Multi-outlet distributed liquid cooling plate heat exchanger

A heat exchanger and liquid cold plate technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problem of increased pressure drop, small heat dissipation improvement effect, and can not only consider the heat dissipation effect, etc. problem, to achieve the effect of large temperature difference, reduction of flow dead zone, and favorable heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present disclosure will be further described below in conjunction with the accompanying drawings and specific embodiments.

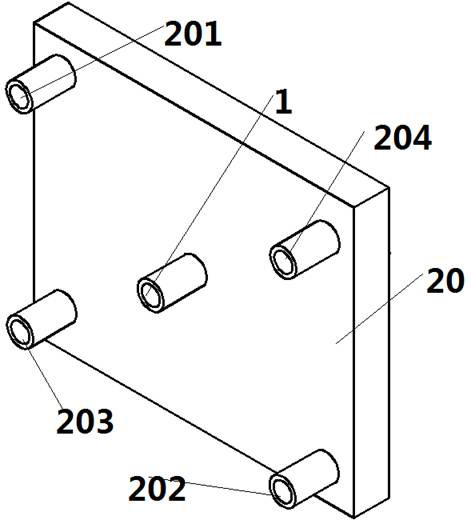

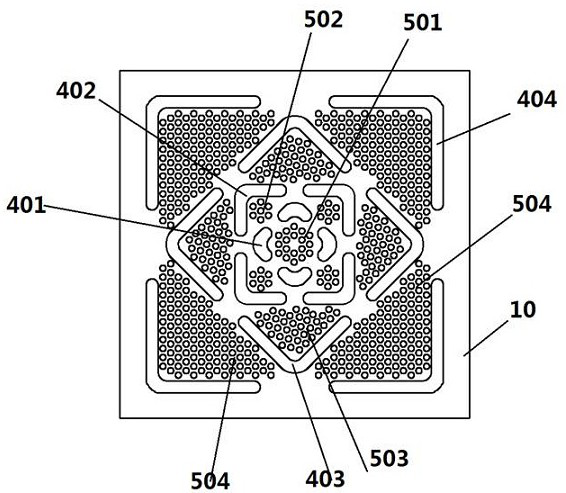

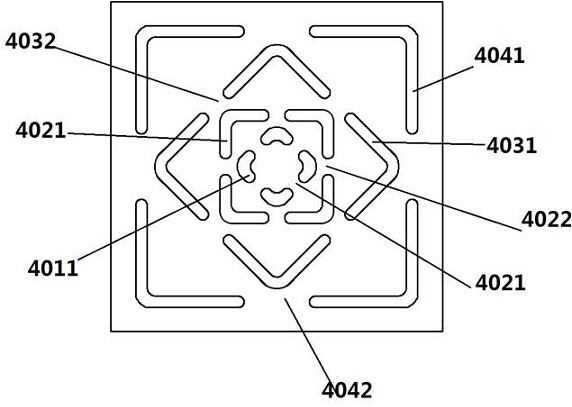

[0046] Such as Figure 1-4 A liquid-cooled plate heat exchanger with a square structure is shown, including a bottom plate 10 and a cover plate 20. The bottom plate 10 and the cover plate 20 are square structures, and the cover plate 20 and the bottom plate 10 are assembled together to form a square cavity. The cooling liquid (preferably water) flows in the cavity, and baffles 401-404 and ribs 501-504 are arranged on the bottom plate 10, and the baffles include the first baffle 401 located in the center of the bottom plate, surrounded by the second A second baffle 402 outside the first baffle 401, a third baffle 403 outside the second baffle 402, and a fourth baffle 404 outside the third baffle 403;

[0047] As preferred, such as Figure 1-3 As shown, the first baffle 401 includes four pieces, and each first baffle 401 includes two baffle wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com