Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Improve the phenomenon that the temperature rises gradually along the flow direction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Prefabricated wall, building and construction component management system thereof

ActiveCN111561068ATo regulateImprove rational utilization efficiencyGeometric CADSolar heating energySolar air collectorInsulation layer

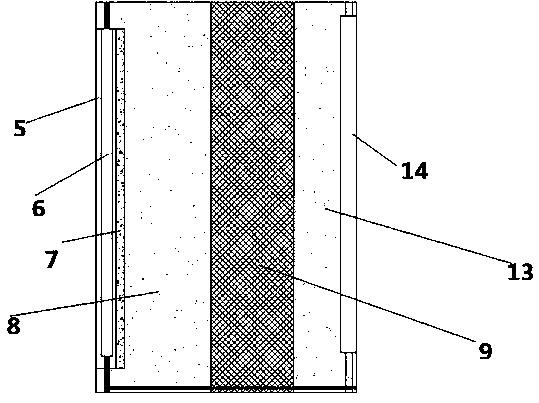

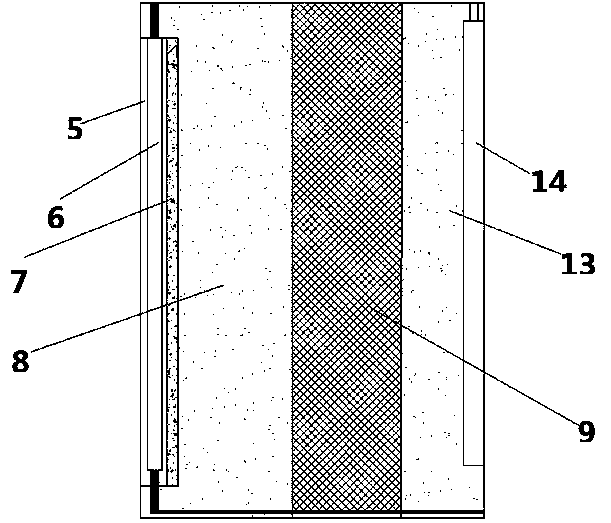

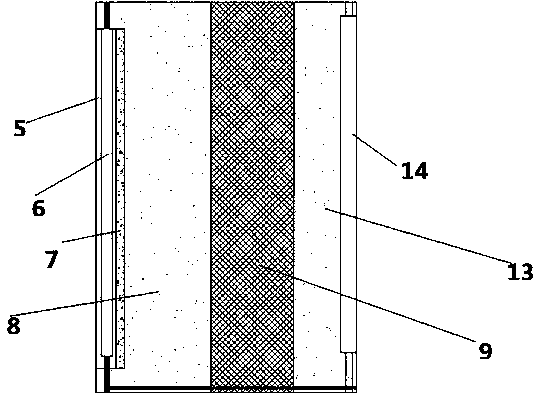

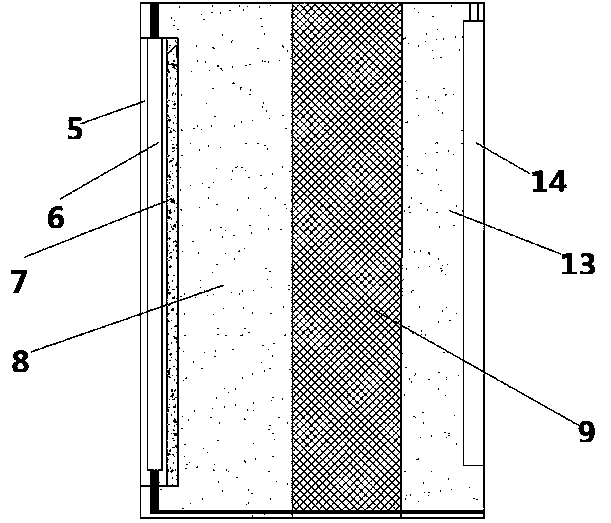

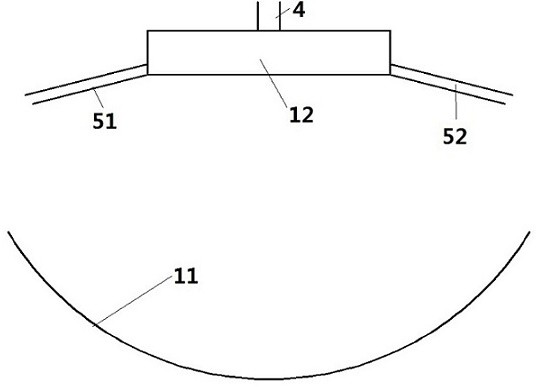

The invention provides a prefabricated wall, a building and a construction component management system thereof. The prefabricated wall includes a transparent board, a preheating tube, a heat insulating layer, an outer bearing wall, an thermal insulation layer, an inner bearing wall, and a ventilation component; the transparent board, the preheating tube and the heat insulating layer are arranged on the outer surface of the outer bearing wall, the transparent board is arranged on the outside of the preheating pipe, the heat insulating layer is arranged on the inner side of the preheating pipe,and the thermal insulation layer is installed between the outer bearing wall and the inner bearing wall; the ventilation component is arranged on the inner surface of the inner bearing wall; the upperentrance of the ventilation component is connected to a solar collector; the preheating tube enters the wall from the upper part of the wall; the lower part of the wall is a closed structure; the preheating tube is provided with branches, and the branch entrance extends into the room inside the wall; and the lower entrance is provided with a fan. The invention provides a new solar air-conditioning building wall located at the bottom of the building, which achieves the air conditioning effect and improves the utilization degree and utilization efficiency of solar energy.

Owner:QINGJIAN GRP CO LTD

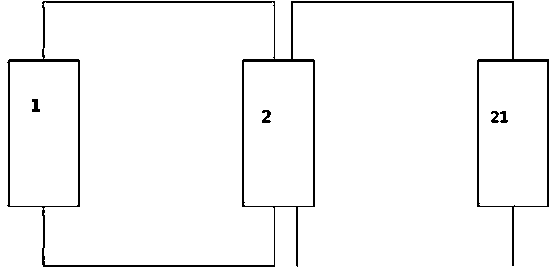

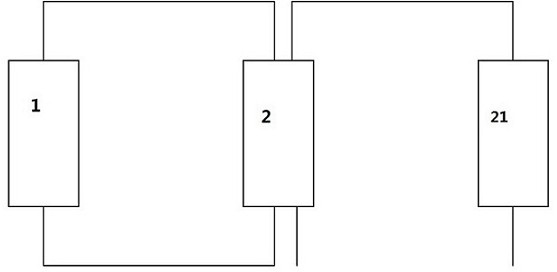

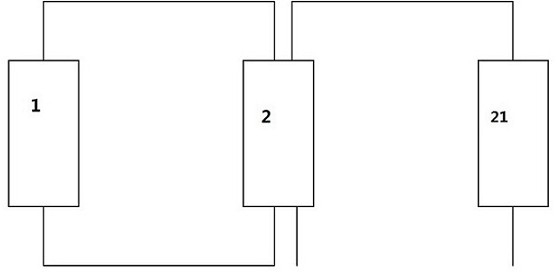

Assembled wall body, building and construction process control system of building

ActiveCN111549930ATo regulateImprove utilizationSolar heating energyWallsControl systemArchitectural engineering

The invention provides an assembled wall body, a building and a construction process control system of the building. The solar assembled building wall body comprises a bottom wall body and non-bottomwall bodies which are assembled, wherein the bottom wall body is arranged at the bottom of the wall body, one non-bottom wall body is assembled at the upper part of the bottom wall body, and another non-bottom wall body is assembled at the upper part of the non-bottom wall body, so that the solar assembled building wall body is formed. The invention provides the novel assembled building wall body.Two assembled wall bodies are respectively arranged at the bottom and the non-bottom part. Through the assembly of the assembled wall body, through the arrangement of transparent plates, preheating pipes and other devices, air entering a heat collector can be preheated first, the air conditioning effect is achieved, and the reasonable utilization efficiency of solar energy is improved.

Owner:青建集团股份公司 +1

Ventilation system using solar energy and building thereof

ActiveCN110986239ATo achieve the effect of purifying the airReduce flow dead zoneSolar heating energyMechanical apparatusFresh airDust control

The invention provides a ventilation system using solar energy and a building thereof. The cold source comprises air, and the air is heated and then conveyed into building rooms, thereby forming an air supply system. The ventilation system further comprises a filtering module which is used for filtering the inlet air, the filtering module is arranged in an air inlet channel, and a primary effect filter, an electrostatic precipitator, an activated carbon filter and a high efficiency filter are sequentially arranged in the filtering module; the primary effect filter is one or more of non-woven fabric, nylon net, fluffy fiberglass felt, plastic net or metal mesh; the electrostatic precipitator comprises an electrostatic dust removal section, the electrostatic dust removal section comprises two stages, the two stages are a first stage and a second stage in the air flow direction, and the electric field strengths of the first stage and the second stage are different; and the material of thehigh efficiency filter is one or more of PP filter paper, glass fiber paper and PET filter paper. The invention provides a fresh air system, the fresh air system is provided with the novel filteringmodule, and the effect of purifying air can be achieved.

Owner:青建集团股份公司 +1

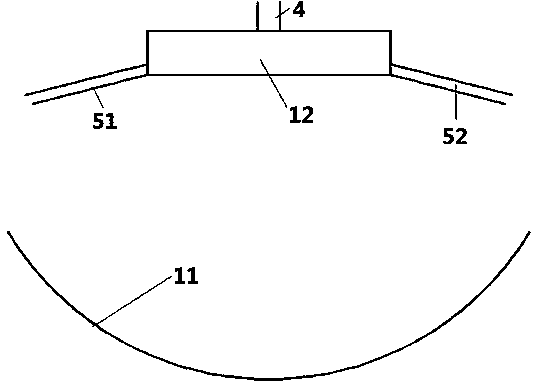

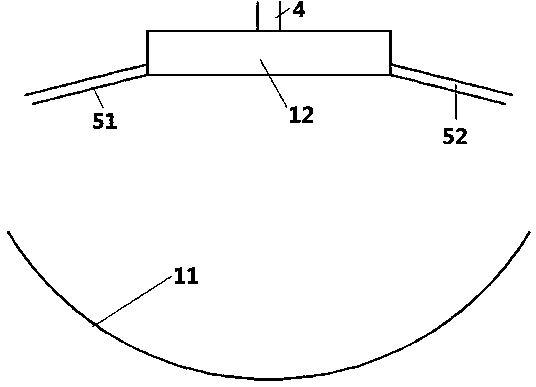

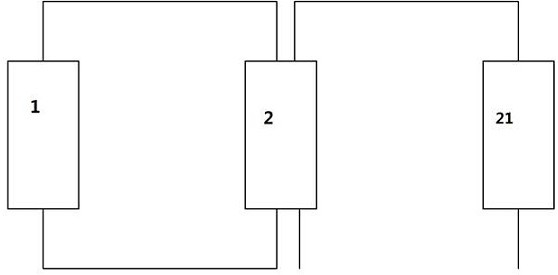

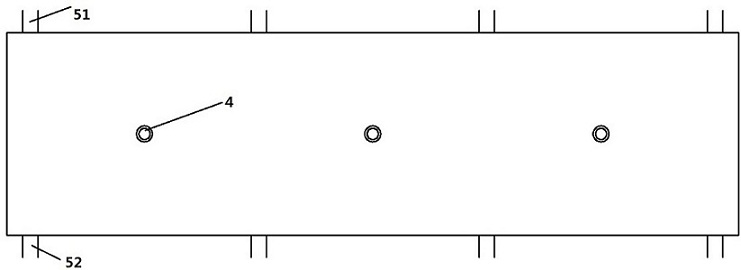

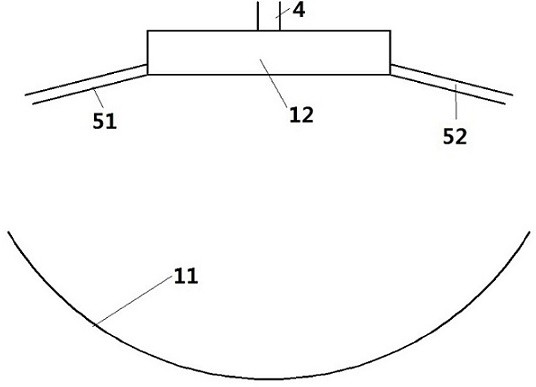

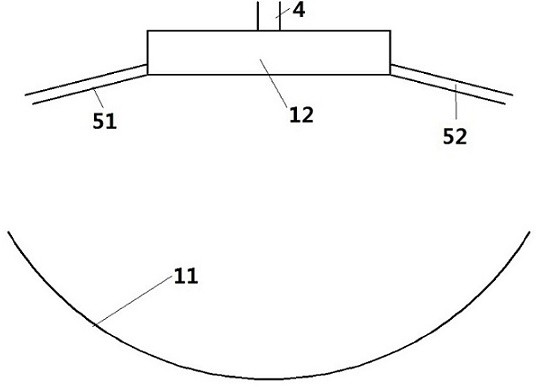

Solar system, heating and ventilating system and building roof with solar system

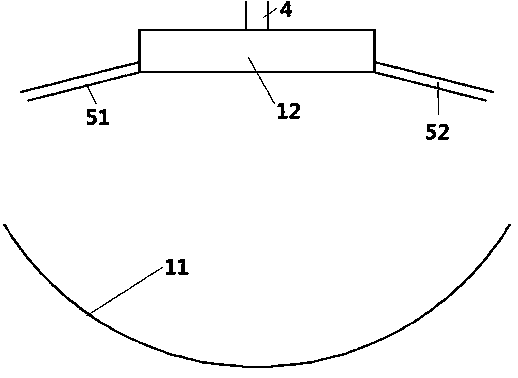

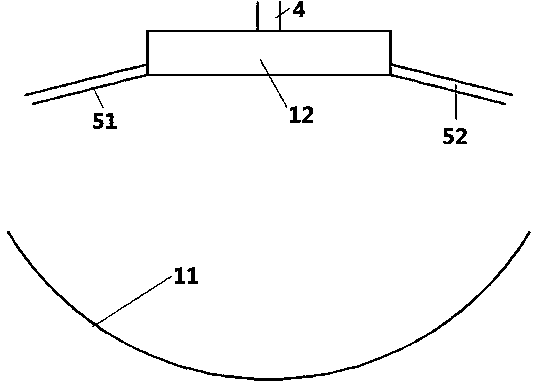

ActiveCN111306812AReduce flow dead zoneImprove temperature uniformitySolar heating energyRoof covering using slabs/sheetsThermodynamicsHeat flow

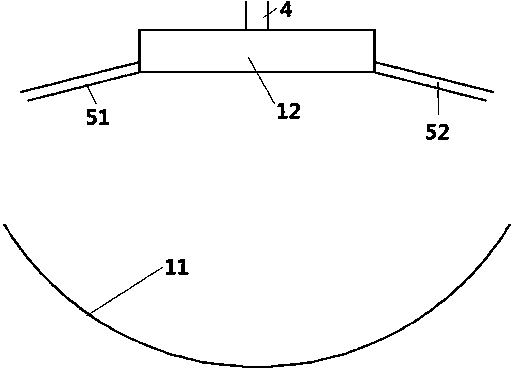

The invention provides a solar system, a heating and ventilating system and a building roof with the solar system. The solar system comprises a collector. The collector comprises heat collecting pipesand a reflecting mirror. The heat collecting pipes are flat pipes. The lower flat surfaces of the flat pipes are opposite to the reflecting surface of the reflecting mirror. Each flat pipe comprise abottom plate on the lower side and an upper cover on the upper side, wherein the upper cover and the bottom plate are assembled together to form a cavity of the flat pipe, and fluid flows in the cavity. Each bottom plate comprises a plurality of heat exchange area. Each heat exchange area comprises vertical plates and column ribs. The novel solar system is developed, and a flow guide structure isarranged in a cold plate of each heat exchange area, so that a refrigerant flowing dead area is effectively reduced, and the thermal homogeneity of a hot flow surface is further improved; and by means of the column ribs, the disturbance to the flow field is enhanced, the heat exchange area is expanded, and heat exchange can be easily reinforced.

Owner:QINGJIAN GRP CO LTD +1

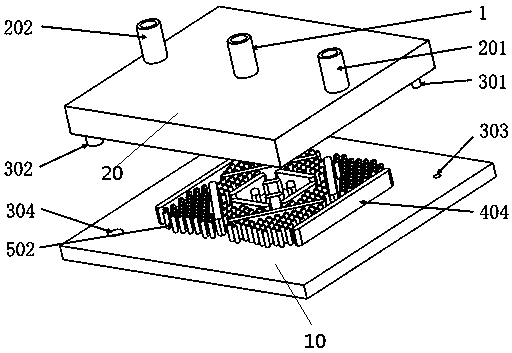

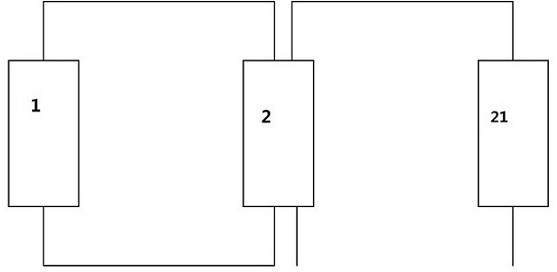

heat exchanger for heat storage, and fresh air system for controlling PM2.5

ActiveCN111536818ALow costImprove heat storage effectSolar heating energyMechanical apparatusEngineeringFresh air

The invention provides a heat exchanger for heat storage and a fresh air system for controlling PM2.5. The heat exchanger for heat storage comprises a heat source inlet, a heat source outlet, a cold source inlet, a cold source outlet and a shell, wherein a plurality of heat storage blocks are arranged in the heat exchanger shell and stacked together, a first hole is formed in each heat storage block, and a channel formed by each first hole is used for circulating the heat source; the heat source enters from the heat source inlet, passes through the first hole and then is discharged from the heat source outlet; and the heat storage capacity of a heat storage material is gradually reduced along a flowing direction of the heat source. The invention aims at providing a novel heat exchanger forheat storage and a fresh air system. The cost of heat storage material can be saved, and the heat storage effect can be improved.

Owner:QINGJIAN GRP CO LTD +1

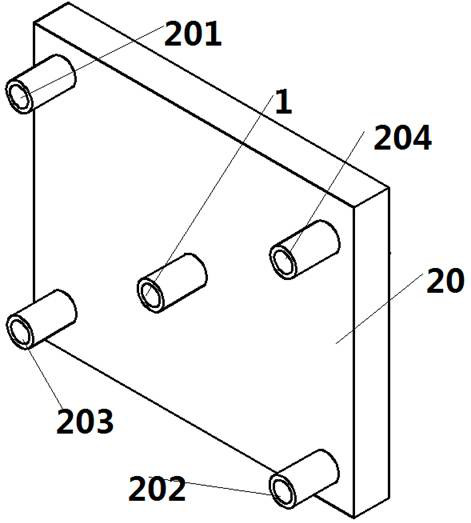

Design method of water-cooled tube plate type heat exchanger

ActiveCN110793370AEstimated heat dissipationEstimated pump power consumptionIndirect heat exchangersDesign optimisation/simulationEngineeringMechanical engineering

The invention provides a design method of a water-cooled tube plate type heat exchanger. The heat exchanger comprises a base plate and a cover plate, the cover pate and the base plate are assembled together to form a fluid space, the base plate is provided with baffles and cylindrical fins, the baffles comprise the first baffle located at the center of the base plate, the second baffle surroundingthe first baffle and the third baffle surrounding the second baffle, and a nusselt number and other formulas are designed through parameters. According to the design method, through a large number ofresearches, the structure of the heat exchanger is simulated, the nusselt number and other formulas of the structure are determined for the first time, and the heat dispersion performance and pump power consumption of a water-cooled plate can be estimated by the formulas.

Owner:SHANDONG UNIV

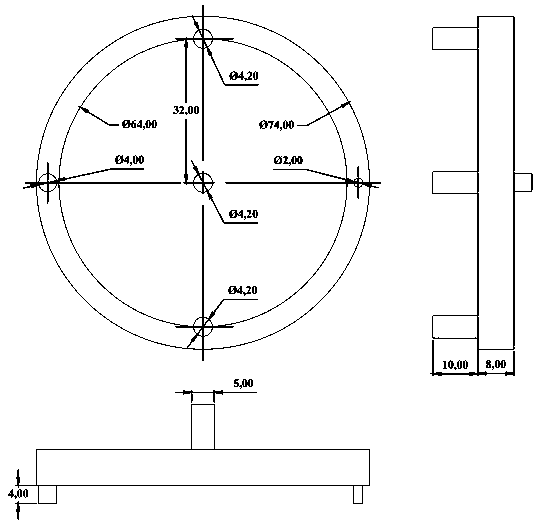

Circular-structure plate heat exchanger for controlling flow by comparing adjacent temperatures

ActiveCN111336844AAffect operationMeet heat transfer needsHeat exchanger casingsHeat transfer modificationData connectionPlate heat exchanger

The invention provides a circular-structure plate heat exchanger for controlling flow by comparing adjacent temperatures. The circular-structure plate heat exchanger comprises a base plate and a coverplate, the base plate and the cover plate are of a circular structure, the cover plate and the base plate are assembled together to form a circular cavity, cooling fluid flows in the cavity, an inletis formed in the center of the cover plate, and a temperature sensor is arranged on the outer wall face of the base plate; the temperature sensor is in data connection with the controller, and the controller automatically controls the fluid flow of the inlet according to the data of the temperature sensor; and the controller extracts the temperature data according to the time sequence, the temperature difference of the temperature data is obtained by comparing the temperature data of the adjacent time periods, and the controller automatically controls the fluid flow of the inlet according tothe temperature difference. According to the circular-structure plate heat exchanger for controlling flow by comparing the adjacent temperatures, the situation that heat exchange and heat dissipationcannot be conducted in time due to too much or too little heat exchange fluid is avoided, and it is avoided that the temperature of a heat source is too high or too low to affect operation of the heatsource.

Owner:SHANDONG UNIV

Plate heat exchanger capable of intelligently controlling according to outlet temperature

ActiveCN111156841AAffect operationTemperature controlHeat exchanger casingsLaminated elementsData connectionTemperature control

The invention provides a plate heat exchanger capable of intelligently controlling according to the outlet temperature. A second temperature sensor and a third temperature sensor are arranged at fluidoutlets separately, are used for detecting the fluid temperature of two outlets and are in data connection with a controller; the controller automatically controls the fluid flow rate of an inlet according to the fluid temperature of the two outlets; when the detected temperature is higher than the set first temperature, the controller controls the opening degree of a first valve to be increasedto increase the fluid flow rate entering the heat exchanger; and when the detected temperature is lower than the set second temperature, the controller controls the opening degree of the first valve to be reduced to reduce the fluid flow rate entering the heat exchanger. The plate heat exchanger avoids that the heat exchanging fluid is too much or too little to realize timely heat exchange and dissipation and also avoids the temperature of a heat source to be too high or too low to not to affect operation of the heat source.

Owner:SHANDONG UNIV

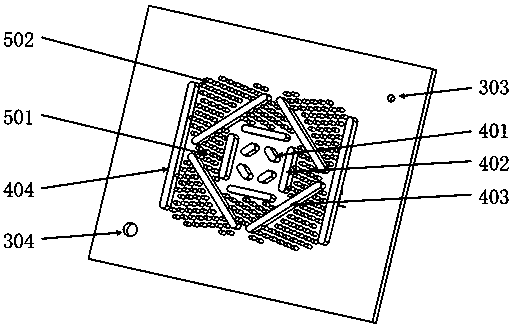

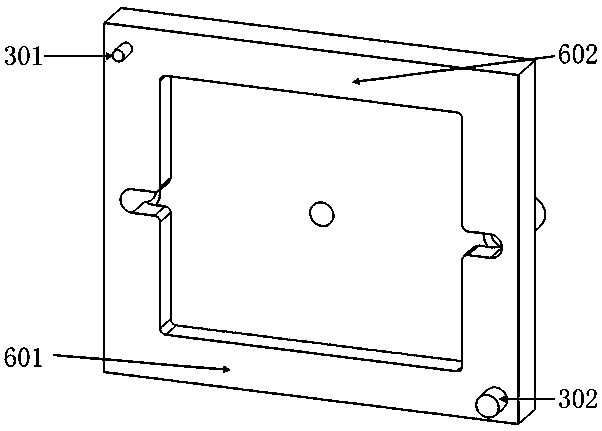

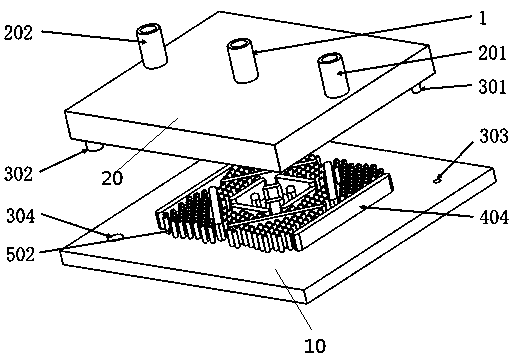

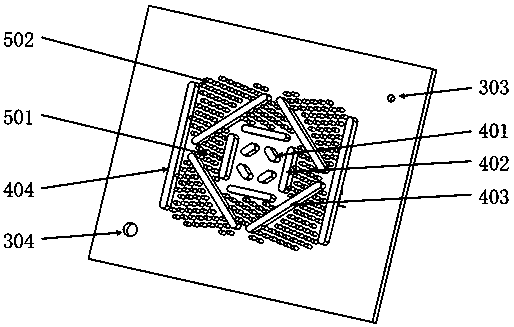

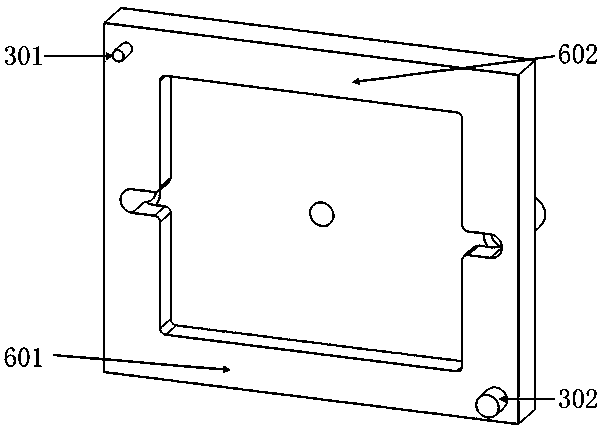

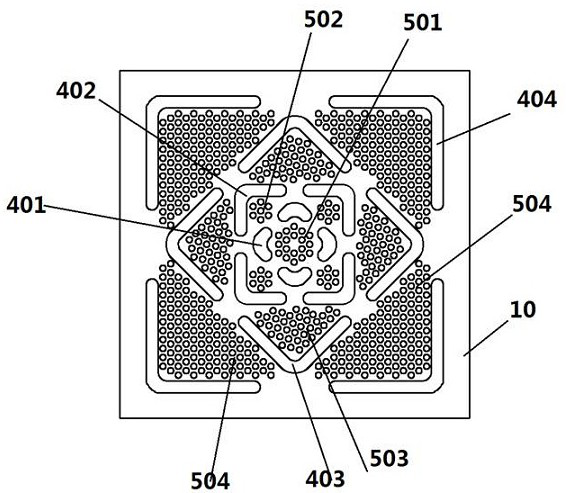

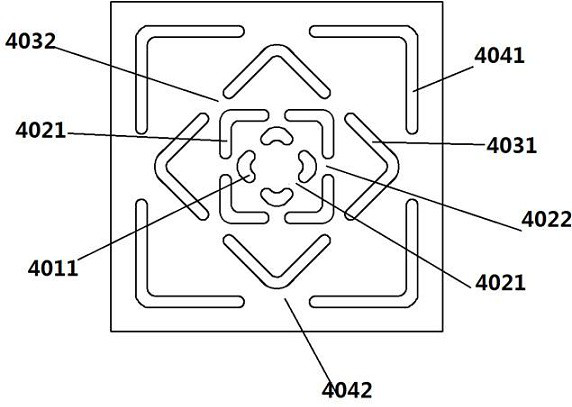

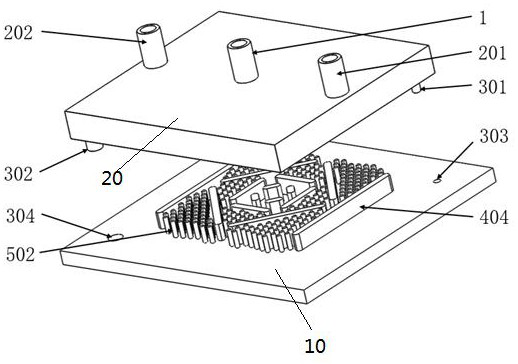

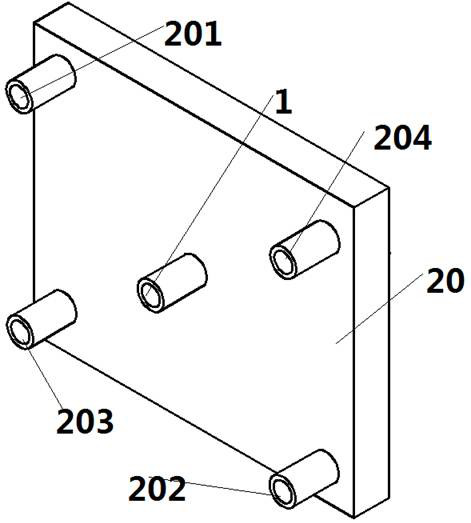

Plate heat exchanger adopting liquid cooling

ActiveCN112033189AImprove heat transfer efficiencyEnhanced heat transferHeat exchanger casingsLaminated elementsPhysicsEngineering

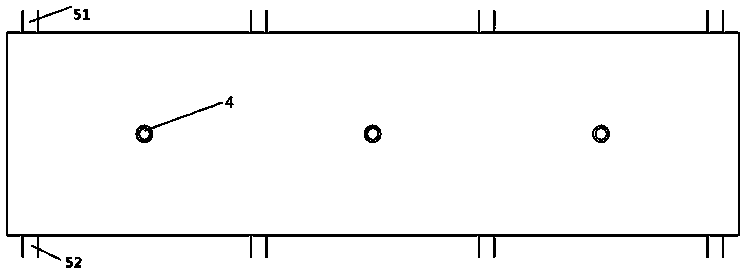

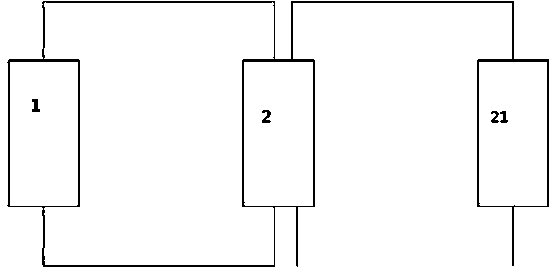

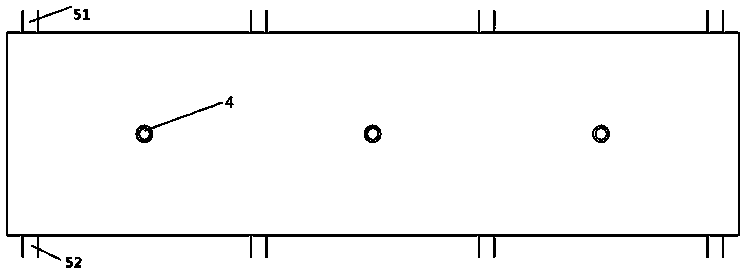

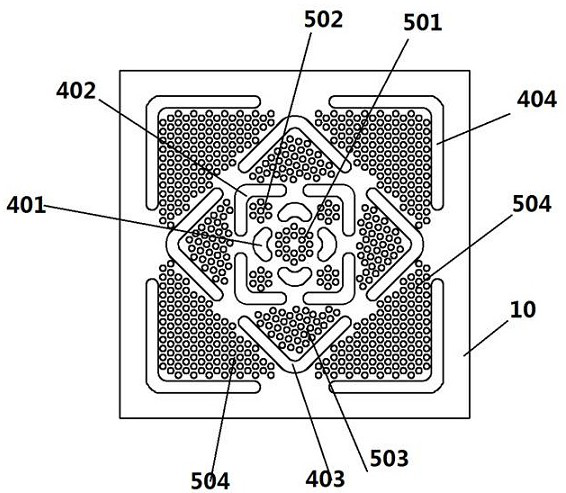

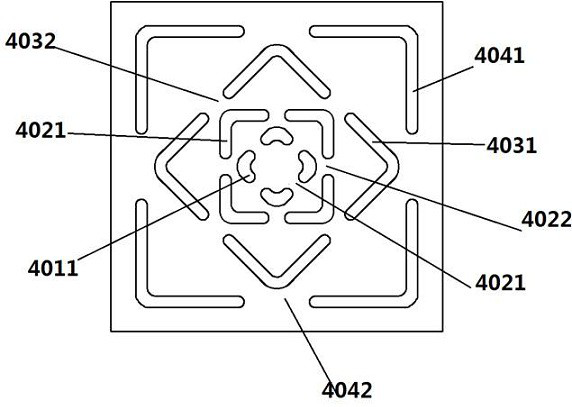

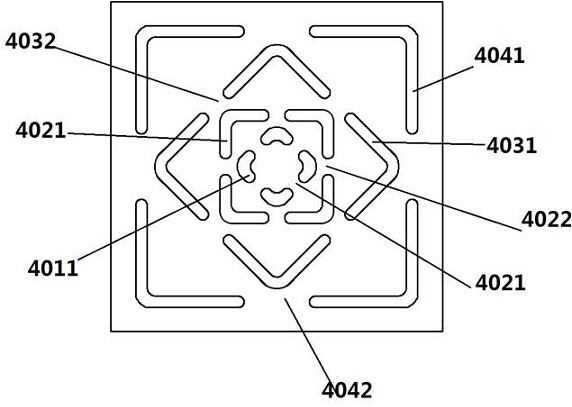

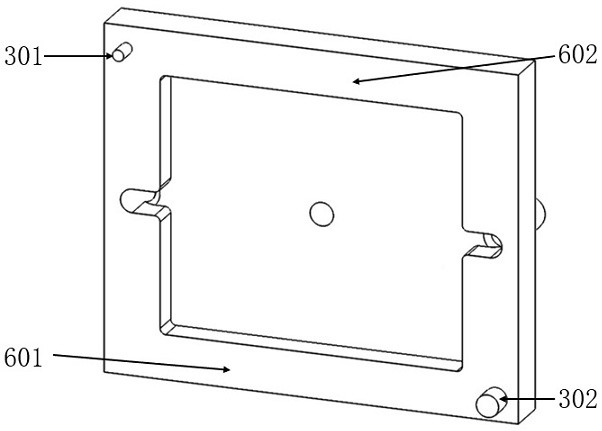

The invention provides a plate heat exchanger adopting liquid cooling. The plate heat exchanger comprises a bottom plate and a cover plate, wherein the bottom plate and the cover plate are of a squarestructure, the cover plate and the bottom plate are assembled together to form a square cavity, cooling liquid flows in the cavity, and baffle plates and fins are arranged on the bottom plate; the baffle plates include first baffle plates located at the center of the bottom plate, second baffle plates surrounding the first baffle plates, third baffle plates surrounding the second baffle plates and fourth baffle plates surrounding the third baffle plates; and a plurality of fins are arranged in the space defined by the first baffle plates, a plurality of fins are arranged between the second baffle plates and the first baffle plates, a plurality of fins are arranged between the second baffle plates and the third baffle plates, and a plurality of fins are arranged between the third baffle plates and the fourth baffle plates. According to the plate heat exchanger of the novel structure, through cooperation of the multiple layers of fins and the baffle plates, the heat exchange efficiencycan be further improved, and heat transfer is enhanced.

Owner:CHINA NORTH VEHICLE RES INST

A uniform temperature control method for a liquid-cooled plate heat exchanger

ActiveCN112344773BOutput temperature equalizationImprove heat transfer efficiencyHeat exchanger casingsLaminated elementsTemperature controlPlate heat exchanger

The invention provides a uniform temperature control method for a liquid-cooled plate heat exchanger, which includes a bottom plate and a cover plate, the highest temperature and the lowest temperature of the four outlet temperatures detected, and when the difference between the highest temperature and the lowest temperature exceeds a certain value, control The device automatically controls the opening of the valve at the outlet with the lowest temperature to decrease, and the opening of the valve at the outlet with the highest temperature to increase, so that the liquid flow at the outlet with the lowest temperature decreases and the liquid flow at the outlet with the highest temperature increases. By adjusting the flow rate of the liquid at the lowest and highest temperature outlets, the heat exchange of liquids participating in the lowest and highest temperature sides can be adjusted. In the present application, by adjusting the liquid flow rate, the overall output temperature can be kept balanced, and the local temperature can be avoided from being too high or too low.

Owner:CHINA NORTH VEHICLE RES INST

Water-cooled plate-type heat exchanger with pulsating vibration

ActiveCN111238265AEnhanced heat transferImprove descaling effectHeat exchanger casingsLaminated elementsPulsatile flowEngineering

The invention provides a water-cooled plate-type heat exchanger with pulsating vibration. The water-cooled plate-type heat exchanger includes a base plate, a cover plate, a fluid inlet and fluid outlets. Each fluid outlet includes a first outlet and a second outlet. The cover plate and the base plate are assembled together to form a fluid space. The base plate is provided with a baffle and a cylindrical rib piece, and the fluid inlet is located in the middle position of the two fluid outlets. The water-cooled plate-type heat exchanger is characterized in that the cylindrical rib piece is of anelastic structure, a pulsation generating device is arranged on an inlet pipeline, and fluid entering the plate-type heat exchanger is enabled to be pulsating flow through the pulsation generating device. According to the water-cooled plate-type heat exchanger, the pulsation generating device is arranged on the inlet pipeline, and the fluid entering the plate-type heat exchanger is enabled to bethe pulsating flow through the pulsation generating device, so that the movement of the cylindrical rib piece as an elastic part is continuously promoted, and thus, heat transfer is enhanced, and thedescaling effect is increased.

Owner:SHANDONG UNIV

Interval-variable liquid cooling plate heat exchanger

ActiveCN112461022AImprove heat transfer effectImprove heat transfer performanceHeat exchanger casingsLaminated elementsPlate heat exchangerCooling fluid

The invention provides an interval-variable liquid cooling plate heat exchanger which comprises a bottom plate and a cover plate, wherein the bottom plate and the cover plate are of a square structureand are assembled together to form a square cavity, cooling liquid flows in the cavity, and baffle plates and fins are arranged on the bottom plate; the baffle plates comprise a first baffle plate positioned in the center of the bottom plate, a second baffle plate surrounding the first baffle plate, a third baffle plate surrounding the second baffle plate and a fourth baffle plate surrounding thethird baffle plate; a plurality of ribs are arranged in the first baffle plate; and the ratio of the first interval to the baffle plate wall length of the first baffle plate, the ratio of the secondinterval to the baffle plate wall length of the second baffle plate, the ratio of the third interval to the baffle plate wall length of the third baffle plate, and the ratio of the fourth interval tothe baffle plate wall length of the fourth baffle plate are from big to small. By changing the ratios of the intervals to the baffle plate walls, the intervals are smaller if diffusion to the outsideis further, so that heat exchange effect is improved, and heat transfer is strengthened.

Owner:CHINA NORTH VEHICLE RES INST

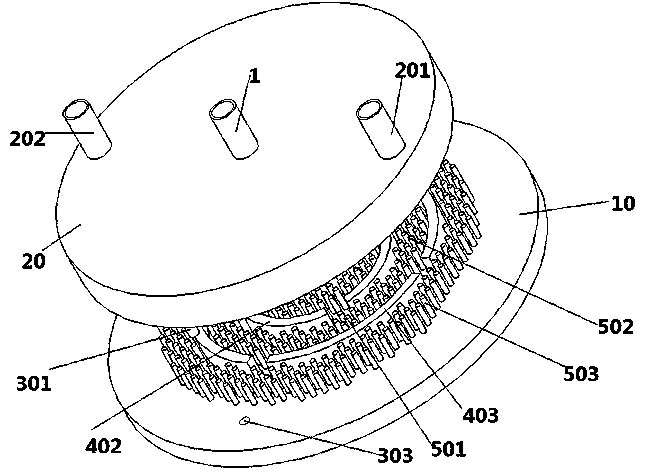

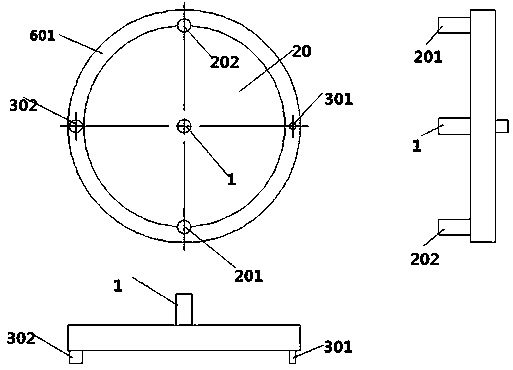

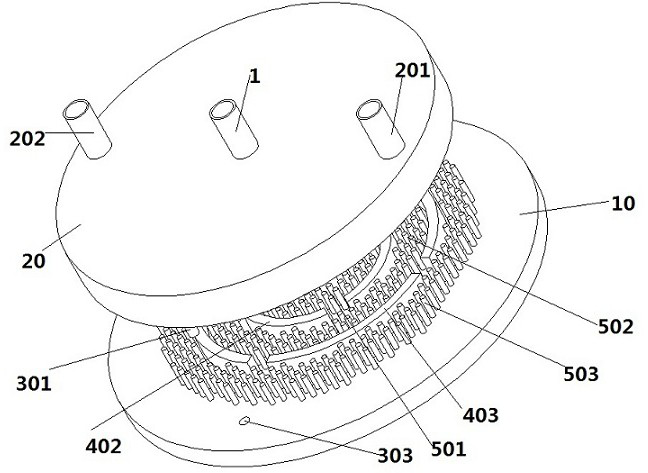

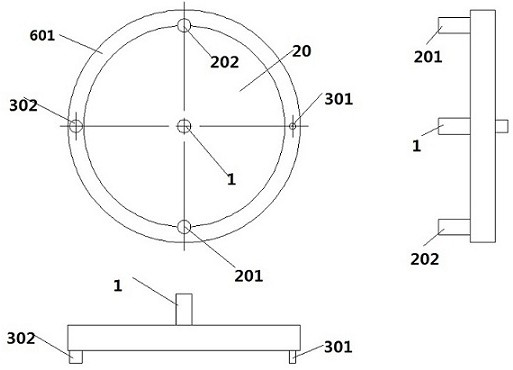

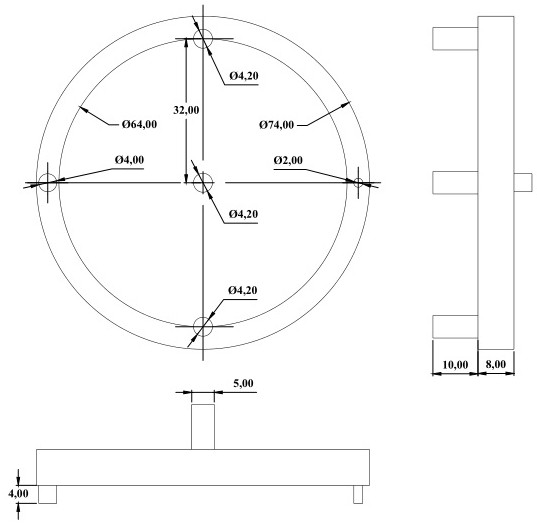

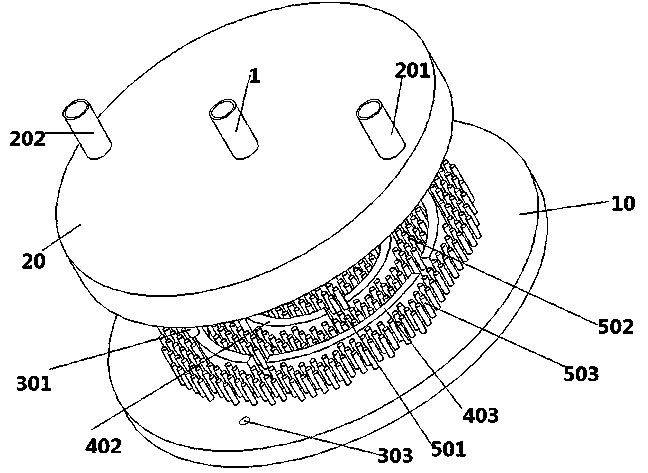

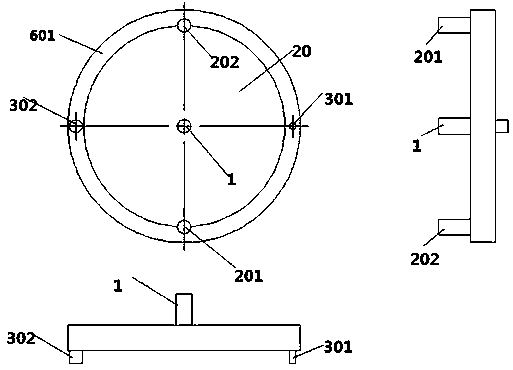

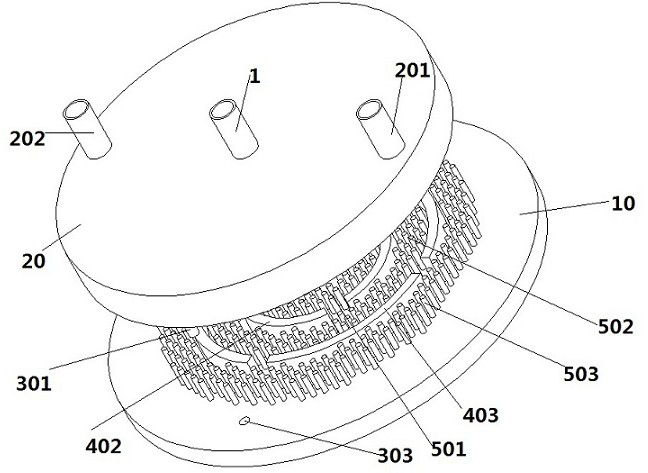

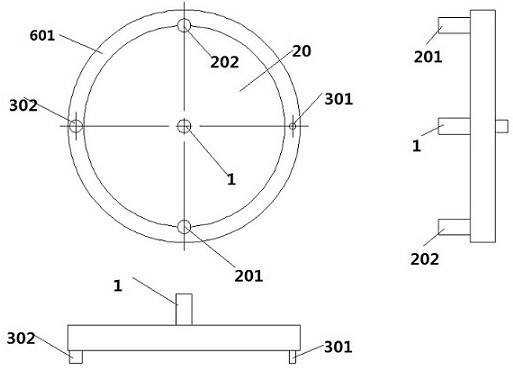

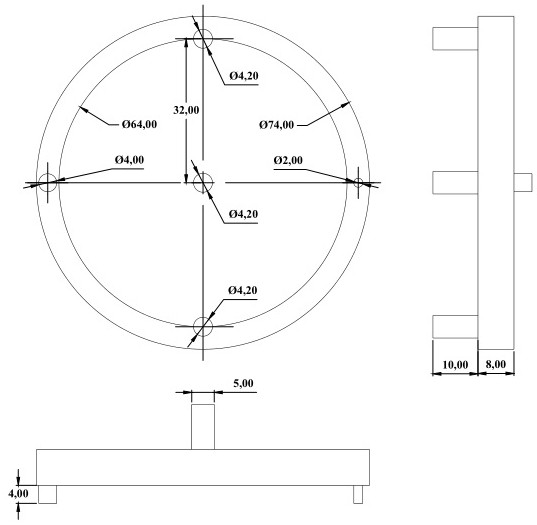

A water-cooled plate heat exchanger with a circular structure

ActiveCN111336843BMeet heat transfer needsTemperature controlHeat exchanger casingsHeat transfer modificationPlate heat exchangerEngineering

The invention provides a water-cooled plate heat exchanger with a circular structure, including a base plate and a cover plate, and the first baffle plate, the second baffle plate, and the third baffle plate are arc structures with the center point of the base plate as the center; the first The baffle includes a plurality of pieces distributed at equal intervals in the circular direction, and intervals are set between adjacent first baffles; the second baffle includes a plurality of pieces distributed at equal intervals in the circular direction, and between adjacent second baffles Spaces are set between them; the third baffle includes a plurality of equidistant distributions in the circular direction, and intervals are set between adjacent third baffles; a plurality of cylindrical ribs are set between the second baffle and the third baffle ; A plurality of cylindrical ribs are arranged between the first baffle and the second baffle; and a plurality of cylindrical ribs are arranged outside the third baffle. The invention adopts a circular structure, which can meet the heat exchange requirement of the circular structure.

Owner:SHANDONG UNIV

Water-cooled plate heat exchanger with circular structure

ActiveCN111336843AMeet heat transfer needsTemperature controlHeat exchanger casingsHeat transfer modificationPlate heat exchangerEngineering

The invention provides a water-cooled plate heat exchanger with a circular structure. The water-cooled plate heat exchanger comprises a base plate and a cover plate, wherein first baffles, second baffles and third baffles are of an arc structure with the center point of the base plate as the circle center. The first baffles are distributed in the circular direction at equal intervals, and intervals are set between the adjacent first baffles. The second baffles are distributed in the circular direction at equal intervals, and intervals are set between the adjacent second baffles. The third baffles are distributed in the circular direction at equal intervals, and intervals are set between the adjacent third baffles. A plurality of cylindrical ribs are arranged between the second baffles andthe third baffle. A plurality of cylindrical ribs are arranged between the first baffles and the second baffles; and a plurality of cylindrical ribs are arranged outside the third baffles. According to the plate heat exchanger, the circular structure is adopted, and the heat exchange requirement of the circular structure can be met.

Owner:SHANDONG UNIV

A solar fresh air system

ActiveCN113108490BImprove the effect of heat storage and heat exchangeTemperature controlSolar heating energyMechanical apparatusWind systemCollector device

The invention provides a solar fresh air system, which includes a heat collector, a heat storage heat exchanger, and a cold source module. The heat collector absorbs solar energy and then transfers it to the heat storage material through the heat storage heat exchanger. The cold source module includes The cold source passage, the cold source passage exchanges heat with the heat storage material, and transfers the heat to the cold source in the cold source passage, the cold source is air, and the air is heated and transported to the room of the building, Thus forming a fresh air system. The present invention provides a new fresh air system, which can rely on heat storage blocks for independent heat storage and heat exchange, saves heat exchange tubes, and can further improve heat storage and heat exchange effects.

Owner:江苏净松环境科技有限公司

A liquid-cooled plate heat exchanger with variable interval

ActiveCN112461022BImprove heat transfer effectImprove heat transfer performanceHeat exchanger casingsLaminated elementsPlate heat exchangerEngineering

The invention provides a liquid-cooled plate heat exchanger with variable intervals, including a bottom plate and a cover plate, the bottom plate and the cover plate are square structures, the cover plate and the bottom plate are assembled together to form a square cavity, and the cooling liquid flows in the cavity. A baffle and a rib are arranged on the bottom plate, and the baffle includes a first baffle located at the center of the bottom plate, a second baffle surrounded outside the first baffle, and a second baffle surrounded by the second baffle. The third baffle on the outside and the fourth baffle surrounding the outside of the third baffle, a plurality of ribs are arranged inside the first baffle; the ratio of the length of the baffle wall between the first interval and the first baffle > The ratio of the length of the baffle wall of the second compartment to the baffle wall of the second baffle > The ratio of the length of the baffle wall of the third compartment to the baffle wall of the third baffle > The ratio of the baffle wall of the fourth compartment to the baffle wall of the fourth baffle ratio of lengths. Through the change of the ratio of the space to the wall of the baffle plate, the more the space diffuses to the outside, the smaller the space is, which can improve the heat exchange effect and enhance the heat transfer.

Owner:CHINA NORTH VEHICLE RES INST

A plate heat exchanger intelligently controlled according to the outlet temperature

ActiveCN111156841BAffect operationTemperature controlHeat exchanger casingsLaminated elementsData connectionTemperature control

The invention provides a plate heat exchanger capable of intelligently controlling according to the outlet temperature. A second temperature sensor and a third temperature sensor are arranged at fluidoutlets separately, are used for detecting the fluid temperature of two outlets and are in data connection with a controller; the controller automatically controls the fluid flow rate of an inlet according to the fluid temperature of the two outlets; when the detected temperature is higher than the set first temperature, the controller controls the opening degree of a first valve to be increasedto increase the fluid flow rate entering the heat exchanger; and when the detected temperature is lower than the set second temperature, the controller controls the opening degree of the first valve to be reduced to reduce the fluid flow rate entering the heat exchanger. The plate heat exchanger avoids that the heat exchanging fluid is too much or too little to realize timely heat exchange and dissipation and also avoids the temperature of a heat source to be too high or too low to not to affect operation of the heat source.

Owner:SHANDONG UNIV

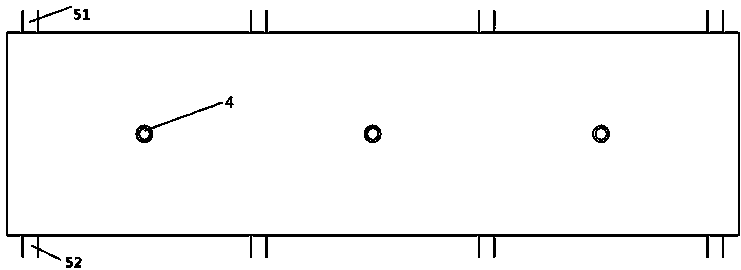

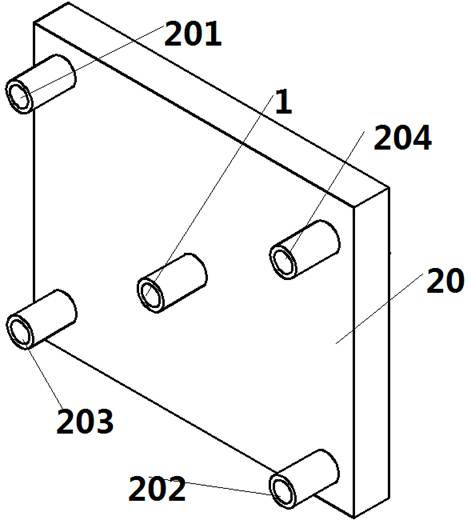

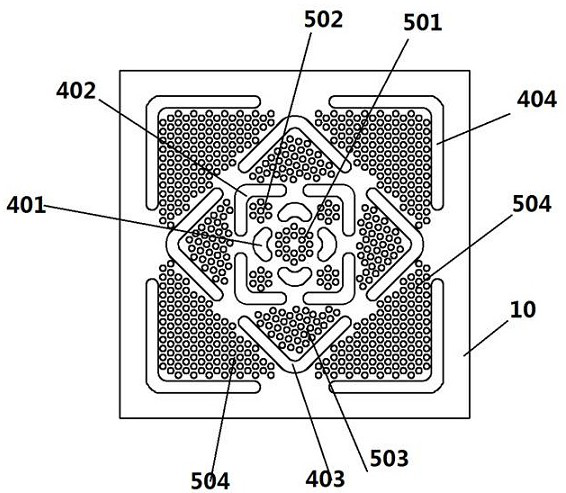

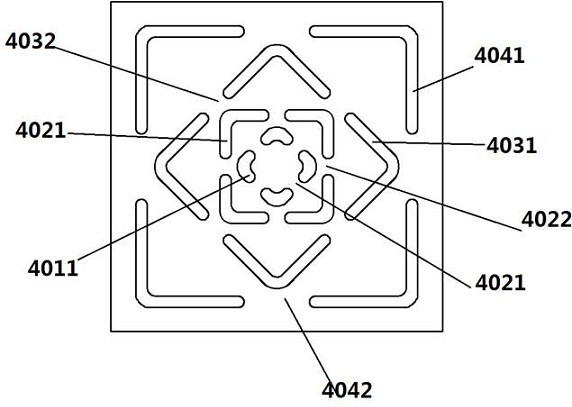

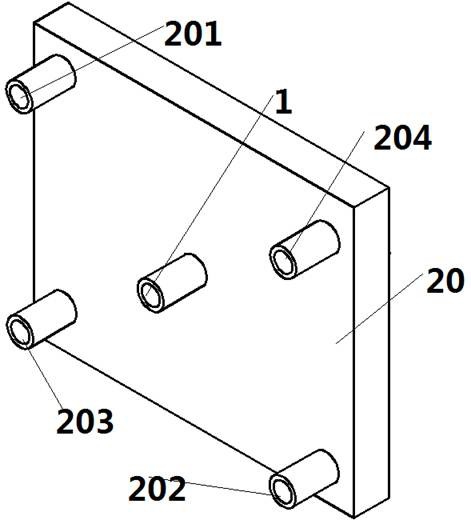

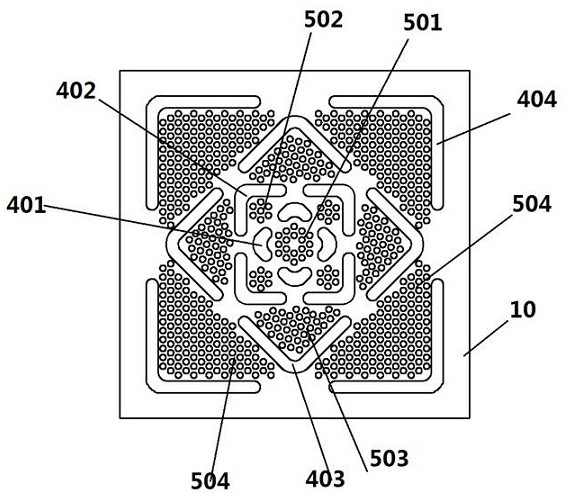

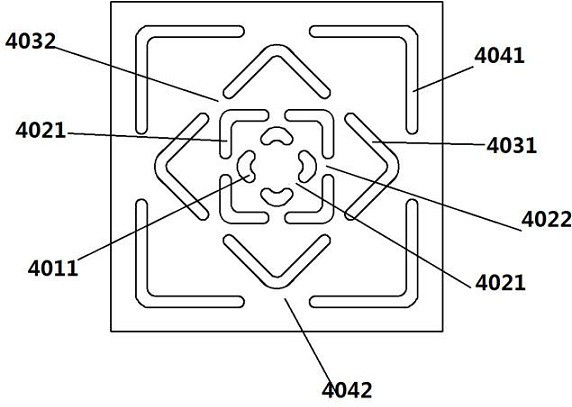

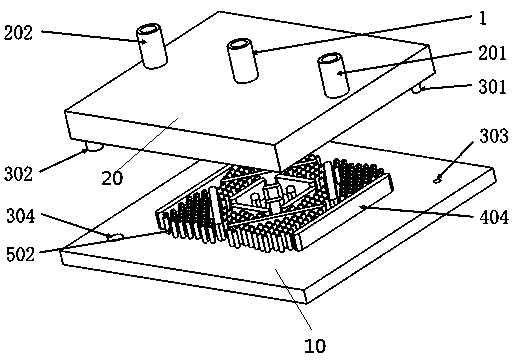

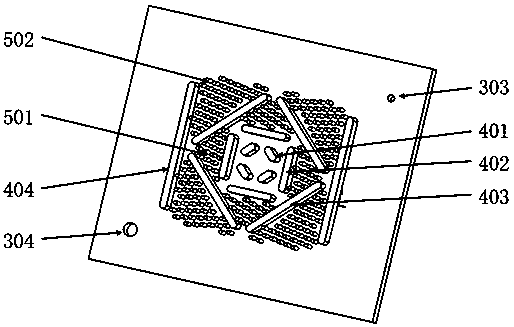

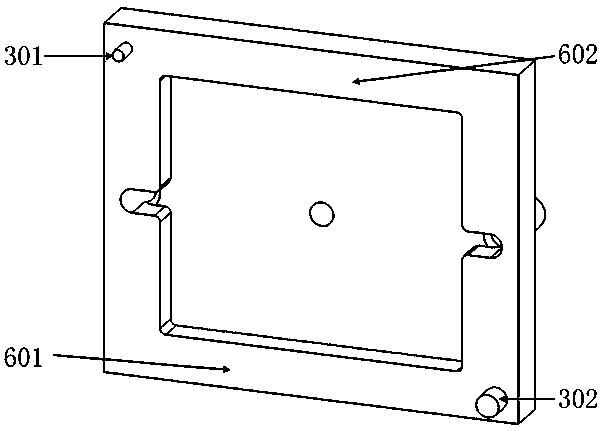

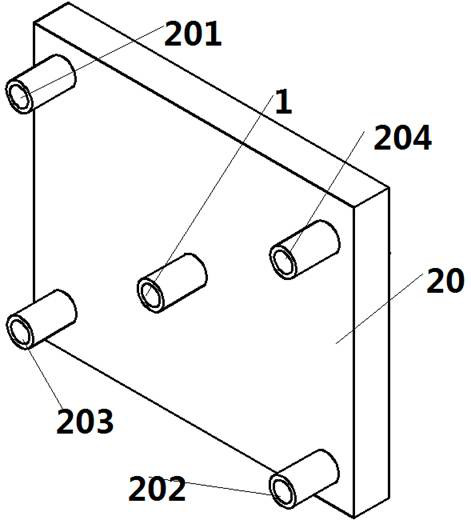

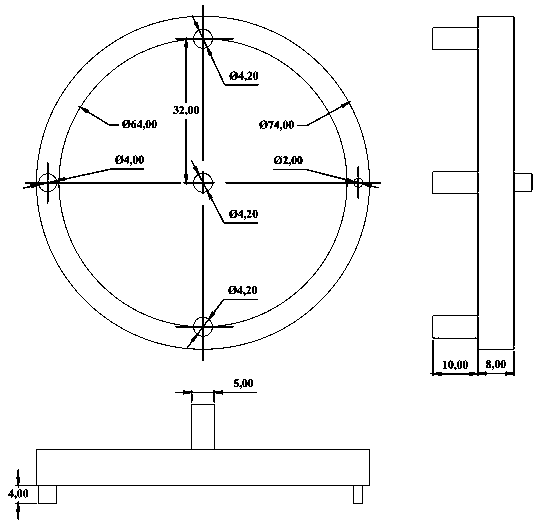

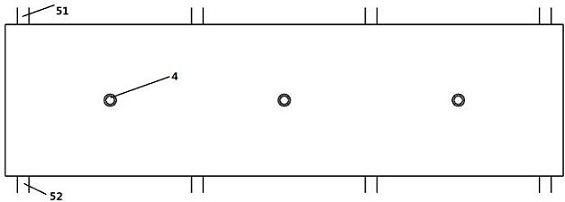

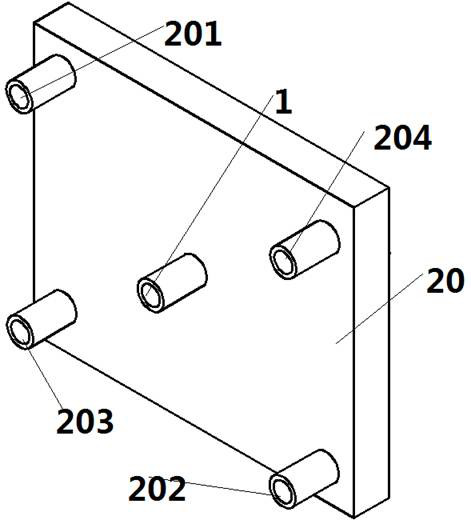

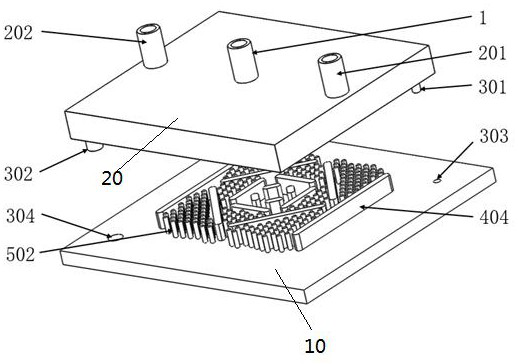

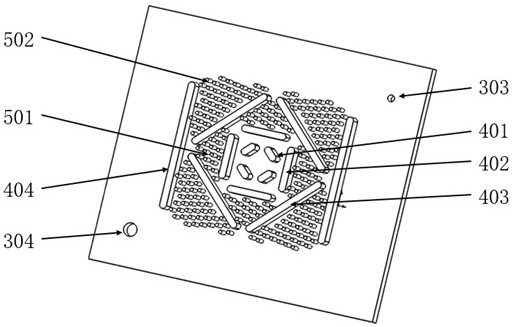

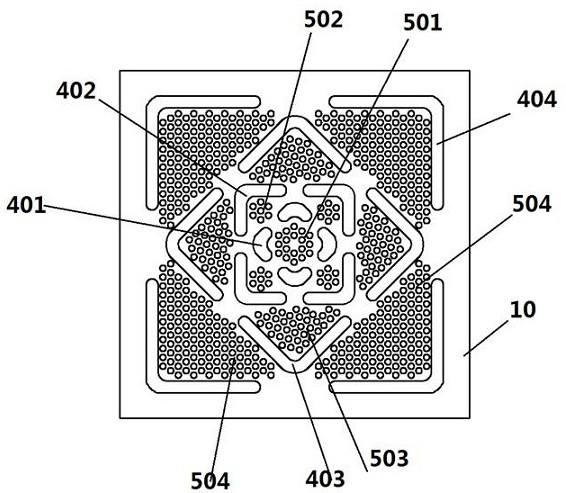

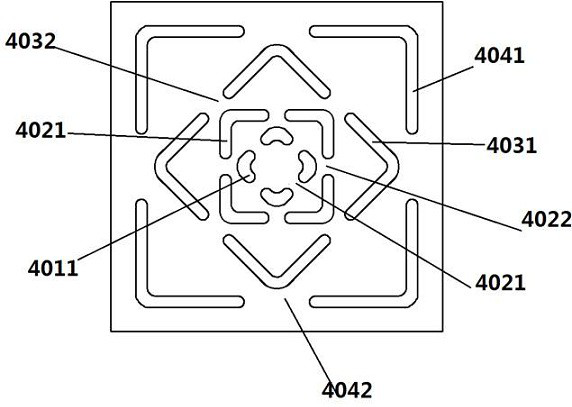

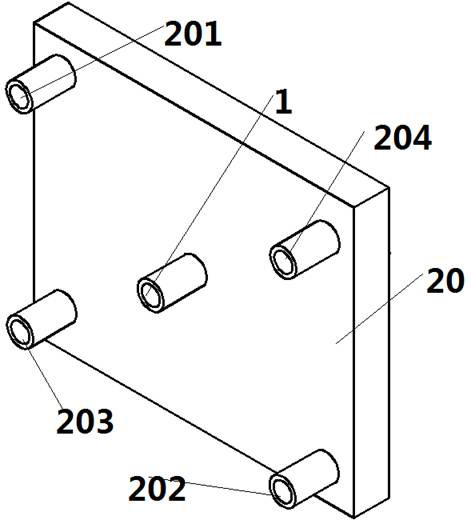

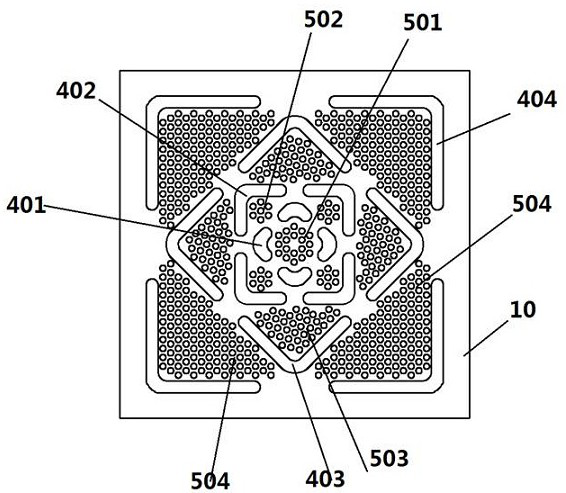

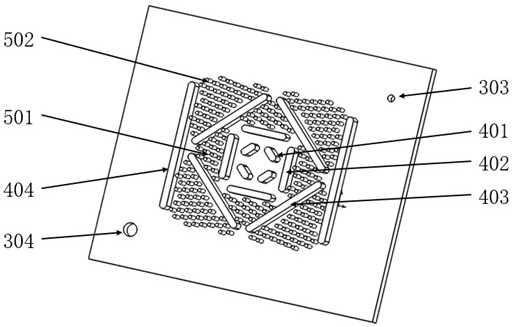

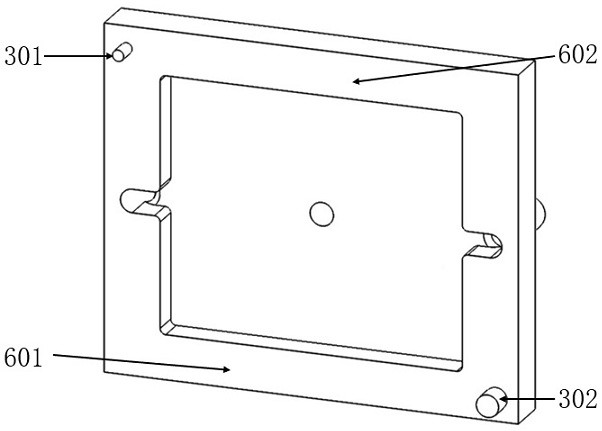

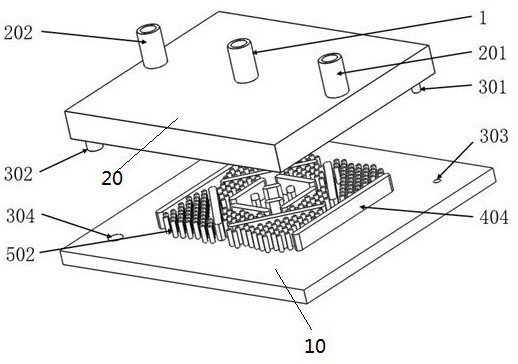

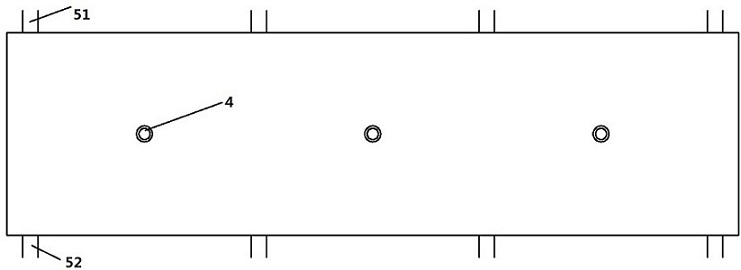

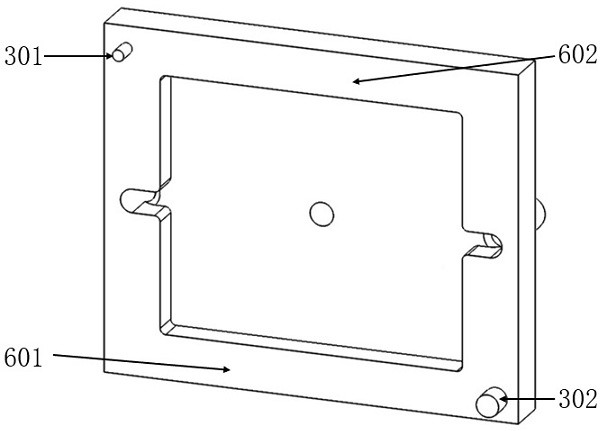

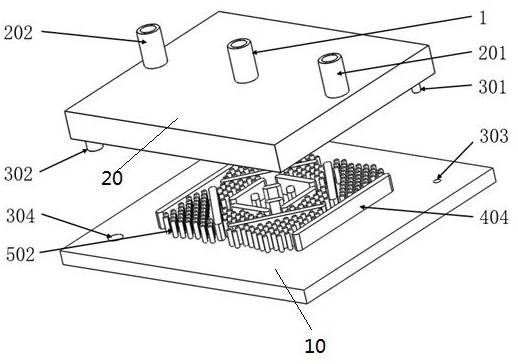

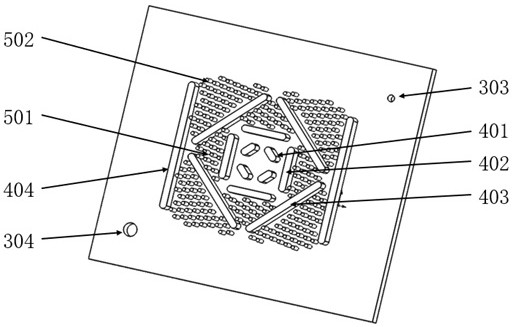

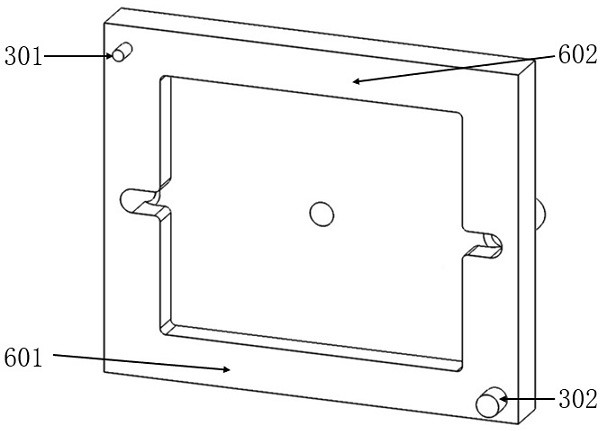

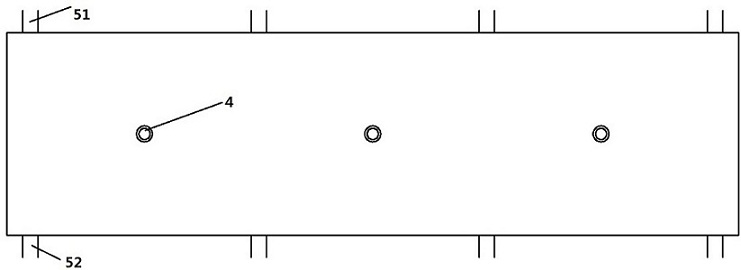

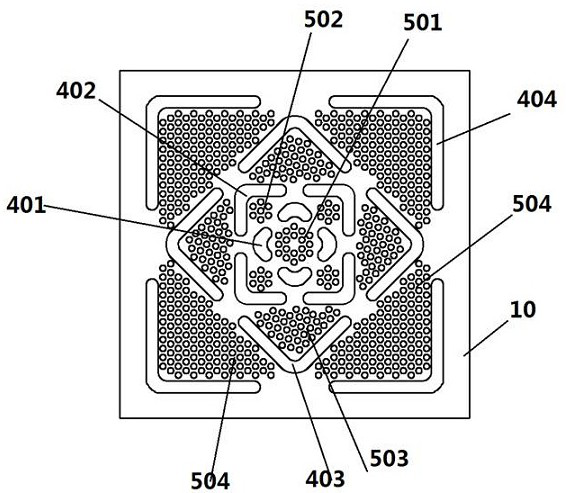

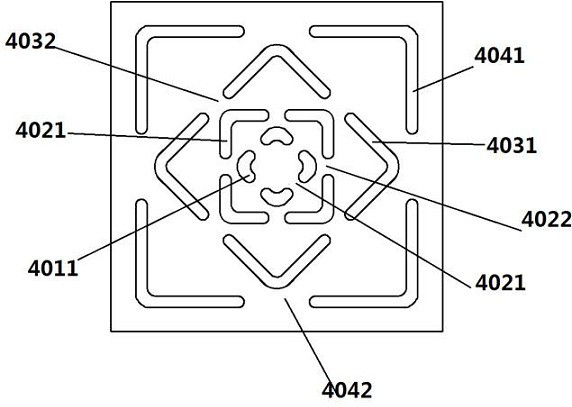

A liquid-cooled plate heat exchanger with multi-outlet distribution

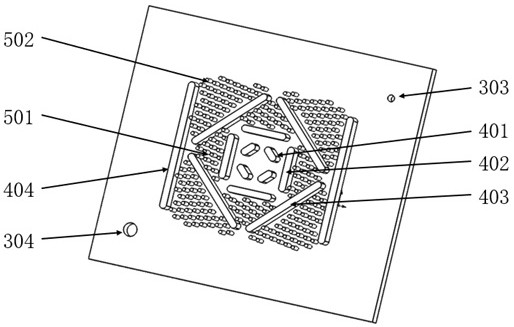

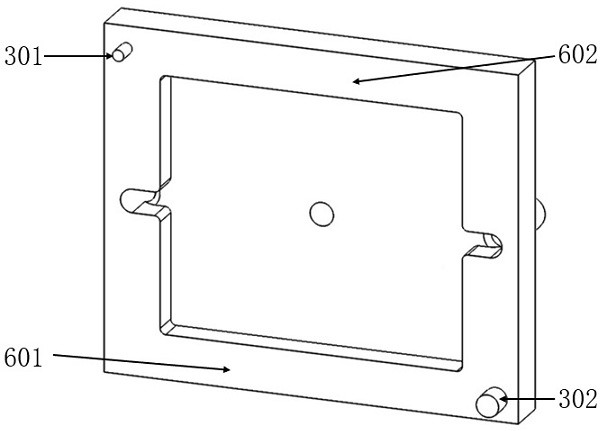

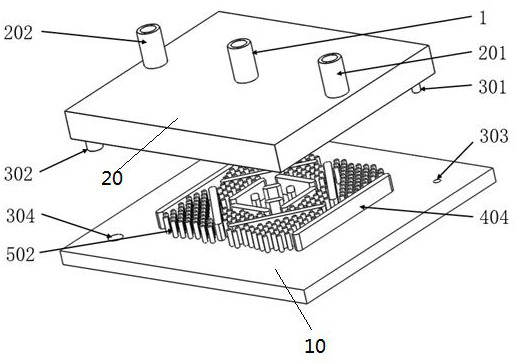

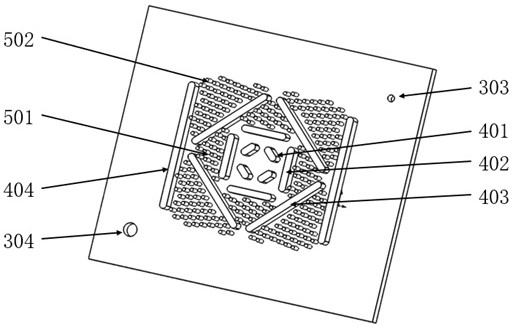

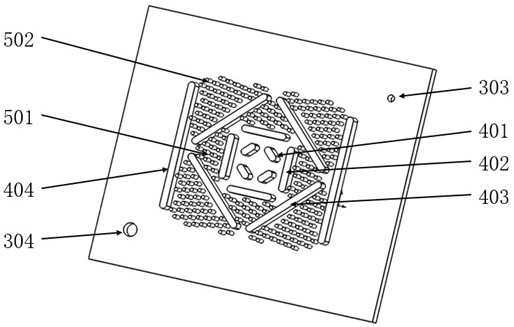

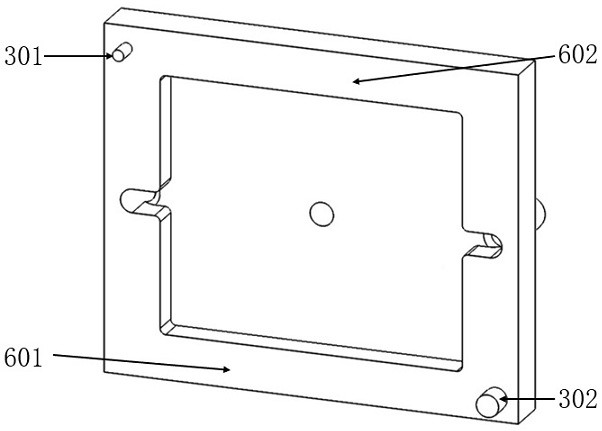

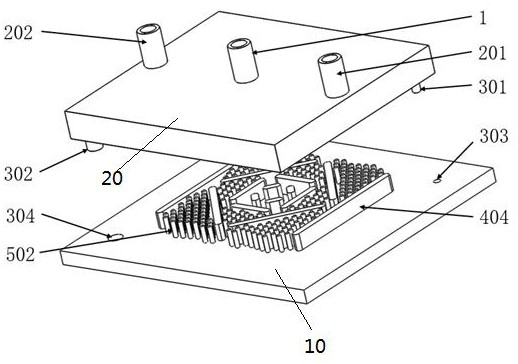

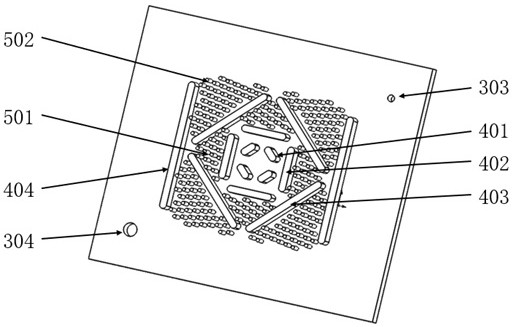

ActiveCN112097551BImprove the phenomenon that the temperature rises gradually along the flow directionImprove temperature uniformityHeat exchanger casingsLaminated elementsCooling fluidSquare cavity

The invention provides a liquid-cooled plate heat exchanger with multi-outlet distribution, including a bottom plate and a cover plate, the bottom plate and the cover plate are square structures, the cover plate and the bottom plate are assembled together to form a square cavity, and the cooling liquid flows in the cavity , it is characterized in that the heat exchanger includes a liquid inlet and a liquid outlet arranged on the cover plate, the liquid inlet is set at the center of the cover plate, and the liquid outlets are set four, which are respectively arranged on the four tops of the cover plate corner position. In the present invention, through the above structure, the cold liquid flows in from the central area of the cover plate. When the cold liquid just enters the heat exchanger, the temperature is still low, the temperature difference with the heat source is large, the heat exchange capacity is strong, and the temperature of the heat source area can be controlled more effectively, so that The uniform outlet distribution can make the liquid distribution more uniform and the heat exchange effect better.

Owner:CHINA NORTH VEHICLE RES INST

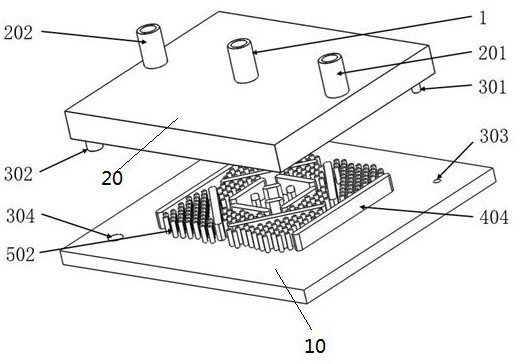

Multi-outlet distributed liquid cooling plate heat exchanger

ActiveCN112097551AImprove temperature uniformityImprove heat transfer efficiencyHeat exchanger casingsLaminated elementsEngineeringCooling fluid

The invention provides a multi-outlet distributed liquid cooling plate heat exchanger. The multi-outlet distributed liquid cooling plate heat exchanger comprises a bottom plate and a cover plate, thebottom plate and the cover plate are of square structures, the cover plate and the bottom plate are assembled together to form a square cavity, and cooling liquid flows in the cavity. The multi-outletdistributed liquid cooling plate heat exchanger is characterized by comprising a liquid inlet and liquid outlets, wherein the liquid inlet and the liquid outlets are formed in the cover plate, the liquid inlet is formed in the center position of the cover plate, and the four liquid outlets are correspondingly formed in the four vertex angles of the cover plate. According to the multi-outlet distributed liquid cooling plate heat exchanger, the cold liquid flows in from the center area of the cover plate, when the cold liquid just enters the heat exchanger, the temperature is low, the temperature difference between the cold liquid and a heat source is large, the heat exchange capacity is high, the temperature of the heat source area can be more effectively controlled, so that outlets are evenly distributed, liquid distribution can be more even, and the heat exchange effect is better.

Owner:CHINA NORTH VEHICLE RES INST

A heat storage heat exchanger and fresh air system

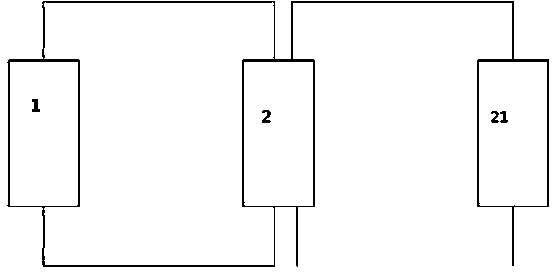

ActiveCN111174618BImprove the effect of heat storage and heat exchangeTemperature controlSolar heating energyMechanical apparatusFresh airEngineering

The invention provides a regenerative heat exchanger and a fresh air system. The regenerative heat exchanger comprises a heat source inlet, a heat source outlet, a cold source inlet, a cold source outlet and a shell, a plurality of heat storage blocks are arranged in the shell of the heat exchanger, the multiple heat storage blocks are stacked together, a first hole and a second hole are formed ineach heat storage block and do not communicate with each other, the first holes of the multiple heat storage blocks form a communicating channel, the channel formed by the first holes is used for circulating a heat source, and the second holes form a communicating channel to circulate a cold source; and the heat source enters from the heat source inlet, passes through the first holes and then isdischarged from the heat source outlet, and the cold source enters from the cold source inlet, passes through the second holes and then is discharged from the cold source outlet. According to the novel regenerative heat exchanger, independent heat storage and heat exchanging can be conducted through the heat storage blocks, heat-exchanging pipes are omitted, and the heat-storage and heat-exchanging effects can be further improved.

Owner:青岛建设集团股份有限公司 +1

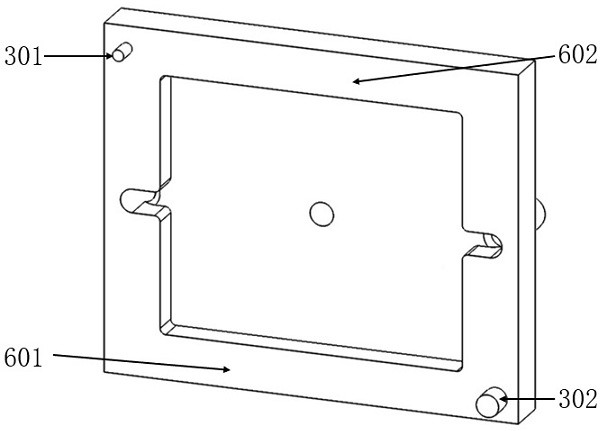

A water-cooled tube-sheet heat exchanger

ActiveCN110779373BTemperature controlImprove cooling effectIndirect heat exchangersPlate heat exchangerEngineering

The invention provides a water-cooling tube plate type heat exchanger which comprises a base plate and a cover plate. The cover plate and the base plate are assembled together to form a fluid space. Abaffle plate and a cylindrical fin are arranged on the base plate. The baffle plate comprises a first baffle plate located at the center of the base plate, a second baffle plate encircling the outerside of the first baffle plate and a third baffle plate encircling the outer side of the second baffle plate. The heat exchanger comprises a fluid inlet and fluid outlets formed in the cover plate. Acold fluid inlet is formed in the center of a first square, and the two fluid outlets are separately formed in outer positions of parallel lines formed by two fourth baffle plates. The invention aimsto provide a center diffusing type water cooling plate. A refrigerant inlet / outlet mode of a common water cooling plate is changed by the water cooling plate, the flow equalizing property of a refrigerant in the cold plate is improved by additionally arranging the baffle plate, and the heat-dissipating characteristic of the water cooling plate is improved by arranging column ribs.

Owner:SHANDONG UNIV

A water-cooled tube-sheet heat exchanger with variable spacing between cylindrical fins

ActiveCN110779372BAvoid damageFluid flow rate is stableIndirect heat exchangersPlate heat exchangerEngineering

The invention provides a water-cooled tube-sheet heat exchanger with variable spacing between cylindrical fins, which includes a base plate and a cover plate, the cover plate and the base plate are assembled together to form a fluid space, and a baffle plate and cylindrical fins are arranged on the base plate, so that The baffle includes a first baffle located at the center of the substrate, a second baffle surrounding the first baffle, and a third baffle surrounding the second baffle; between the second baffle and the third baffle Cylindrical fins are arranged between them, outward from the center of the substrate, the farther away from the center of the substrate, the farther the distance between adjacent cylindrical fins is. The purpose of the present invention is to keep the fluid flow rate relatively stable by setting the distance between adjacent cylindrical fins so that the overall heat transfer can be relatively uniform, and avoid local uneven heating, causing local premature damage .

Owner:SHANDONG UNIV

A water-cooled plate heat exchanger that distributes flow according to wall temperature

ActiveCN111238264BUniform temperatureUniform fluidHeat exchanger casingsLaminated elementsPlate heat exchangerAutomatic control

Owner:SHANDONG UNIV

A circular structural plate heat exchanger with comparative control of adjacent temperatures

ActiveCN111336844BAffect operationMeet heat transfer needsHeat exchanger casingsHeat transfer modificationData connectionAutomatic control

The invention provides a circular structure plate heat exchanger with adjacent temperature comparatively controlling the flow rate, including a base plate and a cover plate, the base plate and the cover plate are of circular structure, the cover plate and the base plate are assembled together to form a circular cavity, and the cavity The cavity is used for cooling fluid to flow, the center of the cover plate is provided with an inlet, and the outer wall of the base plate is provided with a temperature sensor, the temperature sensor is connected with the controller data, and the controller automatically controls the fluid flow of the inlet according to the data of the temperature sensor; The controller extracts the temperature data according to the time sequence, and obtains the temperature difference by comparing the temperature data of adjacent time periods, and the controller automatically controls the fluid flow at the inlet according to the temperature difference. The present invention avoids too much or too little heat exchanging fluid, resulting in failure to conduct heat exchange and heat dissipation in time, and avoids the temperature of the heat source being too high or too low, thereby affecting the operation of the heat source.

Owner:SHANDONG UNIV

A solar energy system, heating and ventilation system and its building roof

ActiveCN111306812BReduce flow dead zoneImprove temperature uniformitySolar heating energyRoof covering using slabs/sheetsThermodynamicsHeat flow

The invention provides a solar system, a heating and ventilating system and a building roof with the solar system. The solar system comprises a collector. The collector comprises heat collecting pipesand a reflecting mirror. The heat collecting pipes are flat pipes. The lower flat surfaces of the flat pipes are opposite to the reflecting surface of the reflecting mirror. Each flat pipe comprise abottom plate on the lower side and an upper cover on the upper side, wherein the upper cover and the bottom plate are assembled together to form a cavity of the flat pipe, and fluid flows in the cavity. Each bottom plate comprises a plurality of heat exchange area. Each heat exchange area comprises vertical plates and column ribs. The novel solar system is developed, and a flow guide structure isarranged in a cold plate of each heat exchange area, so that a refrigerant flowing dead area is effectively reduced, and the thermal homogeneity of a hot flow surface is further improved; and by means of the column ribs, the disturbance to the flow field is enhanced, the heat exchange area is expanded, and heat exchange can be easily reinforced.

Owner:青岛建设集团股份有限公司 +1

A water-cooled plate heat exchanger with uniform heat exchange

ActiveCN111156840BUniform temperatureTemperature controlHeat exchanger casingsLaminated elementsData connectionPlate heat exchanger

The invention provides a water-cooled plate heat exchanger with a uniform heat exchange effect. A second valve and a third valve are arranged on pipelines of a first outlet and a second outlet correspondingly, the second valve and the third valve are in data connection with a controller, the controller controls the opening degrees of the second valve and the third valve, and therefore the flow offluid of the two outlets is controlled. By adjusting the flow of the fluid of the outlets, the heat exchange amount participating in the fluid on the two sides is adjusted, it is guaranteed that the temperatures on the two sides are kept uniform, and the situation that as the local temperature is too high, a heat source is not subjected to heat exchange in time is avoided.

Owner:SHANDONG UNIV

A water-cooled plate heat exchanger with pulsating vibration

ActiveCN111238265BImprove heat transfer performanceGood descaling effectHeat exchanger casingsLaminated elementsPlate heat exchangerEnhanced heat transfer

The invention provides a water-cooled plate-type heat exchanger with pulsating vibration. The water-cooled plate-type heat exchanger includes a base plate, a cover plate, a fluid inlet and fluid outlets. Each fluid outlet includes a first outlet and a second outlet. The cover plate and the base plate are assembled together to form a fluid space. The base plate is provided with a baffle and a cylindrical rib piece, and the fluid inlet is located in the middle position of the two fluid outlets. The water-cooled plate-type heat exchanger is characterized in that the cylindrical rib piece is of anelastic structure, a pulsation generating device is arranged on an inlet pipeline, and fluid entering the plate-type heat exchanger is enabled to be pulsating flow through the pulsation generating device. According to the water-cooled plate-type heat exchanger, the pulsation generating device is arranged on the inlet pipeline, and the fluid entering the plate-type heat exchanger is enabled to bethe pulsating flow through the pulsation generating device, so that the movement of the cylindrical rib piece as an elastic part is continuously promoted, and thus, heat transfer is enhanced, and thedescaling effect is increased.

Owner:SHANDONG UNIV

Design method of a water-cooled tube-sheet heat exchanger

ActiveCN110793370BTemperature controlImprove cooling effectIndirect heat exchangersDesign optimisation/simulationPlate heat exchangerEngineering

Owner:SHANDONG UNIV

A heat storage heat exchanger and a fresh air system for controlling pm2.5

ActiveCN111536818BLow costImprove heat storage capacitySolar heating energyMechanical apparatusWind systemFresh air

The invention provides a heat exchanger for heat storage and a fresh air system for controlling PM2.5. The heat exchanger for heat storage comprises a heat source inlet, a heat source outlet, a cold source inlet, a cold source outlet and a shell, wherein a plurality of heat storage blocks are arranged in the heat exchanger shell and stacked together, a first hole is formed in each heat storage block, and a channel formed by each first hole is used for circulating the heat source; the heat source enters from the heat source inlet, passes through the first hole and then is discharged from the heat source outlet; and the heat storage capacity of a heat storage material is gradually reduced along a flowing direction of the heat source. The invention aims at providing a novel heat exchanger forheat storage and a fresh air system. The cost of heat storage material can be saved, and the heat storage effect can be improved.

Owner:青岛建设集团股份有限公司 +1

A plate heat exchanger with liquid cooling

ActiveCN112033189BImprove heat transfer efficiencyImprove heat transfer performanceHeat exchanger casingsLaminated elementsPlate heat exchangerCooling fluid

The invention provides a liquid-cooled plate heat exchanger, which includes a bottom plate and a cover plate, the bottom plate and the cover plate are square structures, the cover plate and the bottom plate are assembled together to form a square cavity, and the cooling liquid flows in the cavity, so A baffle and ribs are arranged on the bottom plate, and the baffle includes a first baffle located at the center of the bottom plate, a second baffle surrounded outside the first baffle, and a second baffle surrounded outside the second baffle. The third baffle plate and the fourth baffle plate surrounded by the third baffle plate, a plurality of ribs are arranged inside the first baffle plate; multiple ribs are arranged between the second baffle plate and the first baffle plate For the ribs, a plurality of ribs are arranged between the second baffle and the third baffle; and a plurality of ribs are arranged between the third baffle and the fourth baffle. The invention proposes a plate heat exchanger with a new structure, which can further improve the heat exchange efficiency and strengthen the heat transfer by arranging the cooperation between multi-layer fins and baffles.

Owner:CHINA NORTH VEHICLE RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com