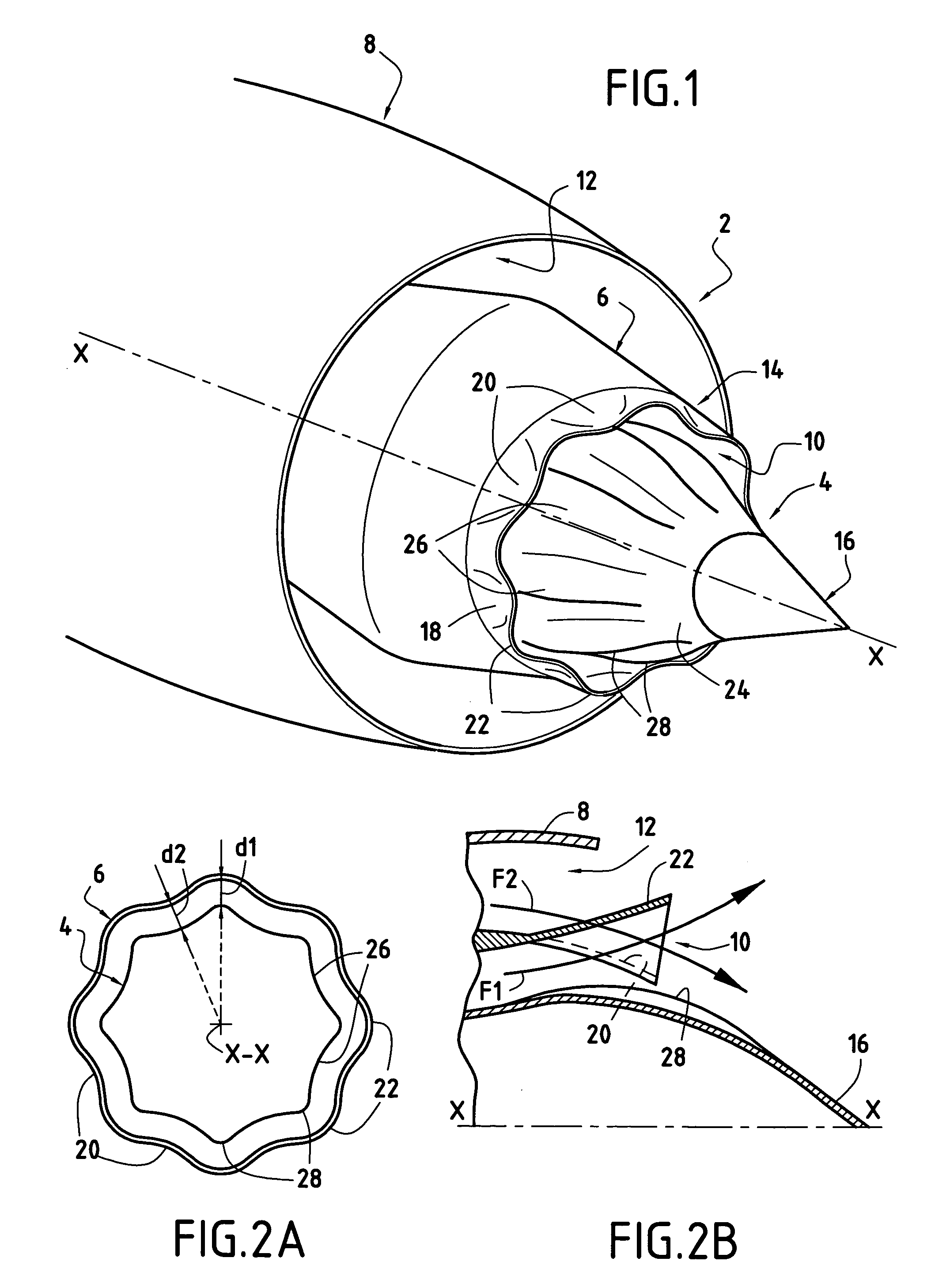

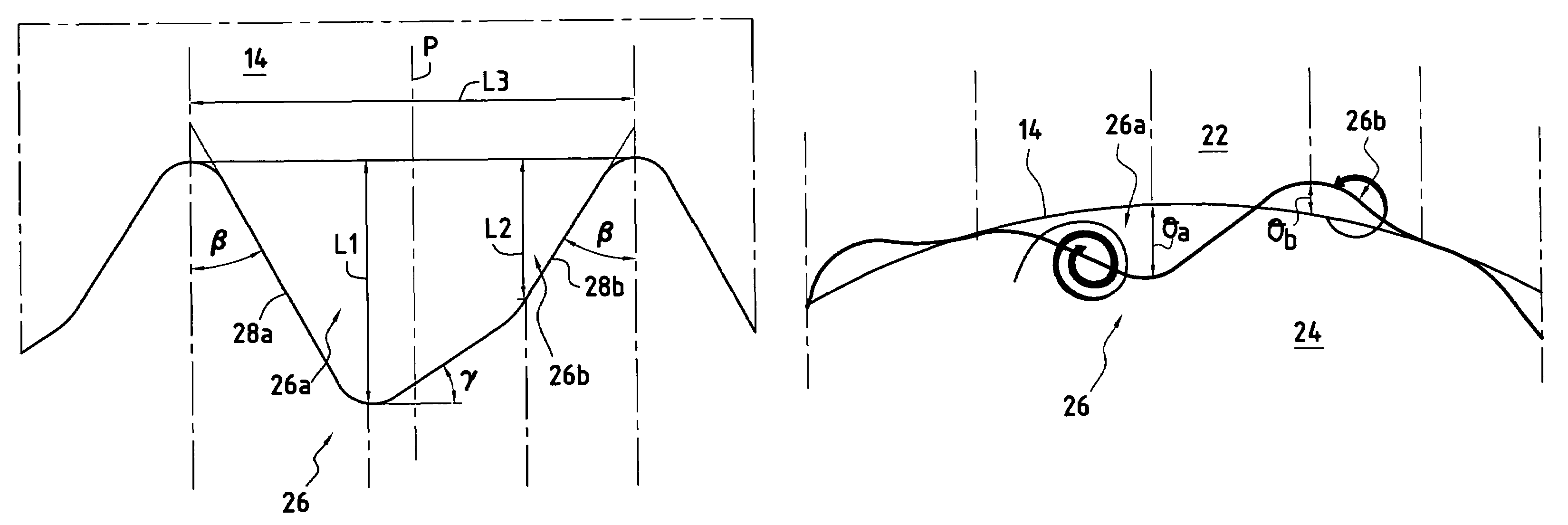

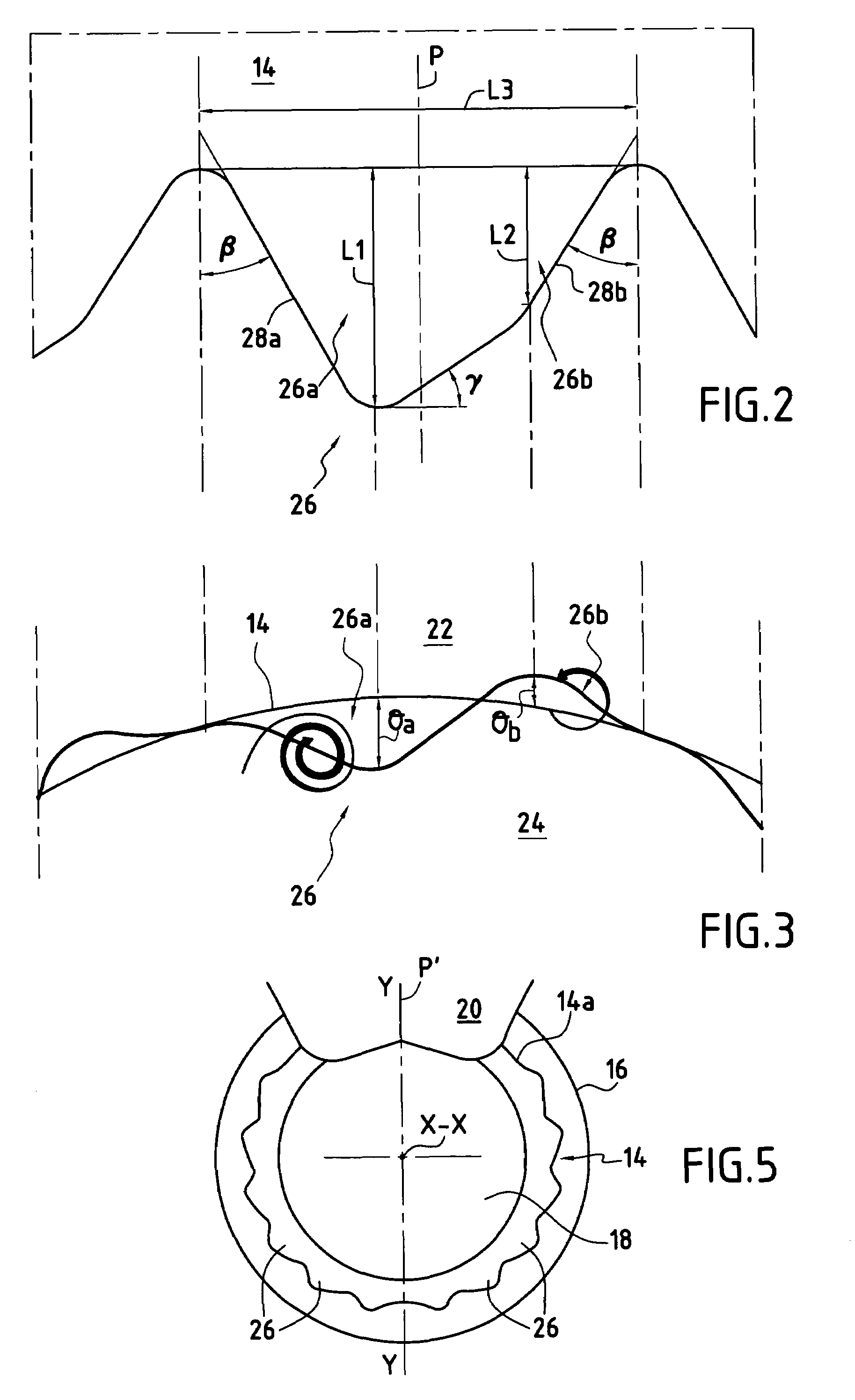

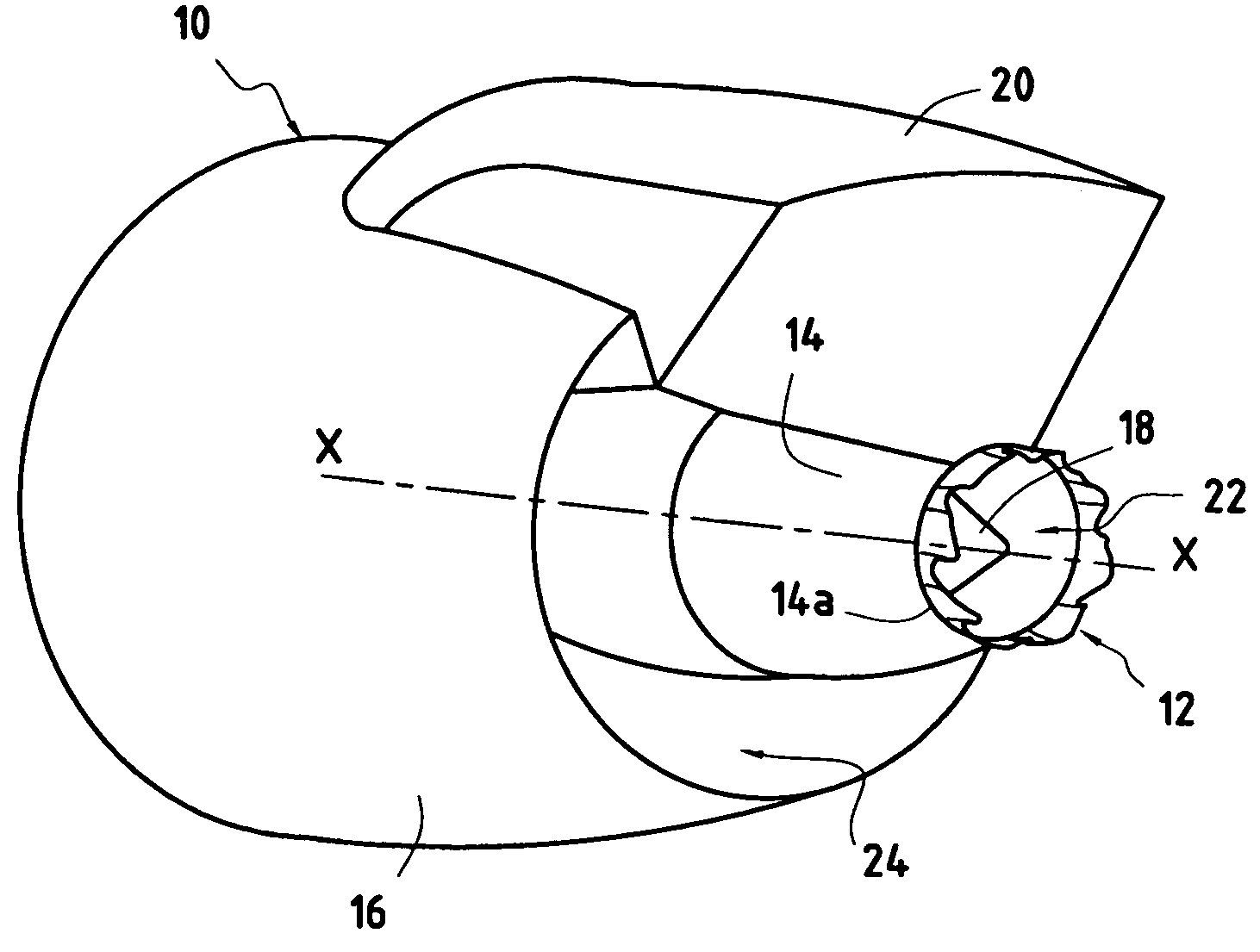

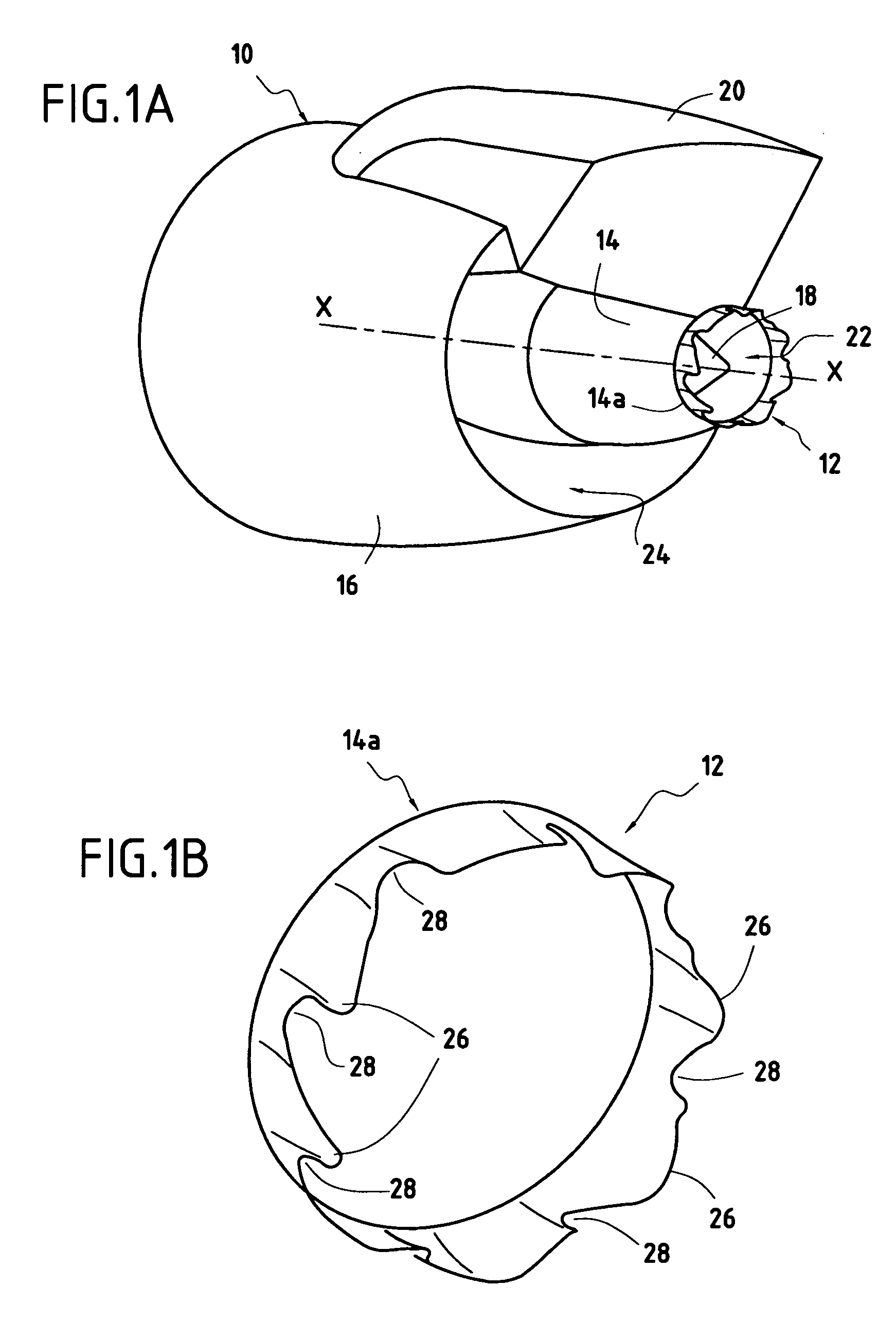

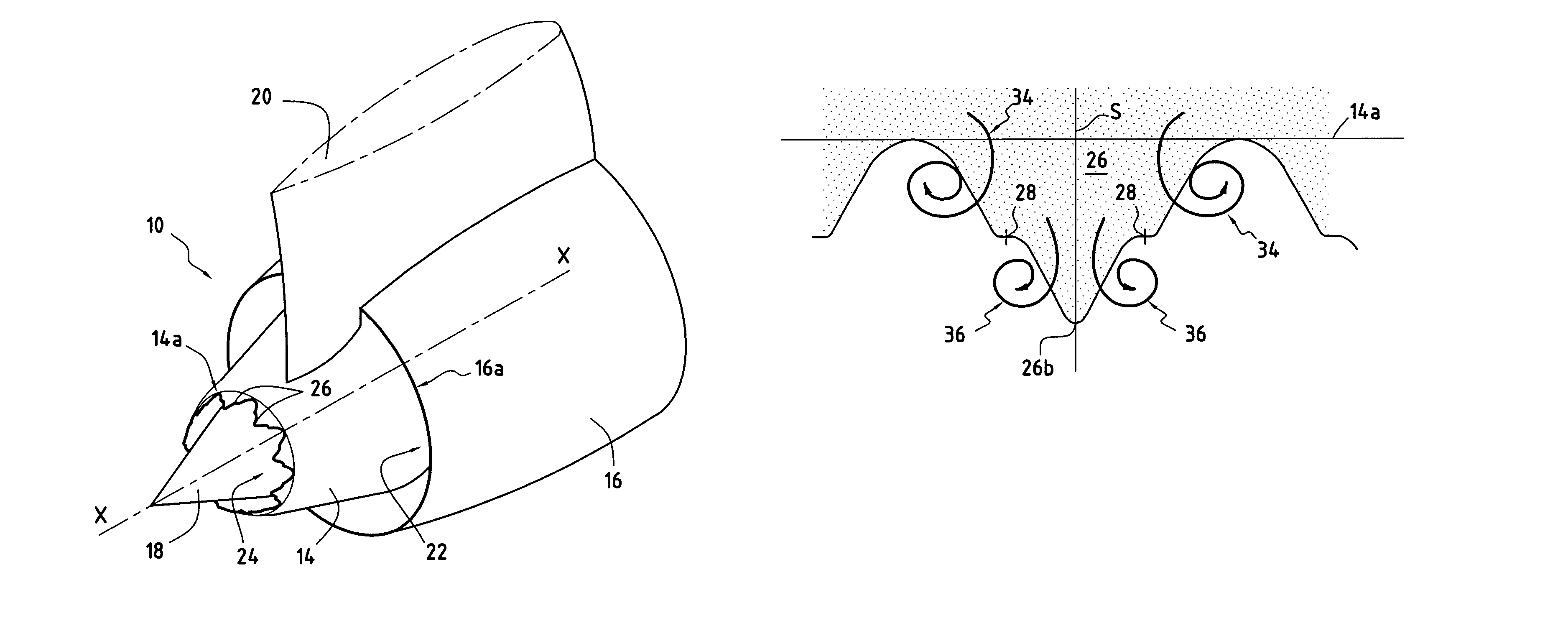

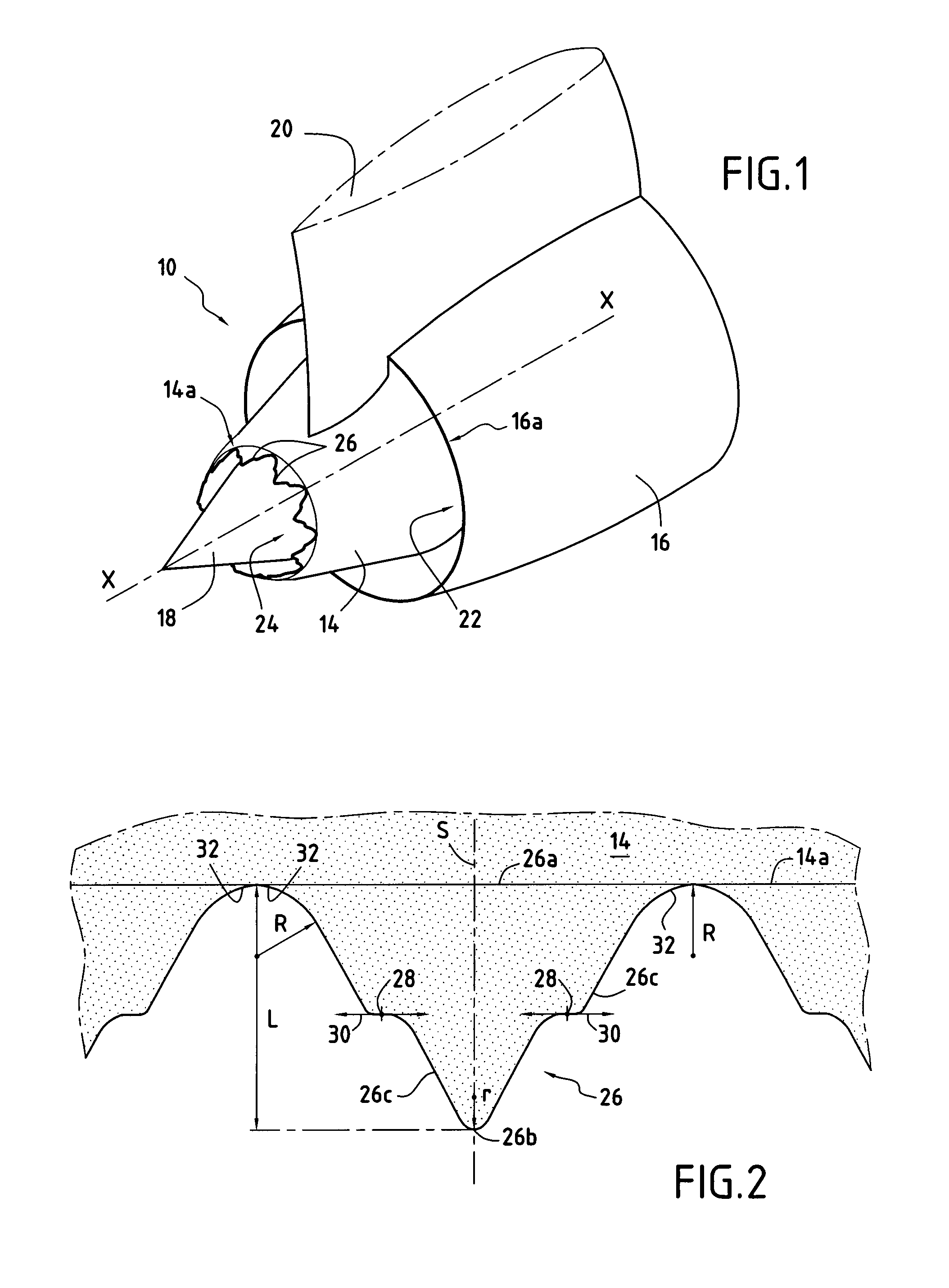

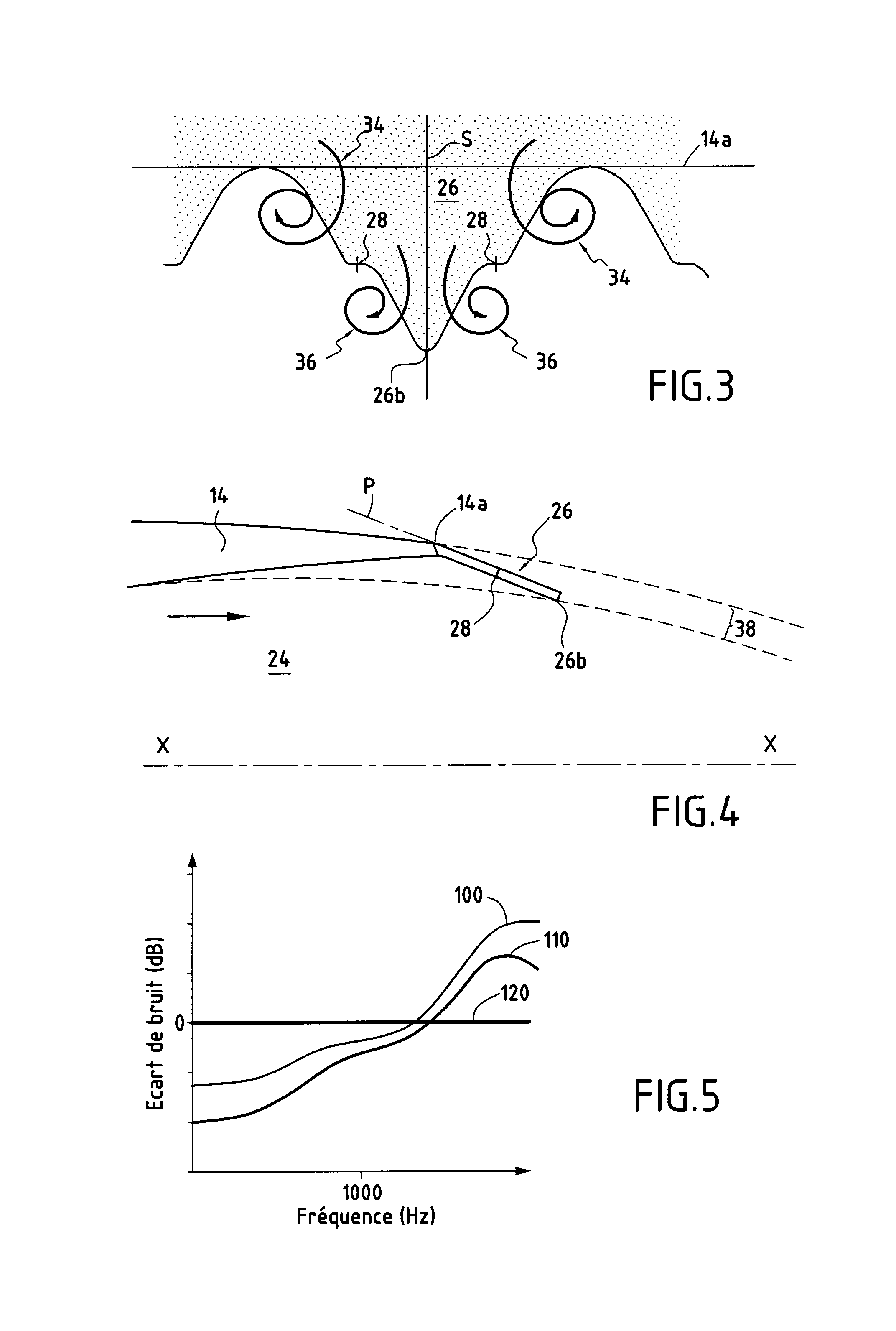

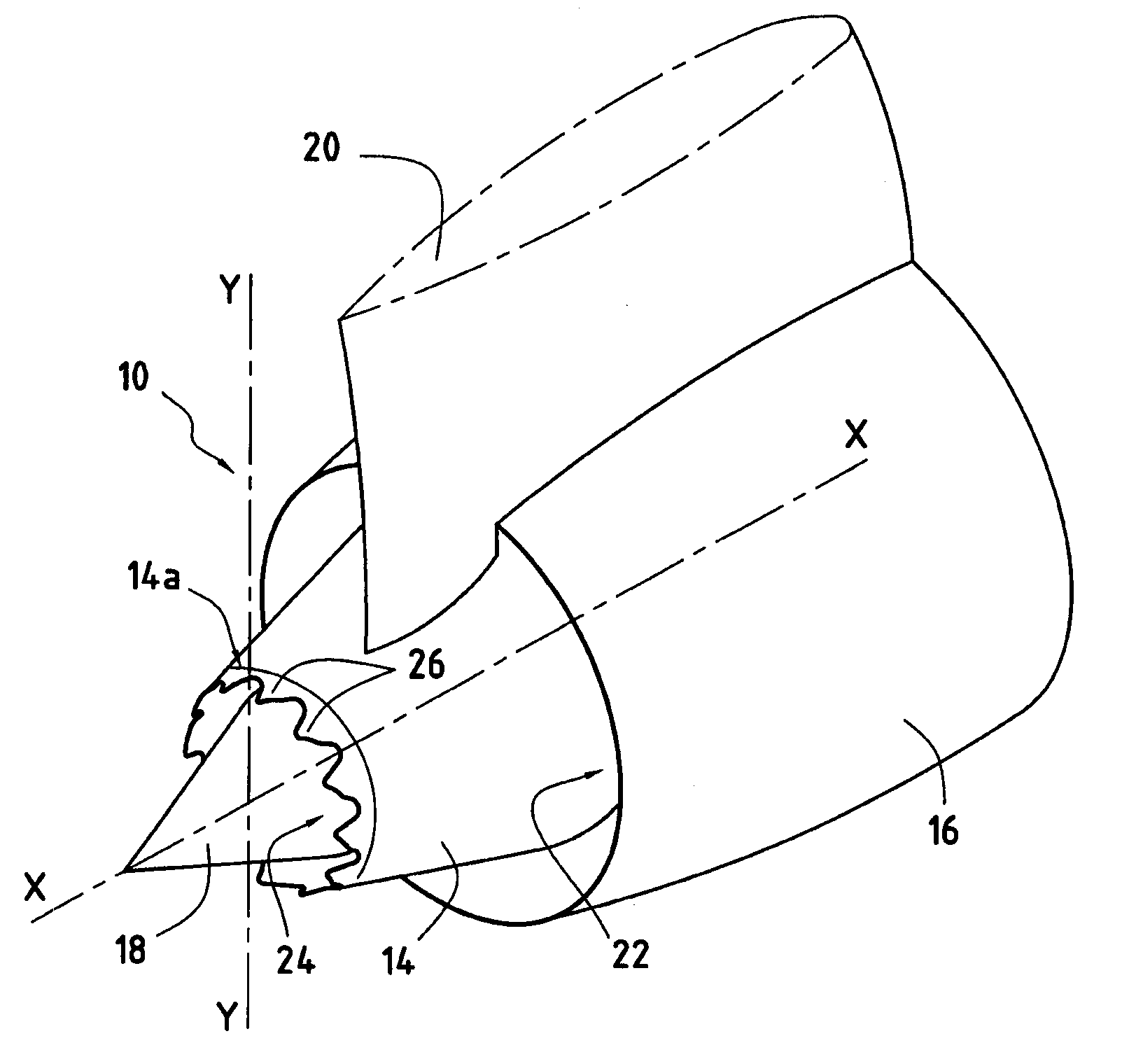

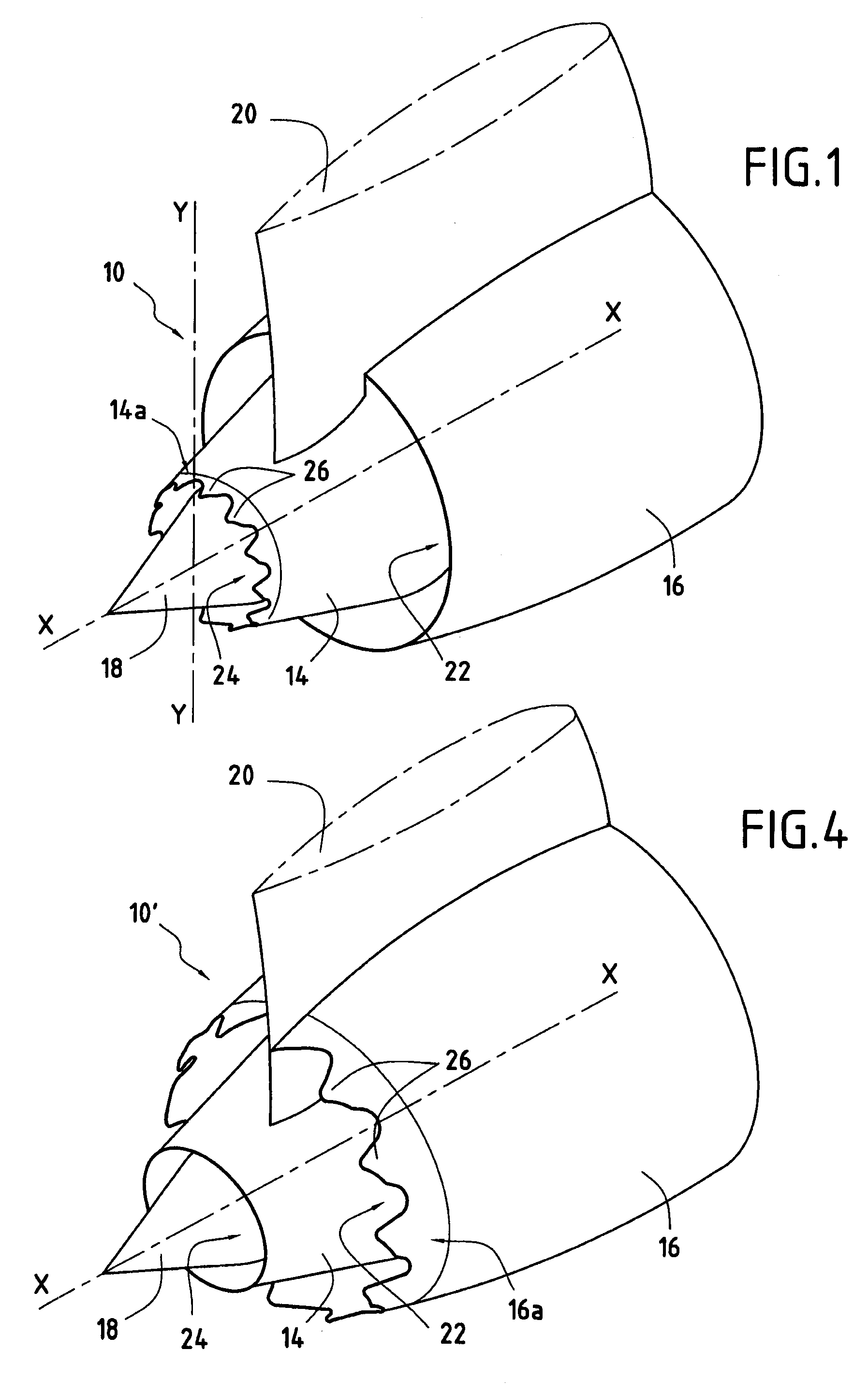

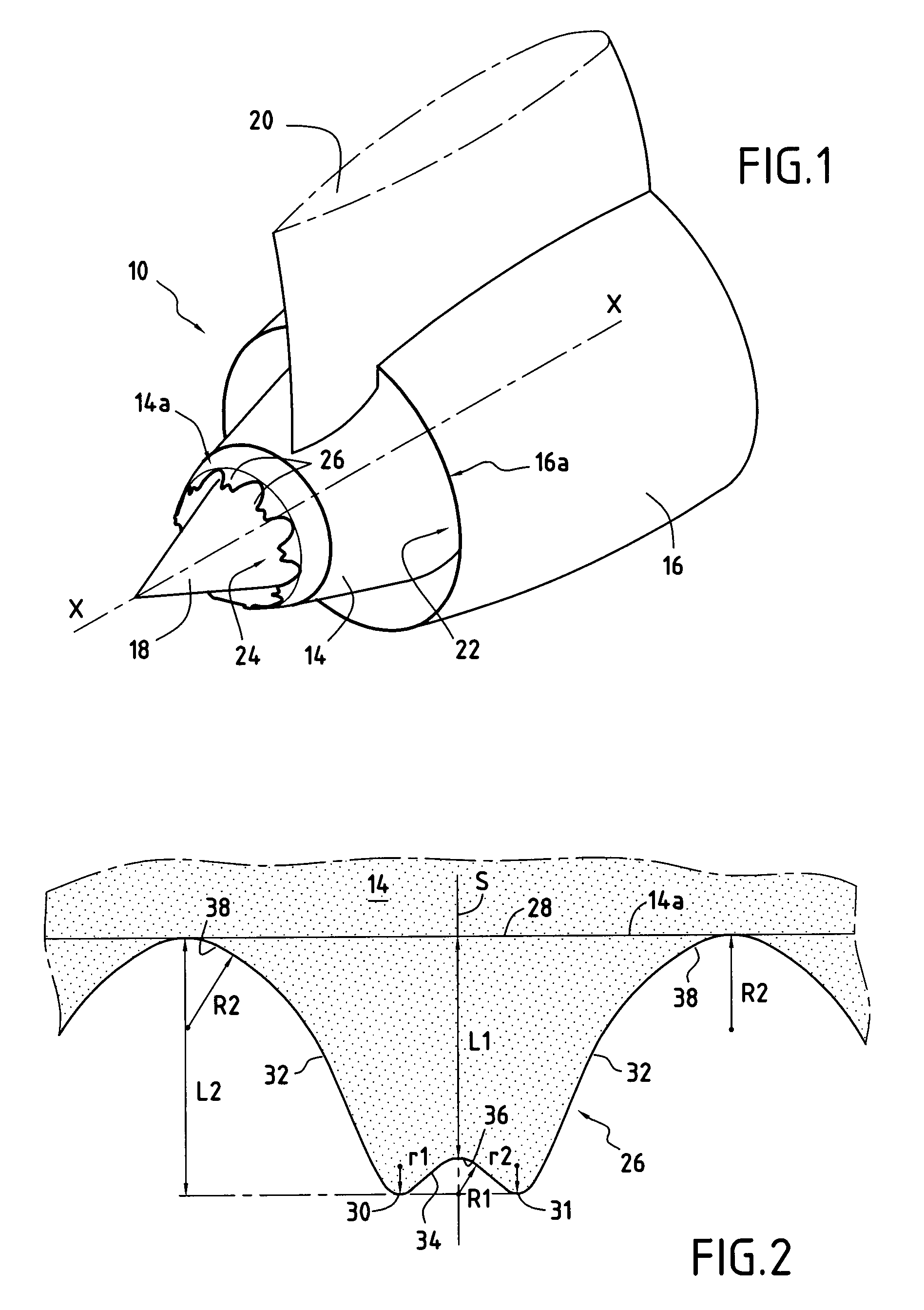

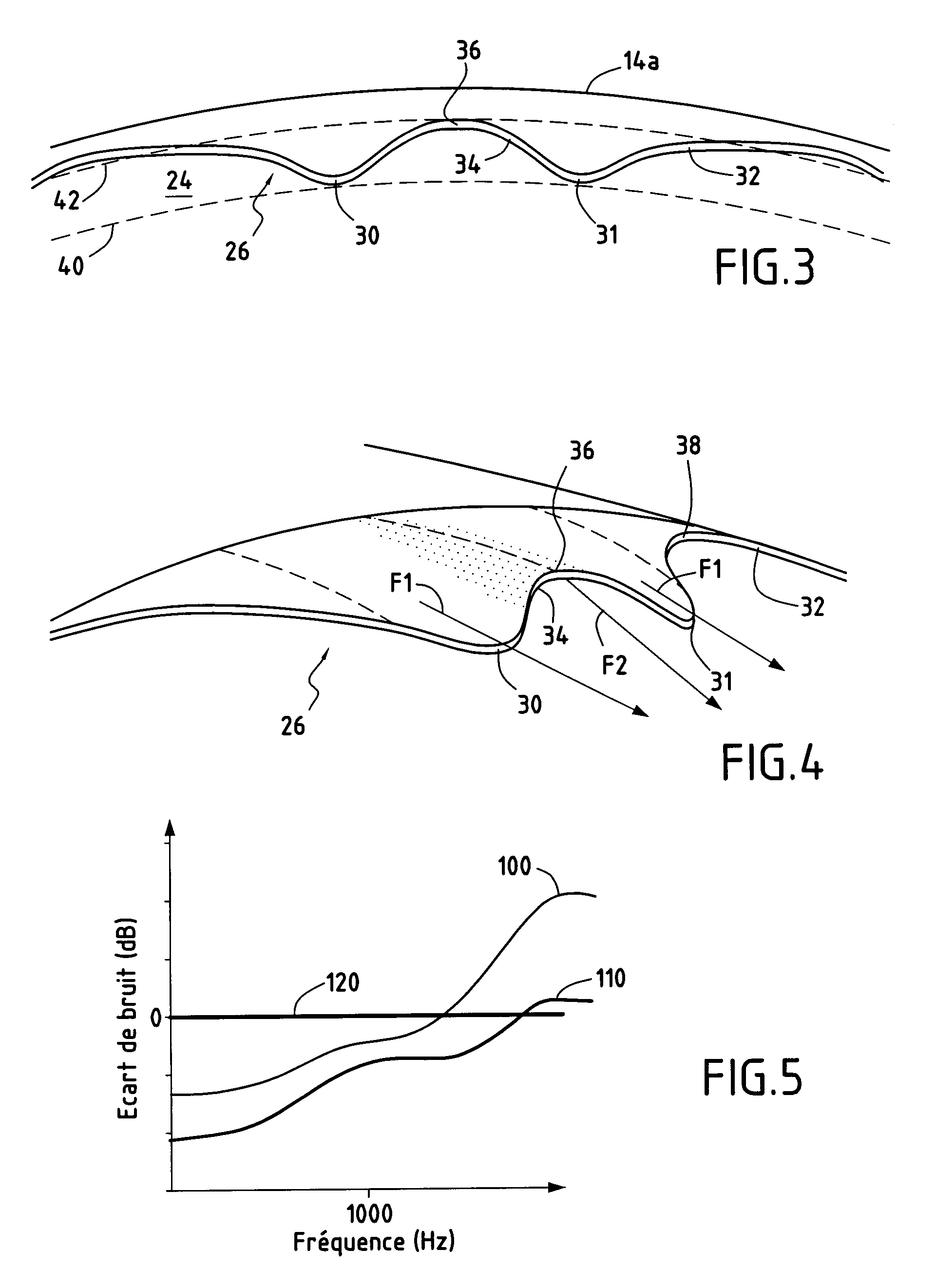

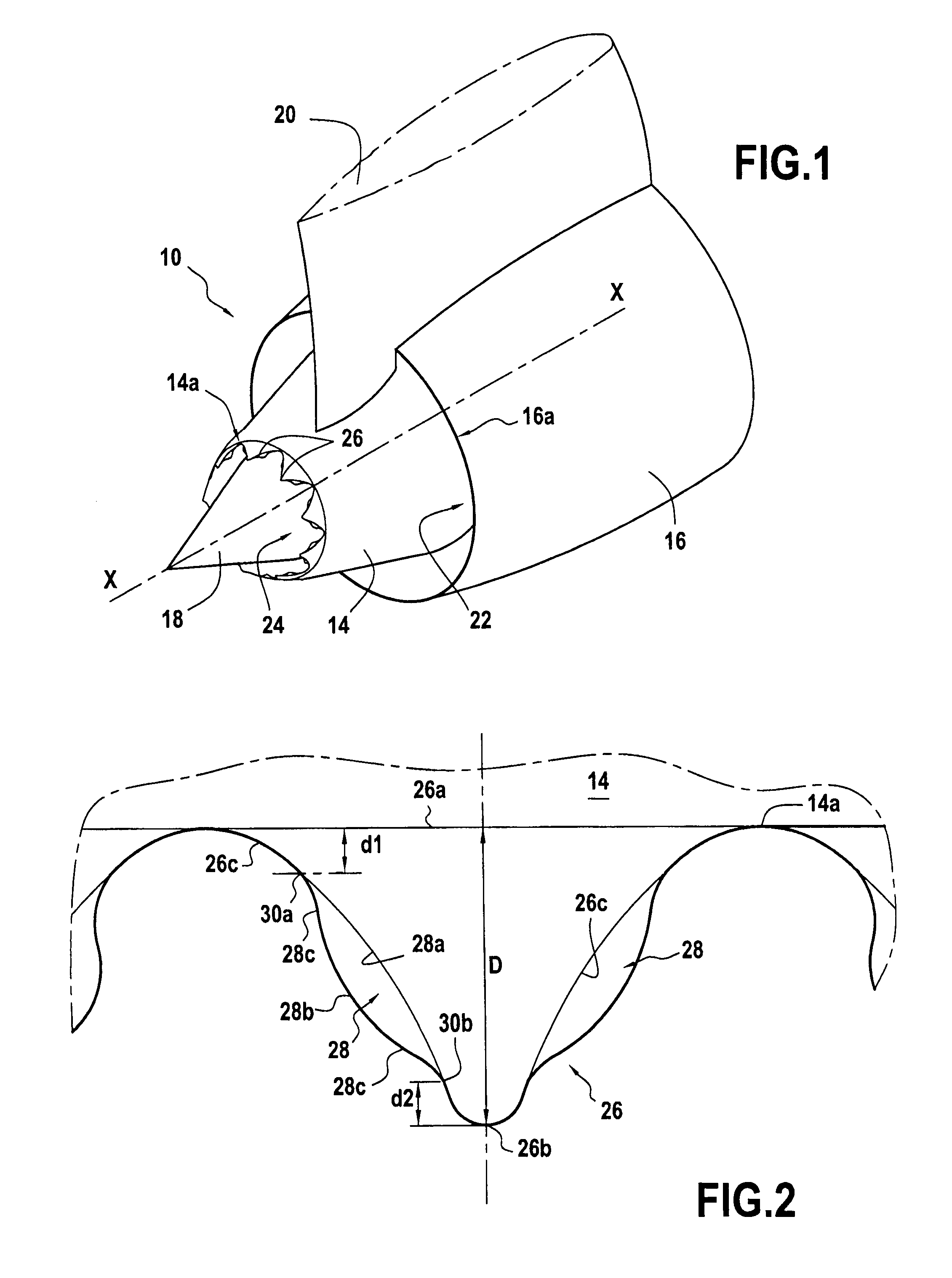

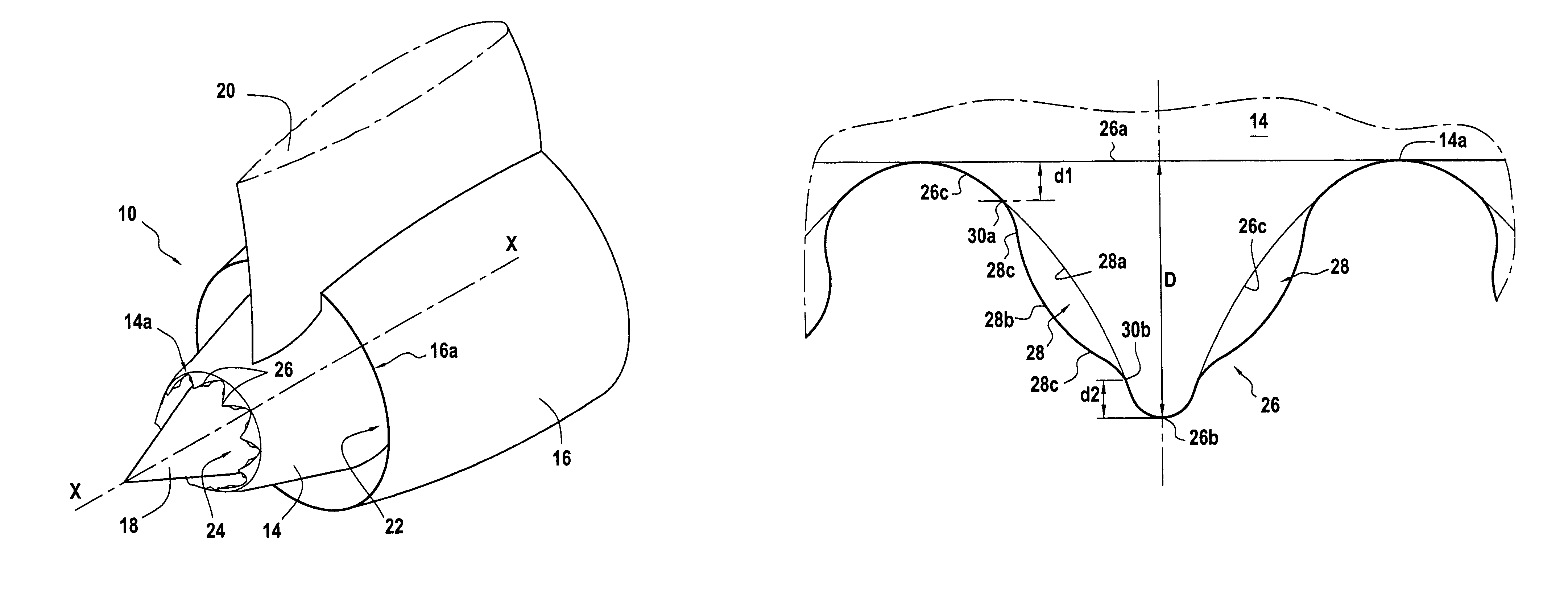

A nozzle comprising an inner barrel, a centerbody disposed inside the inner barrel so as to define a first channel for a primary flow, and an outer barrel surrounding the inner barrel so as to define a second annular channel for a secondary flow, the free end of the inner barrel presenting a surface having a first series of undulations made up of negative undulations alternating with positive undulations, the centerbody presenting a second series of undulations made up of negative undulations alternating with positive undulations, the negative and positive undulations of the series of undulations being of radial height that varies angularly and being disposed in such a manner that the negative undulations of the first series are disposed facing negative undulations of the second series, and vice versa, so as to generate turbulence and radial shear between the primary and secondary flows while conserving a constant flow section around the entire circumference of the nozzle.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

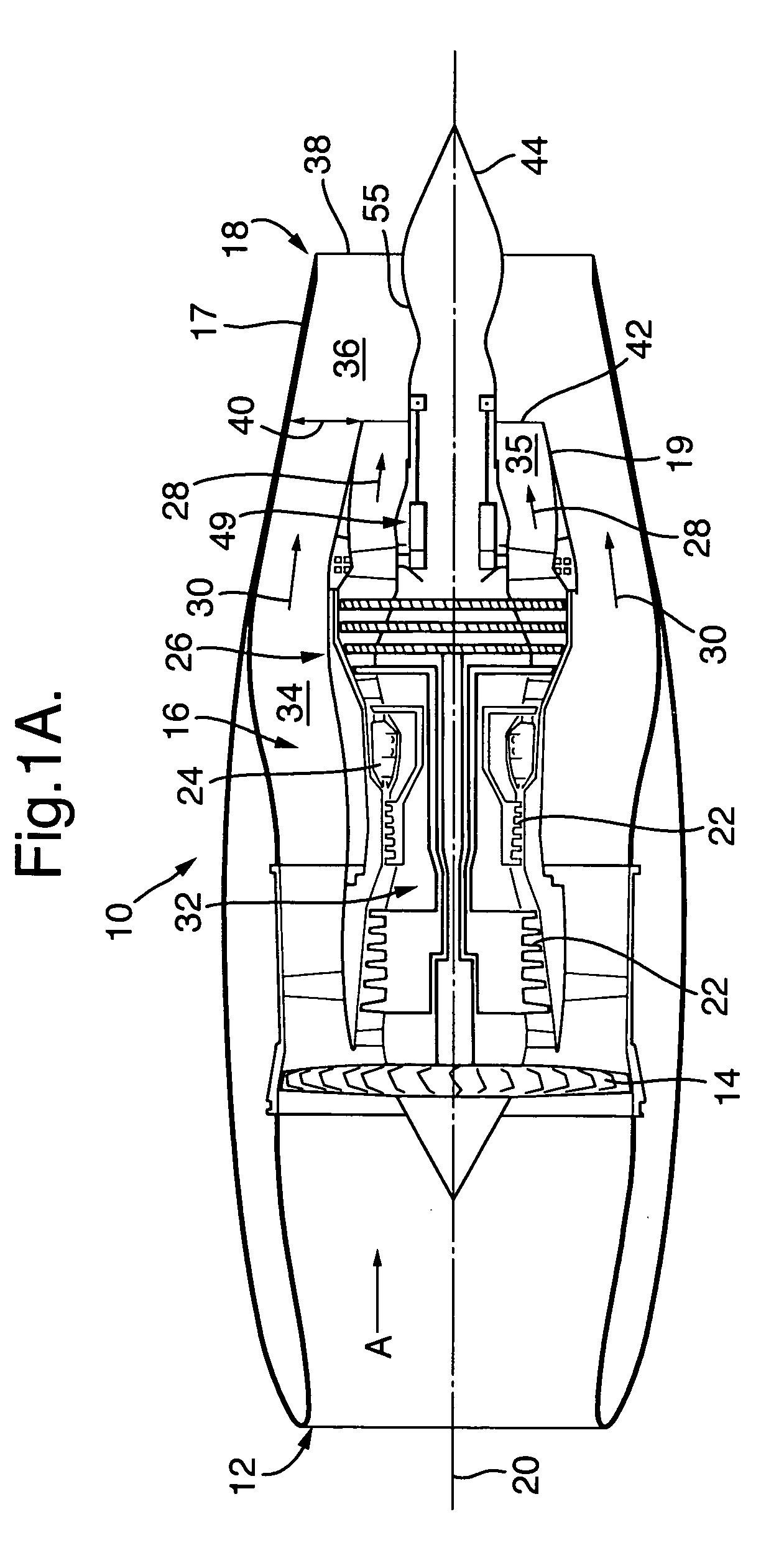

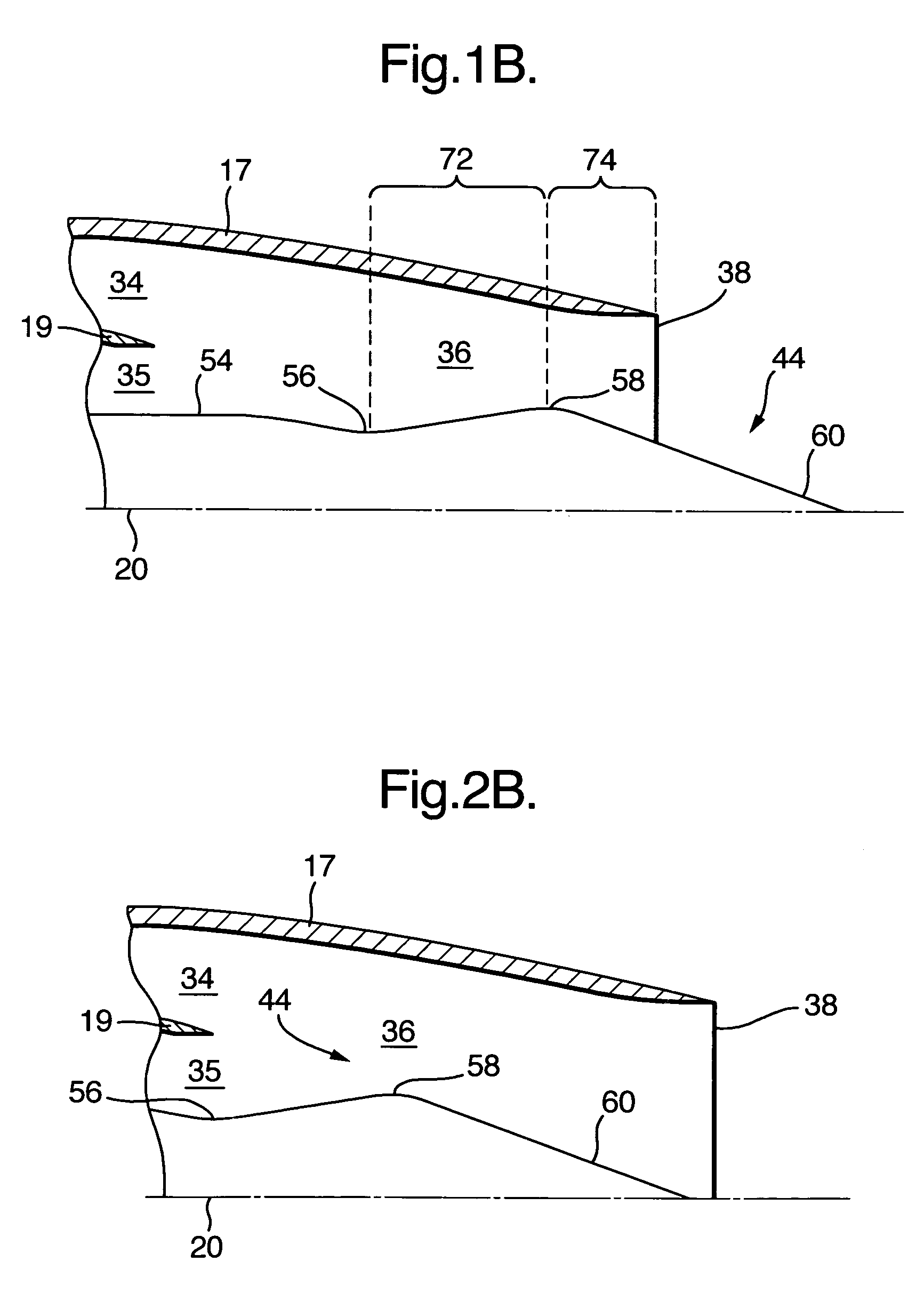

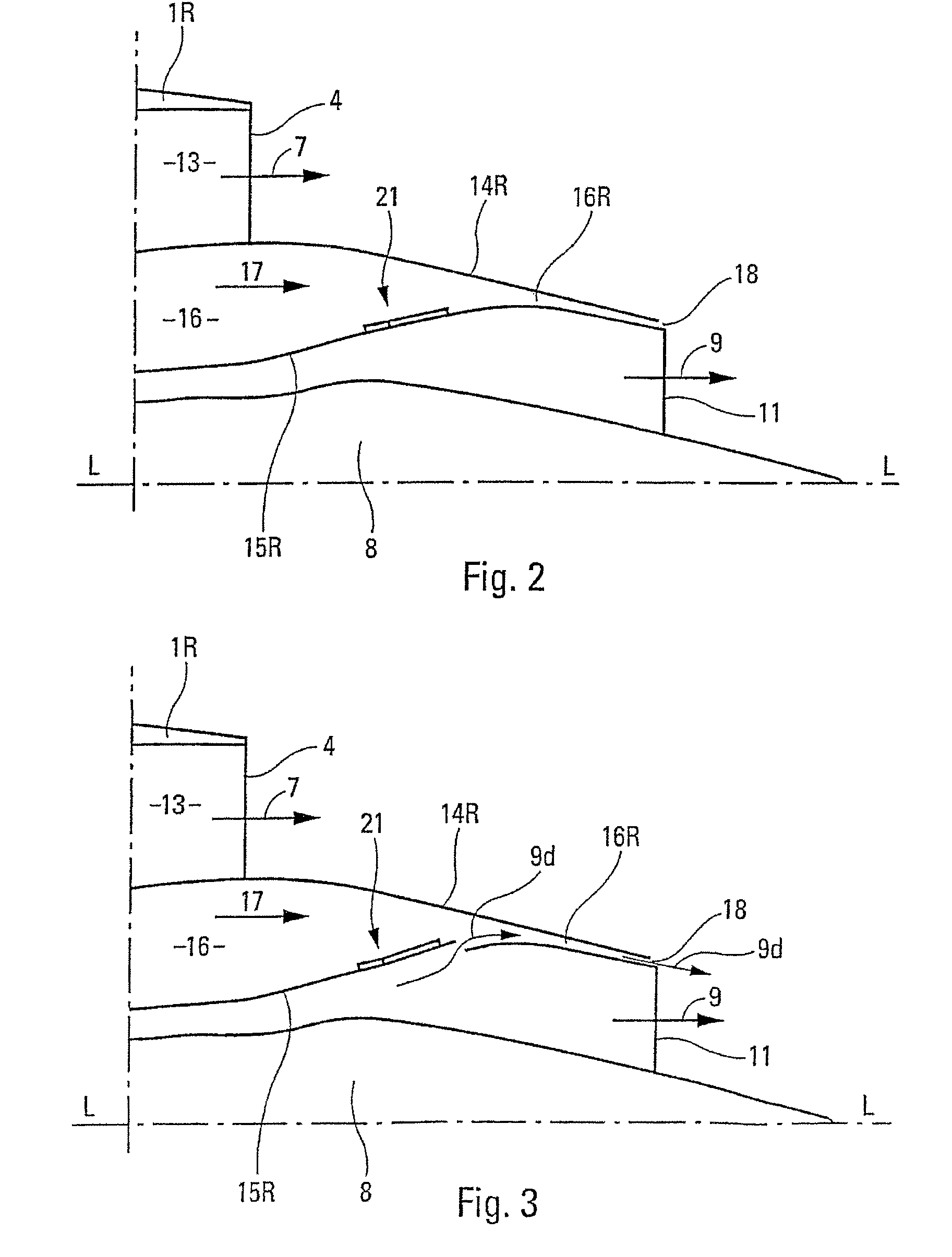

Variable area nozzle

InactiveUS7178338B2Maximize airflowMinimise jet velocityAircraft navigation controlPropulsive elementsActuatorGas turbines

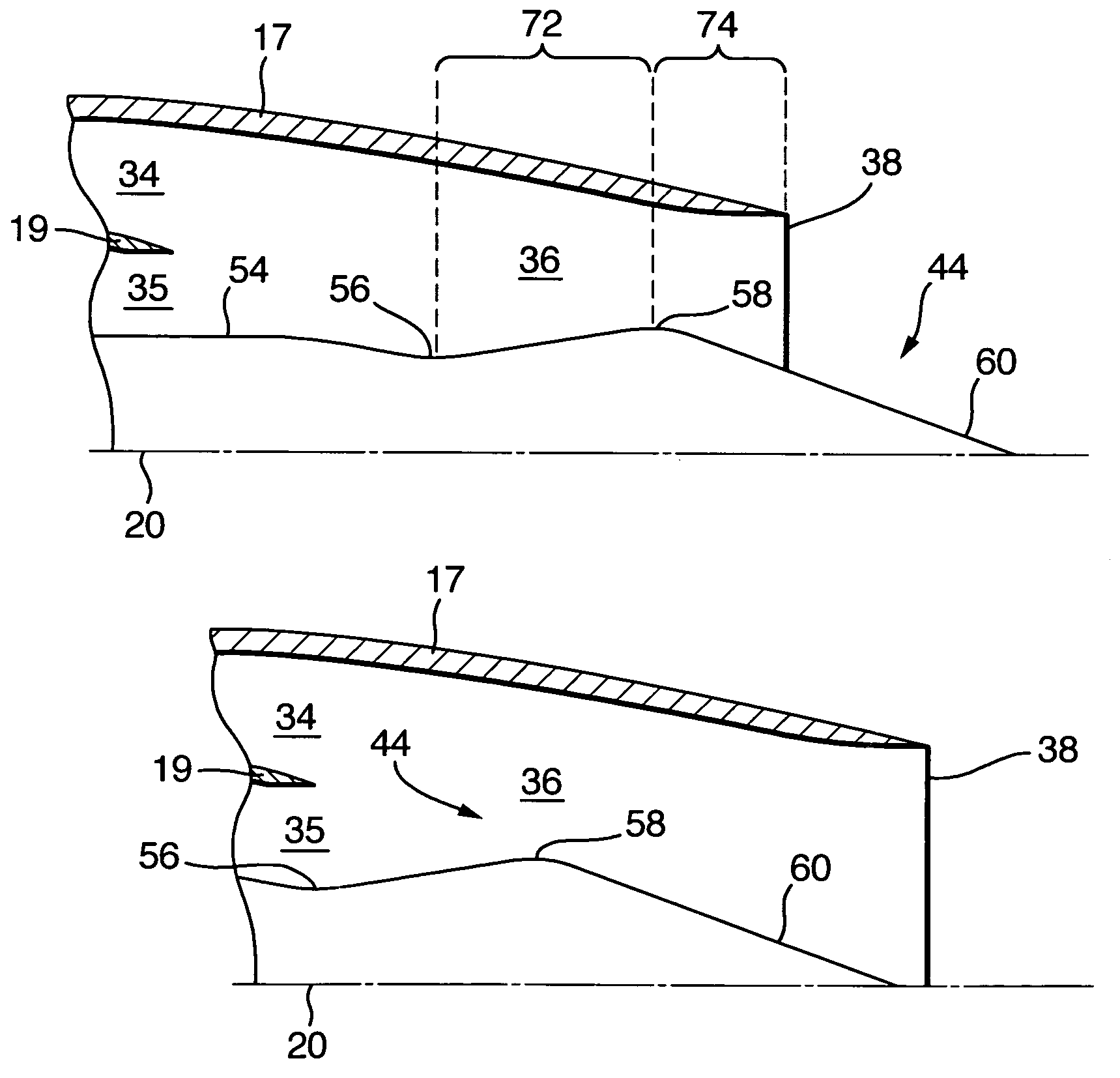

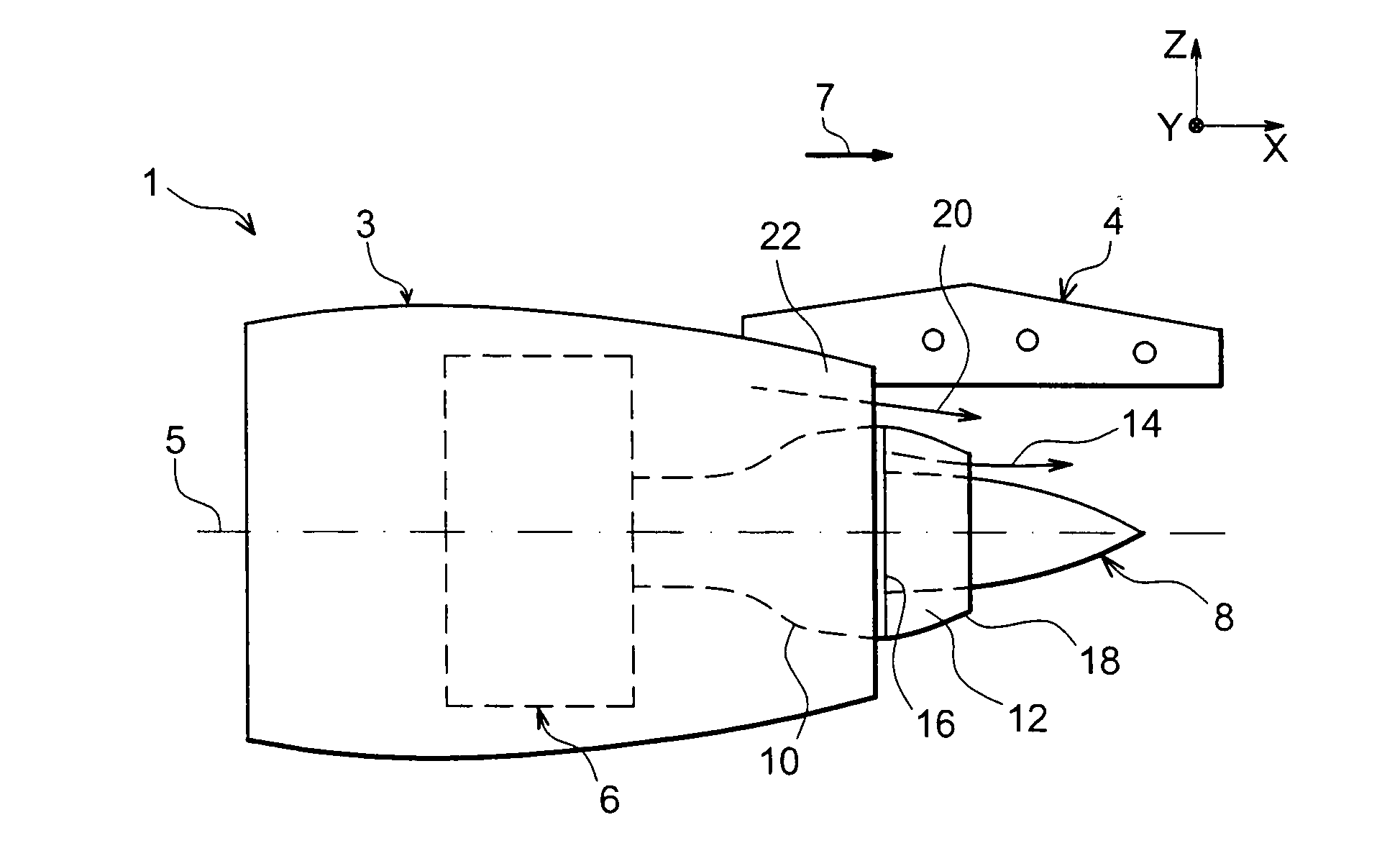

An exhaust nozzle assembly for a gas turbine engine, the assembly comprises a main axis, an inner nozzle, an outer nozzle, a translatable centre-body and an actuator for translating the centre-body between a forward position and a rearward position. The centre-body is disposed radially inwardly of the inner nozzle thereby partly defining an inner duct for a core engine gas flow, an outer duct for a bypass gas flow is defined by the inner nozzle and the outer nozzle. The outer nozzle extends downstream of the inner nozzle and with the centre-body defines a final mixing duct having a final exhaust exit area. When the centre-body is in the forward position the final exhaust exit area is at a maximum area, and when the centre-body is in a rearward position the final exhaust exit area is at a minimum area.

Owner:ROLLS ROYCE PLC

Turbomachine nozzle with noise reduction

ActiveUS20050138915A1AmplitudeIncrease amplitudePower plant exhaust arrangementsJet propulsion plantsEngineeringNoise reduction

A nozzle comprising an inner barrel, a centerbody disposed inside the inner barrel so as to define a first channel for a primary flow, and an outer barrel surrounding the inner barrel so as to define a second annular channel for a secondary flow, the free end of the inner barrel presenting a surface having a first series of undulations made up of negative undulations alternating with positive undulations, the centerbody presenting a second series of undulations made up of negative undulations alternating with positive undulations, the negative and positive undulations of the series of undulations being of radial height that varies angularly and being disposed in such a manner that the negative undulations of the first series are disposed facing negative undulations of the second series, and vice versa, so as to generate turbulence and radial shear between the primary and secondary flows while conserving a constant flow section around the entire circumference of the nozzle.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

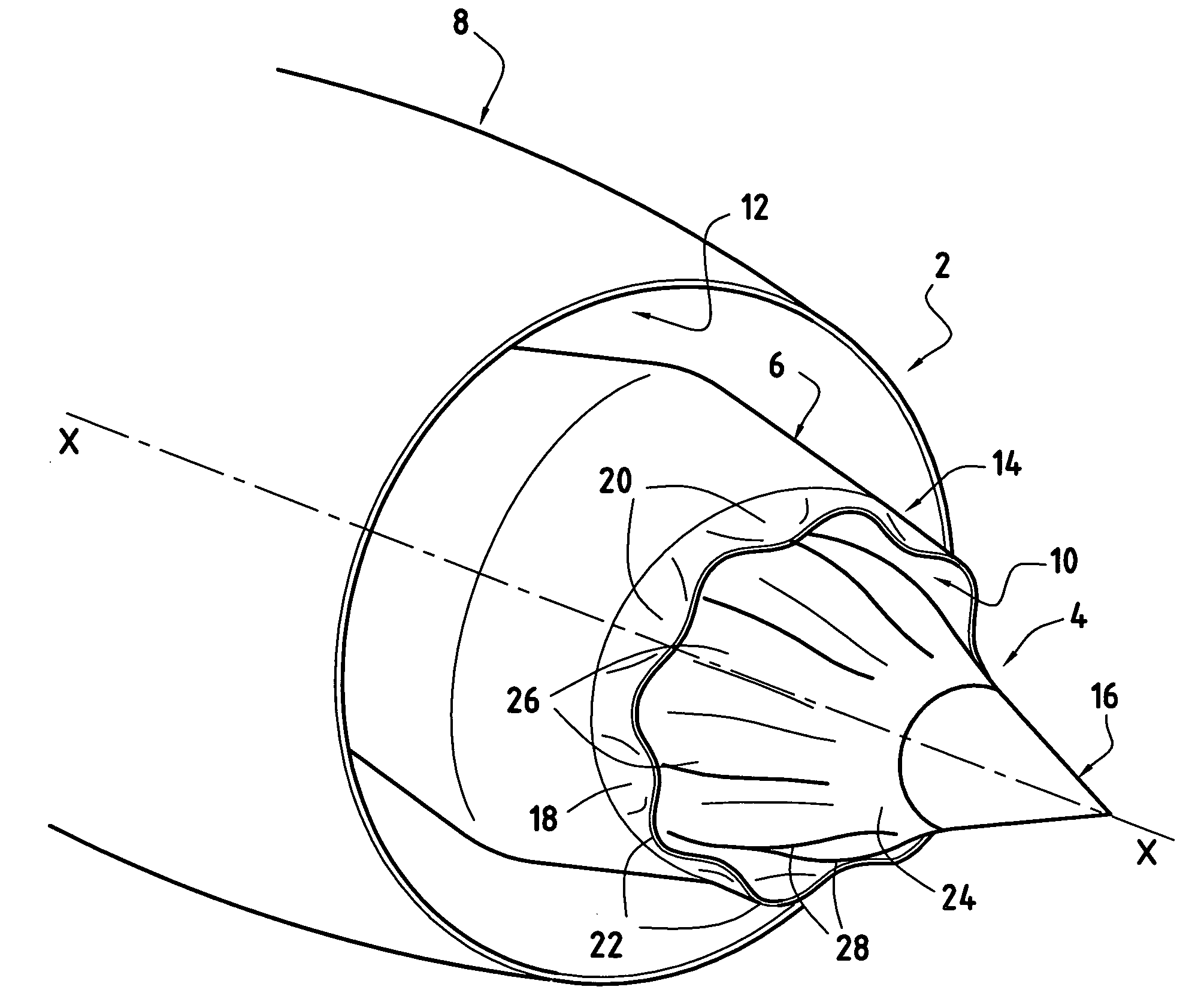

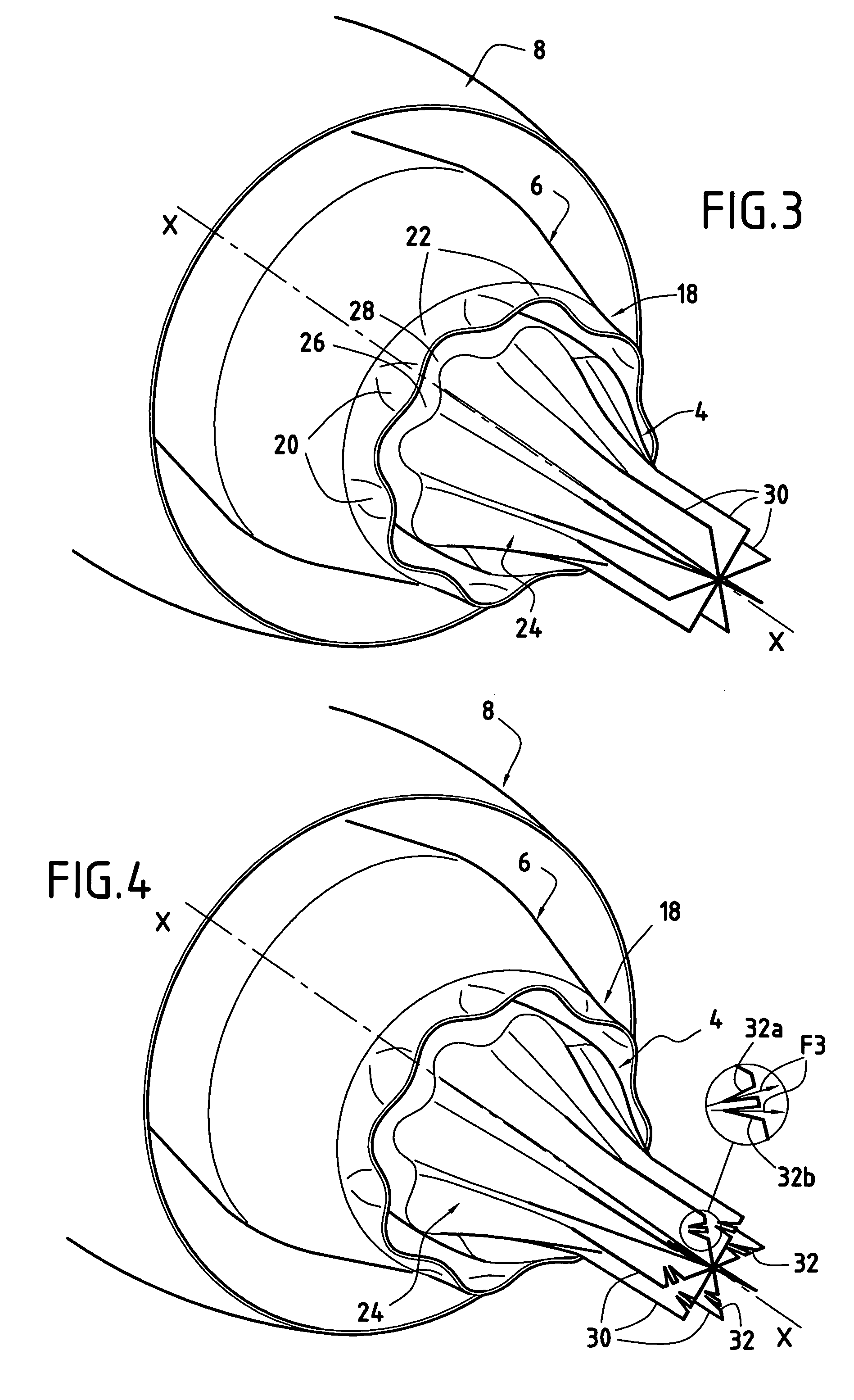

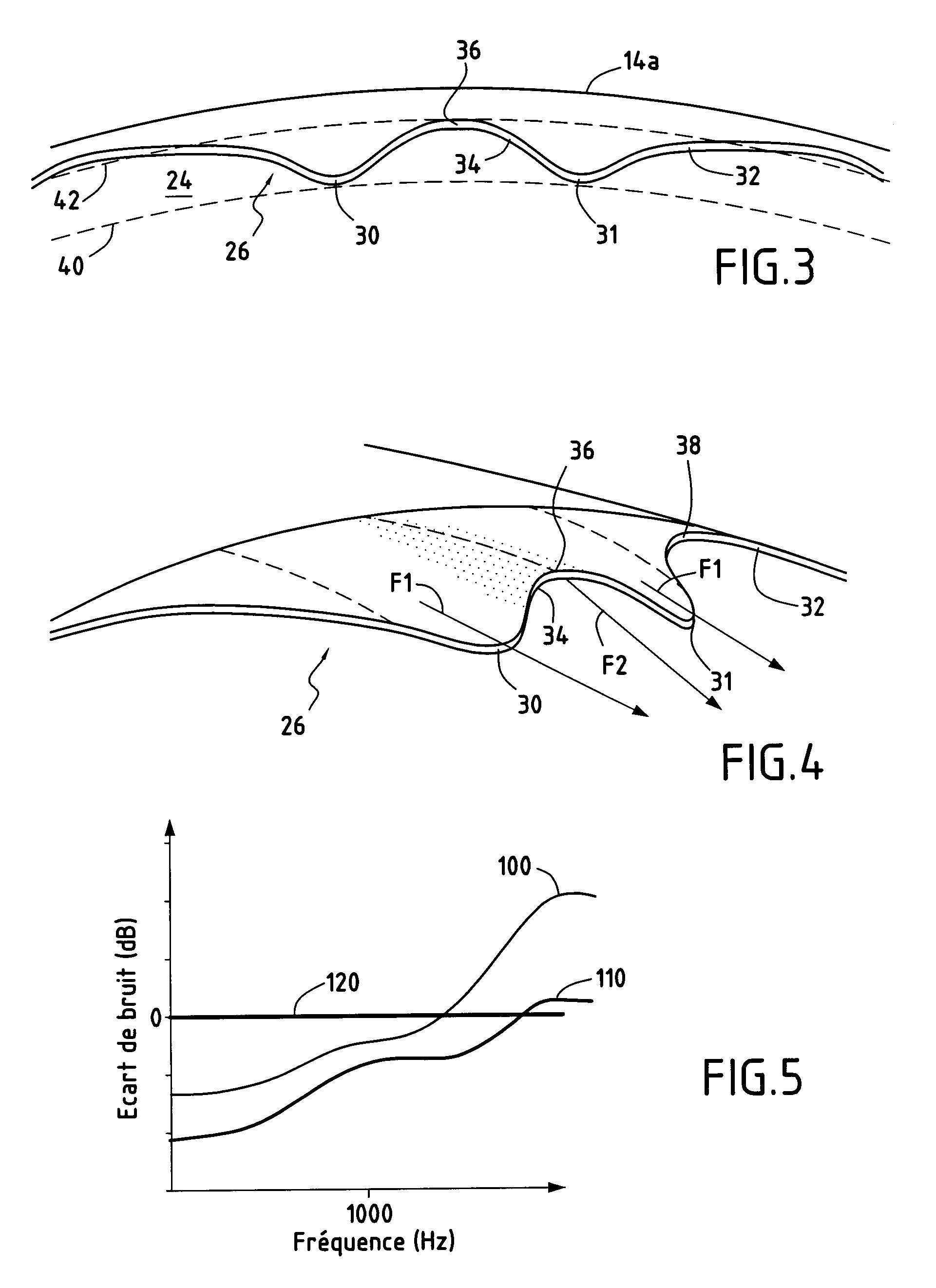

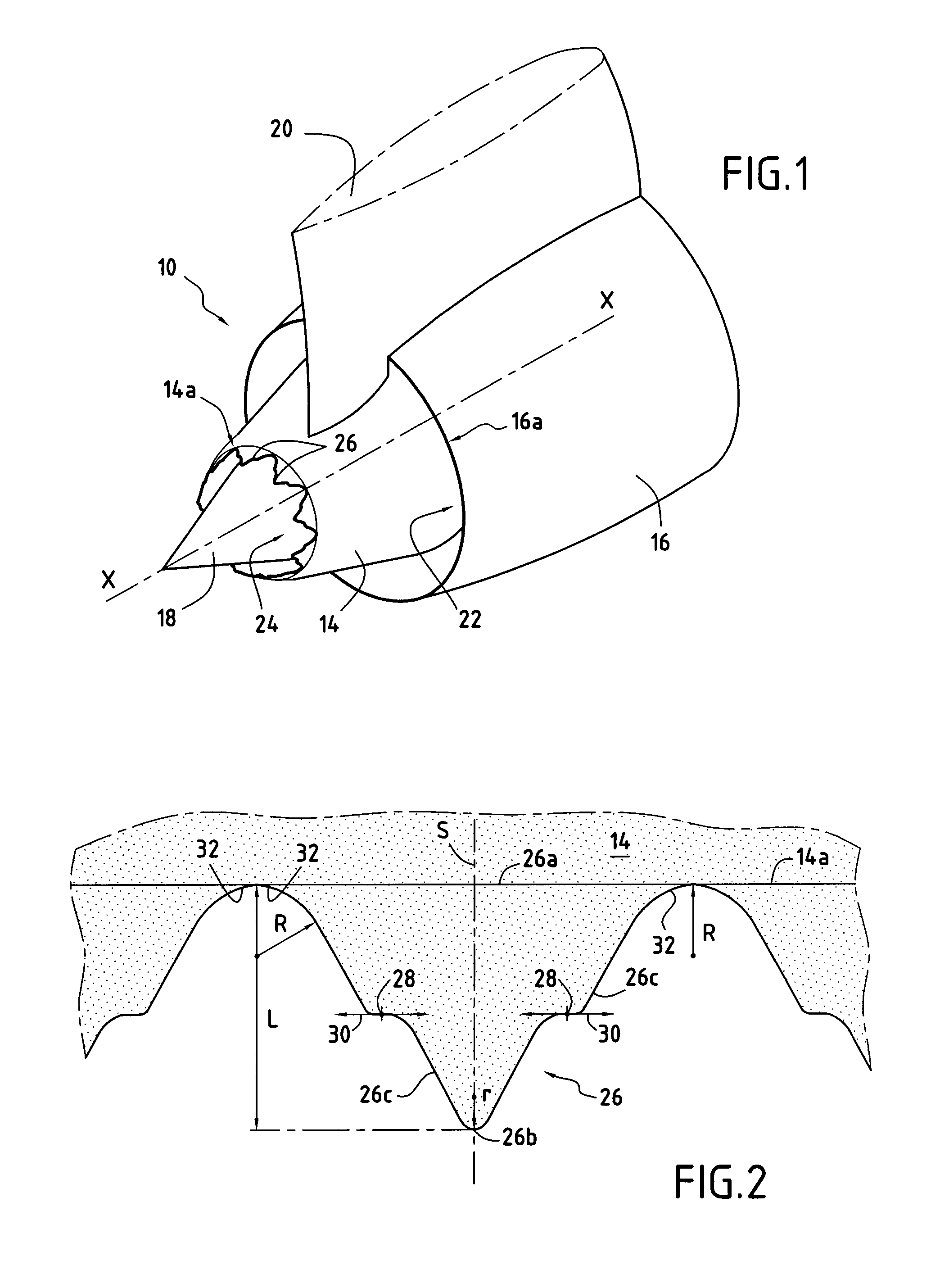

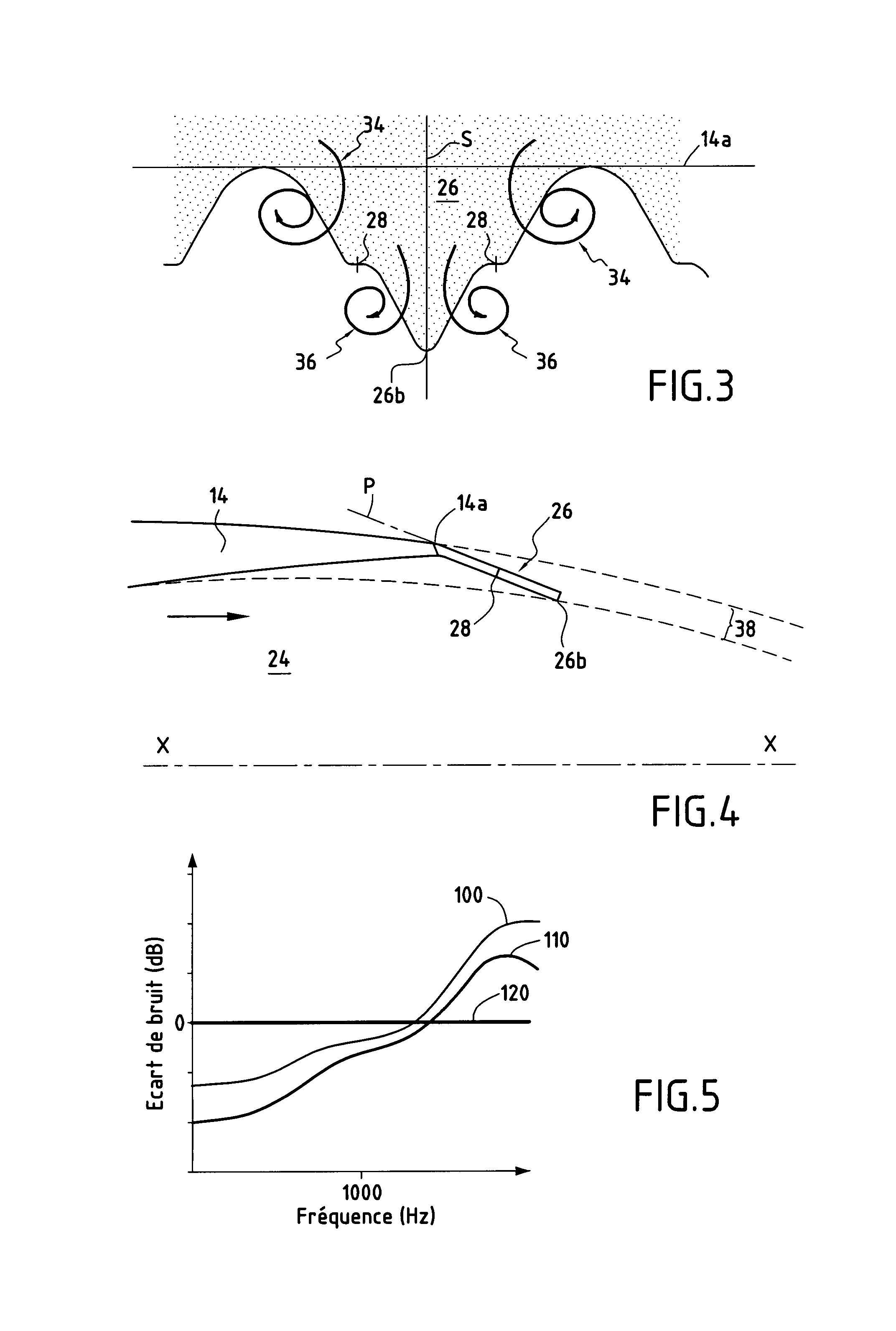

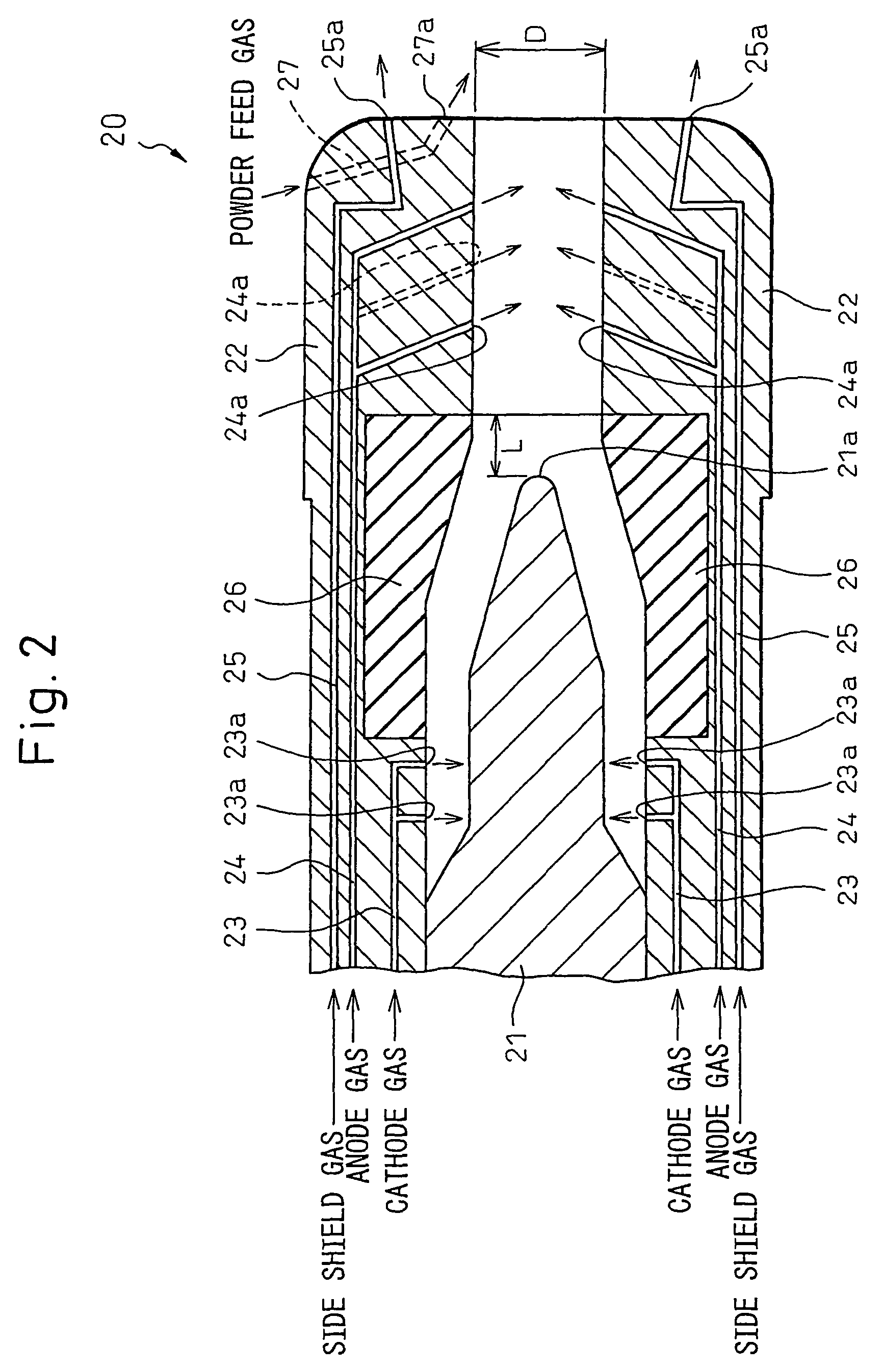

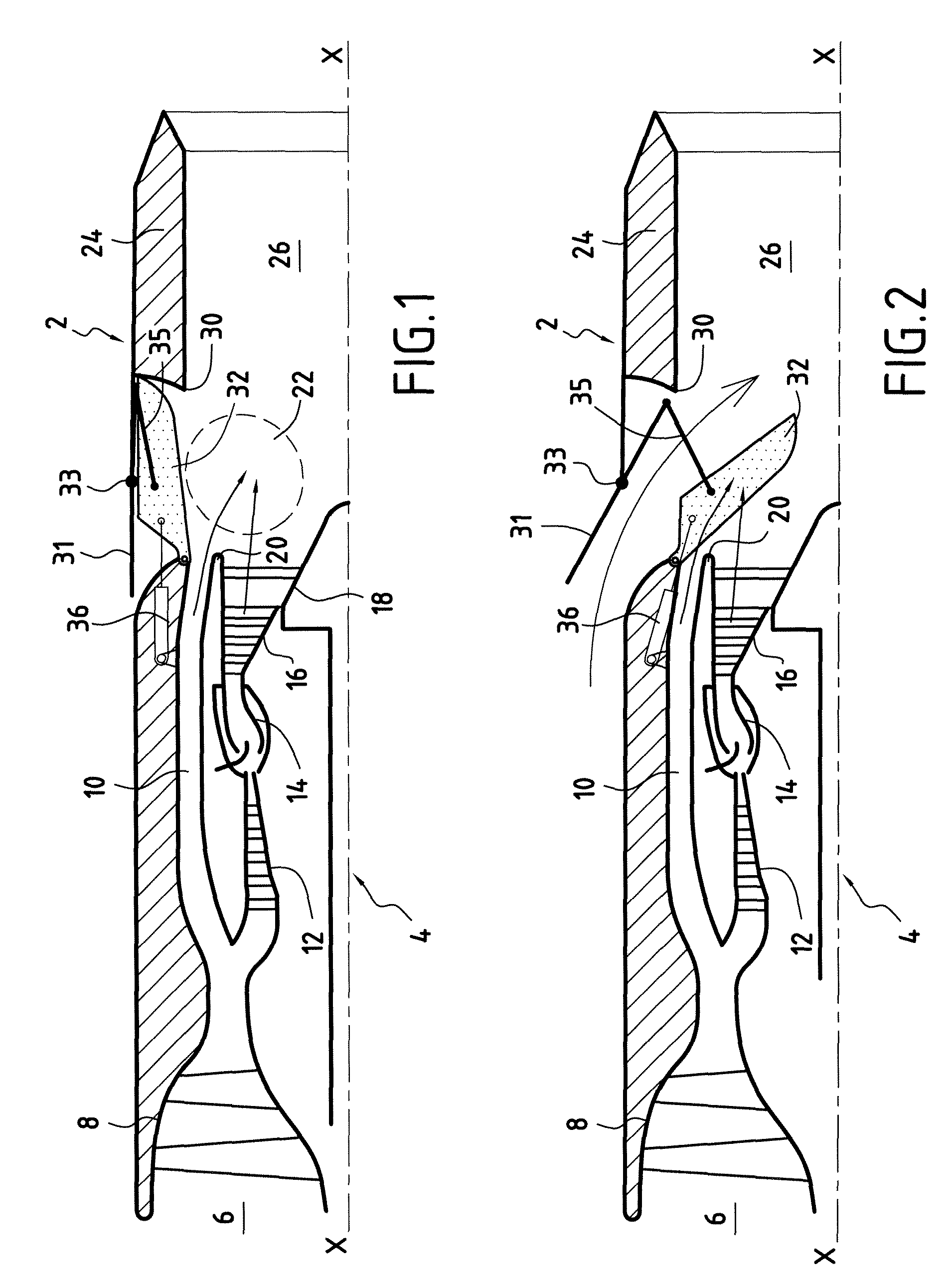

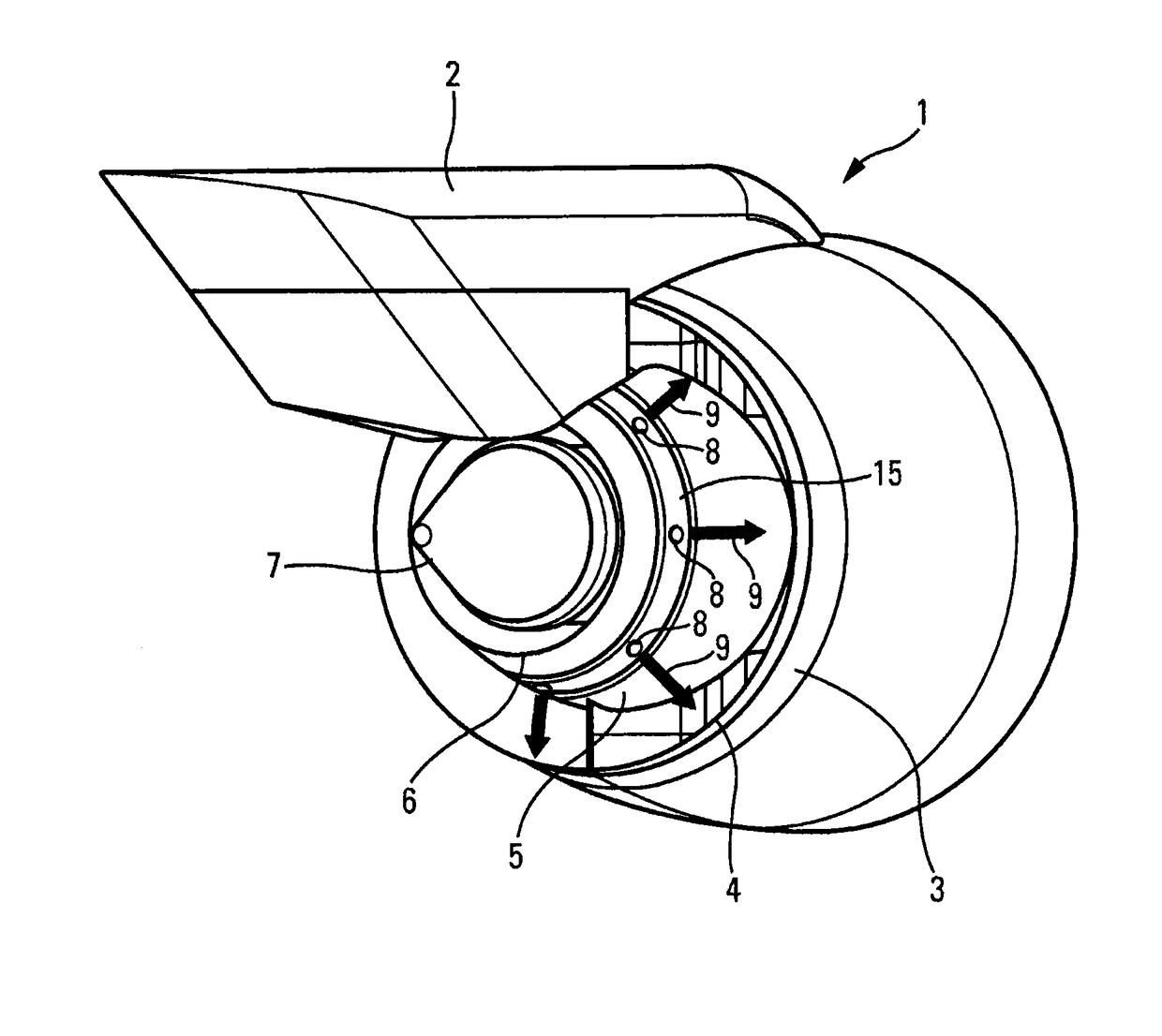

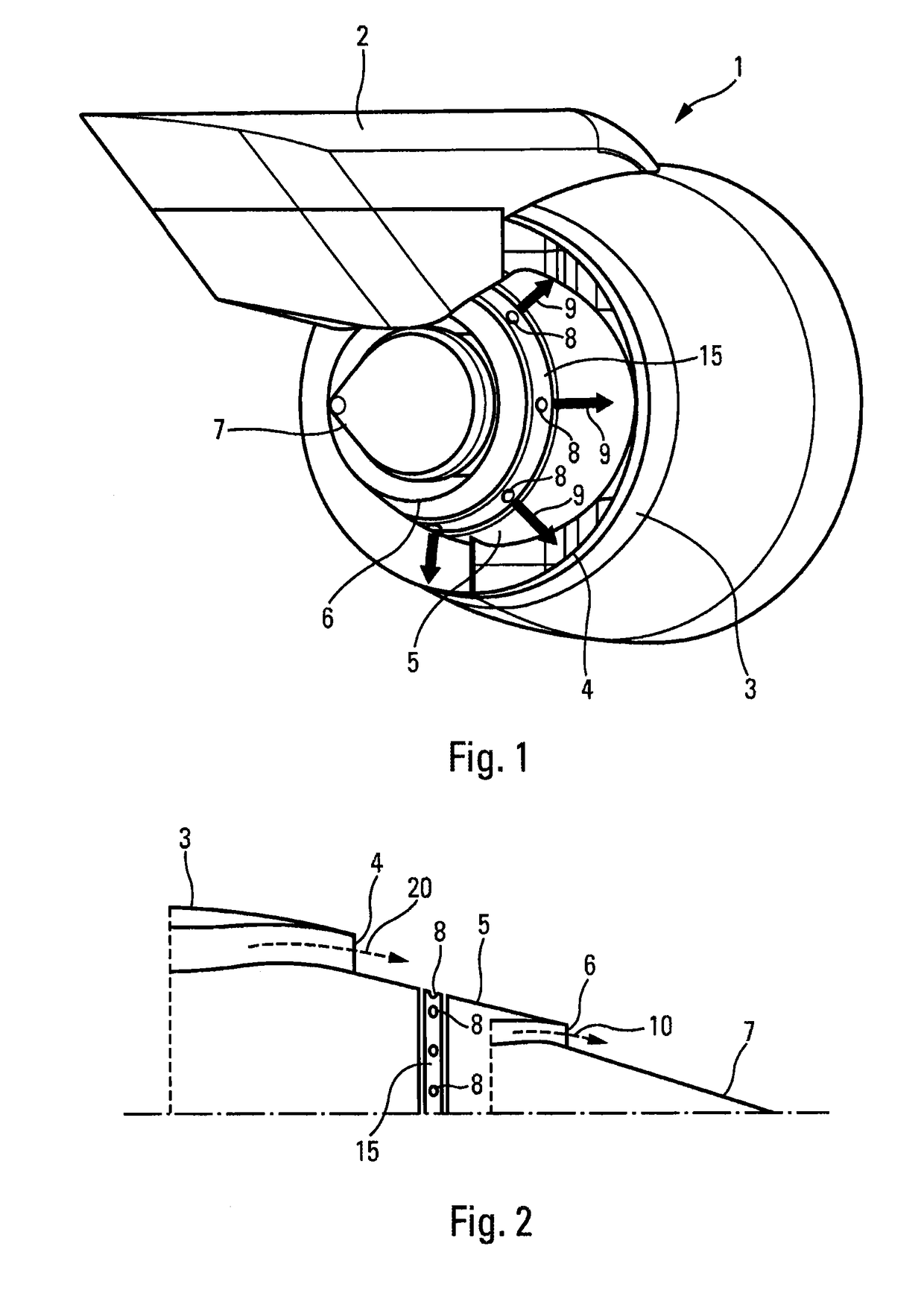

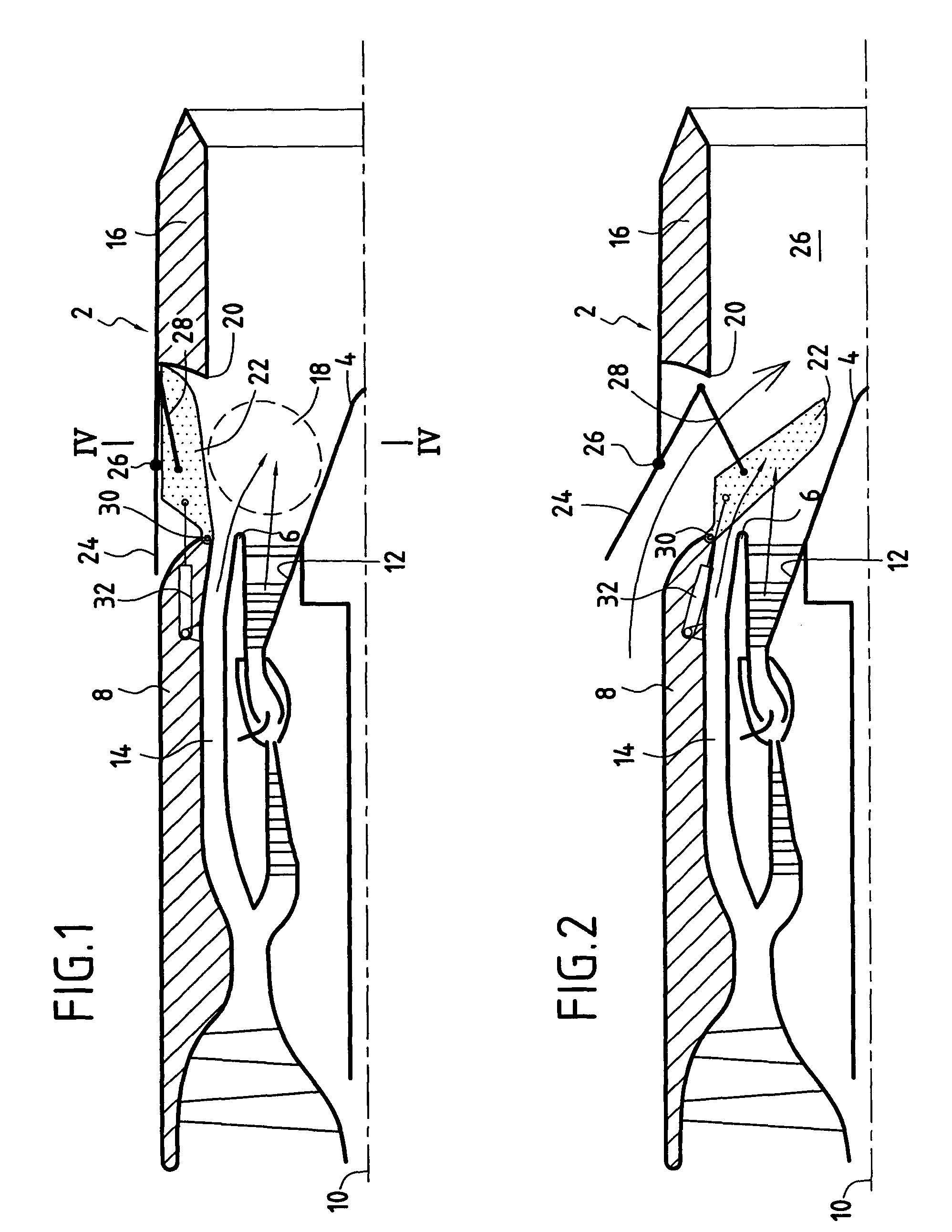

Device for reducing the jet noise of a turbomachine

ActiveUS7310939B2Lower performance requirementsMitigate such drawbackAircraft navigation controlPower plant exhaust arrangementsEngineeringAirflow

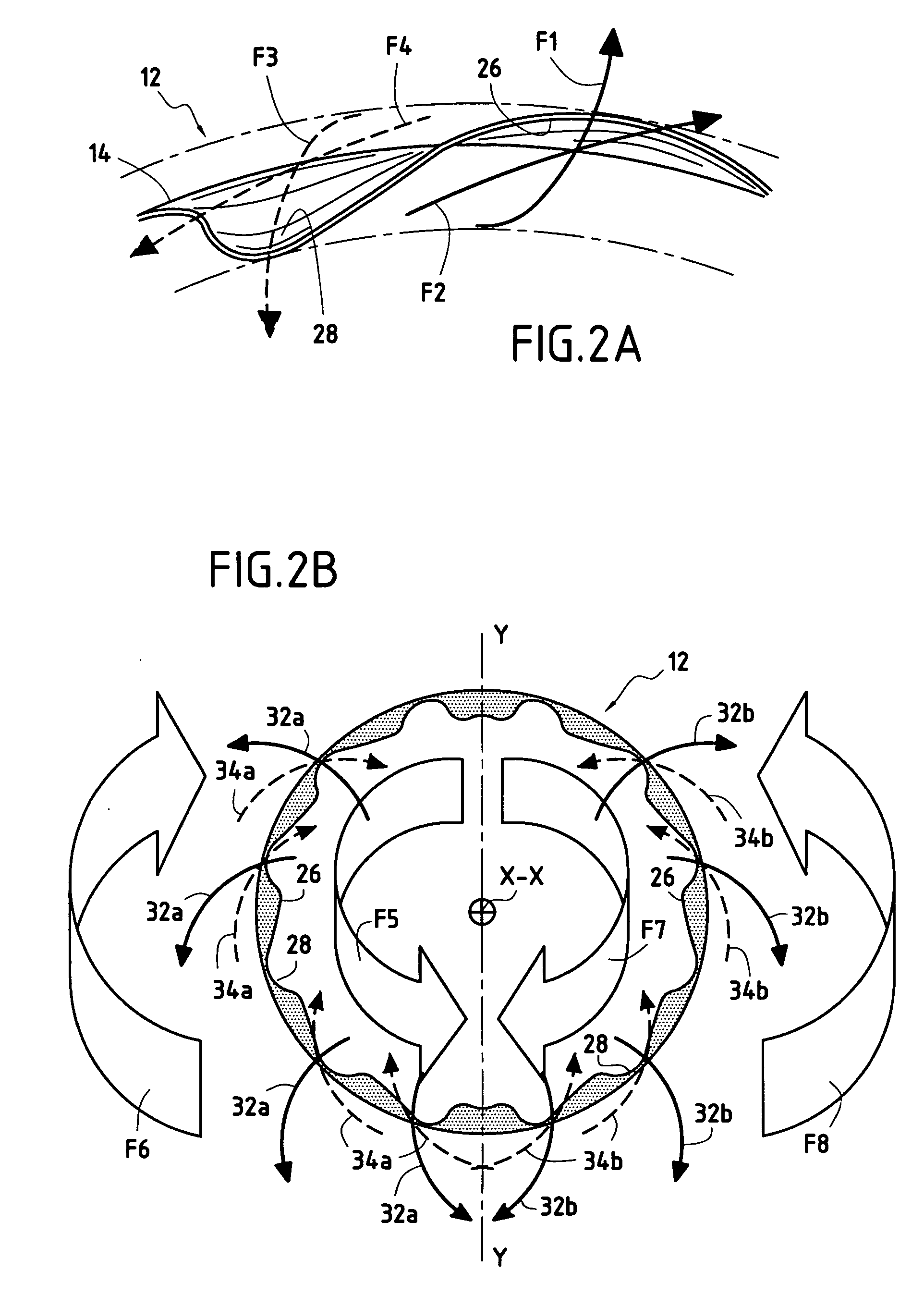

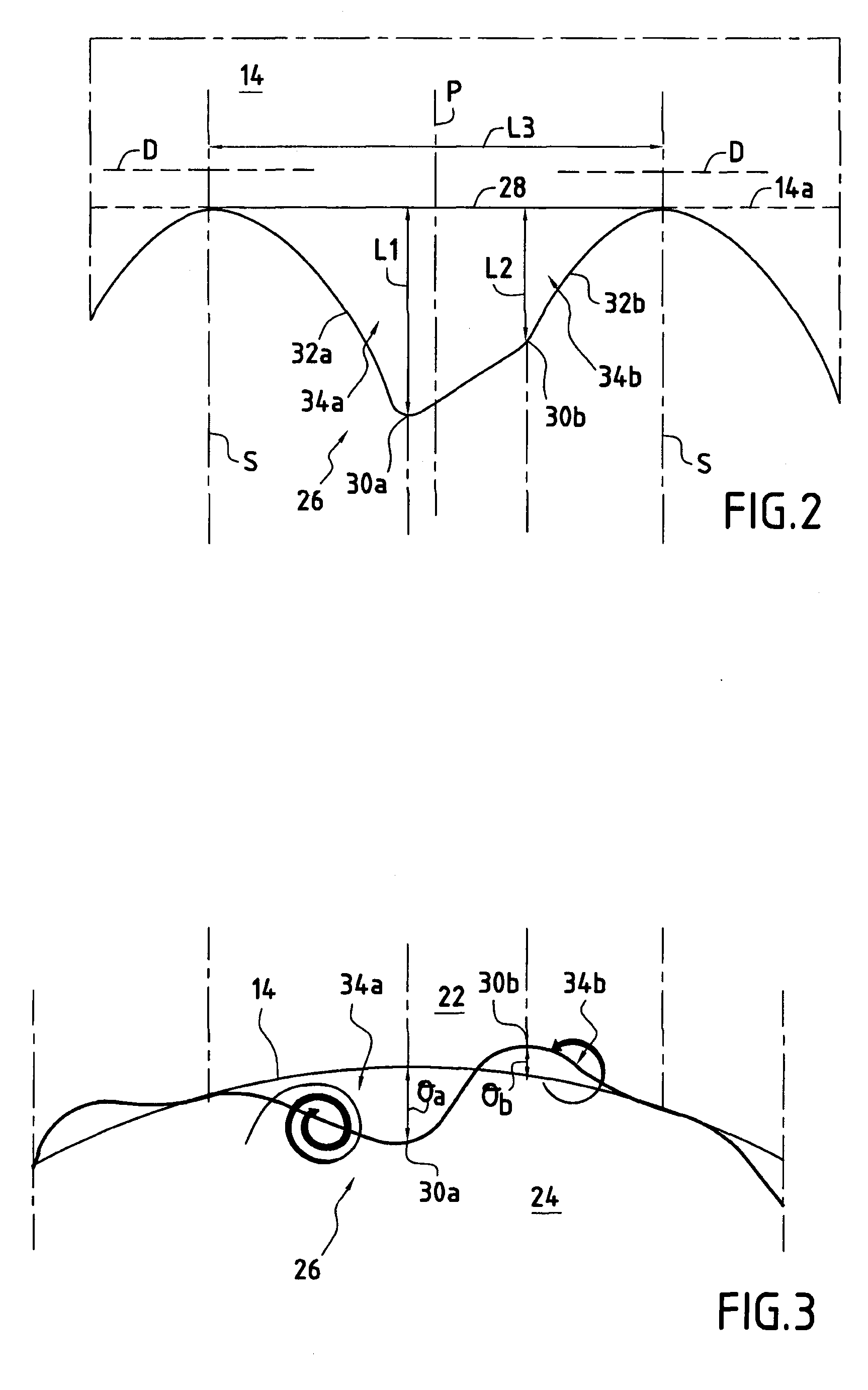

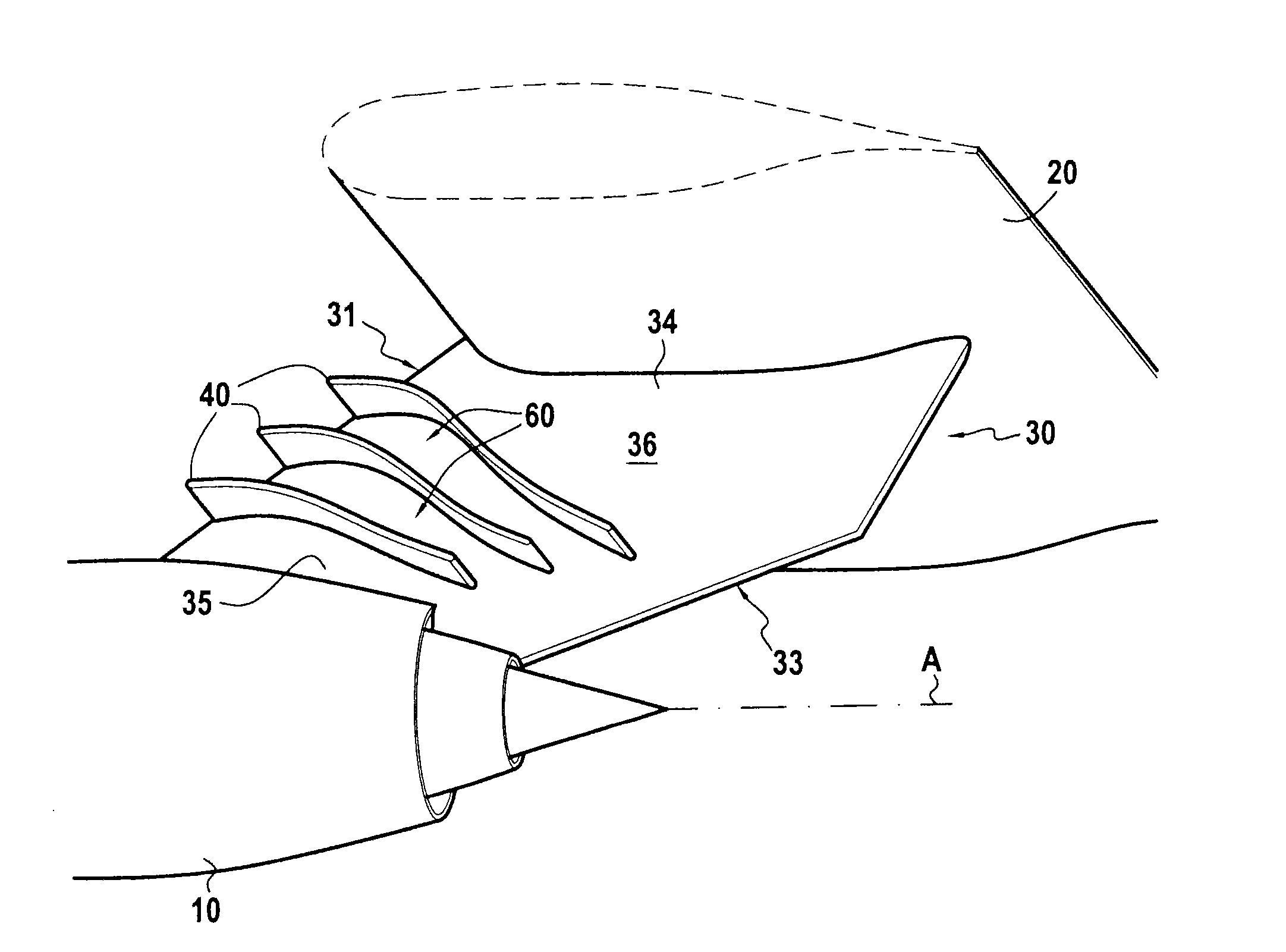

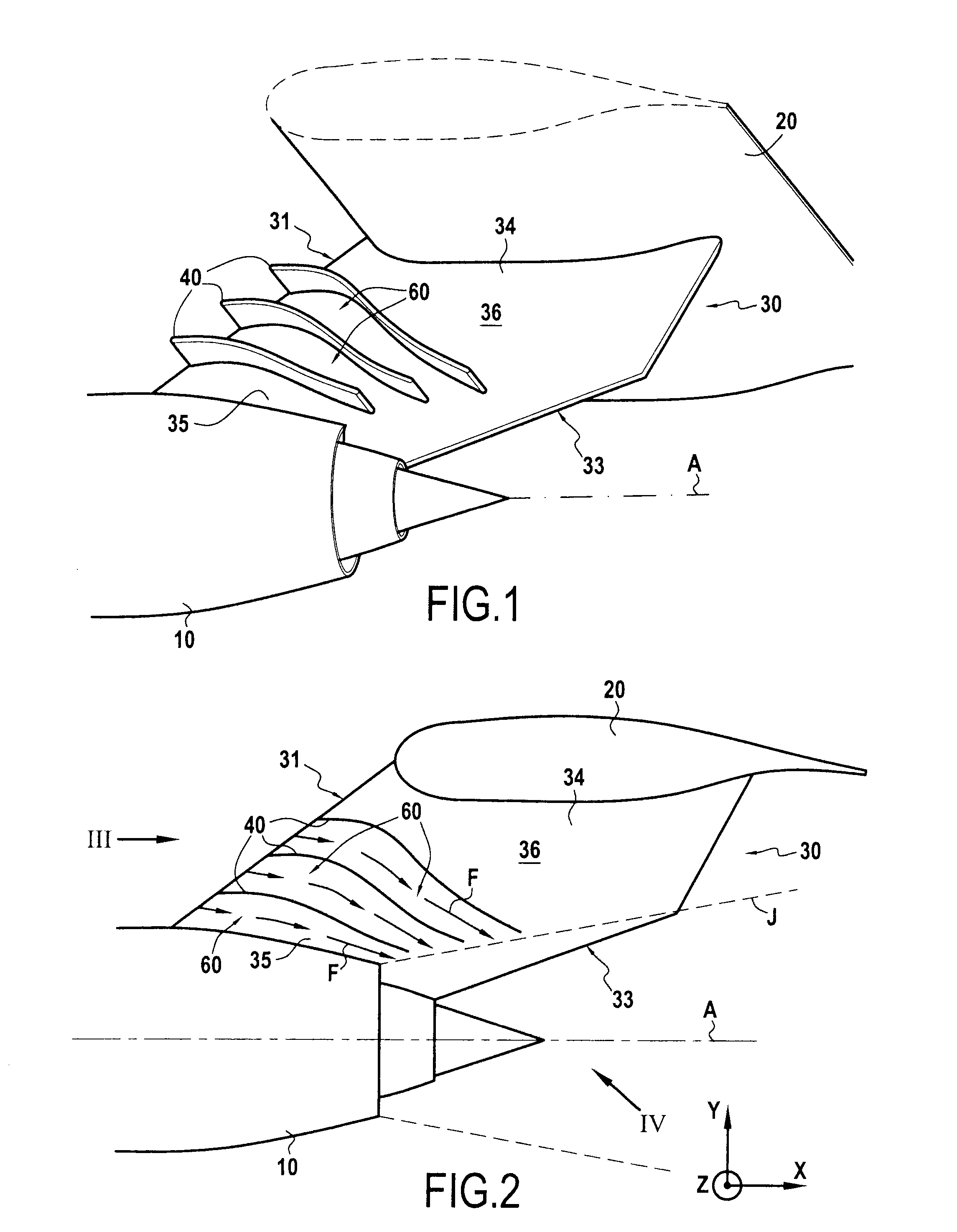

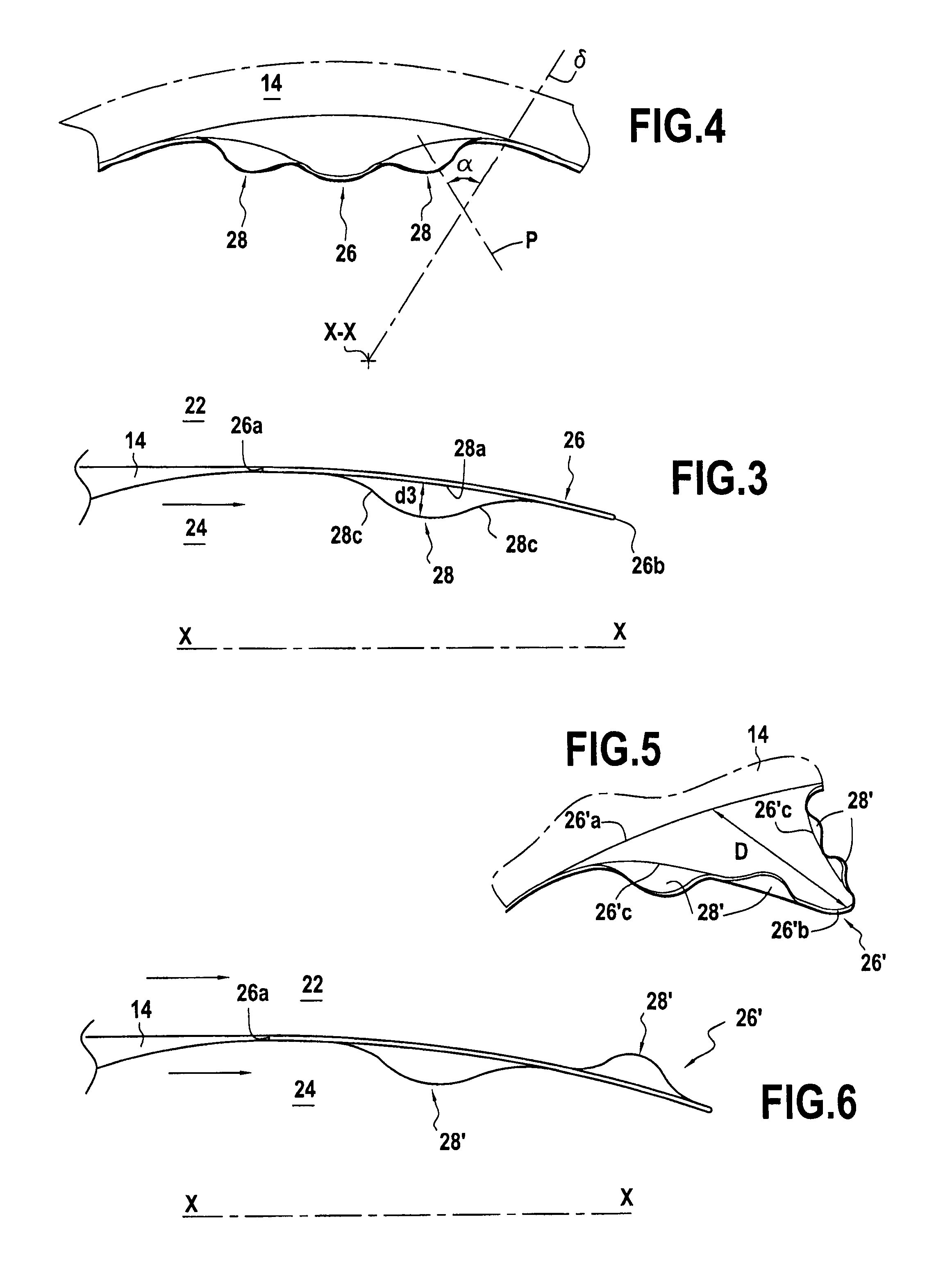

A device for reducing the jet noise of a turbomachine, the turbomachine having a longitudinal axis and a substantially cylindrical nozzle extending along the longitudinal axis of the turbomachine, having a downstream end for mixing the flows of gas inside and outside the nozzle, the device comprising a plurality of corrugations disposed to extend the downstream end of the nozzle, and a plurality of notches disposed between pairs of successive corrugations in the plurality of corrugations, and the plurality of corrugations and the plurality of notches are symmetrical relative to at least one axis perpendicular to the longitudinal axis of the turbomachine so as to generate a dual counter-rotating effect between the gas flows.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

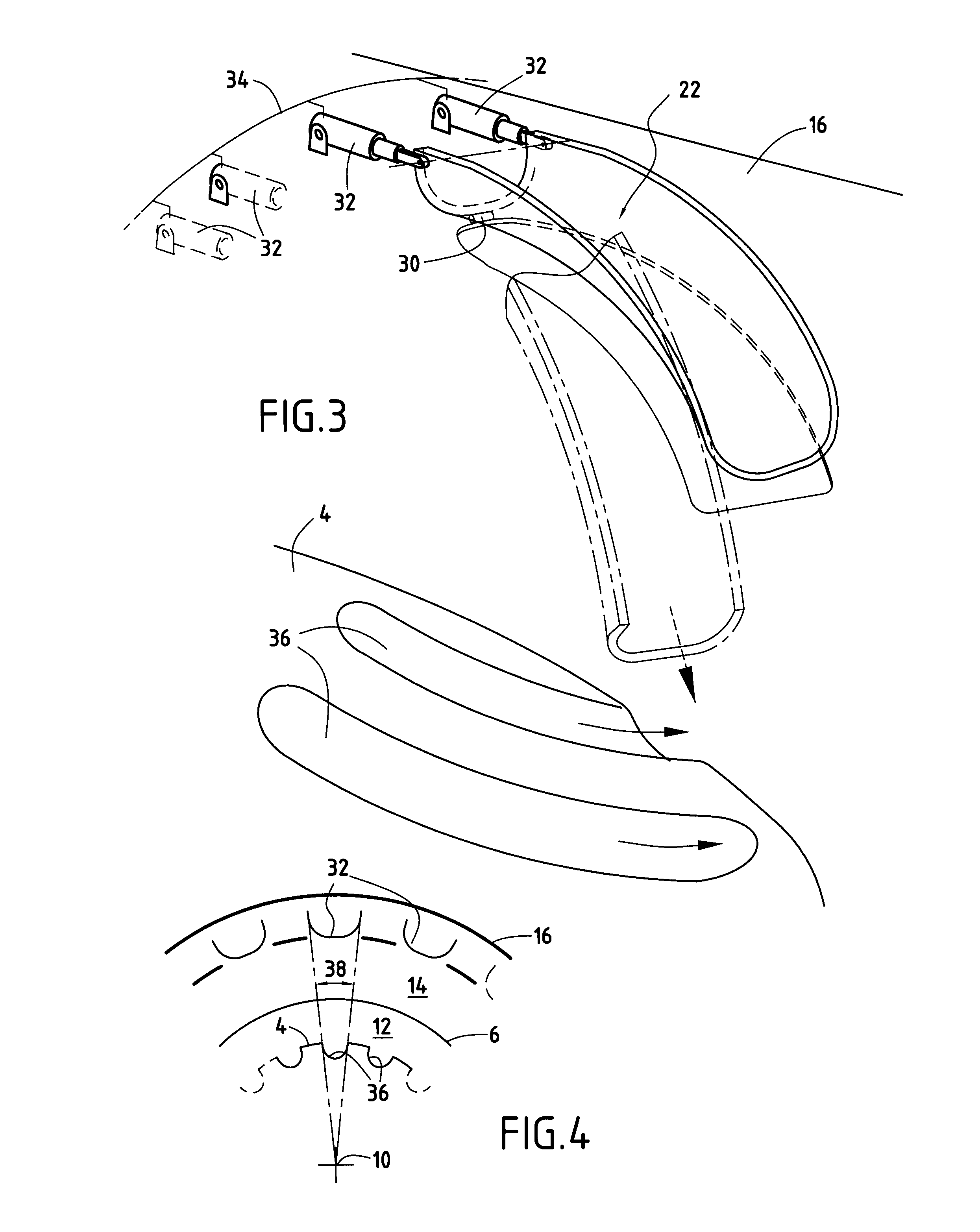

Turbomachine nozzle cover provided with triangular patterns having pairs of vertices for reducing jet noise

ActiveUS20080047273A1Mitigate such drawbackReduce componentsAircraft navigation controlEngine manufactureEngineeringTrailing edge

The pattern relates to a cover for a turbomachine nozzle, the cover having a plurality of patterns each with an outline of triangular shape having a base and two vertices that are spaced downstream and interconnected by a side. For each pattern, the vertices present respective curved outlines and they are interconnected by a curved portion presenting a radius of curvature greater than the radii of curvature of the outlines of said vertices, each side being connected to the trailing edge of the cover via a curved outline presenting a radius of curvature greater than the radii of curvature of the outlines of the vertices and greater than the radius of curvature of the outline of the curved portion, and the vertices and the curved portion are inclined radially towards the inside of the cover, with the curved portion being radially offset outwards relative to the vertices.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

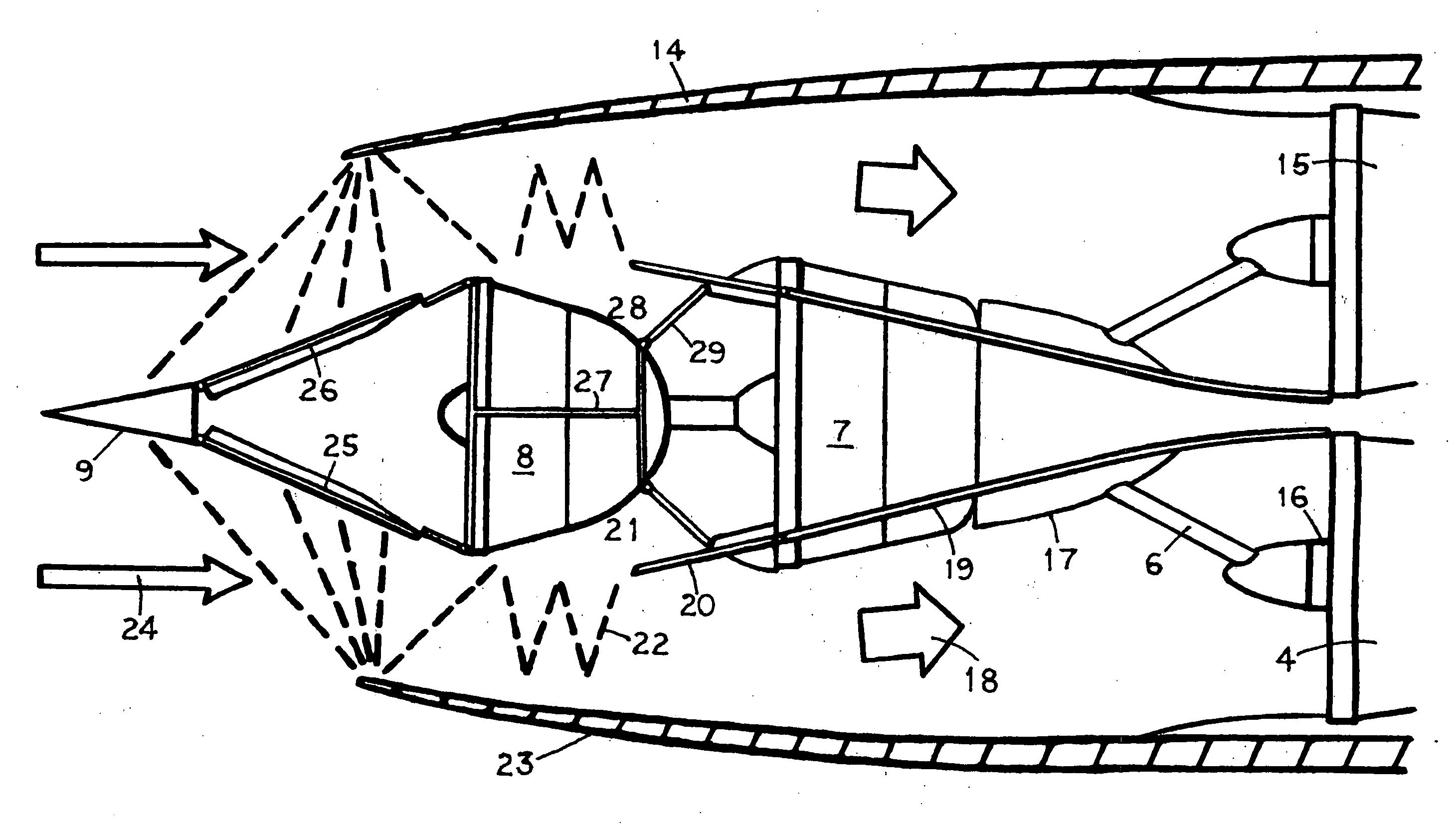

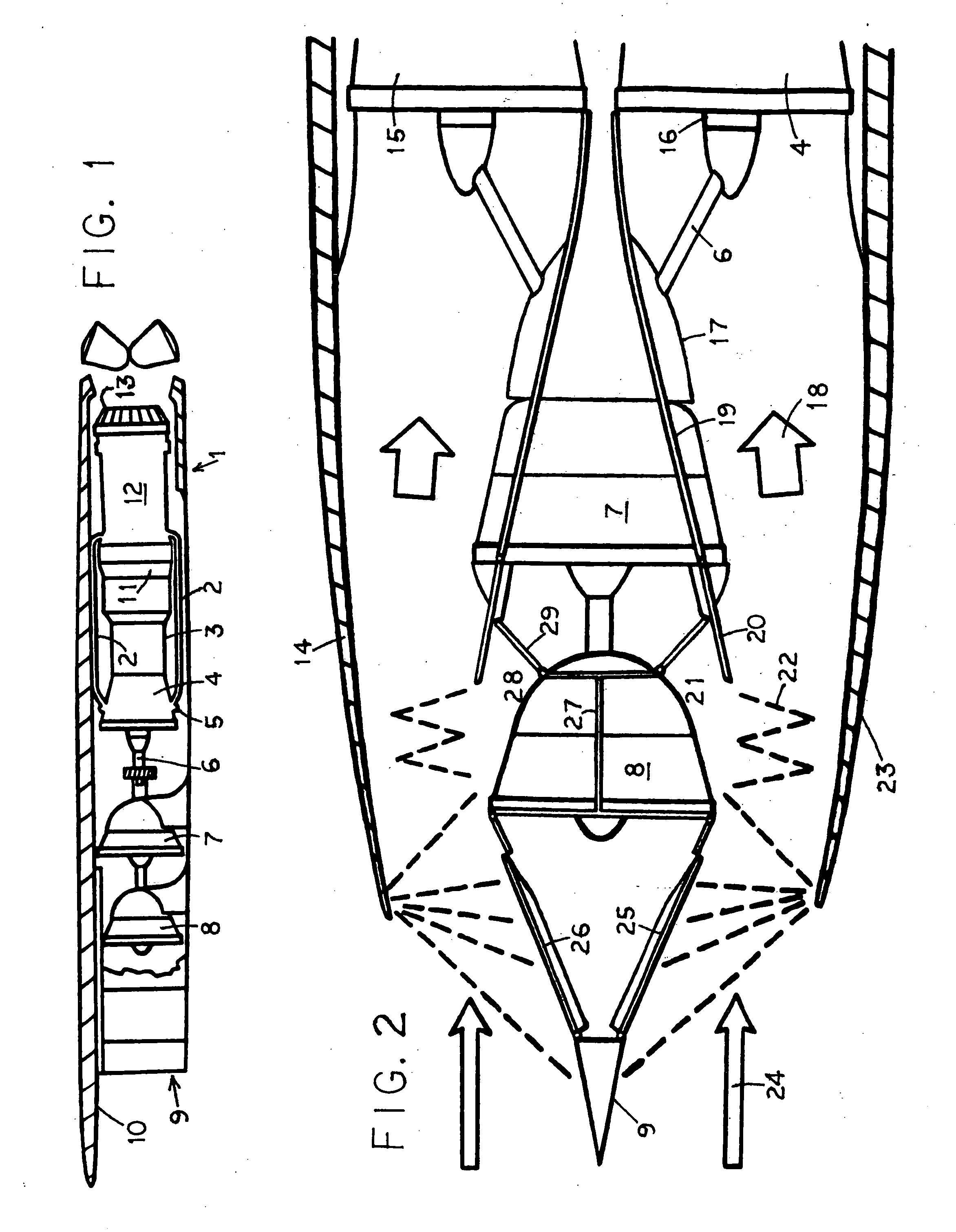

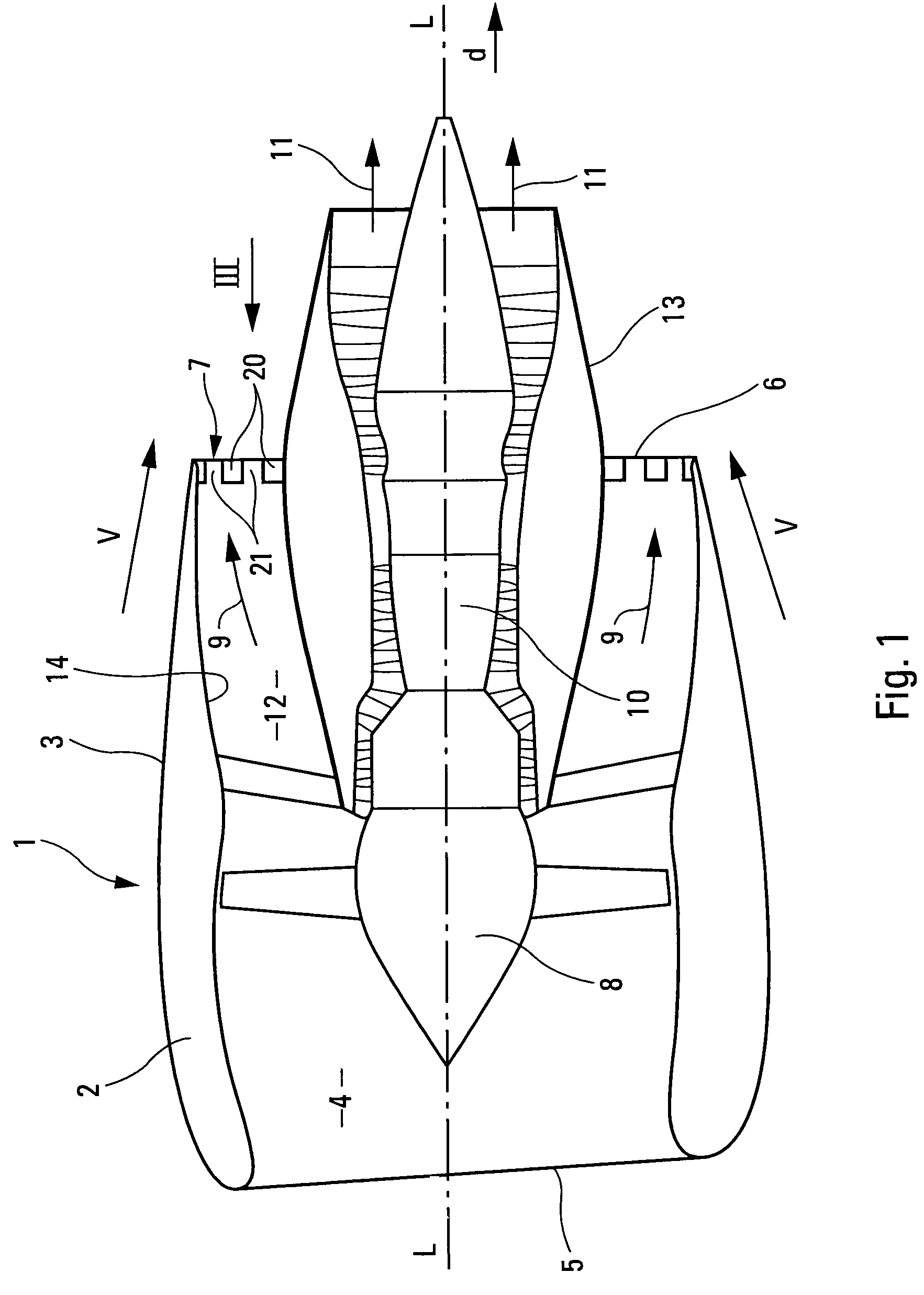

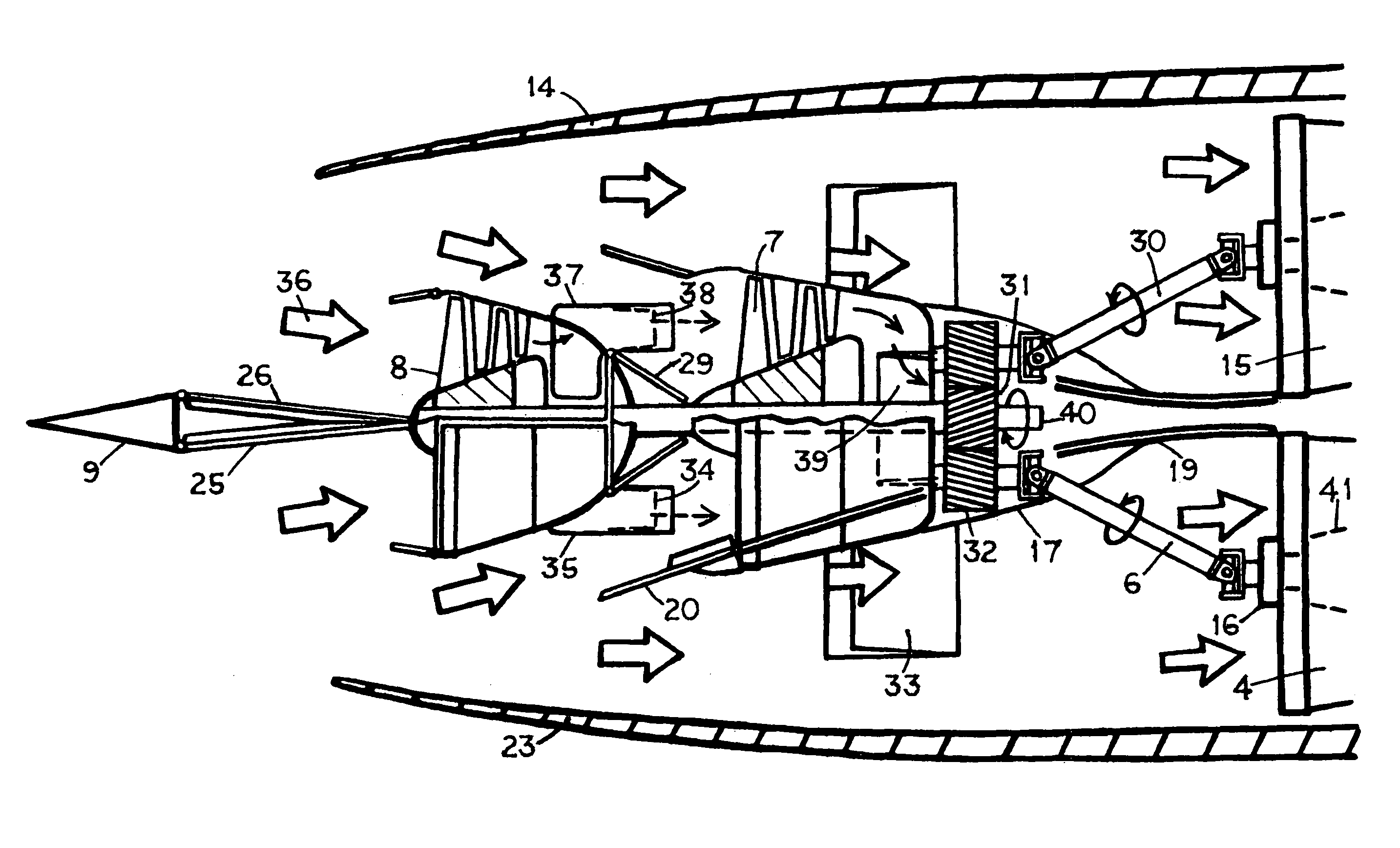

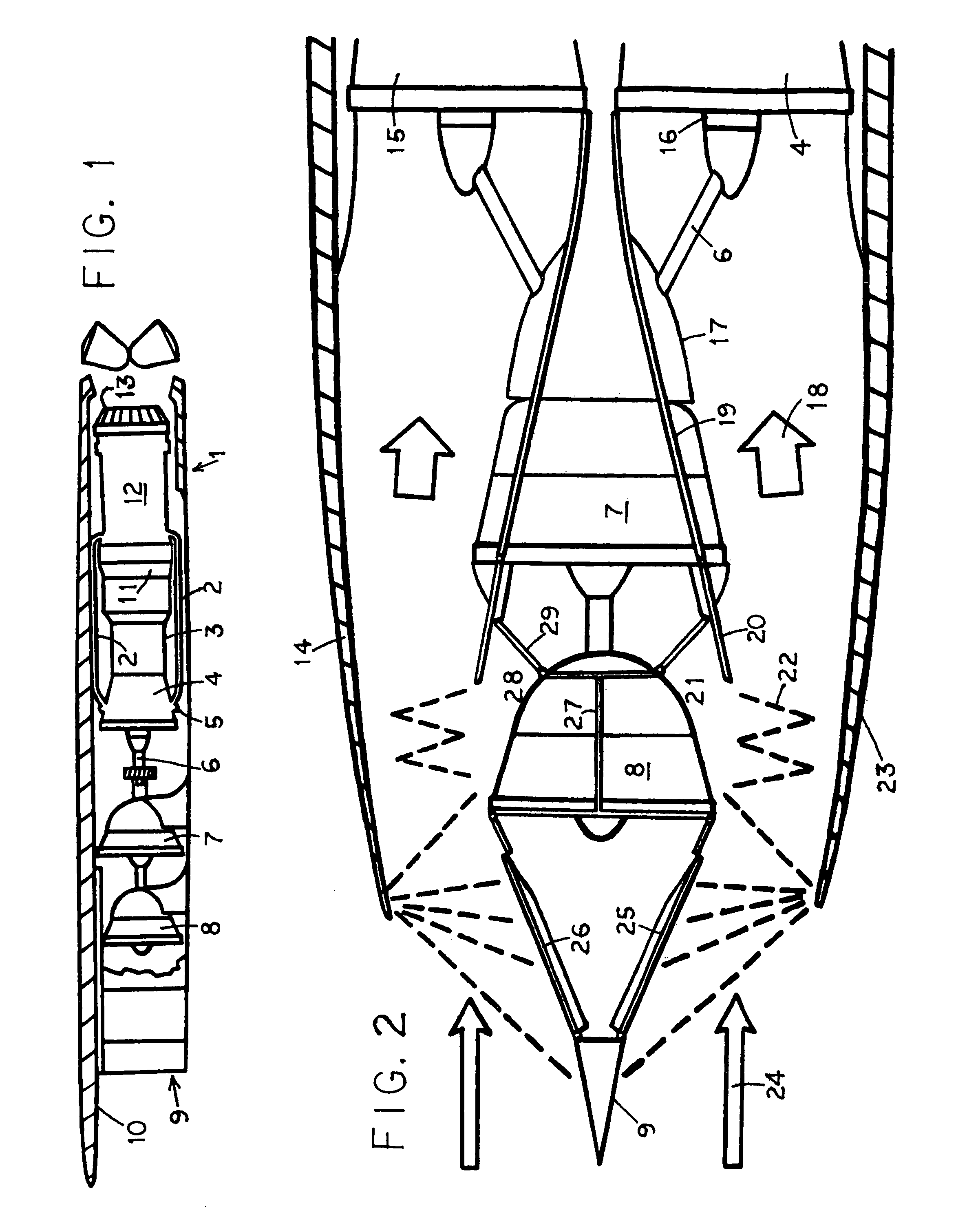

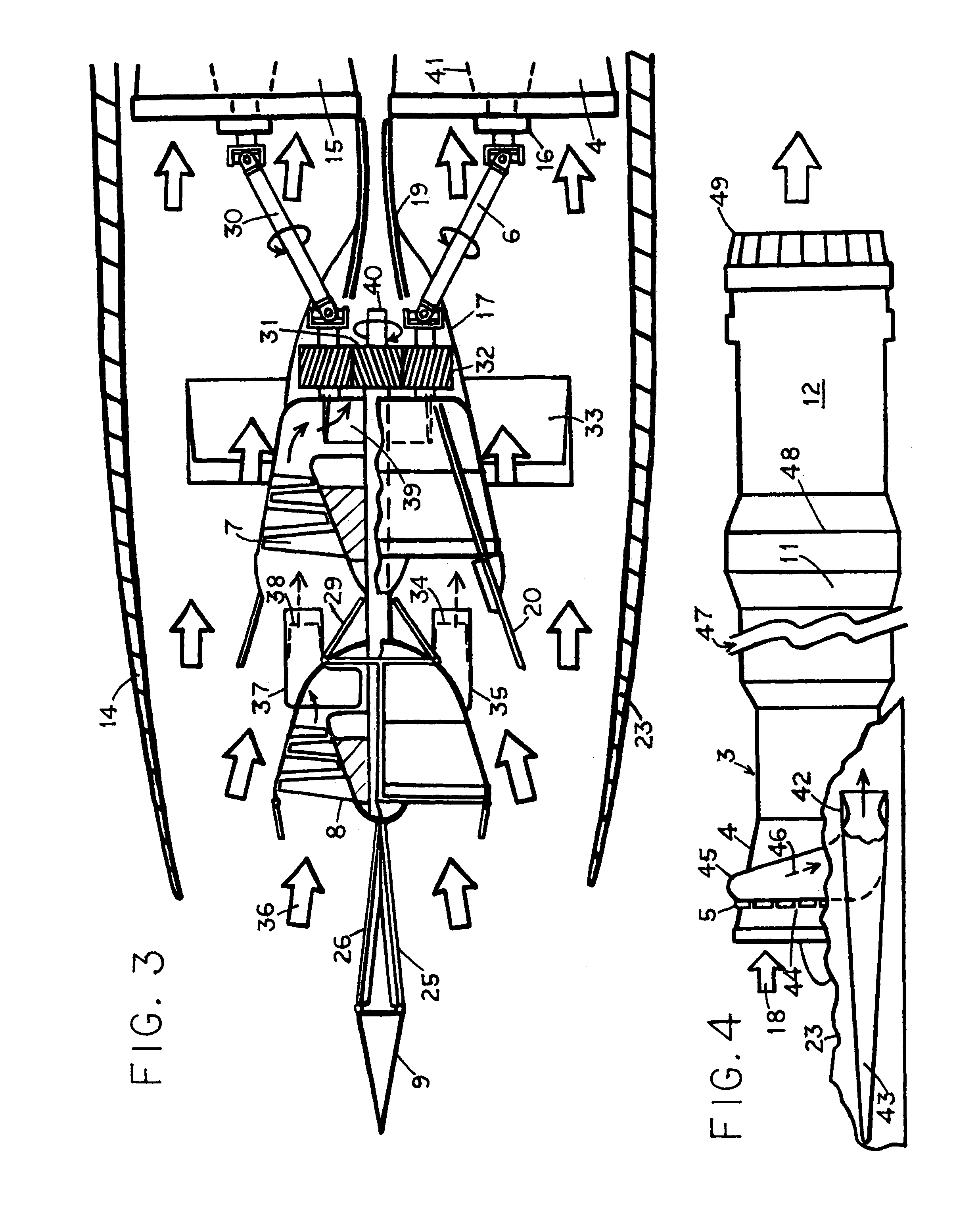

Mass flow increase at takeoff in supersonic airliner

InactiveUS20120292440A1Reduce noiseReduce jet velocityEngine fuctionsEfficient propulsion technologiesJet aeroplaneNacelle

In a supersonic aircraft, turbojet engine nacelles each containing two remote fans in the front half of the nacelle, for noise reduction at takeoff. During supersonic flight, a front wedge at the nacelle nose achieves external compression of intake air. The wedge is vertical, sending the airflow left and right inside the nacelle along its side walls. The two flows follow mirror image curved paths on their way to a turbojet, leaving unused space between them to house the fans in tandem. For takeoff, clutches connected to the turbojets's compressors are engaged. Driveshafts turn pinions against a gear on the same shaft as the remote fans. The fan output is discharged backward under the nacelle to produce thrust. The energy to turn the fans is taken from the turbojet cycle. The reduced exhaust jet velocity decreases its noise. Supercharging produces the extra power to turn the remote fans if multistage.

Owner:KOSHELEFF PATRICK A

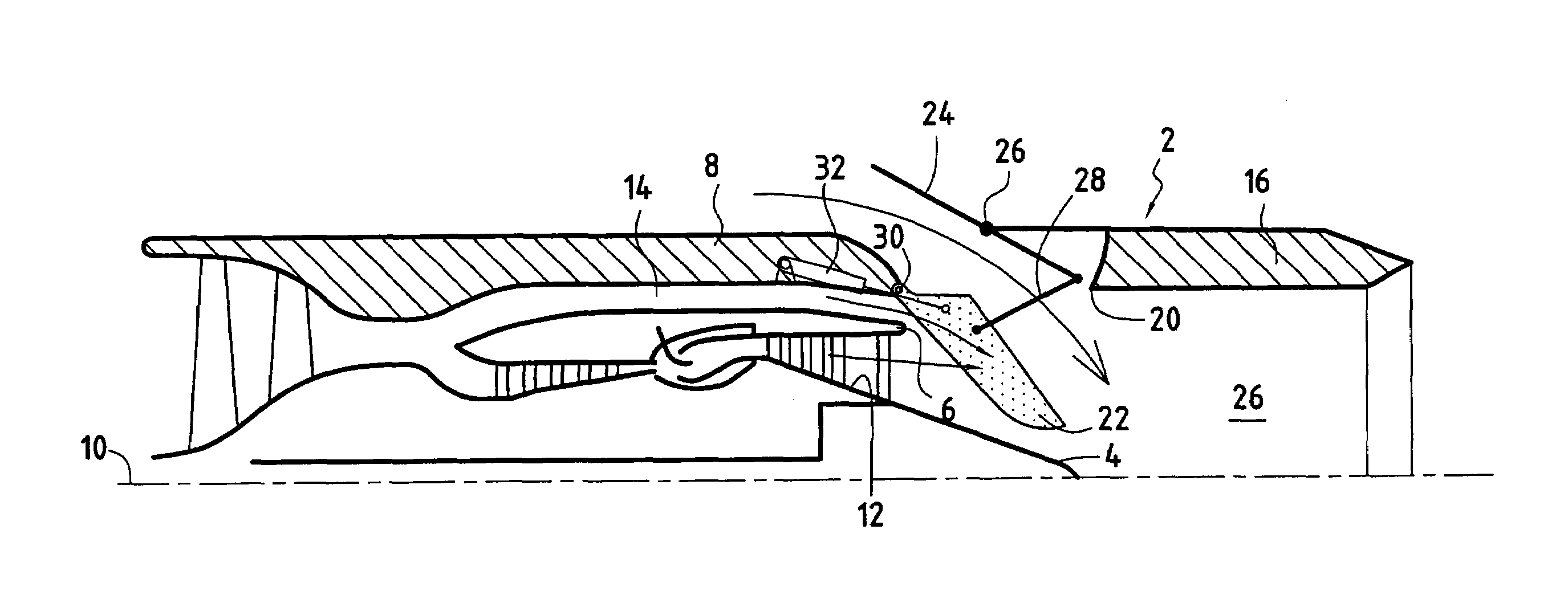

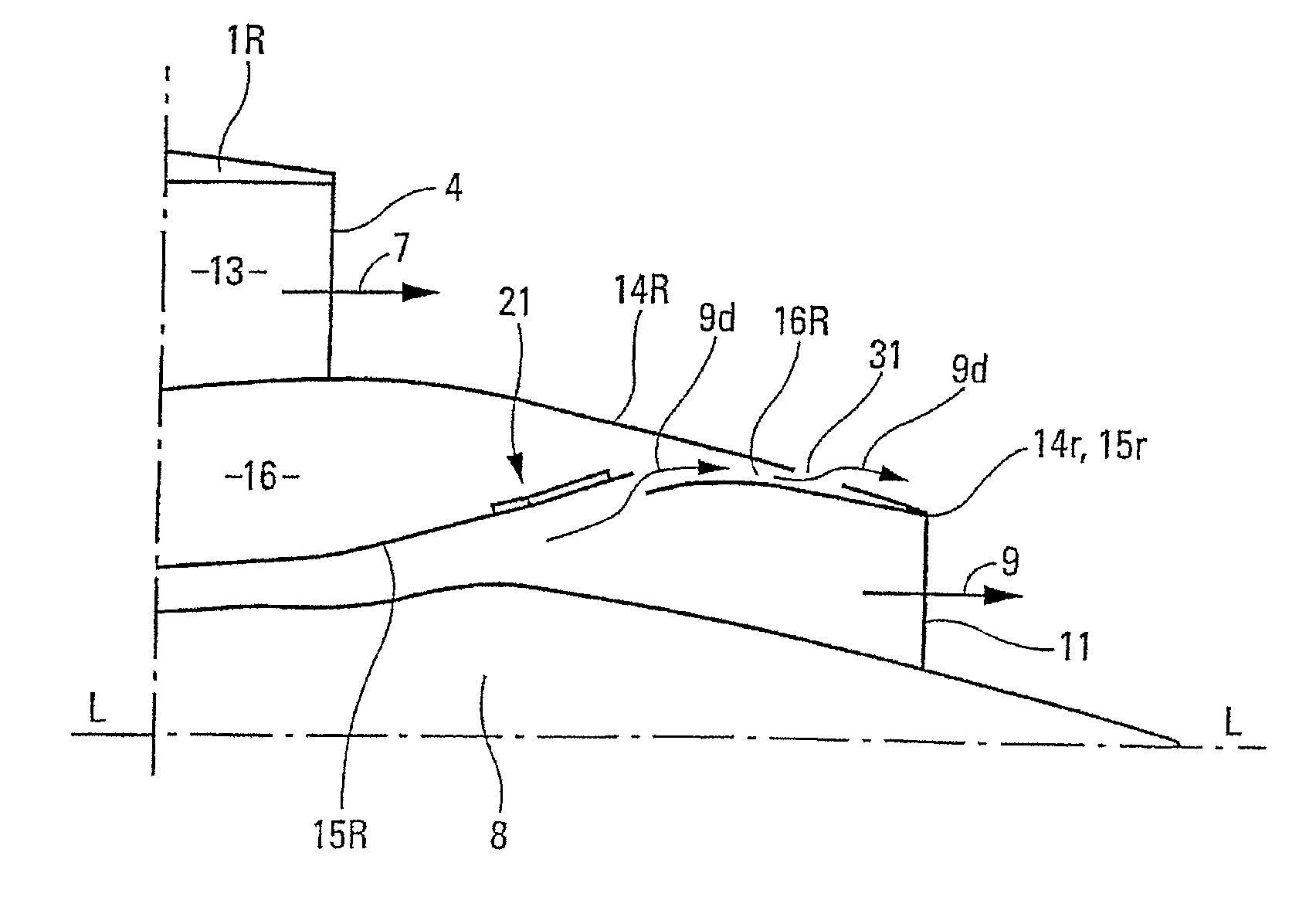

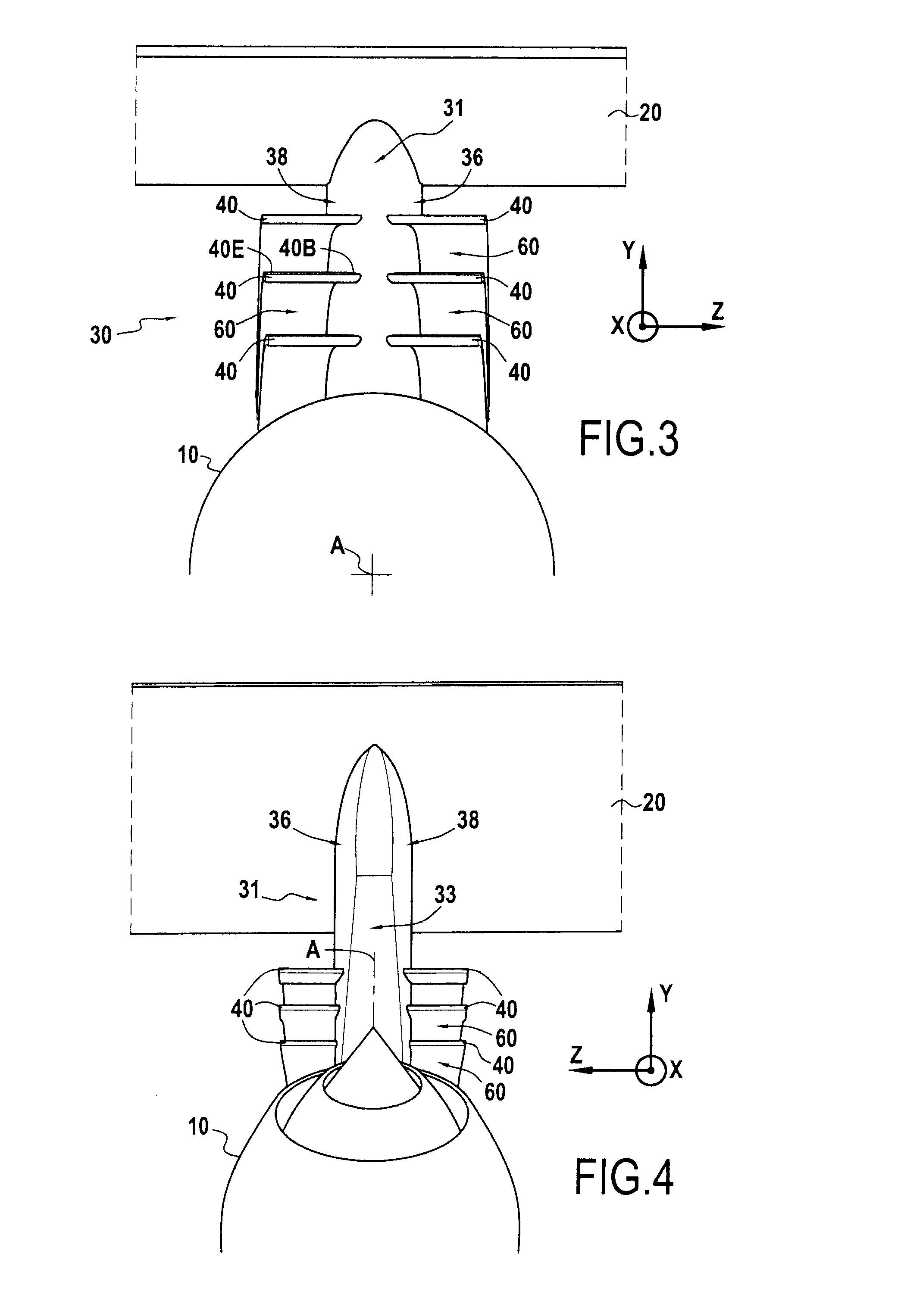

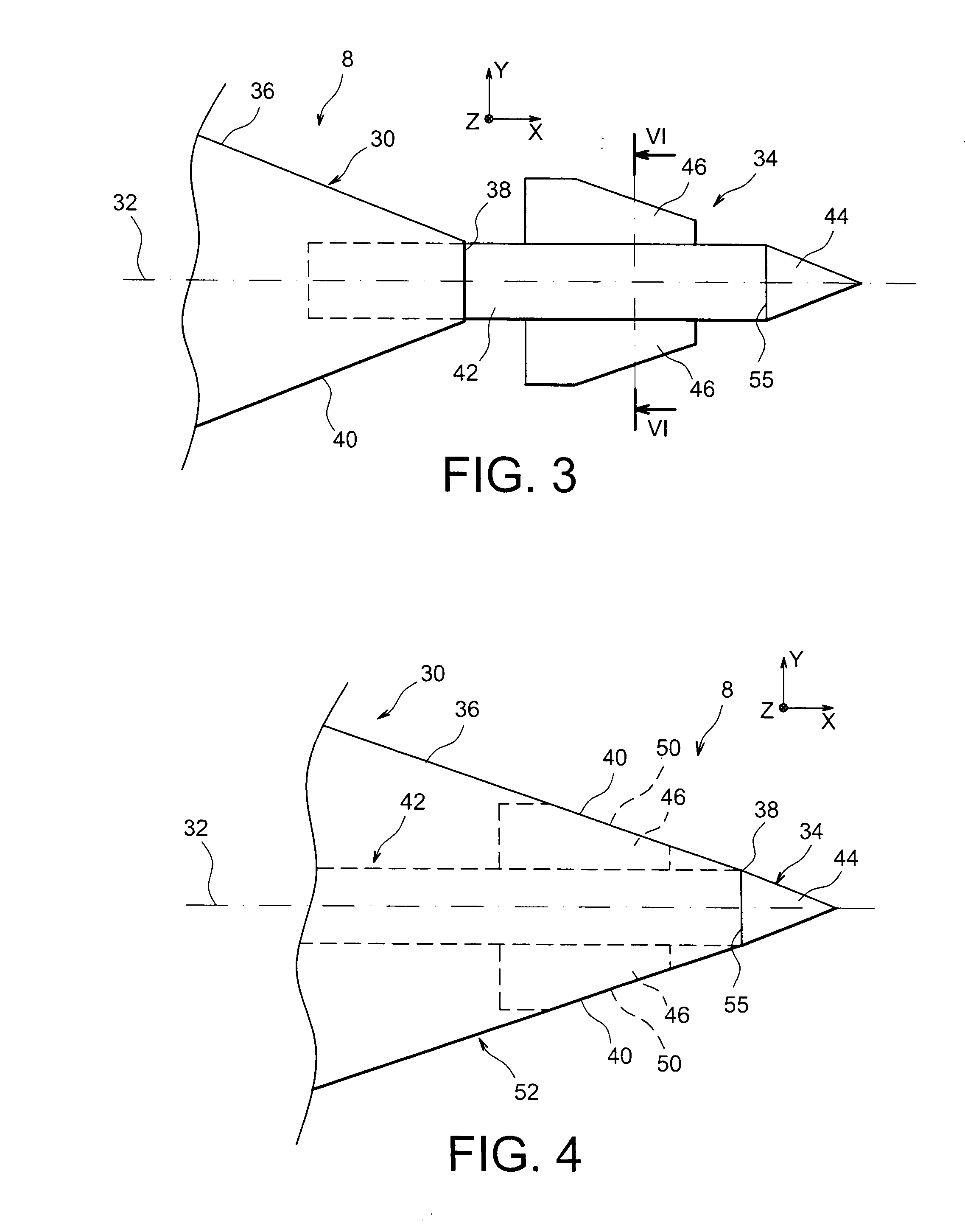

Variable-section flow mixer for a double-flow turbojet for a supersonic airplane

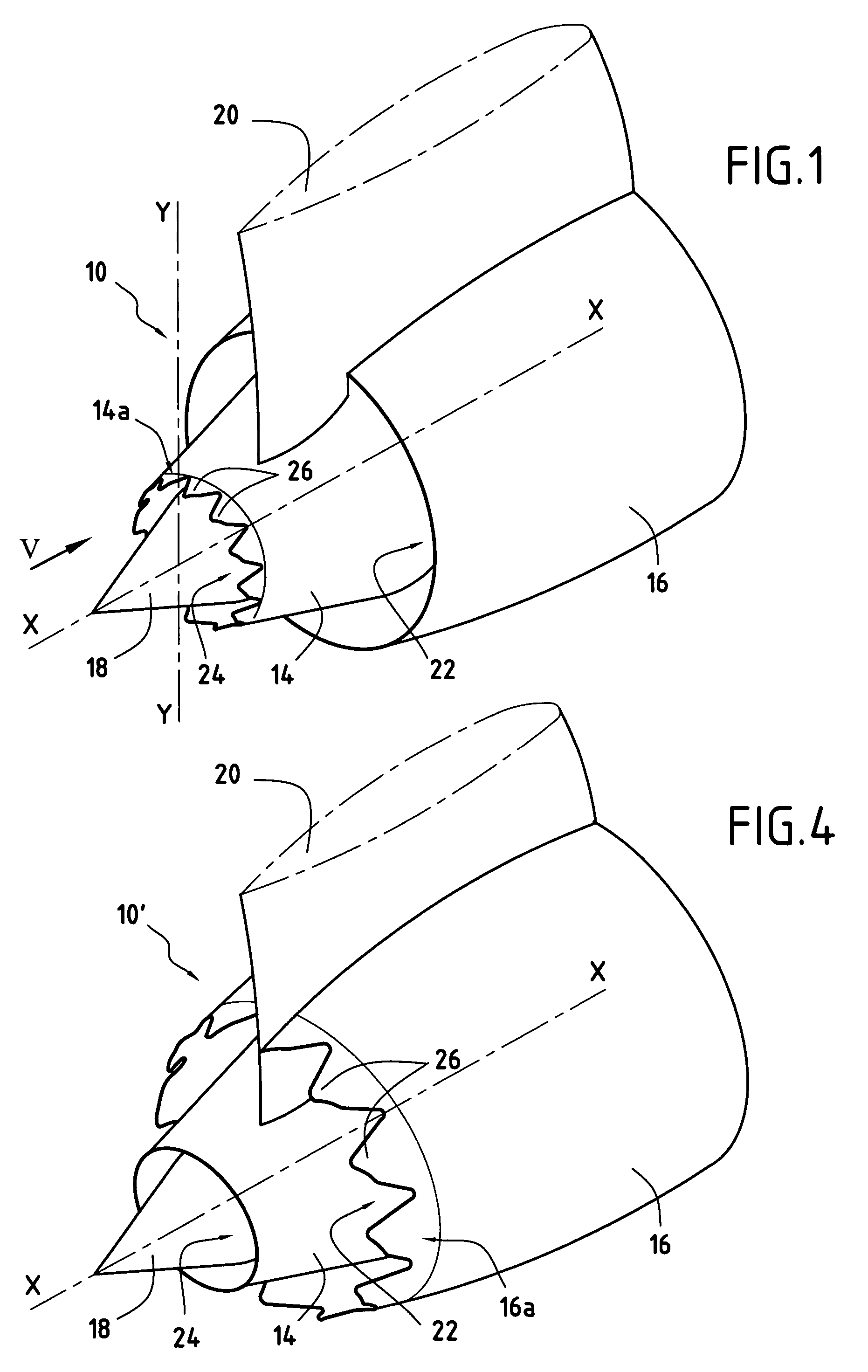

ActiveUS20080236167A1Reduce jet noiseMitigate such drawbackPower plant exhaust arrangementsEngine manufactureAirplaneMoving between two positions

The invention relates to a variable-section flow mixer for a double-flow turbojet for a supersonic airplane, the mixer comprising a central body, a primary cover, a secondary cover, and a nozzle extending the secondary cover. The nozzle has a plurality of external-air admission openings having mounted therein lobes that are movable between two positions: a closed position in which they close the openings; and a deployed position in which they disengage said openings and deploy into the nozzle so as to allow external air to be admitted. All of the lobes present a common azimuth component in a common direction, and the mixer further includes a plurality of longitudinal grooves occupying at least a portion of the central body, all of the grooves presenting a common azimuth component in a common direction that is opposite to the direction of the azimuth component of the lobes.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Turbojet engine with attenuated jet noise

ActiveUS8096105B2Reduce jet noiseIncreased dragPower plant arrangements/mountingEngine fuctionsTurbojet engineAerospace engineering

A plurality of hatches are distributed on the rear periphery of an engine cowl. The hatches are opened only when turbojet engine power is greater than cruising power. In an open position, the hatches draw hot air jets passing through an intermediate chamber before ejecting the jets through longitudinally-distributed communication components.

Owner:AIRBUS OPERATIONS (SAS)

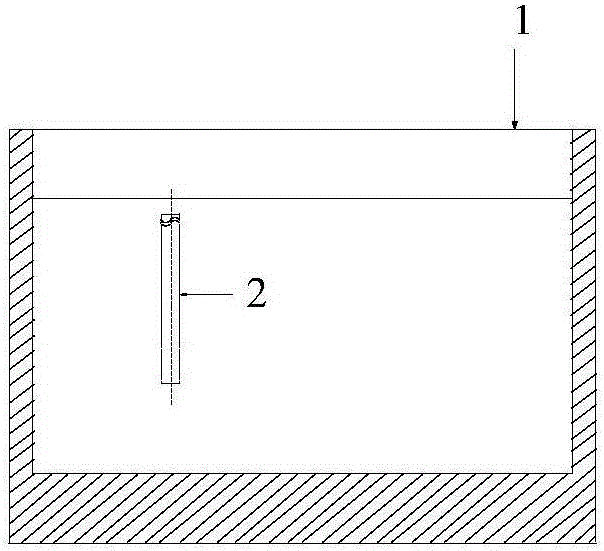

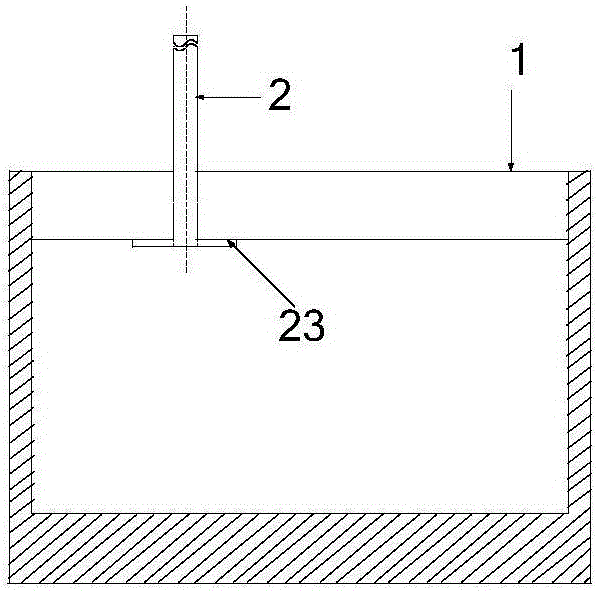

Water pipe flow stabilizing broadband muffler

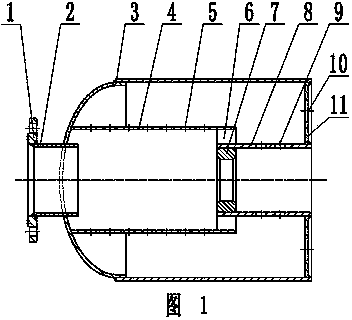

The invention discloses a water pipe flow stabilizing broadband muffler which comprises a water delivery pipe and a muffler casing. An expanded perforated pipe is fixedly installed on the inner side of one end of a muffler casing body fixedly connected with the water delivery pipe. An end plate is fixedly arranged at the other end of the muffler casing. A shunting perforated pipe is further fixedly connected onto the end plate, and a throttle ring is fixedly arranged at the port position of the inner end of the shunting perforated pipe. The inner diameter of the expanded perforated pipe is larger than the outer diameter of the shunting perforated pipe, the inner end of the expanded perforated pipe and the inner end of the shunting perforated pipe are in fixedly sleeved connection in a gapped mode, and the flowing cross area of the water delivery pipe is smaller than the sum of the hole flowing cross area of the end plate and the flowing cross area of the shunting perforated pipe. The water pipe flow stabilizing broadband muffler can achieve broadband muffling of the water pipe, effectively stabilize a flow field at the outlet end of the water pipe, reduce the water spraying-flowing speed and pressure, accordingly reduce water pipe port noise effectively and achieve the effects of flow stabilizing and broadband muffling.

Owner:JIANGSU YEAN IND ENVIRONMENTAL PROTECTION EQUIP TECH

Turbomachine nozzle cover for reducing jet noise

ActiveUS7392651B2Mitigate such drawbackReduce jet noiseAircraft navigation controlEngine manufactureRepeat patternEngineering

A cowl for a turbomachine nozzle, the cowl having a plurality of repeated patterns disposed circumferentially at a trailing edge, each pattern being asymmetrical about a midplane of the pattern containing a longitudinal axis of the cowl, and each pattern having a first portion inclined radially towards the inside of the cowl and a second portion inclined radially towards the outside of the cowl.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Device for reducing the jet noise of a turbomachine

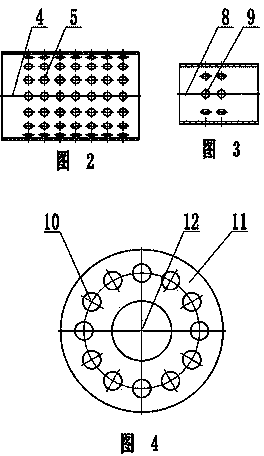

ActiveUS20050115245A1Reduce jet noiseDegrading aerodynamic performanceAircraft navigation controlPower plant exhaust arrangementsAirflowCounter rotating

A device for reducing the jet noise of a turbomachine, the turbomachine having a longitudinal axis and a substantially cylindrical nozzle extending along the longitudinal axis of the turbomachine, having a downstream end for mixing the flows of gas inside and outside the nozzle, the device comprising a plurality of corrugations disposed to extend the downstream end of the nozzle, and a plurality of notches disposed between pairs of successive corrugations in the plurality of corrugations, and the plurality of corrugations and the plurality of notches are asymmetrical relative to at least one axis perpendicular to the longitudinal axis of the turbomachine so as to generate a dual counter-rotating effect between the gas flows.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

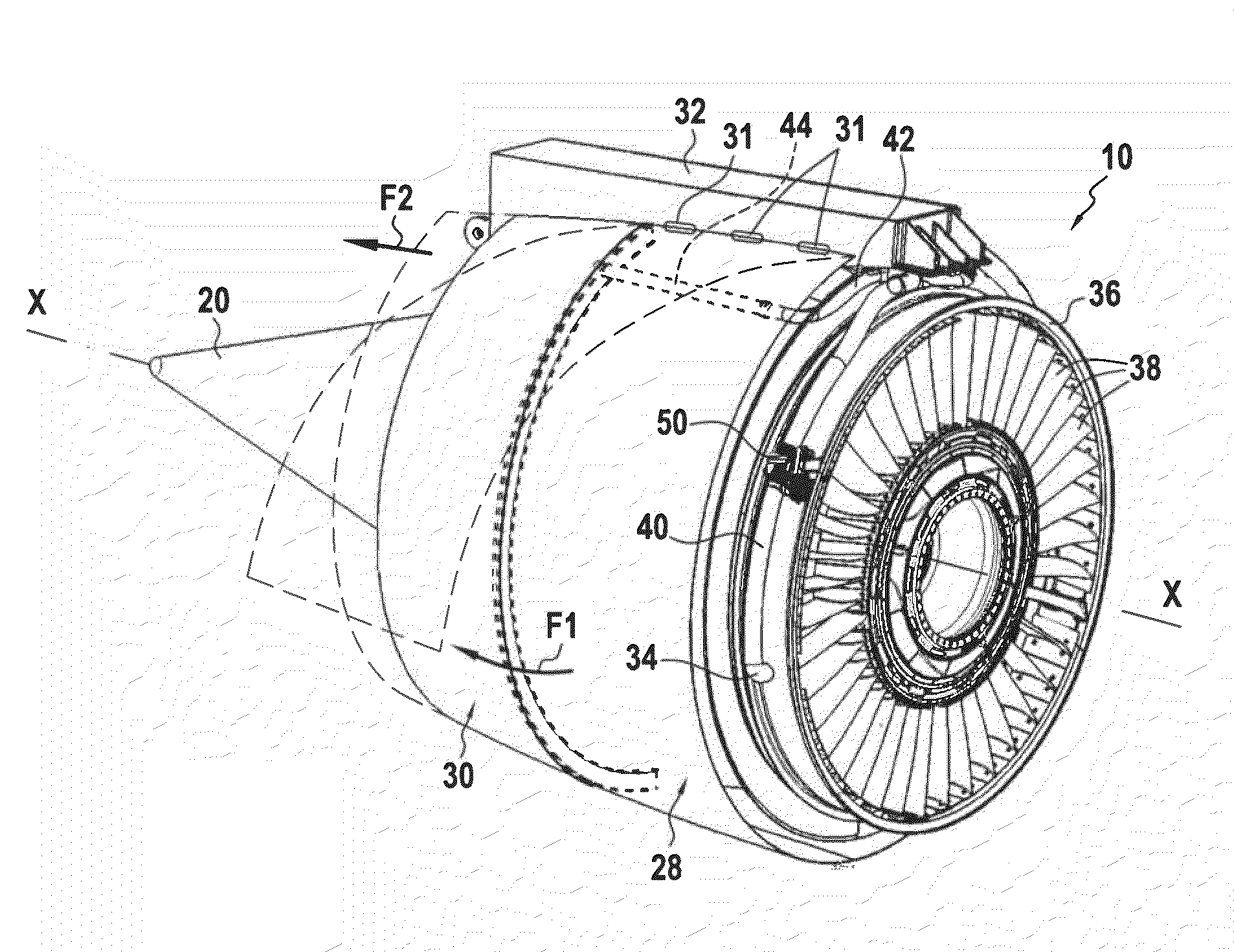

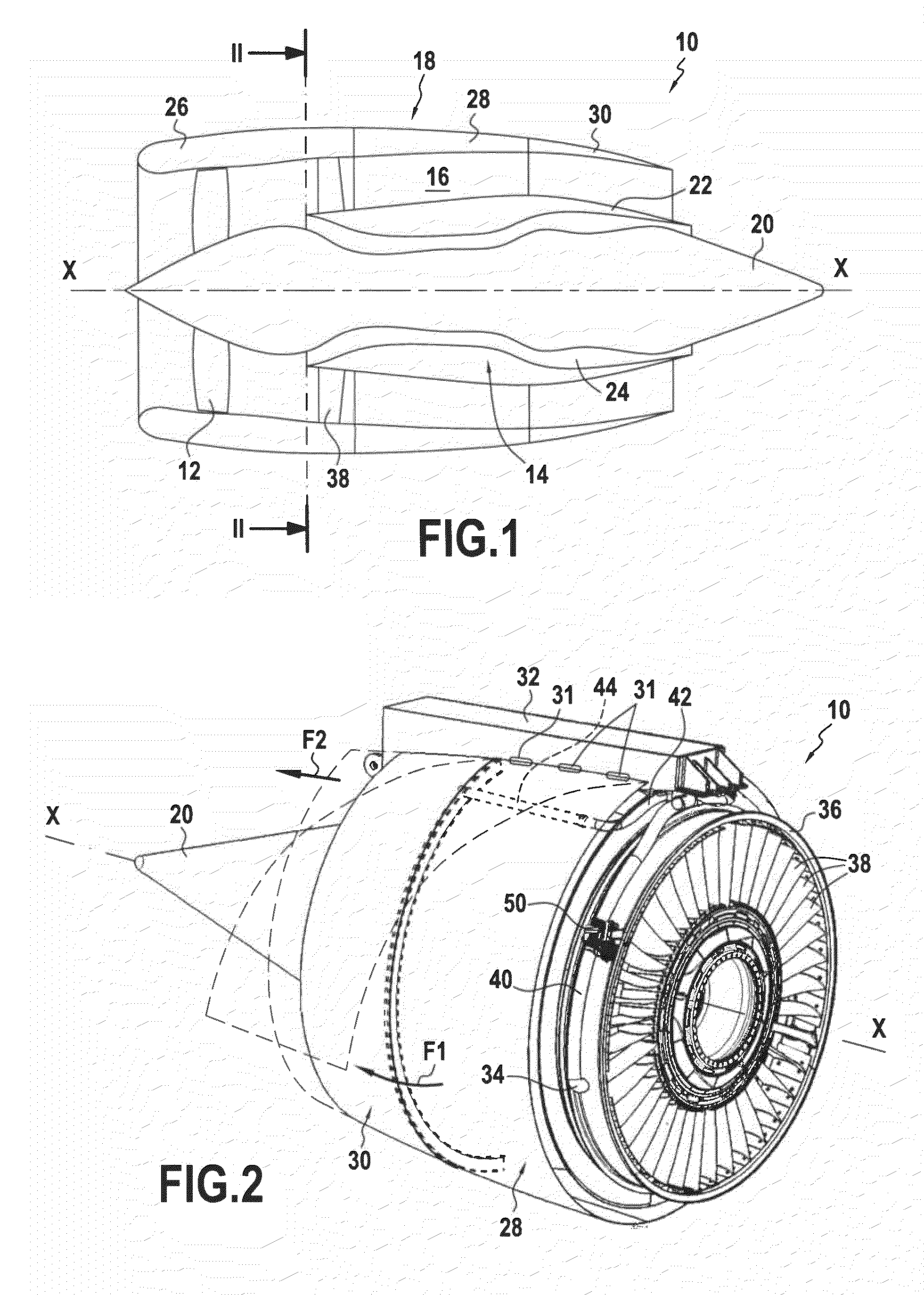

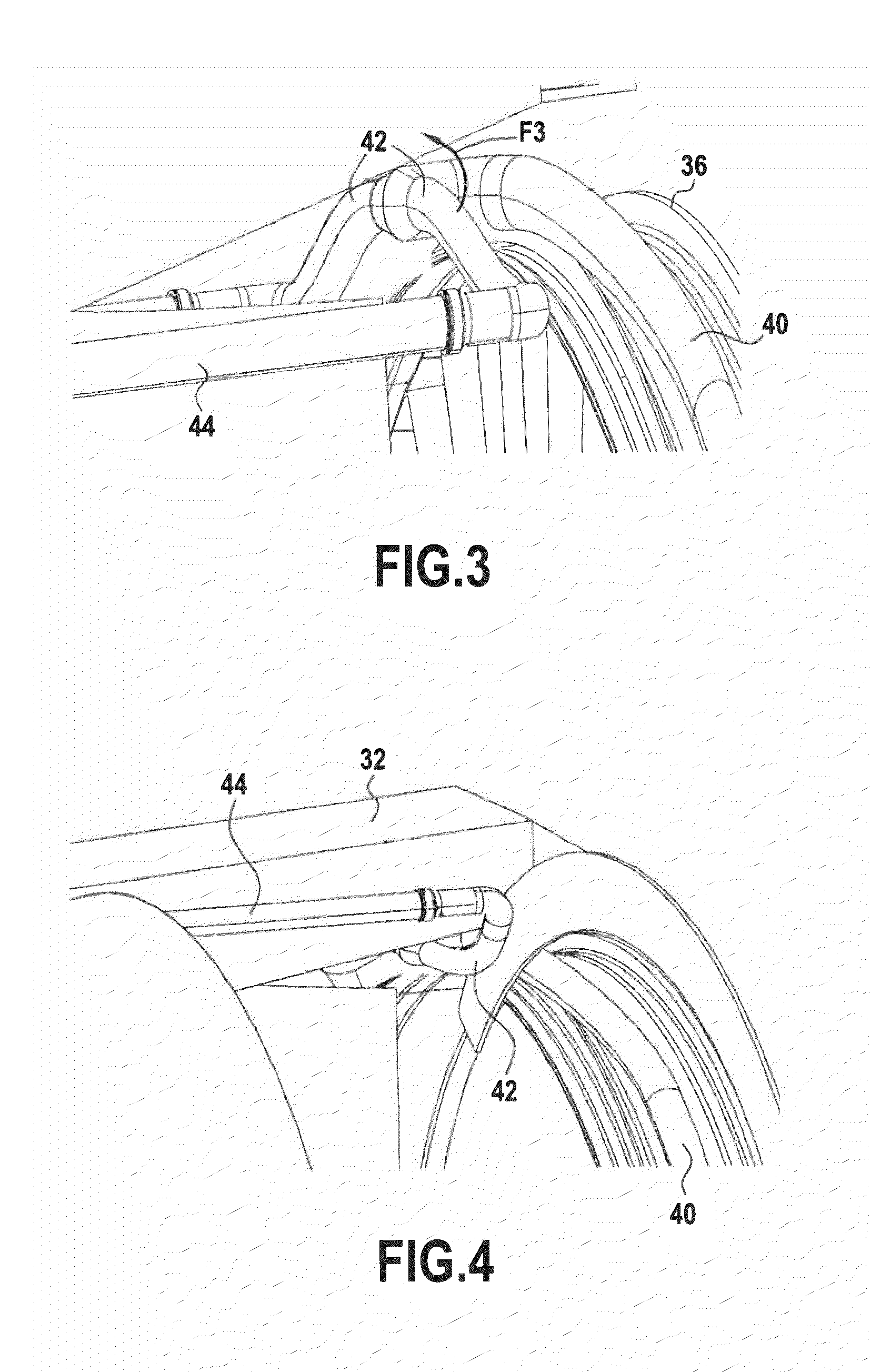

Bypass turbomachine with reduction of jet noise

ActiveUS20090064658A1Simple configurationReduce jet noiseAircraft navigation controlPower plant exhaust arrangementsPrimary channelNacelle

In a bypass turbomachine, at least one air takeoff orifice is provided in the primary channel, said orifice leading to an air takeoff pipe housed inside an air inlet sleeve of the nacelle. The air takeoff pipe opens out in the vicinity of the pylon into two air diffusion pipes each secured to a respective maintenance cover, each air diffusion pipe opening out into an air injection pipe secured to a thrust reverser cover and itself opening out to the outside of the nacelle via the trailing edge thereof, each air injection pipe being suitable for uncoupling from the corresponding air diffusion pipe when the corresponding thrust reverser cover slides downstream.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Method for calculating radiation noise generated by pipe wall of water-filling pipeline during reverberation method

ActiveCN105698923ARadiation resistance is smallReduced sound radiation capabilitySubsonic/sonic/ultrasonic wave measurementCalculation methodsReverberation

The invention discloses a method for calculating the radiation noise generated by the pipe wall of a water-filling pipeline during the reverberation method. According to the method, firstly, the radiation noise and the jet noise, generated due to the vibration of the pipe wall of a water-filling pipeline, are measured based on the reverberation method. Secondly, only the jet noise of the water-filling pipeline is measured and obtained based on the reverberation method, so that the radiation noise of the underwater water-filling pipeline generated during the vibration process is obtained. The above method is simple in calculation and high in efficiency. The radiation noise and the jet noise, generated by the pipe wall of the water-filling pipeline in a single non-noise-elimination pool and measured based on the reverberation method, is subtracted by the jet noise of the water-filling pipeline measured based on the reverberation method. In this way, the radiation noise of the water-filling pipeline generated during the vibration process is obtained.

Owner:HARBIN ENG UNIV

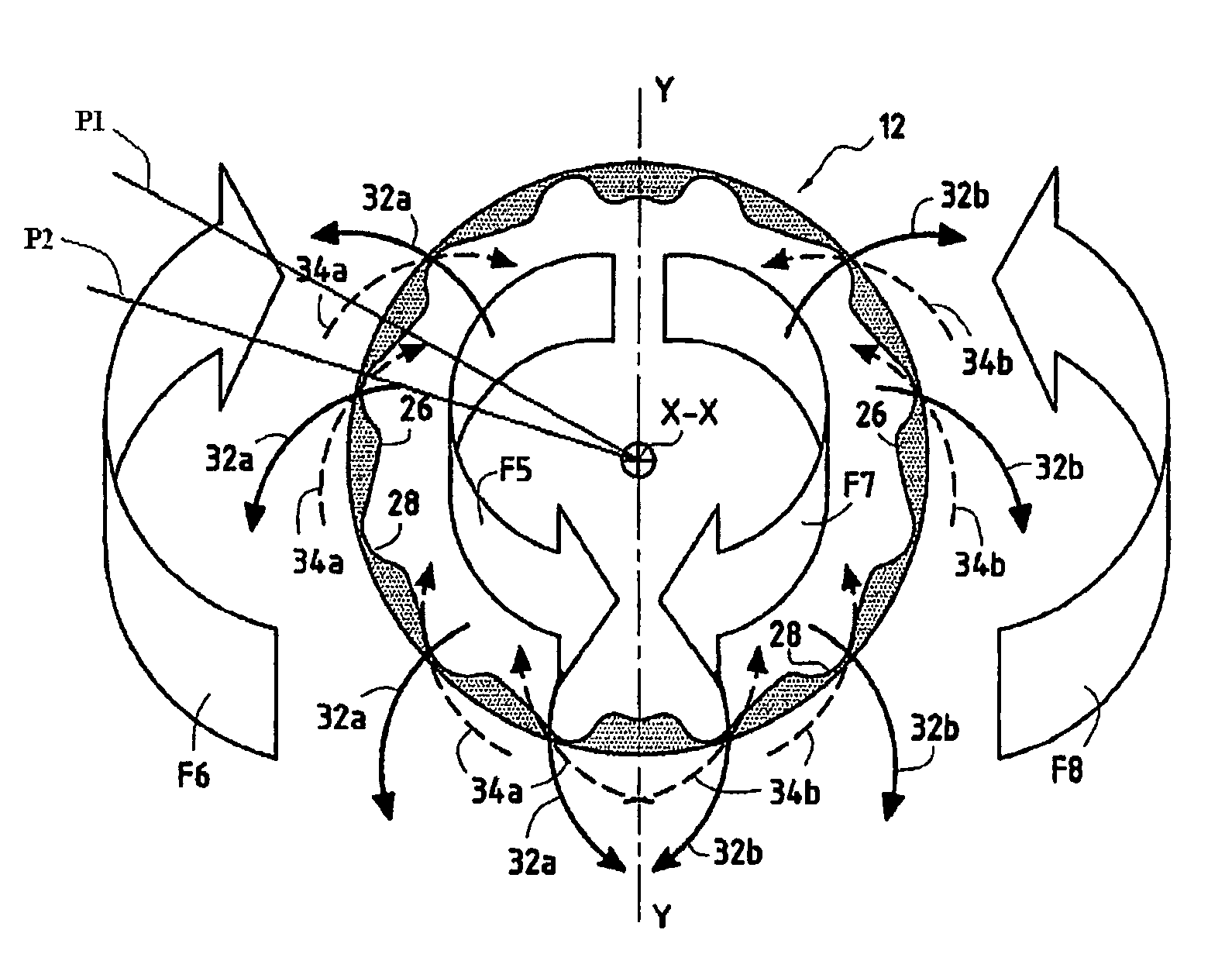

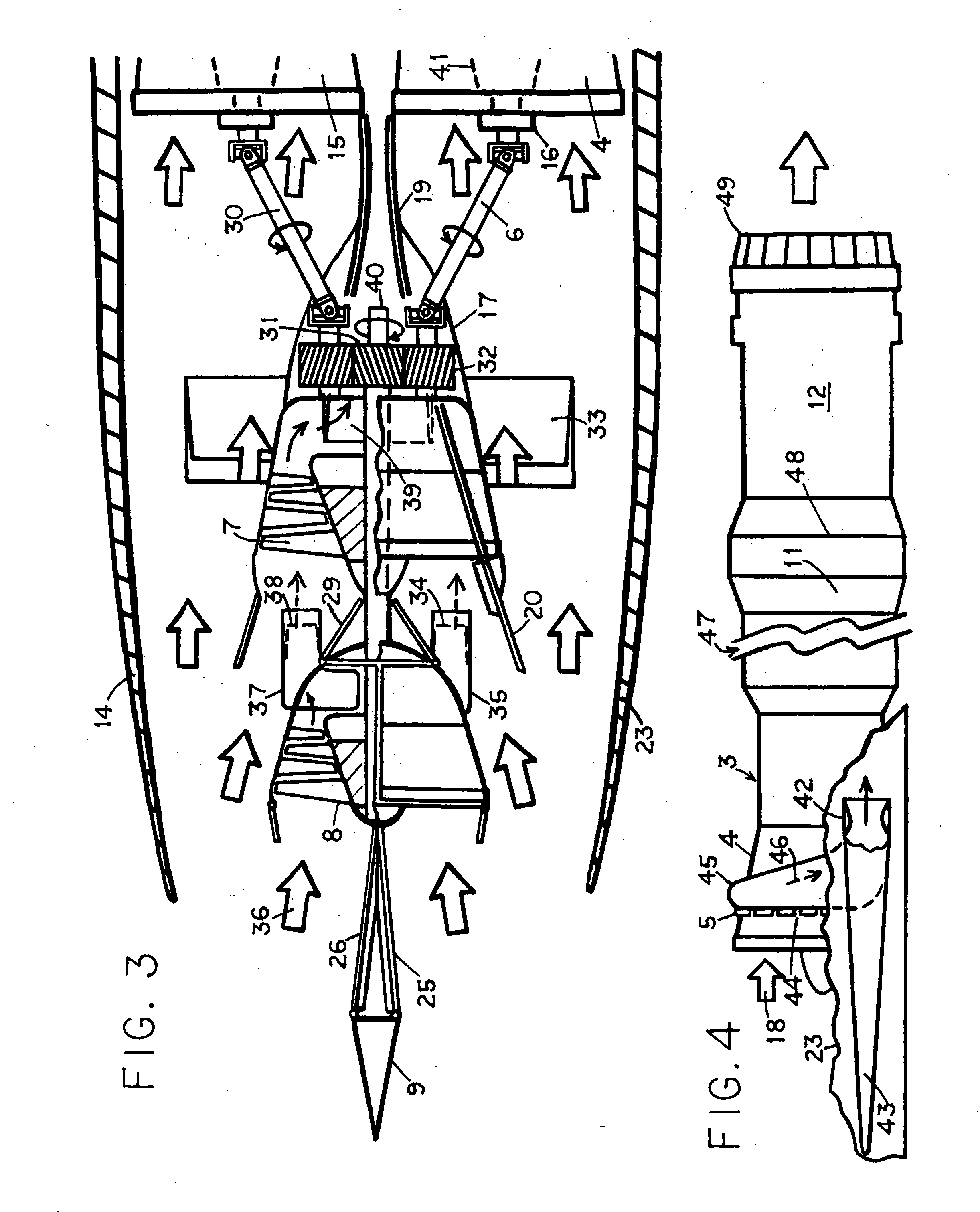

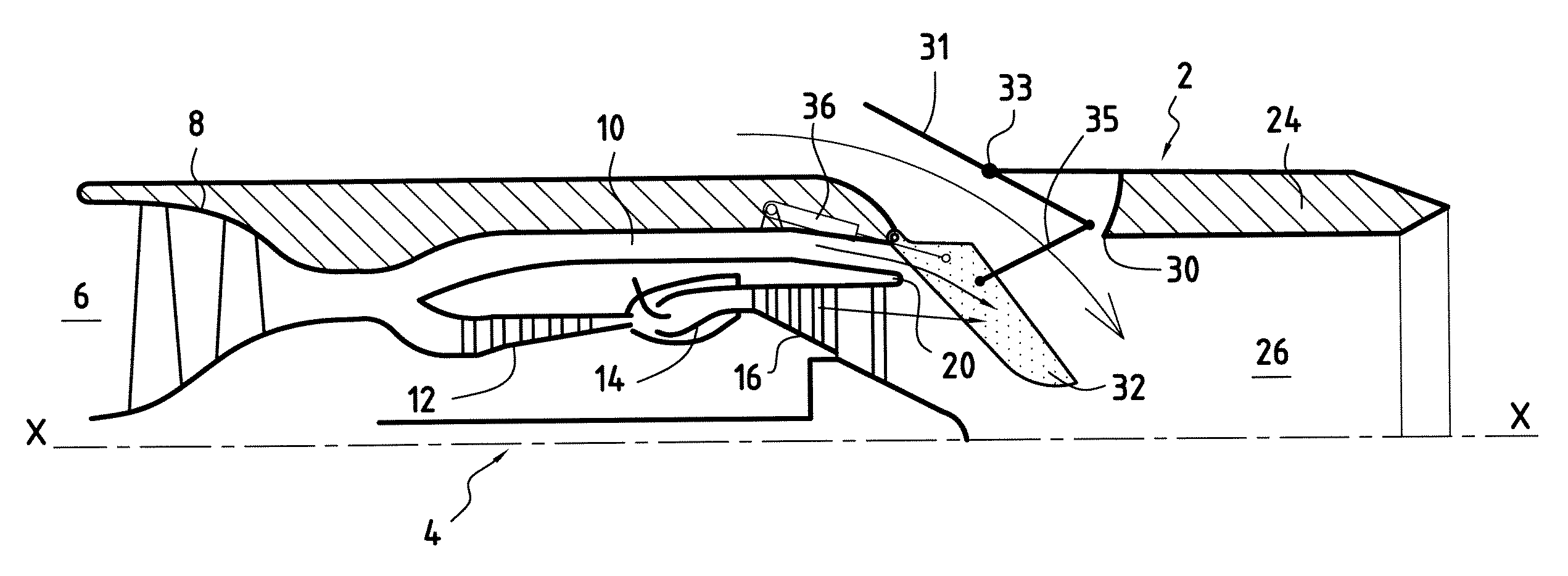

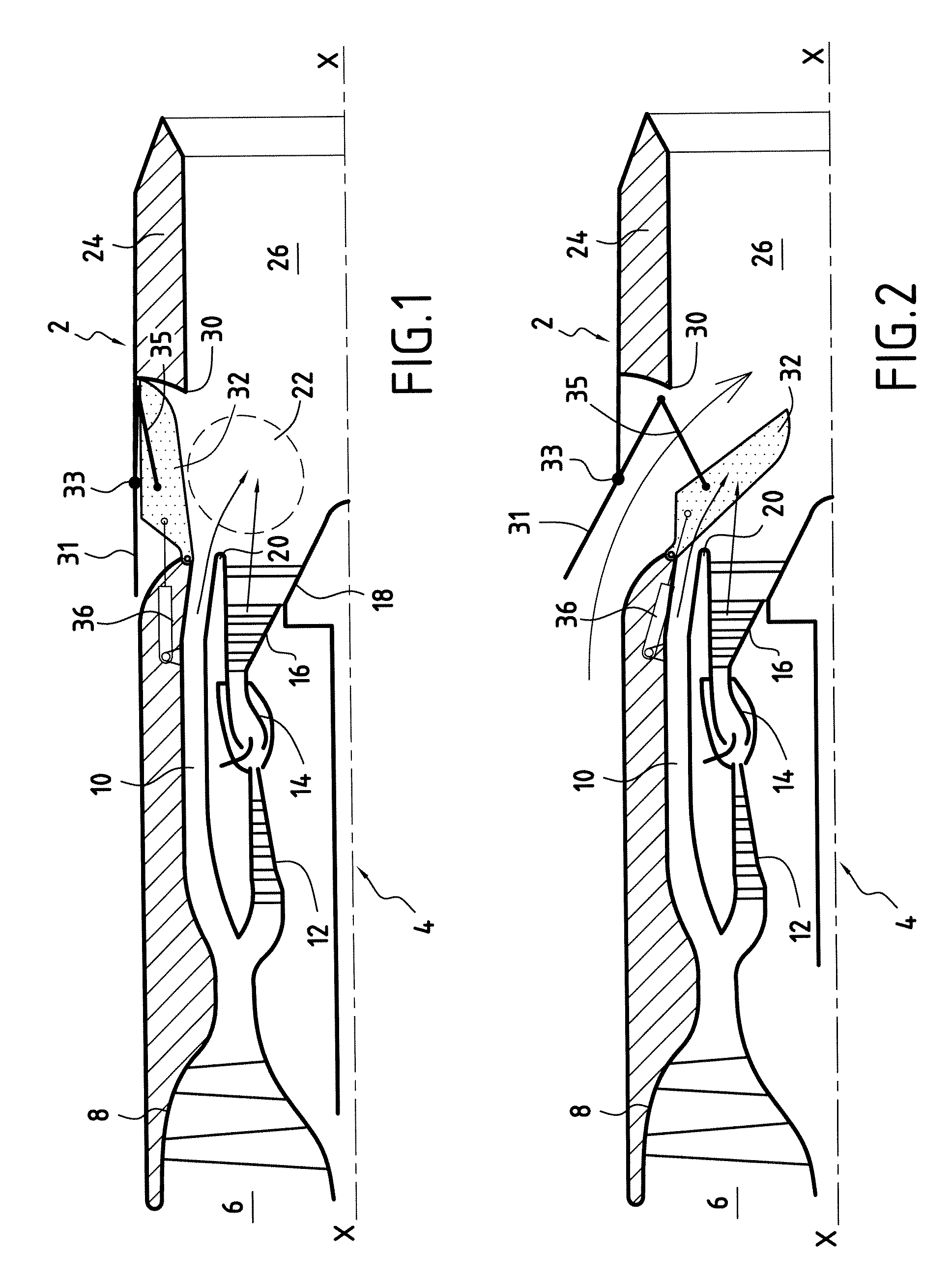

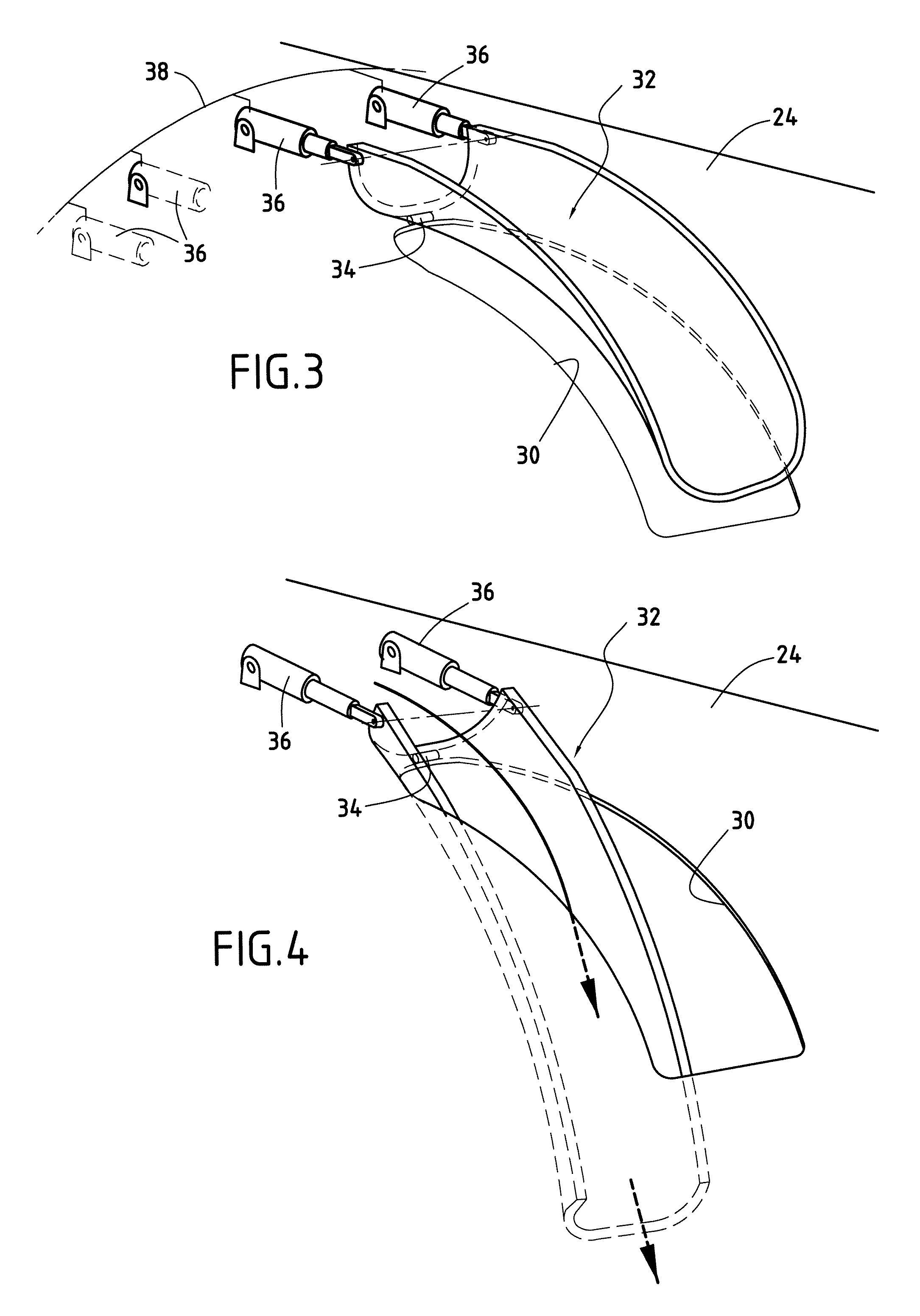

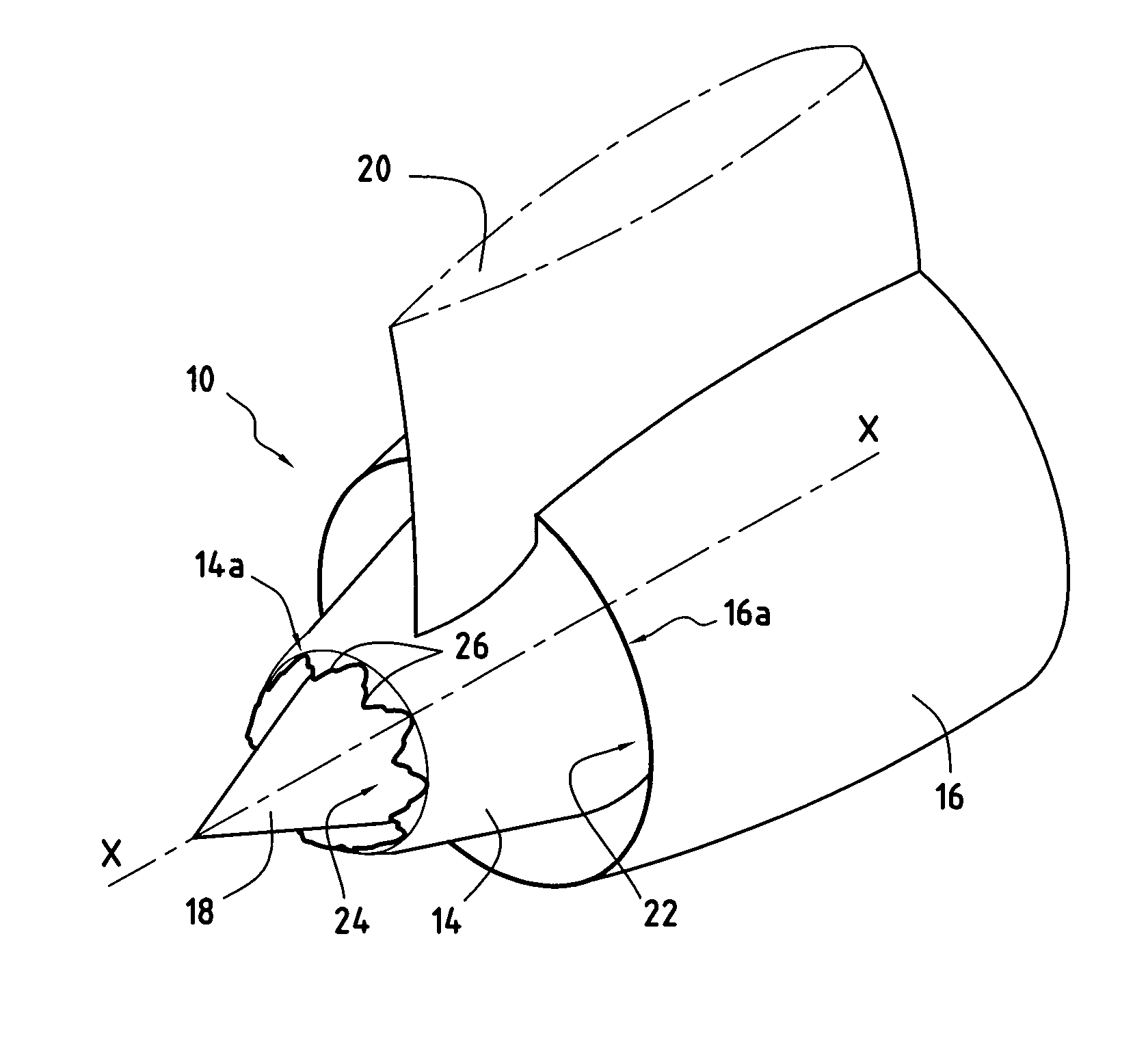

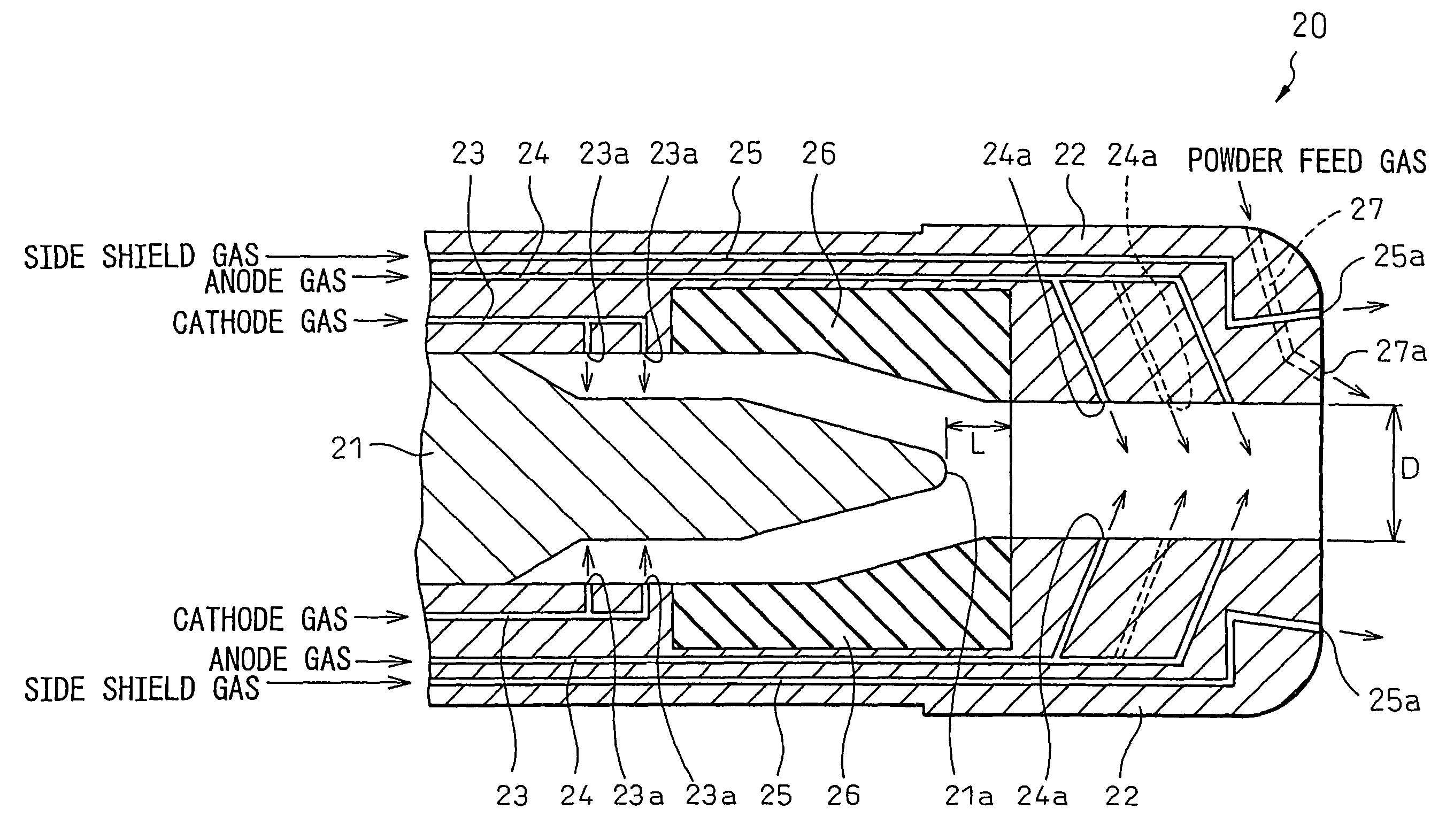

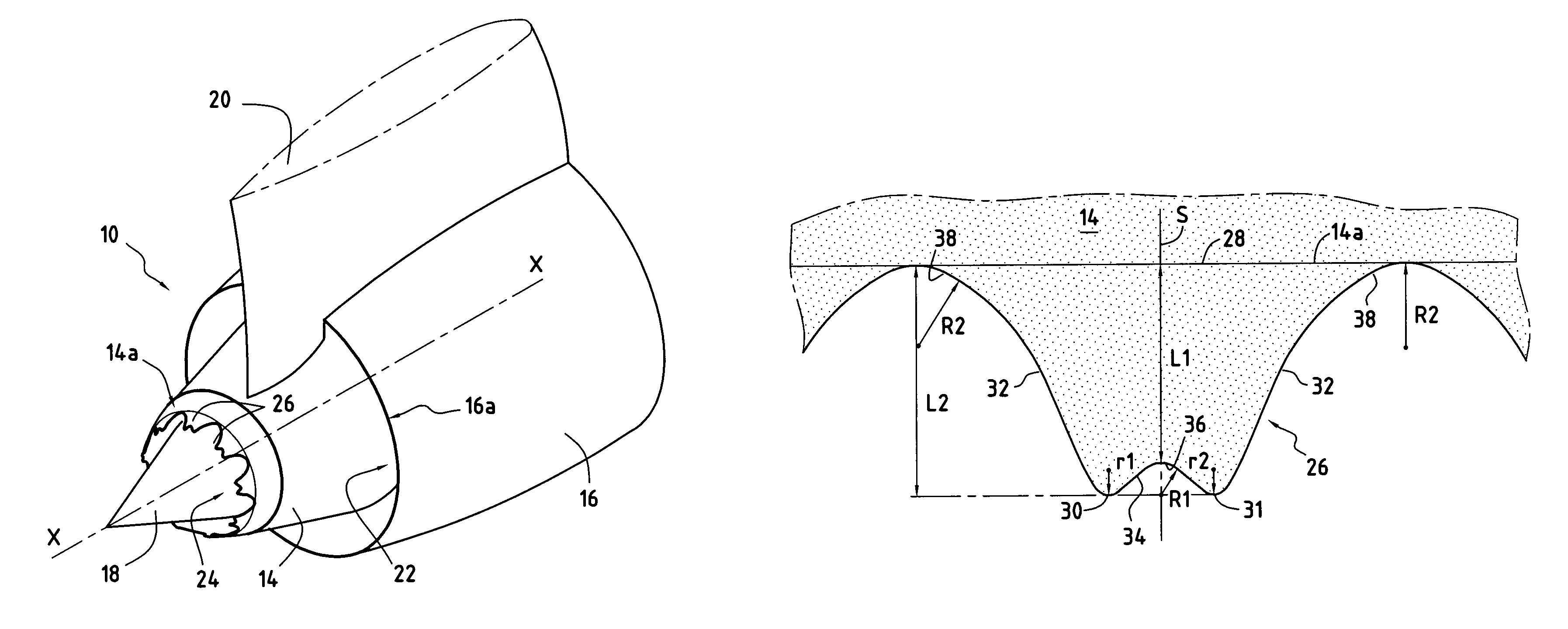

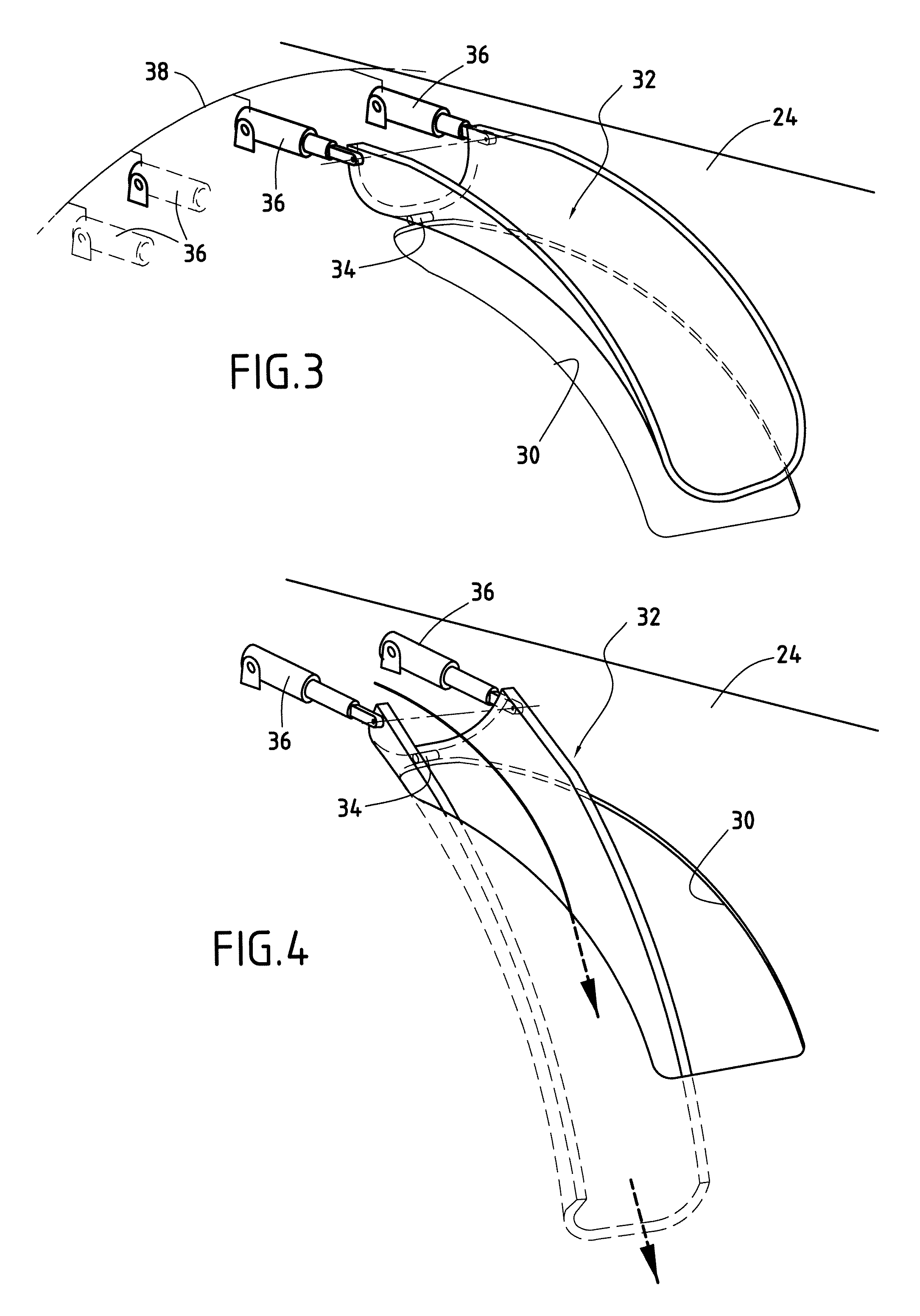

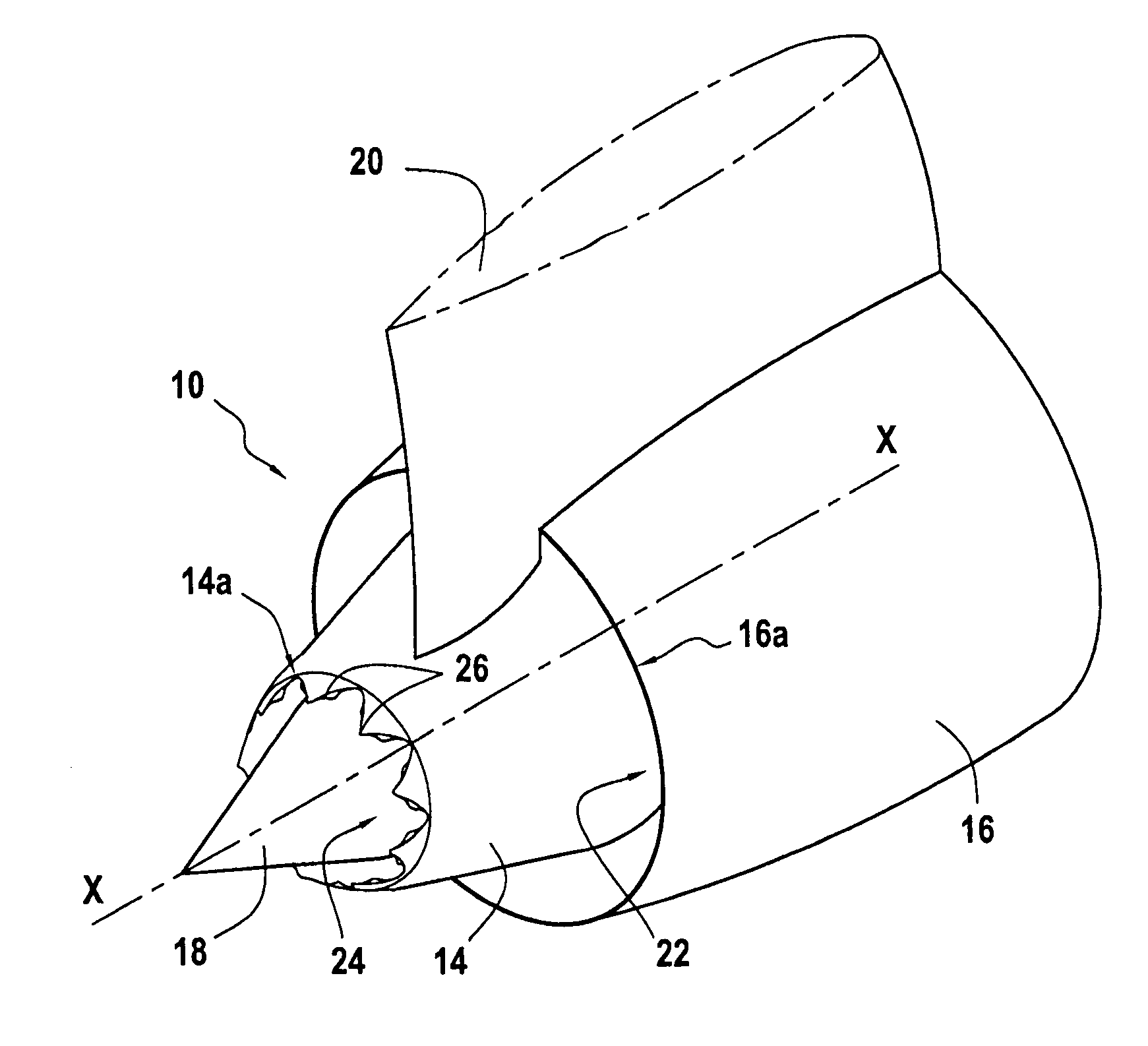

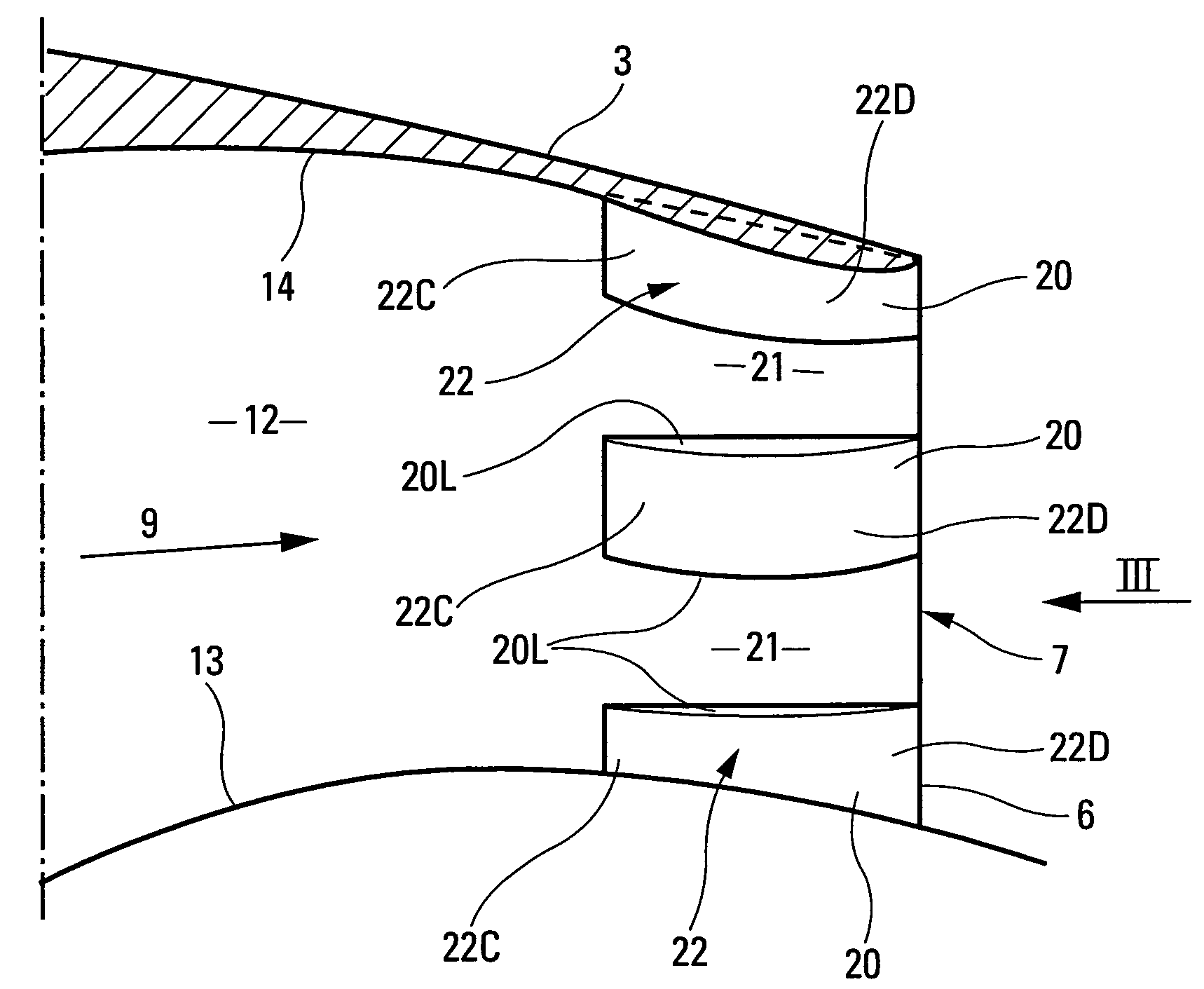

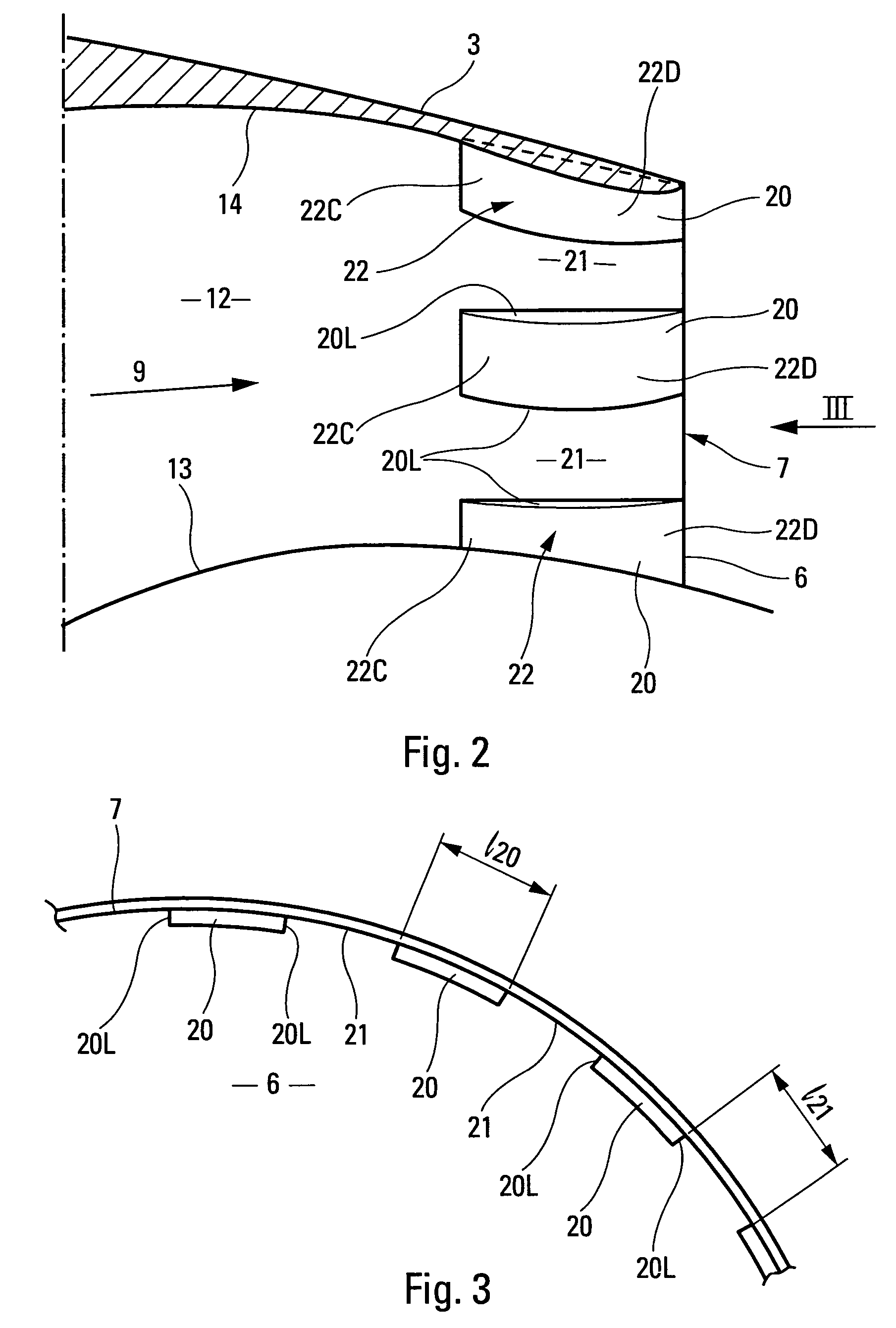

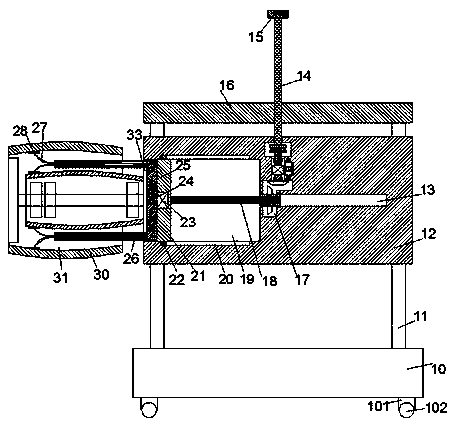

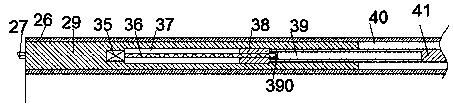

Core exhaust mixer, having a variable area, for turbo-fan jet engines of supersonic aircraft

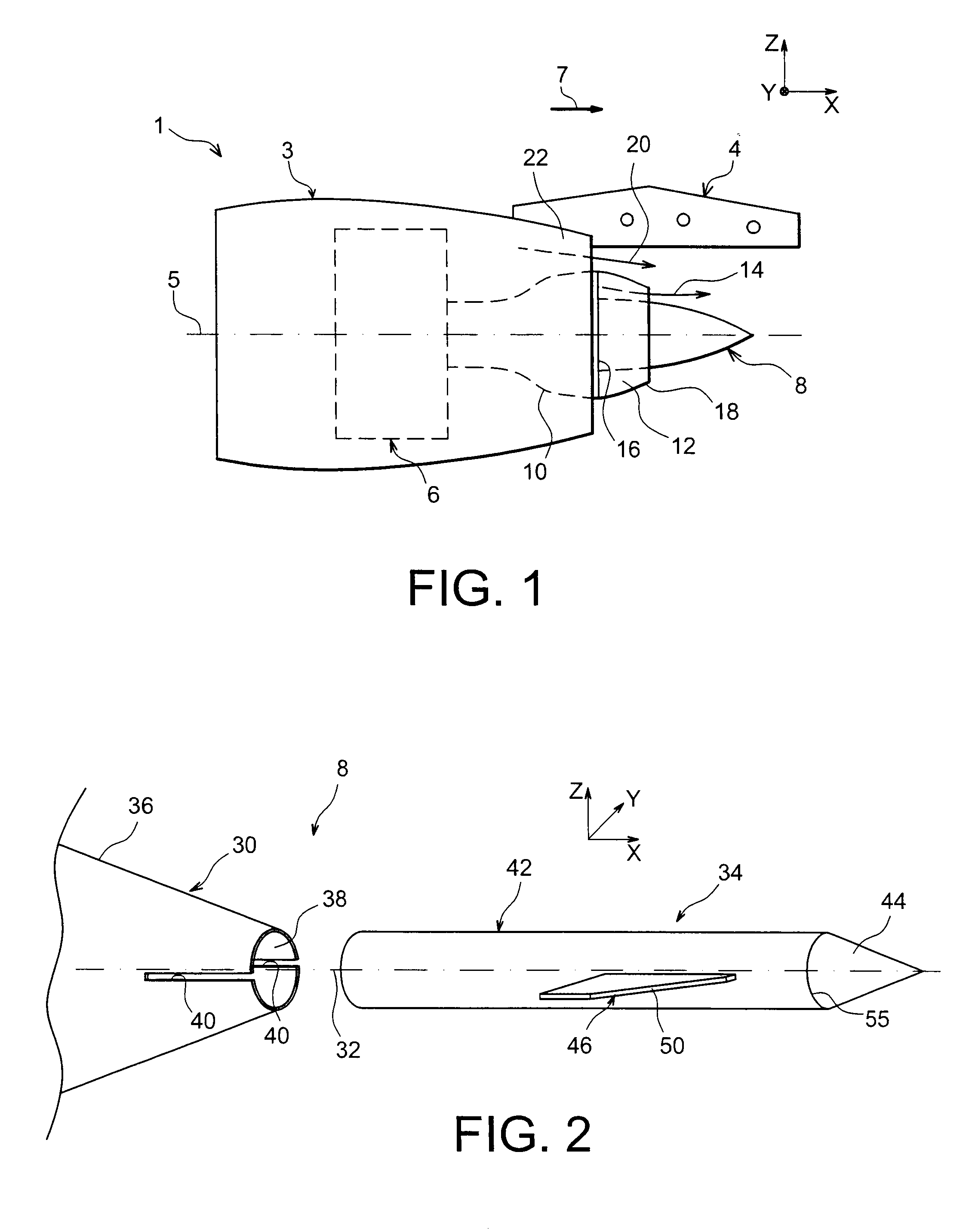

ActiveUS20070163230A1Reduce noise levelMitigate such drawbackPower plant exhaust arrangementsEngine fuctionsHeat flowJet engine

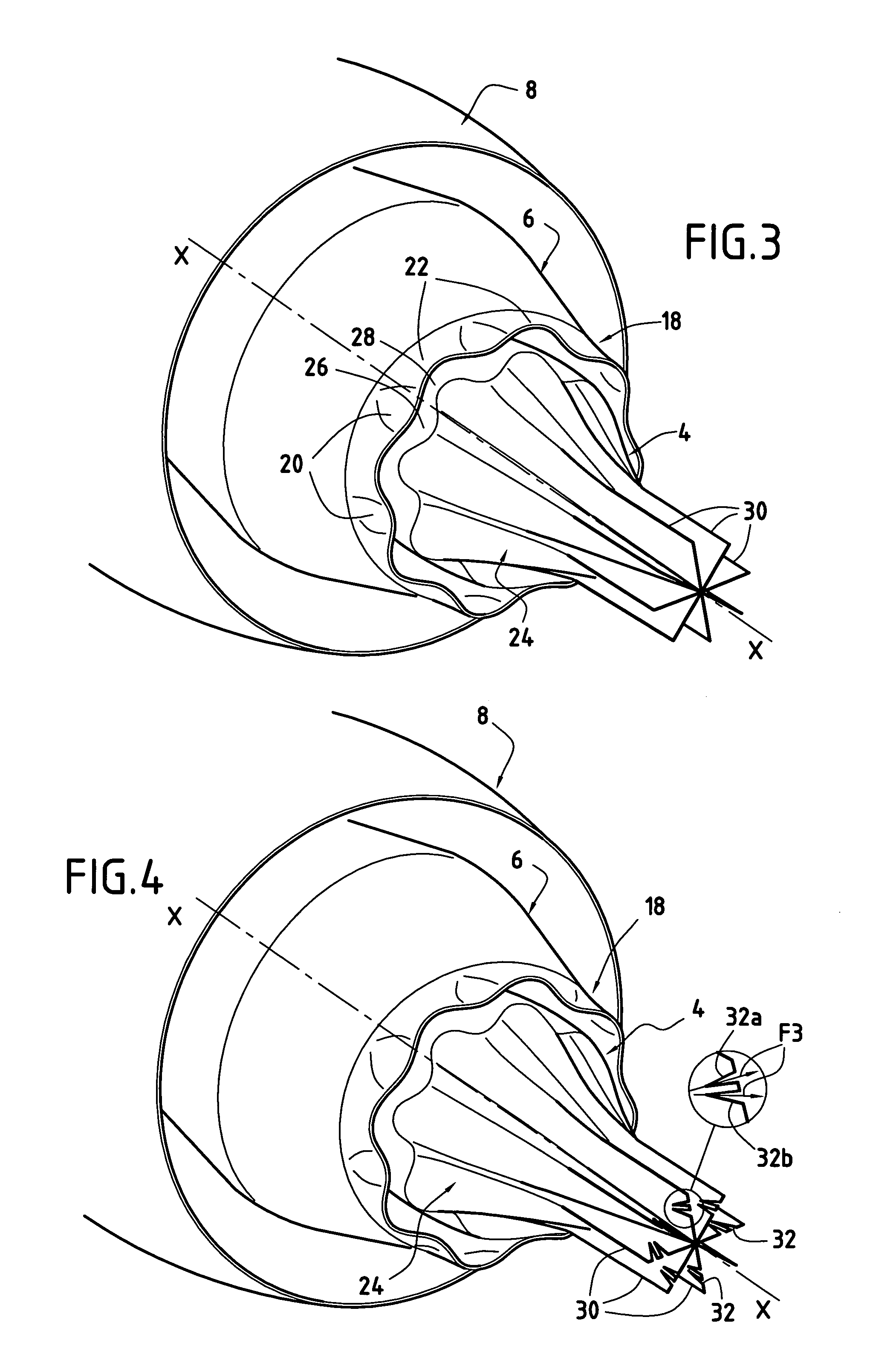

The invention relates to a core exhaust mixer, having a variable area, for turbo-fan jet engines of supersonic aircraft, comprising a nozzle (24) intended to be arranged about a gas generator of the jet engine, the nozzle comprising a plurality of external air intake apertures (30) emerging in a convergence zone between cold and hot flows from the gas generator and in which lobes (32), movable between two positions, are mounted; a first position in which they block the apertures (30) of the nozzle (24) and a second position, different from the first, in which they unblock said apertures and extend radially into the nozzle (24) in order to admit external air, the lobes (32) having an azimuthal component in the same direction in order to give a swirling motion to the external air admitted into the convergence zone when the lobes are in the second position.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Turbomachine nozzle cover provided with triangular patterns having a point of inflexion for reducing jet noise

ActiveUS20080041062A1Mitigate such drawbackReduce componentsAircraft navigation controlEngine manufactureTrailing edgeNozzle

The invention relates to an annular cover for a turbomachine nozzle, the cover having a plurality of patterns extending a trailing edge of said cover and spaced apart circumferentially from one another, each pattern having an outline that is substantially triangular in shape, with a base formed by a portion of the trailing edge of the cover and a vertex spaced downstream from the base and connected thereto by two sides. For each pattern, the vertex presents an outline that is substantially curved; each side is connected to the trailing edge of the cover following an outline that is substantially curved having a radius of curvature that is greater than the radius of curvature of the outline of the vertex; and the outline of each of the sides includes at least one point of inflexion having a tangent that is substantially parallel to the base.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Turbomachine nozzle cover provided with triangular patterns having a point of inflexion for reducing jet noise

ActiveUS7581384B2Reduce componentsReduce frequencyAircraft navigation controlEngine manufactureTrailing edgeNozzle

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Turbomachine nozzle cowl having jet noise reduction patterns

InactiveUS20090084111A1Reduce jet noiseSmall sizeEngine manufactureSilencing apparatusEngineeringTrailing edge

The invention relates to a cowl for a turbomachine nozzle, the cowl including a plurality of repetitive patterns disposed to extend a trailing edge of said cowl and spaced circumferentially apart from one another. Each pattern is in the form of a quadrilateral having a base that is formed by a portion of the trailing edge of the cowl and two vertices that are spaced downstream from the base and that are connected thereto via two sides, each side having the shape of a parabola. Each pattern is asymmetrical relative to a midplane of the pattern containing a longitudinal axis of said cowl, and it comprises a first portion inclined radially towards the inside of the cowl, and a second portion inclined radially towards the outside of the cowl.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

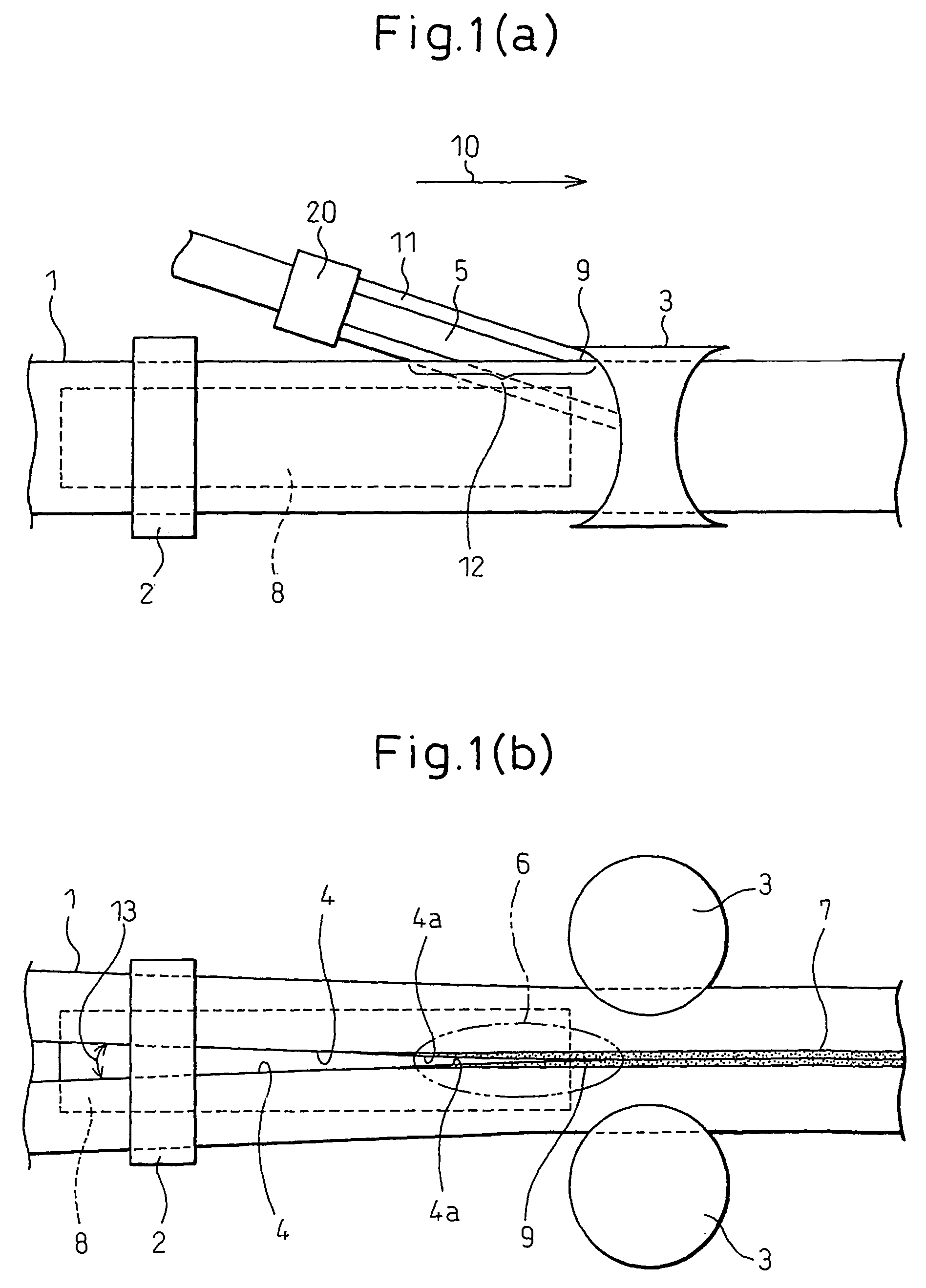

Method of production of electric resistance welded steel pipe and high Si or high Cr electric resistance welded steel pipe

InactiveUS9050681B2StablyReduce jet noisePipeline systemsHigh frequency current welding apparatusPlasma jetElectrical resistance and conductance

The present invention provides a method of production of electric resistance welded steel pipe able to stably reduce weld defects due to oxides by firing plasma and furthermore able to reduce plasma jet noise and comprises shaping steel plate 1 into a tube and electric resistance welding the abutting end faces 4 during which blowing on at least the abutting end faces 4a in the region 6 at the welding upstream side from the weld point 9 where the temperature becomes 650° C. or more a reducing high temperature (pseudo) laminar plasma obtained by applying voltage to a reducing gas containing H2 gas: 2 to 50 vol % to which is added a balance of Ar gas alone or a mixed gas of Ar gas to which N2 gas, He gas, or both are added. At that time, it is preferable to make the applied voltage over 120V and the make the plasma blowing conditions satisfy the following formula (1).150<4×(∑GiMi)π×D×μava,T=7000<400<1>

Owner:NIPPON STEEL CORP

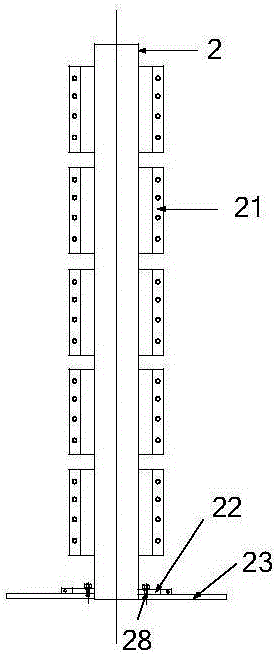

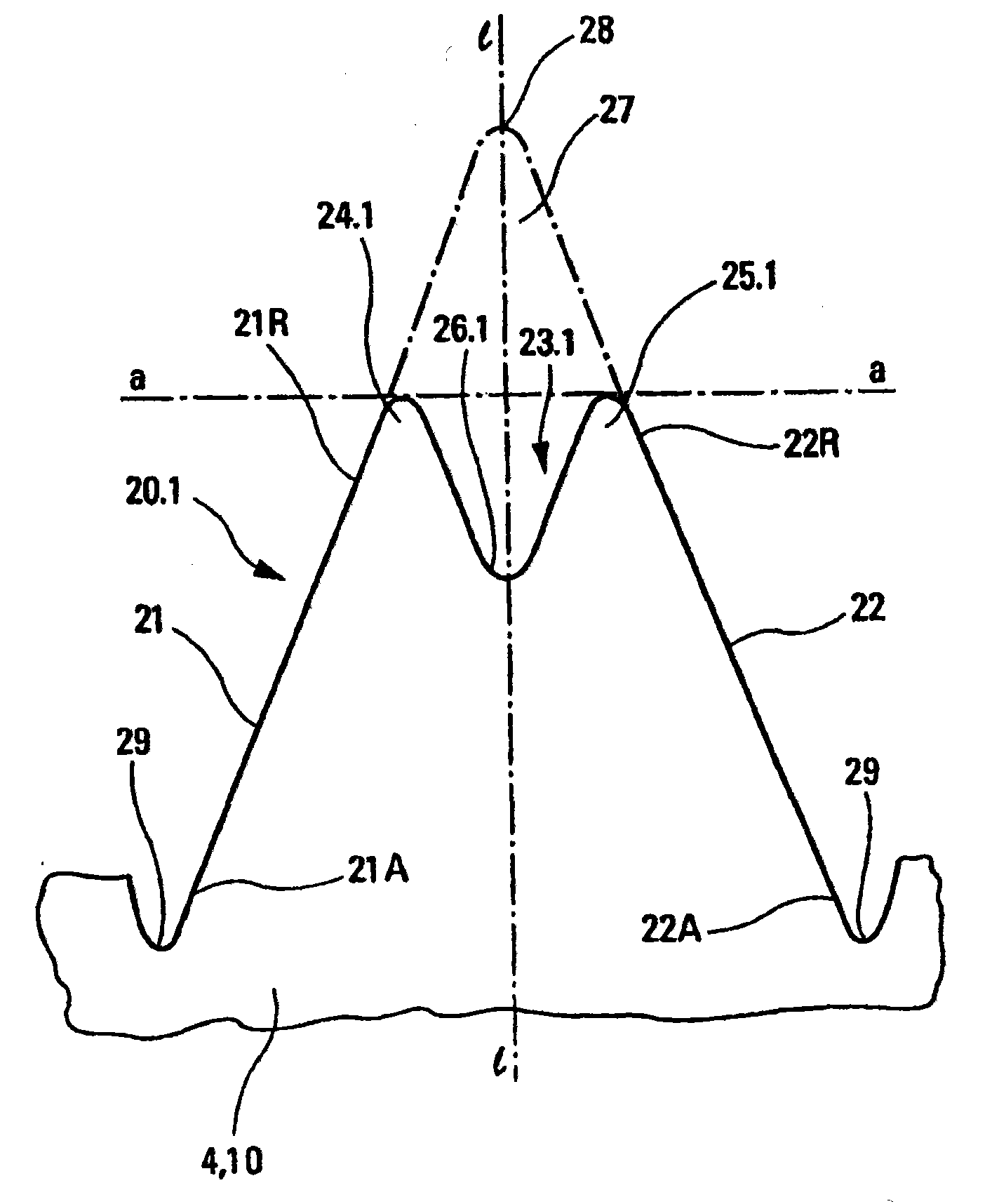

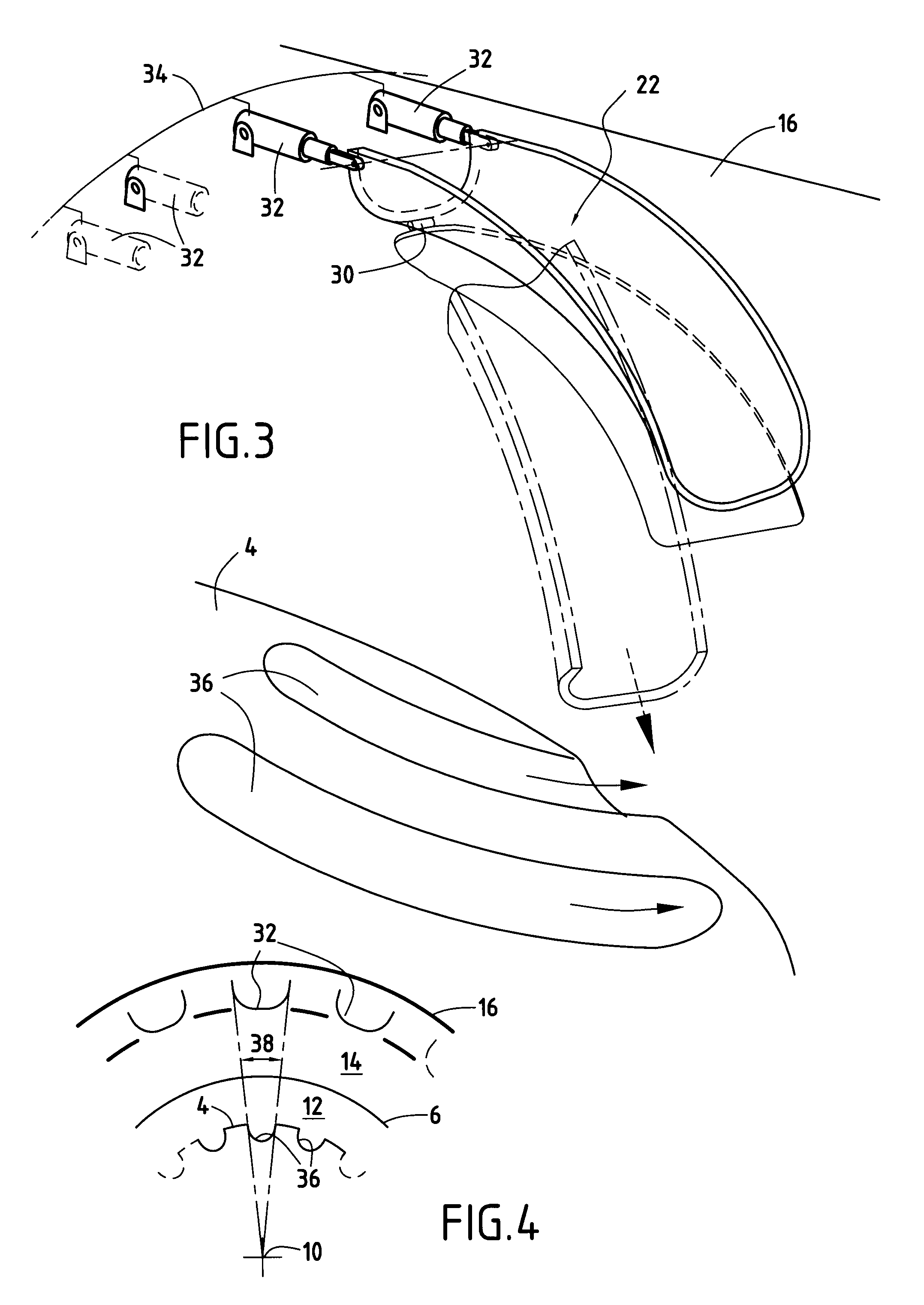

Noise control chevron for a nozzle, and nozzle and turboshaft engine provided with such a chevron

InactiveCN101809272AReduce jet noiseLight in massEngine manufactureEfficient propulsion technologiesNoise controlEngineering

According to the invention, the shape of each of said chevrons is defined: by two lateral sides (21, 22) having front ends (21A, 22A) that are connected to said nozzle (4, 10) and that, when moving away from the latter, converge towards each other without joining so that the rear ends (21R, 22R) of said lateral walls (21, 22) are spaced from each other; and by a curvilinear transverse line (23.1) connecting the rear ends (21R, 22R) of said lateral walls (21, 22) by forming two rounded side protrusions (24.1, 25.1 ) separated by an intermediate rounded recess (26.1).

Owner:AIRBUS OPERATIONS (SAS)

Turbomachine nozzle cover provided with triangular patterns having pairs of vertices for reducing jet noise

ActiveUS7854123B2Reduce componentsReduce frequencyAircraft navigation controlEngine manufactureEngineeringTrailing edge

The pattern relates to a cover for a turbomachine nozzle, the cover having a plurality of patterns each with an outline of triangular shape having a base and two vertices that are spaced downstream and interconnected by a side. For each pattern, the vertices present respective curved outlines and they are interconnected by a curved portion presenting a radius of curvature greater than the radii of curvature of the outlines of said vertices, each side being connected to the trailing edge of the cover via a curved outline presenting a radius of curvature greater than the radii of curvature of the outlines of the vertices and greater than the radius of curvature of the outline of the curved portion, and the vertices and the curved portion are inclined radially towards the inside of the cover, with the curved portion being radially offset outwards relative to the vertices.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Attachment pylon for a turbine engine

ActiveUS20140290270A1Reduce jet noiseDecrease the velocity gradientAircraft power plant componentsJet type power plantsLeading edgeTrailing edge

A pylon for attaching a turbine engine, the pylon configured to connect the engine to a structural element of an aircraft. The pylon includes a streamlined profile defined by two opposite lateral faces and defined longitudinally between a leading edge and a trailing edge. On each of its lateral faces the pylon includes a series of deflectors that are transversely spaced apart from one another and that define between them convergent and curved channels configured to accelerate air streams flowing within the channels on aircraft takeoff or in flight to deflect the air streams towards a jet of the engine.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Core exhaust mixer, having a variable area, for turbo-fan jet engines of supersonic aircraft

ActiveUS7810335B2Reduce noise levelMitigate such drawbackPower plant exhaust arrangementsEngine fuctionsHeat flowJet engine

The invention relates to a core exhaust mixer, having a variable area, for turbo-fan jet engines of supersonic aircraft, comprising a nozzle (24) intended to be arranged about a gas generator of the jet engine, the nozzle comprising a plurality of external air intake apertures (30) emerging in a convergence zone between cold and hot flows from the gas generator and in which lobes (32), movable between two positions, are mounted; a first position in which they block the apertures (30) of the nozzle (24) and a second position, different from the first, in which they unblock said apertures and extend radially into the nozzle (24) in order to admit external air, the lobes (32) having an azimuthal component in the same direction in order to give a swirling motion to the external air admitted into the convergence zone when the lobes are in the second position.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

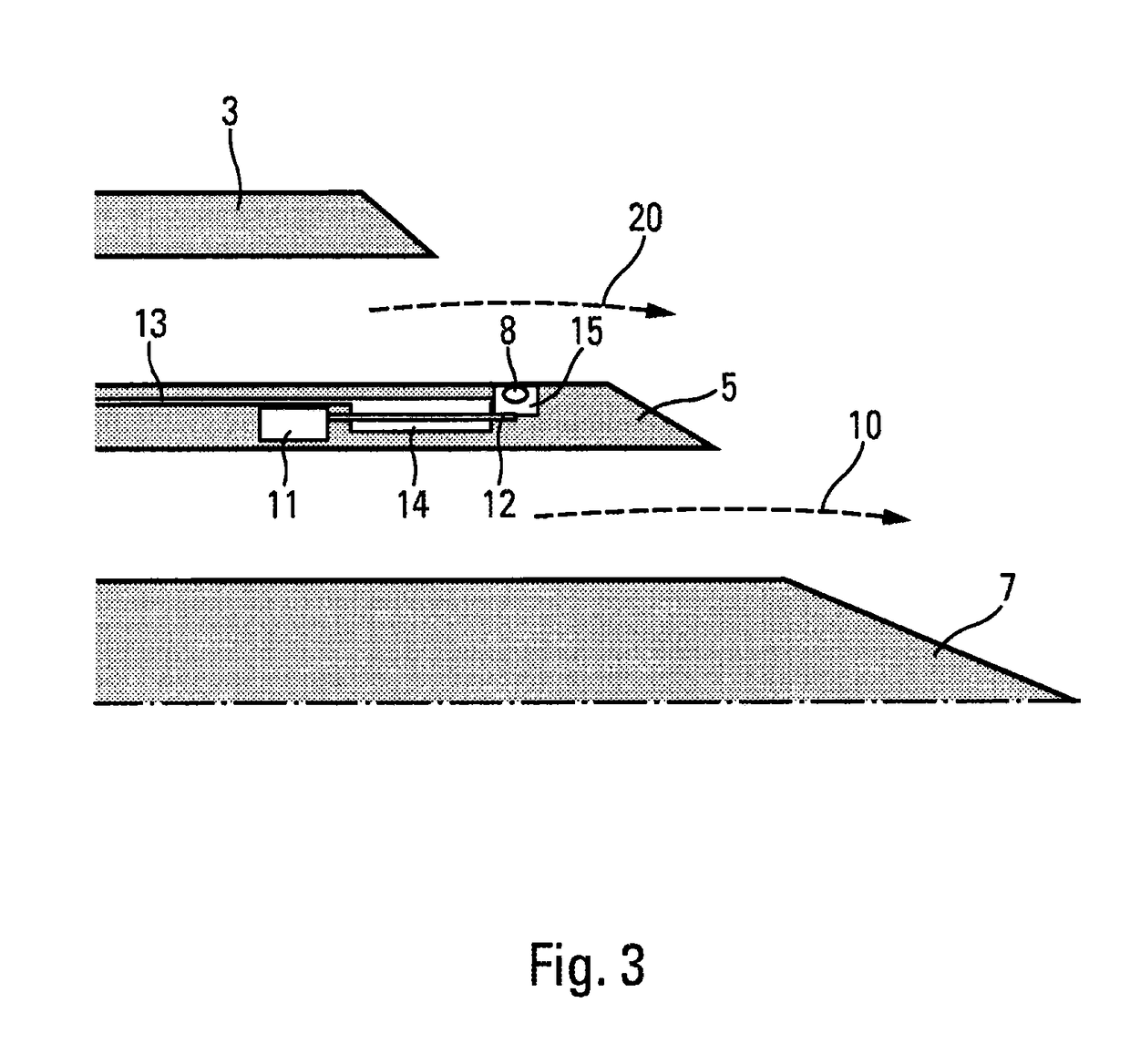

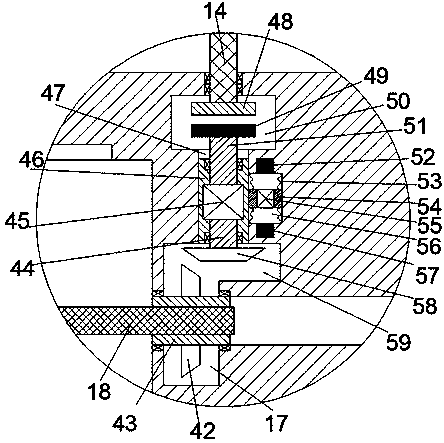

Primary cowl of a turbofan comprising a rotating ring having micro-jets

ActiveUS9617954B2Reduce jet noisePerforms betterPower plant exhaust arrangementsEfficient propulsion technologiesCouplingSpray nozzle

The invention relates to a primary cowl for a turbofan comprising a primary body generating a primary stream to be ejected through a primary nozzle, and a secondary body generating a secondary stream to be ejected through a secondary nozzle, the primary cowl being shaped so as to be positioned downstream from the primary body and to define, on the inside of the turbofan, the path followed by the primary stream downstream from the primary nozzle and, on the outside, the path followed by the secondary stream downstream from the secondary nozzle. The primary cowl comprises a coupling to a system for supplying a pressurized gas and at least one perforation for injecting the pressurized gas, through the perforation, into the secondary stream. The primary cowl preferably comprises a ring which has perforations and which is rotated about the axis of rotation of the turbofan.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Turbomachine nozzle cowl having patterns with lateral fins for reducing jet noise

ActiveUS20120118398A1Control impactMitigate such drawbackCombustion enginesThin material handlingTrailing edgeNozzle

An annular cowl for a turbomachine nozzle, the cowl including a plurality of patterns arranged to extend a trailing edge of the cowl and circumferentially spaced apart from one another. Each pattern has an outline of substantially polygonal shape with a base formed by a portion of the trailing edge of the cowl and at least one vertex that is spaced downstream from the base and that is connected thereto by lateral edges, and in each of its lateral edges, each pattern includes at least one fin, each fin being inclined radially relative to the pattern in a plane that is inclined at an angle lying in the range 0° to 45° relative to a radial direction.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Gas ejection cone for an aircraft turbojet equipped with a device for generating turbulence in a primary flow limiting jet noise

InactiveUS20110203254A1Improve acoustic impactReduce jet noiseAircraft navigation controlPower plant exhaust arrangementsAirplaneJet engine

A gas ejection cone for an aircraft turbojet, the cone including a hollow main body defining, on the outside, a radially inner skin of an annular primary flow channel, and a device generating turbulence in the primary flow limiting jet noise, mounted so as to move on the main body so as to be able to be displaced from an extracted position in which the device projects toward downstream in relation to a downstream end of the hollow main body, and a retracted position in which the device is retracted into the hollow main body, and vice versa. Further, the device includes a cylindrical support body having an axis parallel to an axis of the ejection cone, and at least one fin supported by the body.

Owner:AIRBUS OPERATIONS SAS

Turboshaft engine with reduced noise emission for aircraft

ActiveUS8544278B2Reduce jet noiseReduction in shock cell noiseAircraft navigation controlSilencing apparatusNoise emissionTurboshaft

Owner:AIRBUS OPERATIONS (SAS)

Mass flow increase at takeoff in supersonic airliner

InactiveUS8622339B2Reduce noiseReduce jet velocityEngine fuctionsAircraft power plant componentsJet aeroplaneNacelle

In a supersonic aircraft, turbojet engine nacelles each containing two remote fans in the front half of the nacelle, for noise reduction at takeoff. During supersonic flight, a front wedge at the nacelle nose achieves external compression of intake air. The wedge is vertical, sending the airflow left and right inside the nacelle along its side walls. The two flows follow mirror image curved paths on their way to a turbojet, leaving unused space between them to house the fans in tandem. For takeoff, clutches connected to the turbojets's compressors are engaged. Driveshafts turn pinions against a gear on the same shaft as the remote fans. The fan output is discharged backward under the nacelle to produce thrust. The energy to turn the fans is taken from the turbojet cycle. The reduced exhaust jet velocity decreases its noise. Supercharging produces the extra power to turn the remote fans if multistage.

Owner:KOSHELEFF PATRICK A

Turbomachine nozzle cowl having patterns with lateral fins for reducing jet noise

ActiveUS8322144B2Control impactMitigate such drawbackThin material handlingJet propulsion plantsTrailing edgeNozzle

An annular cowl for a turbomachine nozzle, the cowl including a plurality of patterns arranged to extend a trailing edge of the cowl and circumferentially spaced apart from one another. Each pattern has an outline of substantially polygonal shape with a base formed by a portion of the trailing edge of the cowl and at least one vertex that is spaced downstream from the base and that is connected thereto by lateral edges, and in each of its lateral edges, each pattern includes at least one fin, each fin being inclined radially relative to the pattern in a plane that is inclined at an angle lying in the range 0° to 45° relative to a radial direction.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Double-duct turbine engine device

InactiveCN109098790AEasy transferEffective cleaning operationHollow article cleaningEngine componentsEngineeringTurbine

The invention discloses a double-duct turbine engine device. The double-duct turbine engine device is used for washing an outer duct of a double-duct turbine engine and comprises a base, a top frame and a movable frame located between the base and the top frame. Guiding rods are slidably mounted on the periphery of the movable frame, the upper ends of the guiding rods are fixedly connected with the top frame, and the lower ends of the guiding rods are fixedly connected with the base. A first sliding groove with a leftward opening is formed in the movable frame, and a first sliding frame is slidably mounted in the first sliding groove. A rotating cavity with a leftward opening is formed in the first sliding frame, and a rotating block is mounted in the rotating cavity in a rotating fit mode. Fixing sleeves are fixedly mounted on the left end face of the rotating block in a vertically symmetrical mode. Rectangular grooves which communicate in the left-right direction are formed in the fixing sleeves. Sliding strips are slidably mounted in the rectangular grooves. Vertically-symmetrical reeds are fixedly mounted on the left end faces of the sliding strips, and flexible cleaning blocksare fixedly mounted at the ends, away from the sliding strips, of the reeds.

Owner:深圳市汇呈实业有限公司

Variable-section flow mixer for a double-flow turbojet for a supersonic airplane

ActiveUS7827802B2Mitigate such drawbackReduce jet noisePower plant exhaust arrangementsEngine manufactureMoving between two positionsTurbojet

The invention relates to a variable-section flow mixer for a double-flow turbojet for a supersonic airplane, the mixer comprising a central body, a primary cover, a secondary cover, and a nozzle extending the secondary cover. The nozzle has a plurality of external-air admission openings having mounted therein lobes that are movable between two positions: a closed position in which they close the openings; and a deployed position in which they disengage said openings and deploy into the nozzle so as to allow external air to be admitted. All of the lobes present a common azimuth component in a common direction, and the mixer further includes a plurality of longitudinal grooves occupying at least a portion of the central body, all of the grooves presenting a common azimuth component in a common direction that is opposite to the direction of the azimuth component of the lobes.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com