Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Efficient backwash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

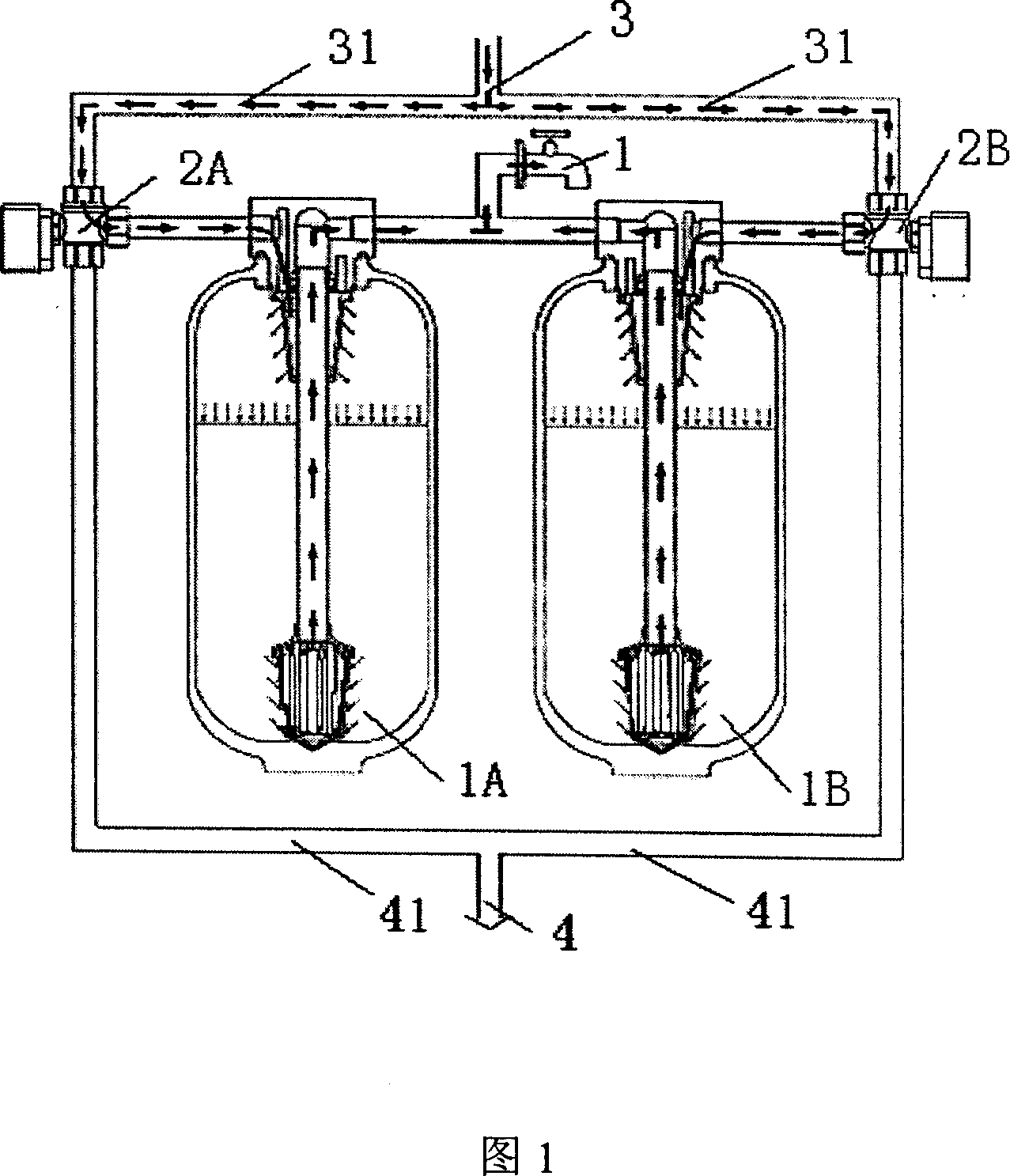

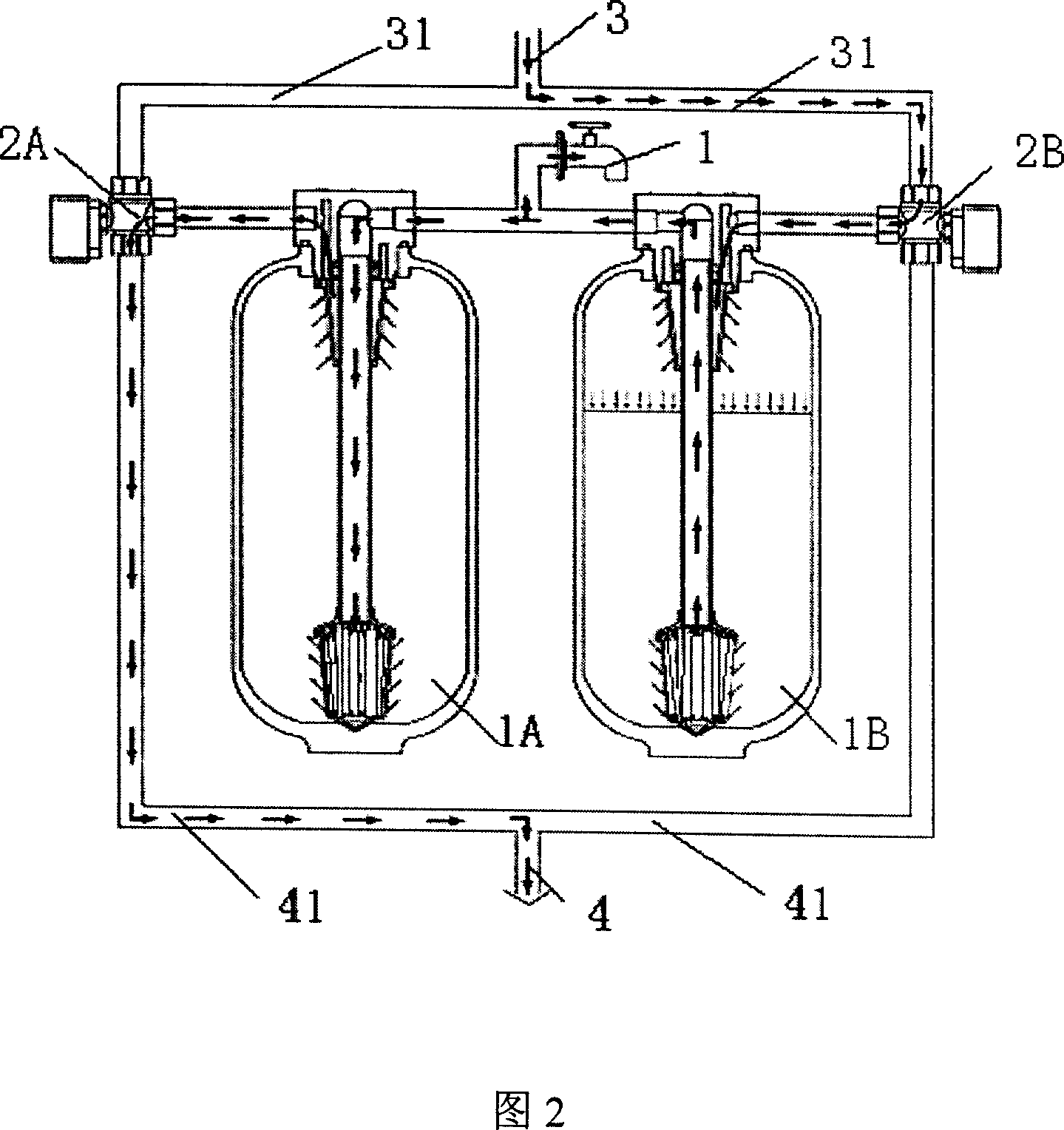

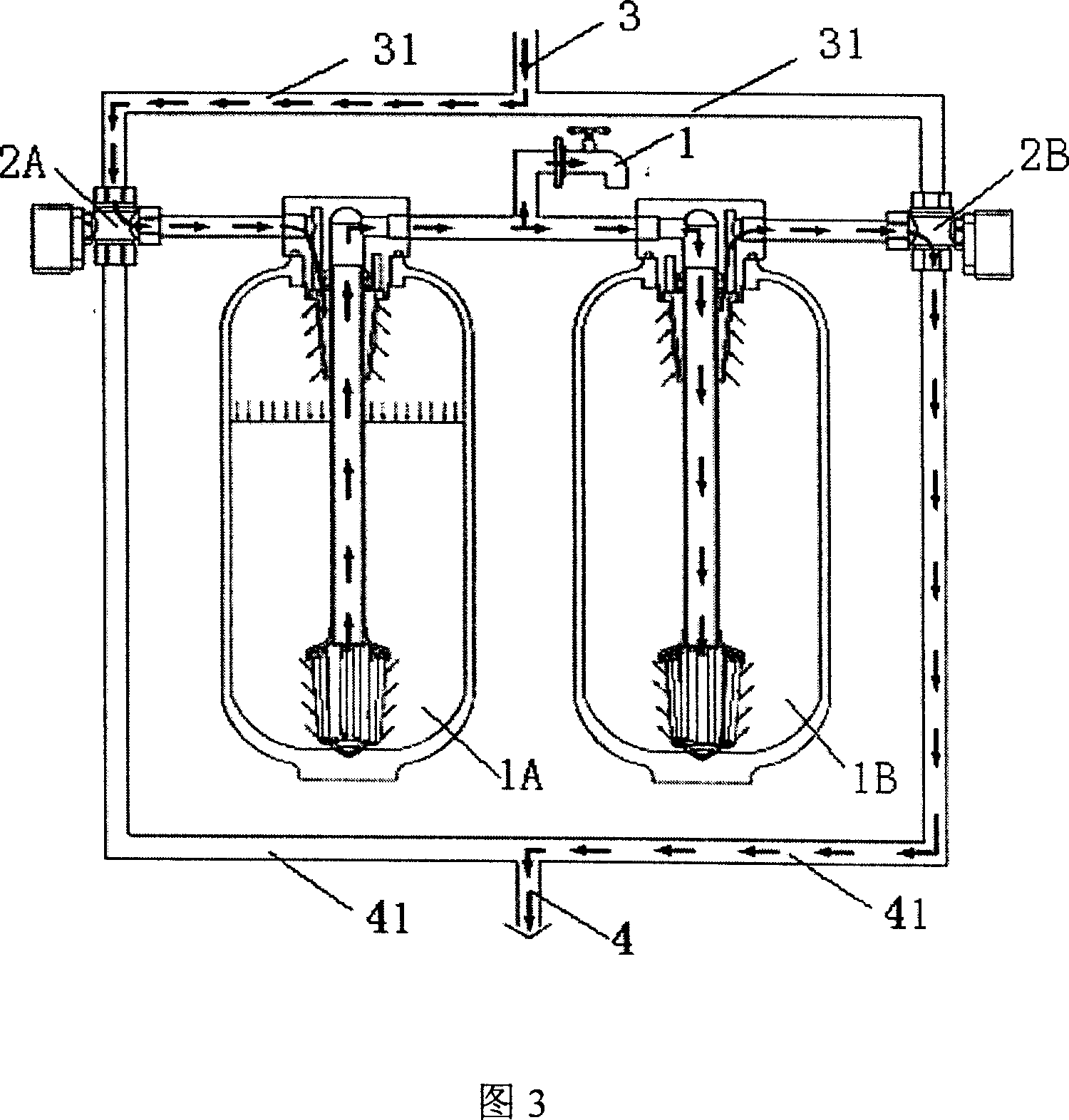

Water purifying appliance

InactiveCN101032673ARecovery responseRestore adsorption capacityWater/sewage treatmentFiltration circuitsWater qualityEnvironmental engineering

The water purifying machine includes at least two water purifying tanks connected in parallel and with parallel draining pipes connected to the water inlet pipes. It can provide purified water in 24 hr a day including the time during reverse rinsing, and has effective complete reverse rinsing to ensure high water quality, long filter material life and low use cost.

Owner:CANATURE HEALTH TECH GRP CO LTD

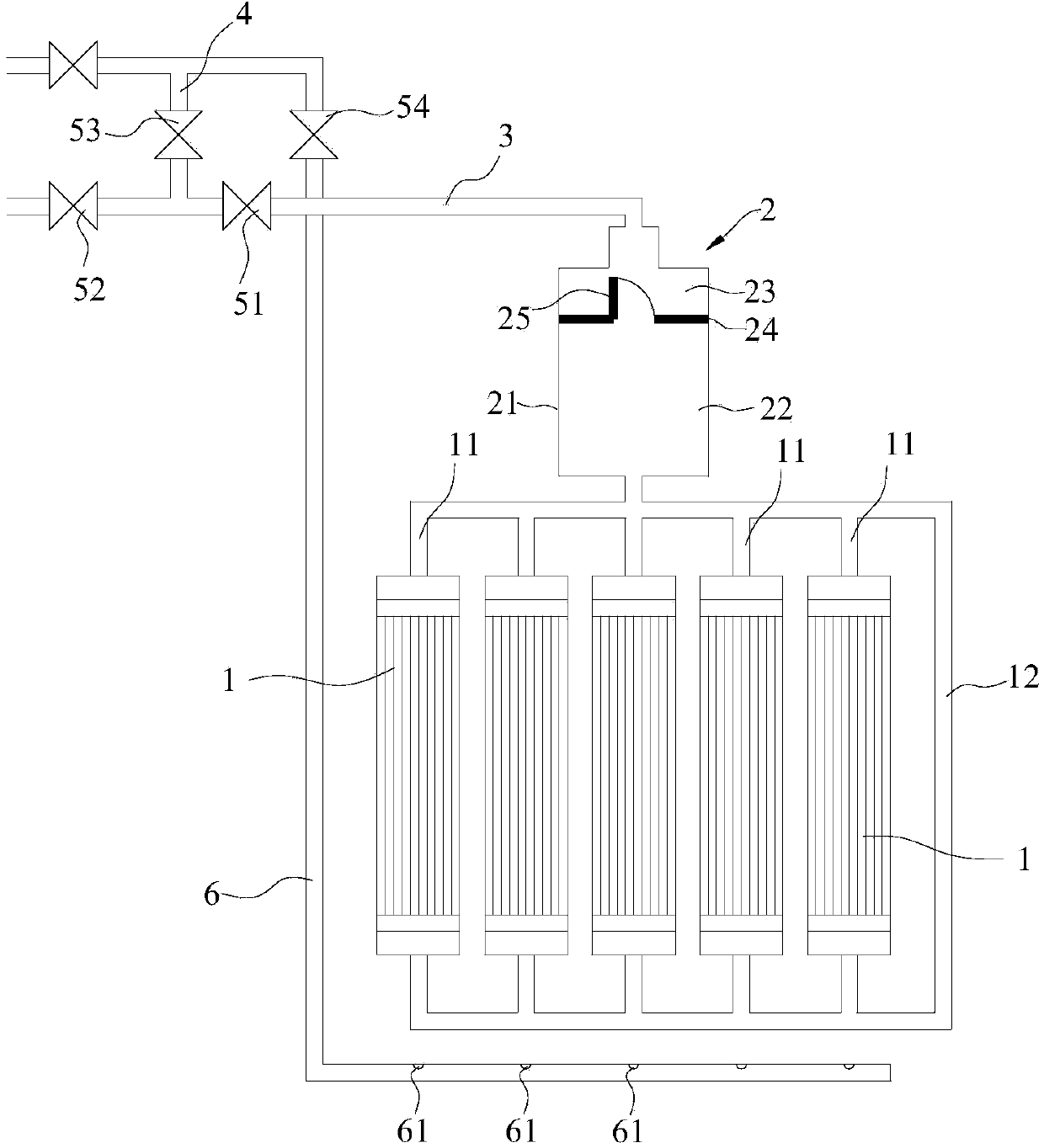

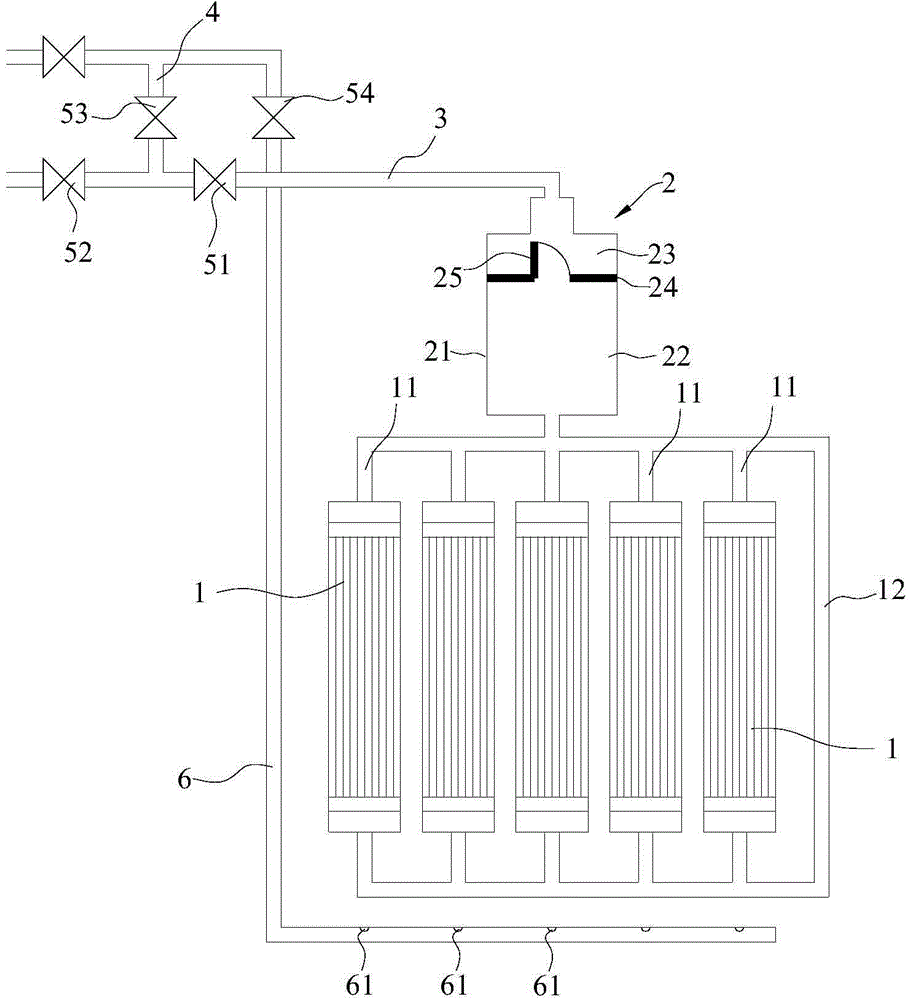

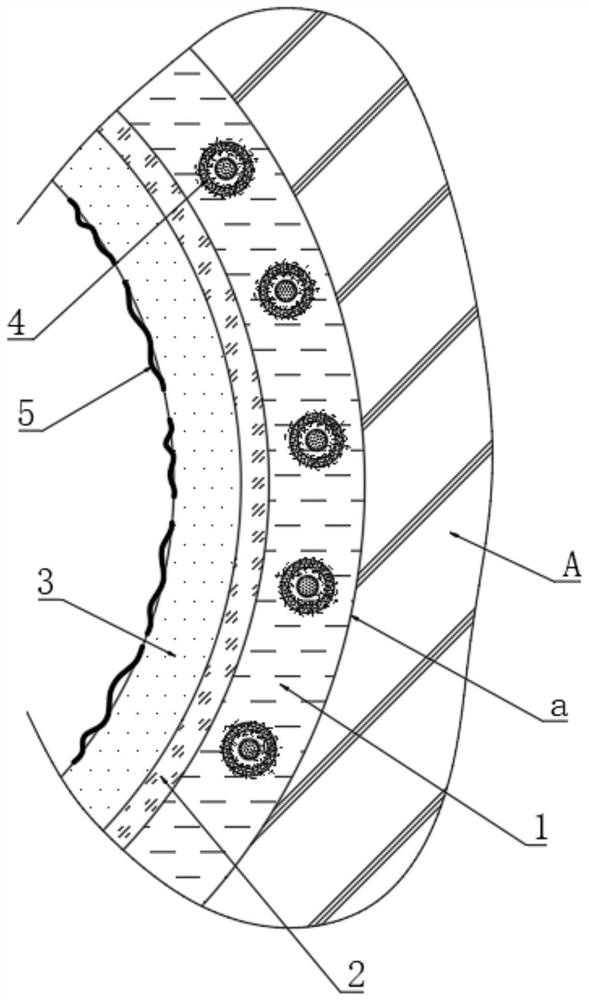

Membrane bioreactor

ActiveCN104192994AAct as backwash cleaningReduce engineering costsSustainable biological treatmentBiological water/sewage treatmentWater productionMembrane surface

The invention discloses a membrane bioreactor which comprises a membrane assembly and a gas-water separation device, wherein the membrane assembly can be arranged in a mud-water mixed solution; the membrane assembly comprises a filter membrane and a water production inner cavity which is formed by the filter membrane; the water production inner cavity is communicated with the gas-water separation device through a water production pipe; the gas-liquid separation device comprises a piston barrel and a piston which is arranged in the piston barrel and used for dividing the inner cavity of the piston barrel into a front cavity and a rear cavity; a check valve which is capable of communicating from the front cavity to the rear cavity is arranged on the piston; the water production pipe is communicated with the front cavity of the piston barrel; and a water outlet pipe which is externally connected with a water production pump and a gas supply pipe which is externally connected with a gas source are communicated with the rear cavity of the piston barrel. According to the membrane bioreactor, the gas-water separation device is arranged and the gas source is used as a power source of the backwashing, so that large-scale equipment such as a backwashing water pump is not used and thus the engineering cost and the water charge per ton are reduced. Practices prove that the rise of pressure is faster than that of the backwashing water pump, so that the membrane surface can be more effectively cleaned, the processing effect is good and the unit energy consumption is low.

Owner:CITIC ENVIROTECH GUANGZHOU CO LTD +1

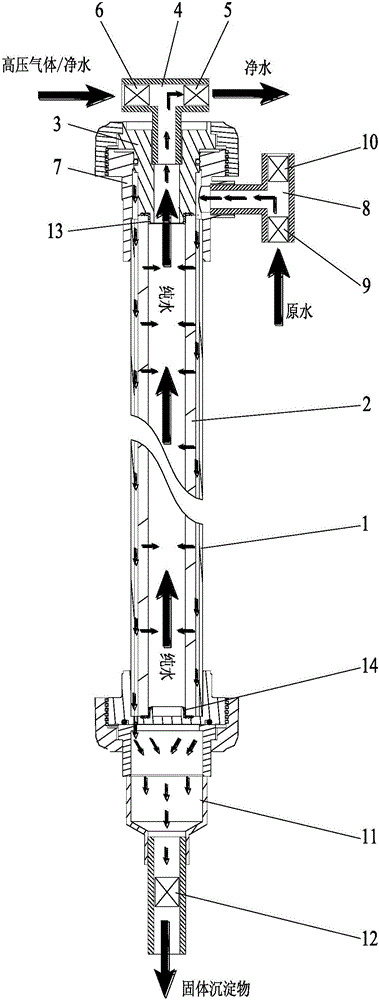

Solid-liquid separator structure with automatic backwash function

InactiveCN106422464AImprove efficiencyExtended service lifeStationary filtering element filtersSlagEngineering

The invention discloses a solid-liquid separator structure with an automatic backwash function. The solid-liquid separator structure comprises a pipe body and a filter element, wherein an annular cavity is formed between the outer wall of the filter element and the inner wall of the pipe body; a water outlet seat is connected to the upper end of the filter element; a three-way pipe A is connected to the upper end of the water outlet seat; an electromagnetic valve A is arranged on a second pipe mouth of the three-way pipe A; an electromagnetic valve B is arranged on a third pipe mouth of the three-way pipe A; in addition, the third pipe mouth of the three-way pipe A is connected with a high-pressure air pump or a high-pressure water pump; a water inlet seat is connected to the upper end of the pipe body; a three-way pipe B is connected onto a water inlet; a first pipe mouth of the three-way pipe B is communicated with the water inlet; an electromagnetic valve C is arranged on a second pipe mouth of the three-way pipe B; a pressure relay is arranged on a third pipe mouth of the three-way pipe B; a slag discharging component is connected to the lower end of the pipe body; a slag discharging cavity is formed inside the slag discharging component and is communicated with the annular cavity; a slag discharging outlet is formed in the bottom of the slag discharging cavity; an electromagnetic valve D is arranged at the slag discharging outlet. According to the solid-liquid separator structure disclosed by the invention, high-efficiency backwash can be realized, the service efficiency of the filter element is improved, and the service life of the filter element is prolonged.

Owner:FUJIAN SEEHI ENVIRONMENTAL PROTECTION TECH CO LTD

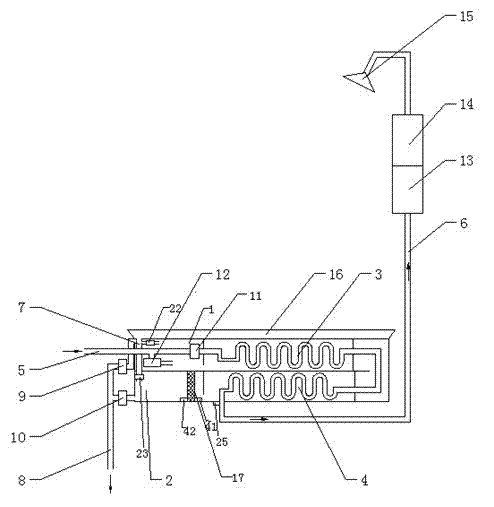

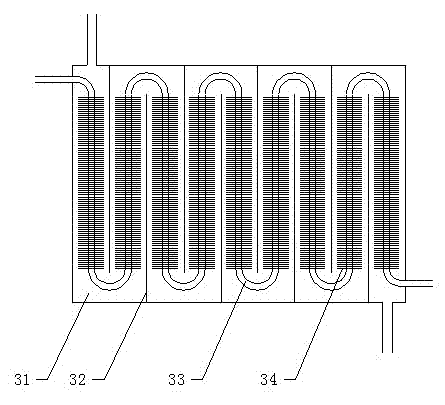

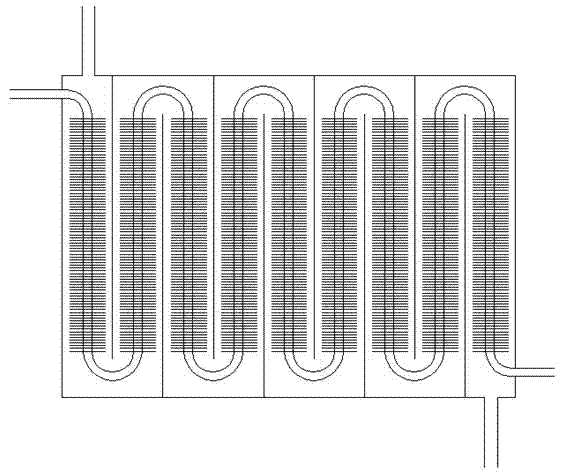

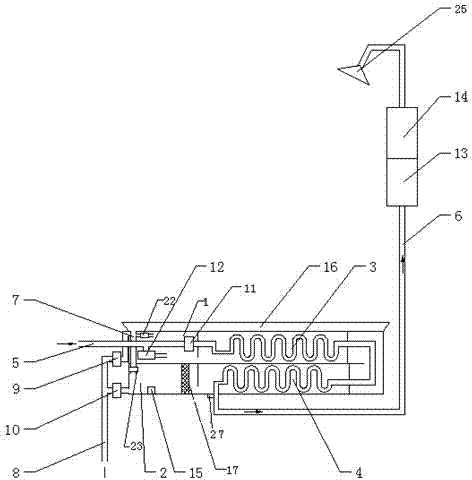

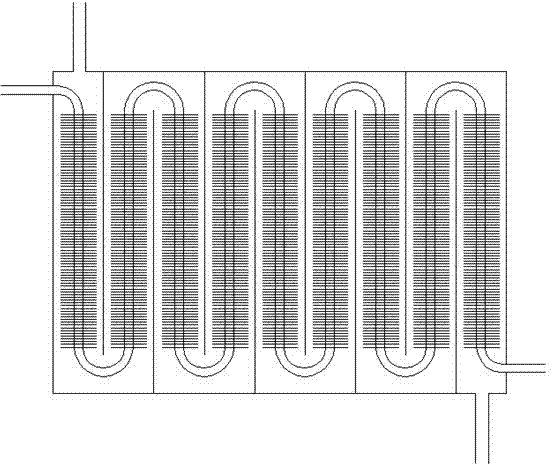

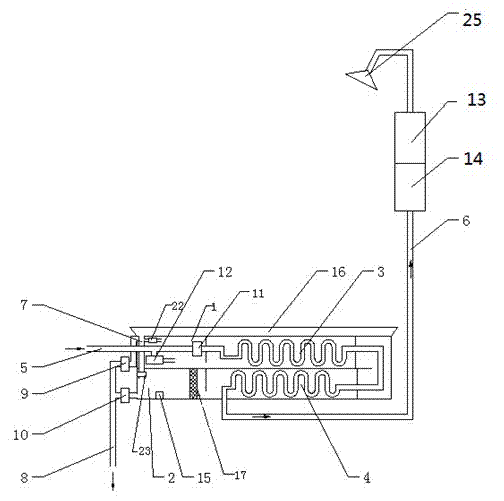

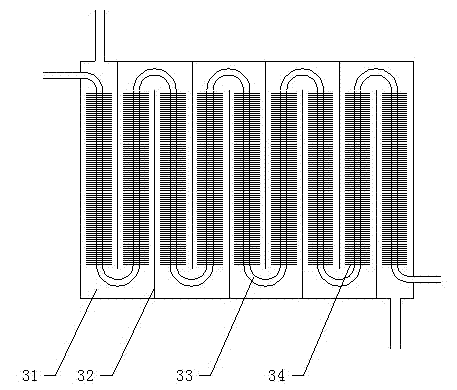

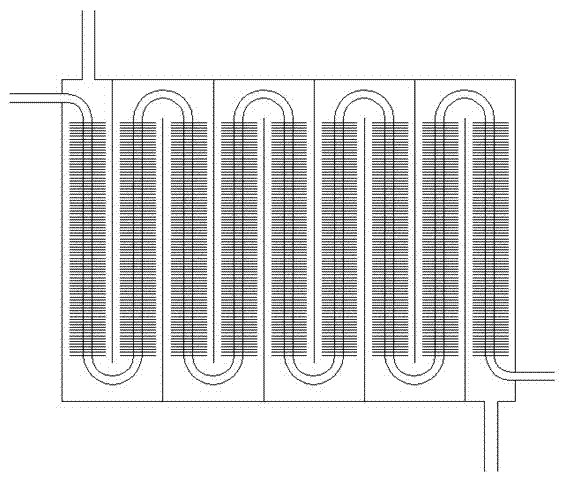

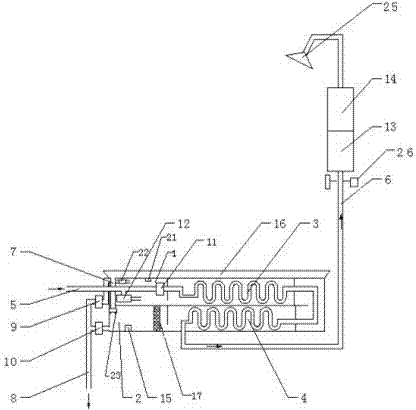

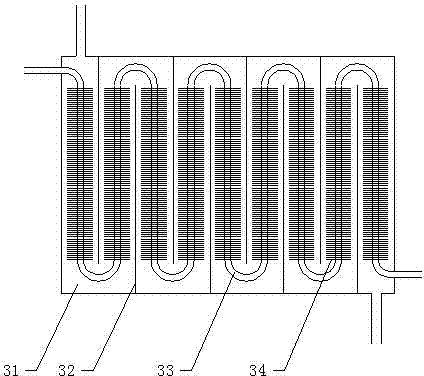

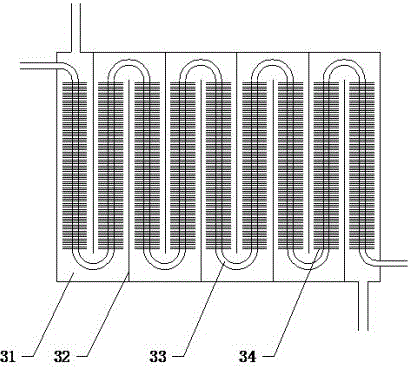

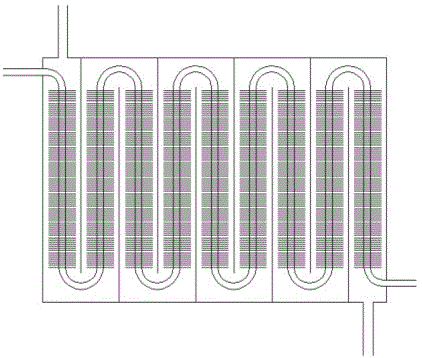

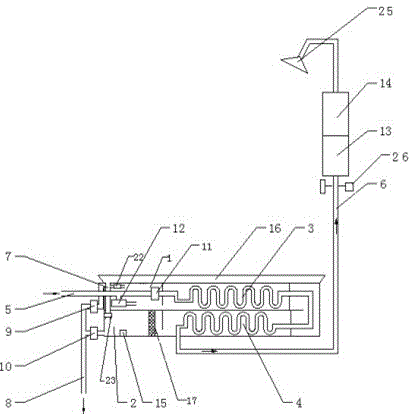

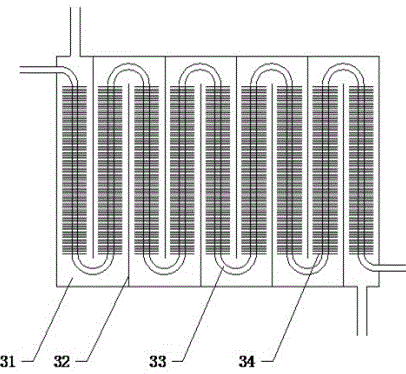

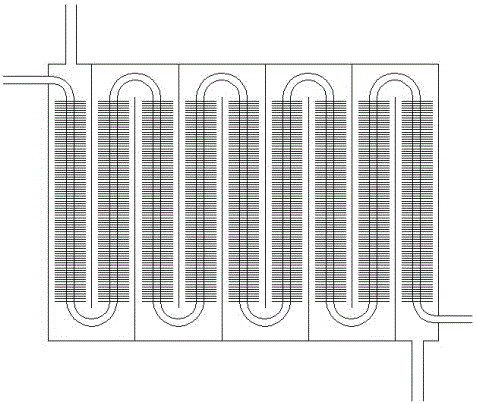

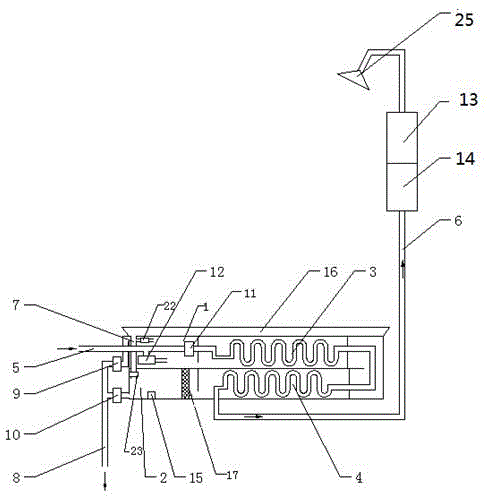

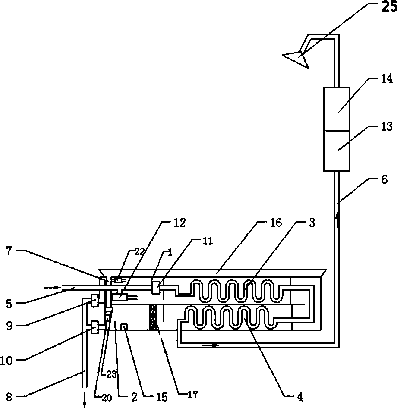

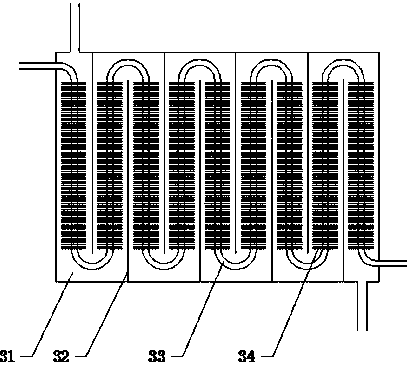

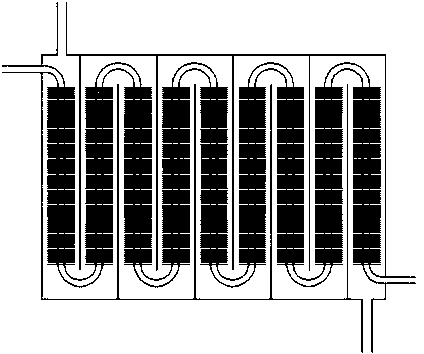

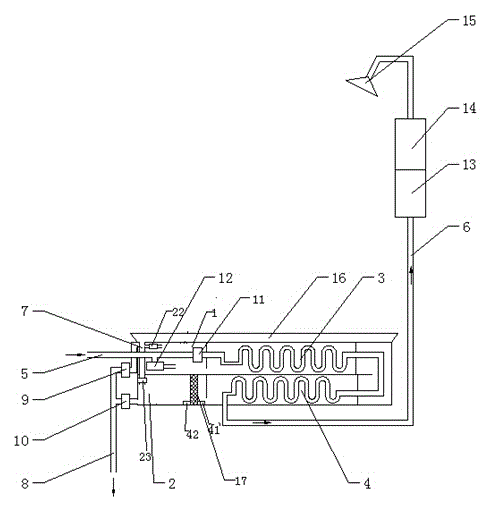

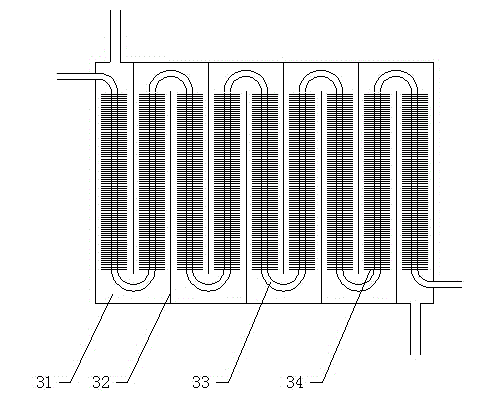

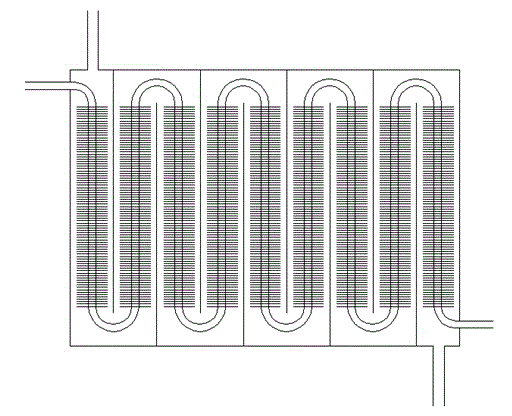

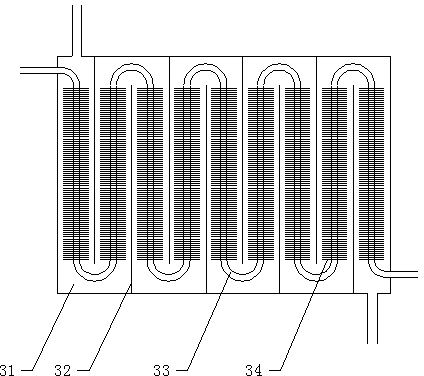

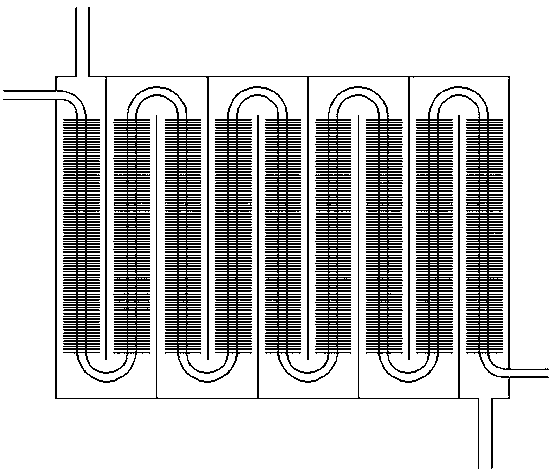

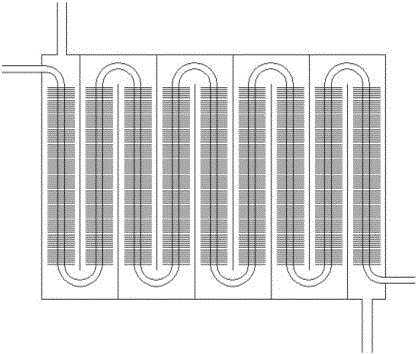

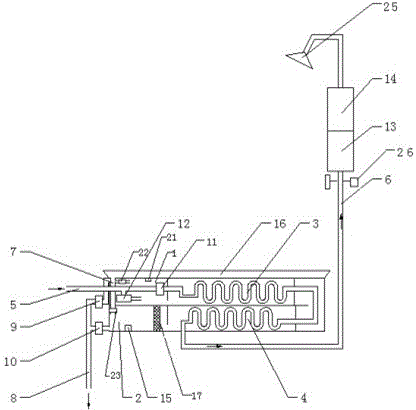

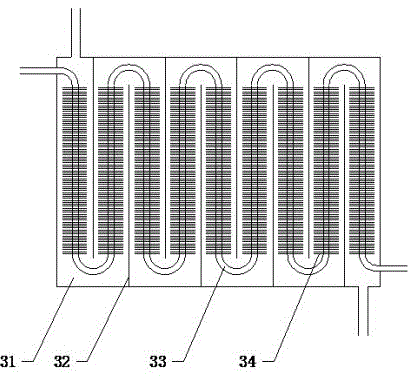

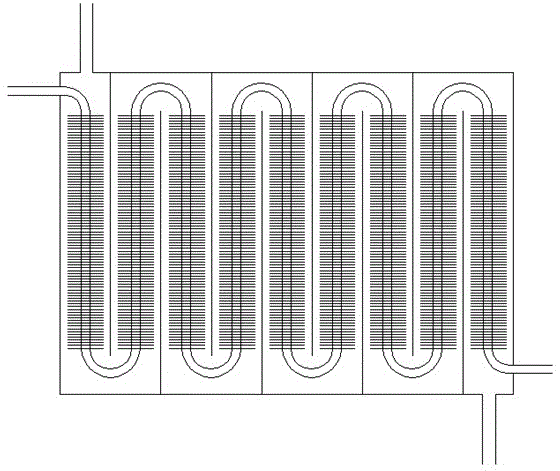

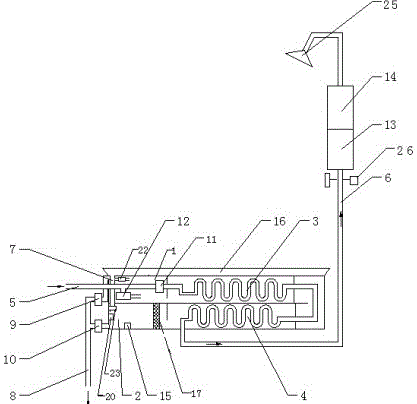

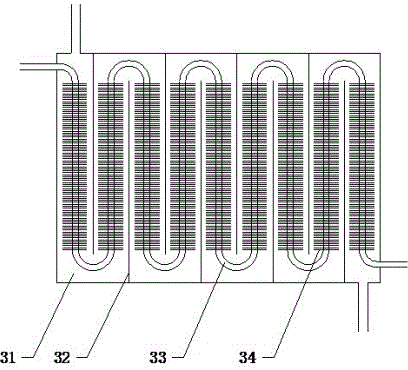

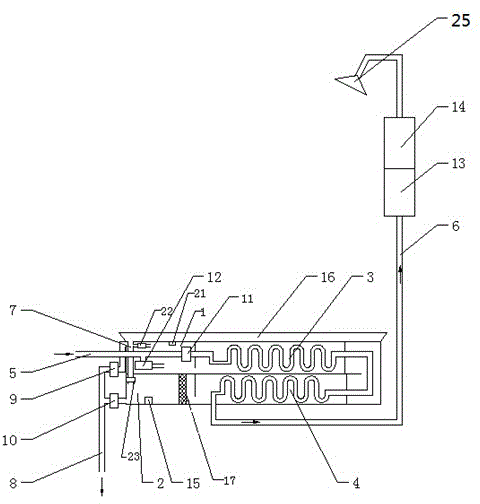

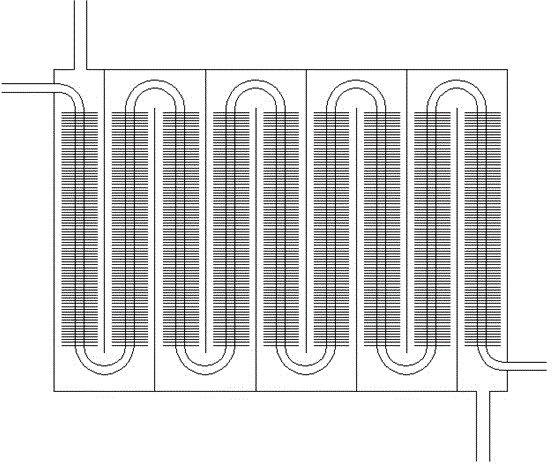

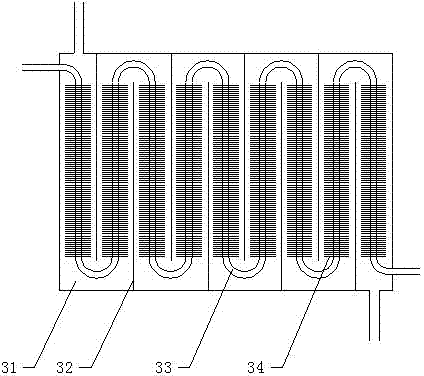

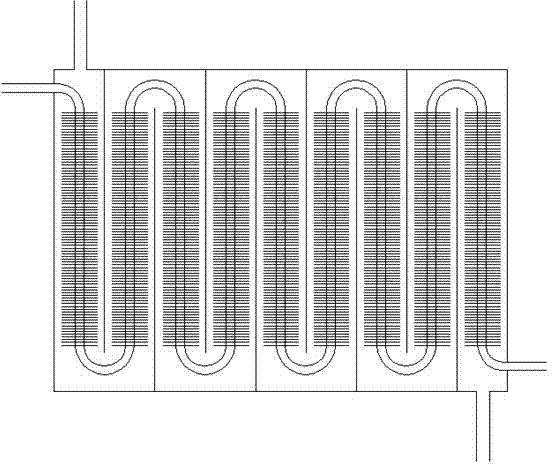

Backflushing type heat exchange system with water pressure and temperature detecting function

InactiveCN103528403AEasy to backwashEfficient backwashCorrosion preventionStationary tubular conduit assembliesWastewaterPore water pressure

The invention discloses a backflushing type heat exchange system with a water pressure and temperature detecting function. The backflushing type heat exchange system comprises a cold water inlet pipe (5), a hot water outlet pipe (6), a waste water inlet pipe (7), a waste water outlet pipe (8), a nozzle (15), an upper heat exchange trough (1) and a lower heat exchange trough (2). An upper heat exchange device (3) and a lower heat exchange device (4) are respectively arranged in the upper heat exchange trough (1) and the lower heat exchange trough (2), a detachable filter screen (17) is arranged in the lower heat exchange trough (2), a first pressure sensor (42) and a second pressure sensor (41) are arranged on two sides of the filter screen (17) and respectively connected with a controller (14), and the controller (14) comprises a comparing module (143) respectively connected with a setting module (144), the first pressure sensor (42), the second pressure sensor (41) and a temperature sensor (25). The backflushing type heat exchange system solves the technical problem that dirt is prone to accumulating in the heat exchangers and cannot be automatically cleaned.

Owner:许东雪 +2

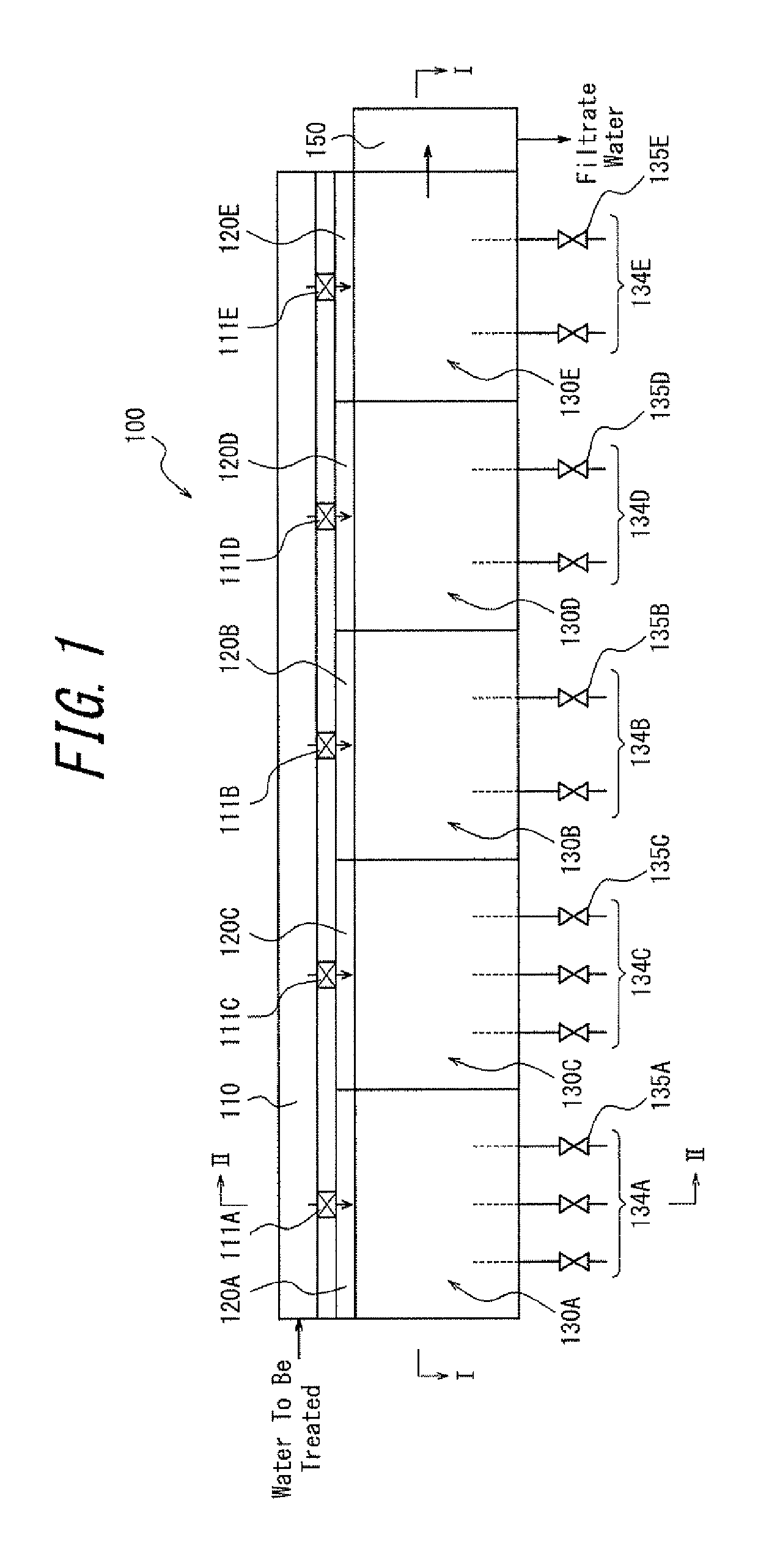

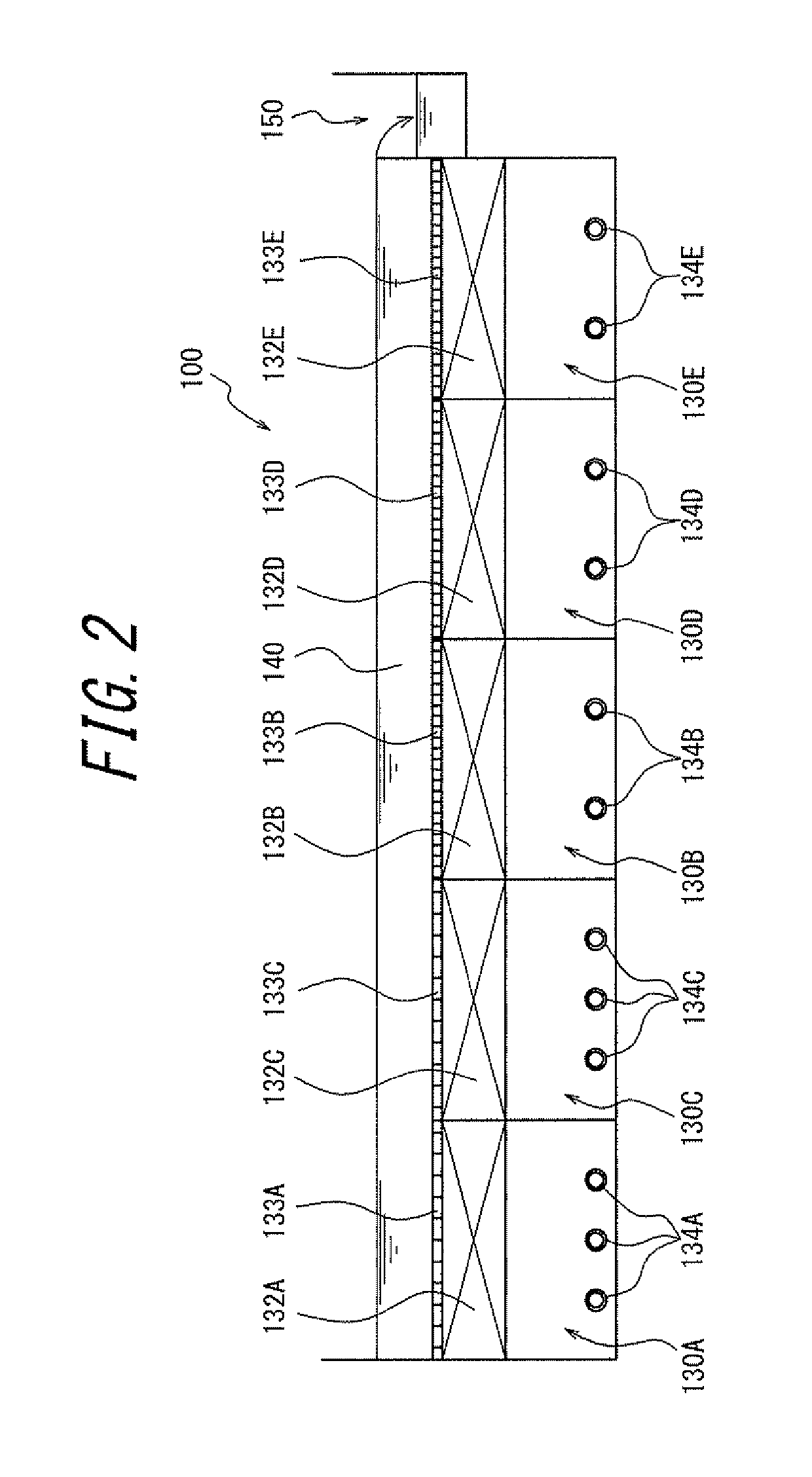

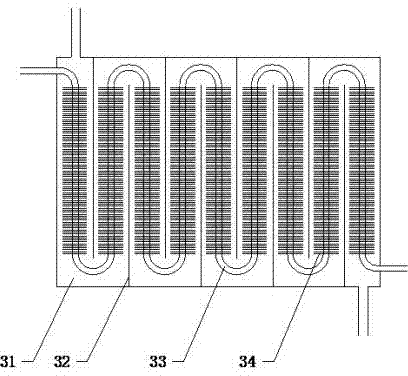

Floating filter media filtration system with backwash

ActiveUS10407317B2Efficient backwashLow costTreatment involving filtrationMultistage water/sewage treatmentFilter mediaFilter system

The filtration system of the present invention comprises first and second filtration tanks. The first filtration tank has a first floating filter media layer, a first upper screen with a first aperture ratio, a first inlet, a first backwash water supply source, and a first backwash water outlet means. The second filtration tank has a second floating filter media layer, a second upper screen with a second aperture ratio, a second inlet, an inflow blocking mechanism capable of blocking inflow of water to be treated through the second inlet, a second backwash water supply source, and a second backwash water outlet means. The first aperture ratio is smaller than the second aperture ratio.

Owner:METAWATER CO LTD

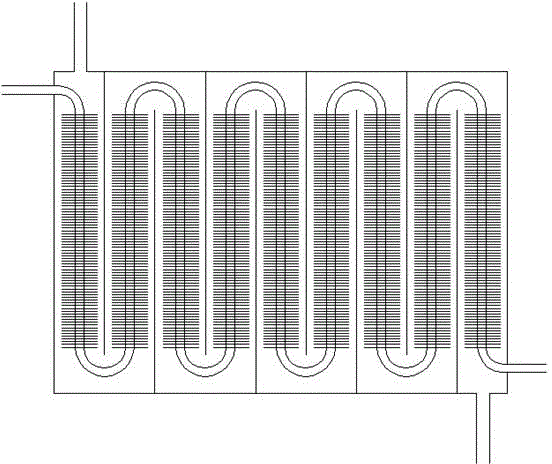

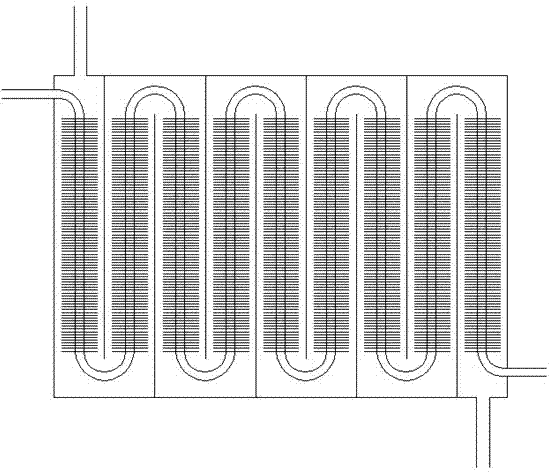

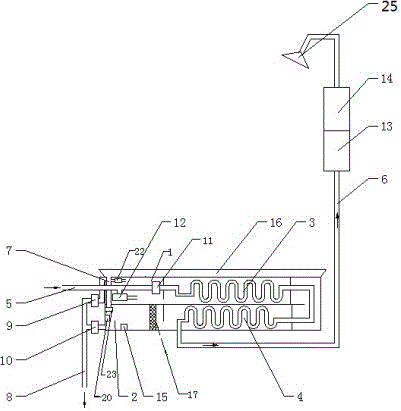

Backflushing type heat exchange system with water quality and temperature detecting function

ActiveCN103528401AEasy to backwashEfficient backwashCorrosion preventionStationary tubular conduit assembliesWastewaterWater quality

The invention discloses a backflushing type heat exchange system with a water quality and temperature detecting function. The backflushing type heat exchange system comprises a cold water inlet pipe (5), a hot water outlet pipe (6), a waste water inlet pipe (7), a waste water outlet pipe (8), a nozzle (25), an upper heat exchange trough (1) and a lower heat exchange trough (2). An upper heat exchanger (3) and a lower heat exchanger (4) are respectively arranged in the upper heat exchange trough (1) and the lower heat exchange trough 92). The hot water outlet pipe (6) is provided with a heater (13), a detector (15) is arranged in the lower heat exchange trough (2) and used for detecting water quality and is connected with a controller (14), and the controller (14) comprises a comparing module (143) respectively connected with a setting module (144), the detector (15) and a temperature sensor (27). The backflushing type heat exchange system solves the technical problem that dirt is prone to accumulating in the heat exchangers and cannot be automatically cleaned.

Owner:安徽宇测线缆质检技术有限公司

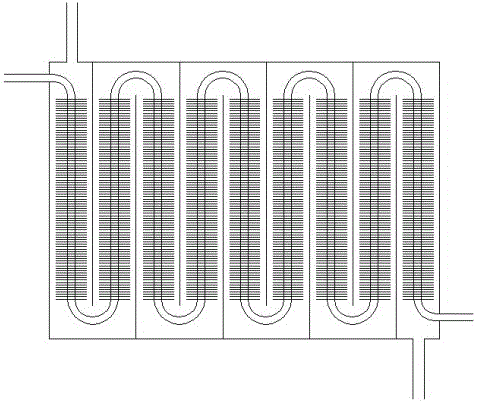

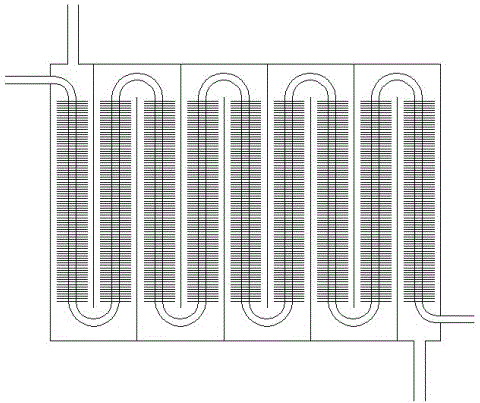

Back-flushable type heat exchange system having flow velocity and temperature detecting functions

ActiveCN103542530AEasy to backwashEfficient backwashFluid heatersFlush cleaningWater channelWastewater

The invention discloses a back-flushable type heat exchange system having flow velocity and temperature detecting functions. The back-flushable type heat exchange system comprises a cold water inlet pipe (5), a hot water outlet pipe (6), a waste water inlet pipe (7), a waste water outlet pipe (8), a spraying head (25), an upper heat exchange water channel (1) and a lower heat exchange water channel (2), wherein an upper heat exchange device (3) and a lower heat exchange device (4) are respectively arranged in the upper heat exchange water channel (1) and the lower heat exchange water channel (2). A heater (13) is further arranged on the hot water outlet pipe (6), and a detector (15) is arranged in the lower heat exchange water channel (2) and used for detecting flow velocity. The detector (15) is connected with a controller (14). The controller (14) comprises a comparison module (143) connected with a setting module (144), the detector (15) and a temperature sensor (27) respectively. The technical problem that stains easily accumulates inside the heat exchange devices and cannot be automatically cleaned is solved.

Owner:江阴戴勒姆动力设备有限公司

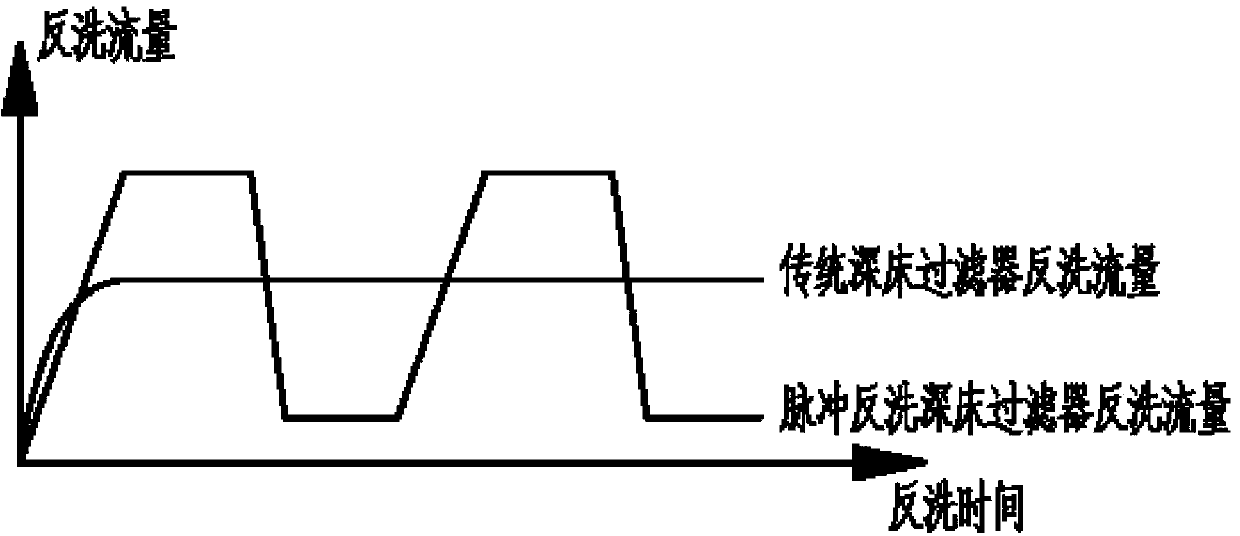

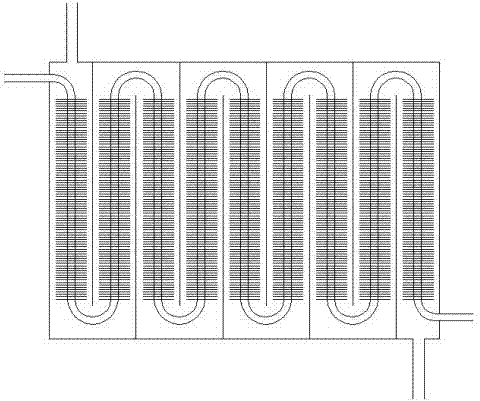

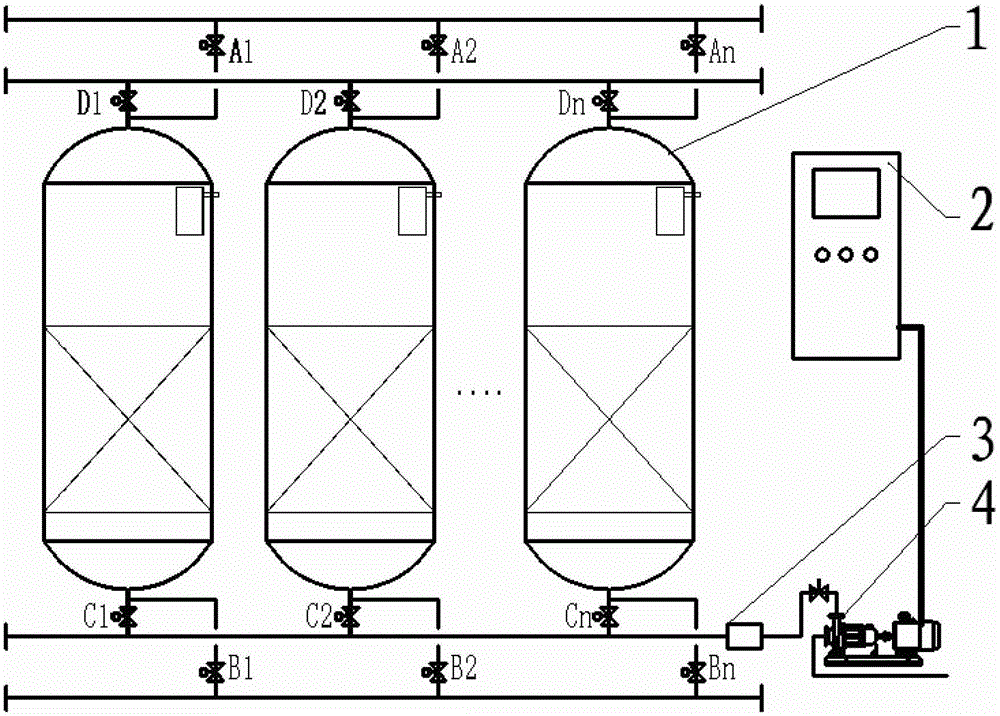

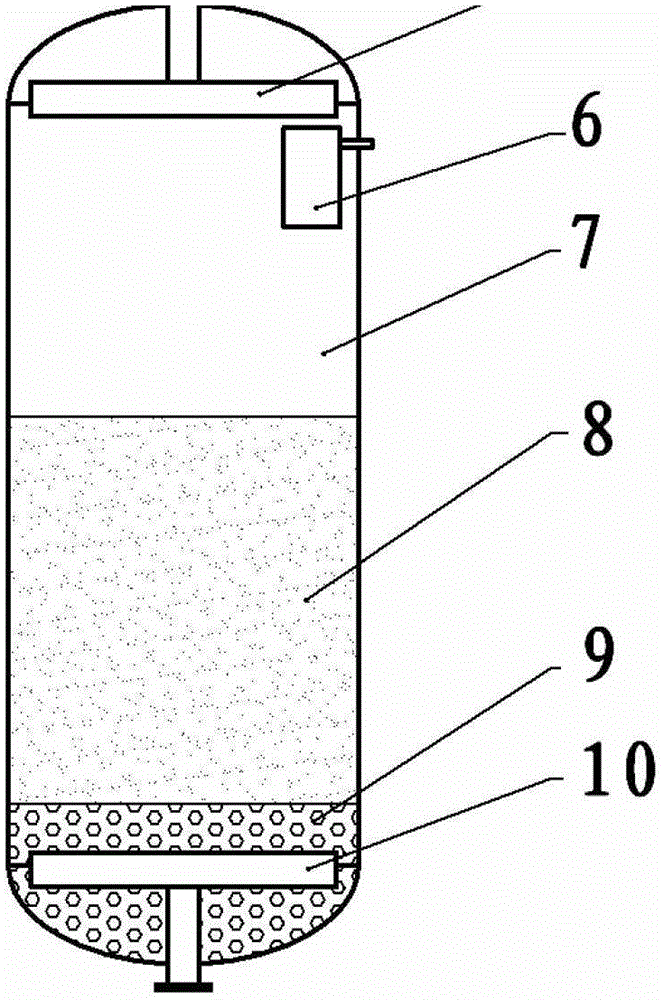

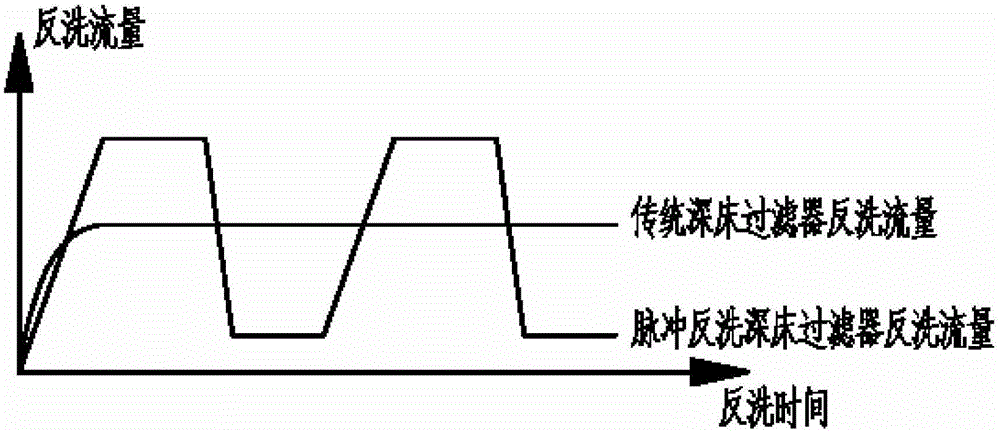

Pulse backwashing deep bed filter device and method

ActiveCN104208928AAlleviate the momentary shockEasy to desorbLoose filtering material filtersGravity filtersWater savingFrequency changer

The invention discloses a pulse backwashing deep bed filter device and a method, and belongs to the technical field of automatic control. A set of device may be provided with 1, 2.....n pulse backwashing deep bed filters; the pulse backwashing deep bed filter comprises a casing, a water collection mechanism arranged on the lower part of the casing and a connecting tube thereof, a water distributing mechanism arranged on the upper part of the casing and a connecting tube thereof, a filter material cushion layer arranged on the lower part of the casing, a filter material arranged in the middle part of the casing, and a filter material height detection device arranged on the upper part of the casing; a backwashing pump is a centrifugal pump, the rotating speed of an arranged motor can be regulated in variable frequency; a flow detection device is arranged on a main backwashing pipeline of a backwashing pump outlet; a control cabinet is provided with a PLC (programmable logic controller), and also provided with a frequency converter for regulating the rotating speed of the backwashing pump; the flow detection device and the filter material height detection device are provided with detection signal output ends which are connected with signal acquisition ends of the PLC. The effect of the pulse backwashing deep bed filter device is that: water-saving high-efficiency cleaning of a filtering layer can be performed by used of backwash water producing flow fluctuation.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

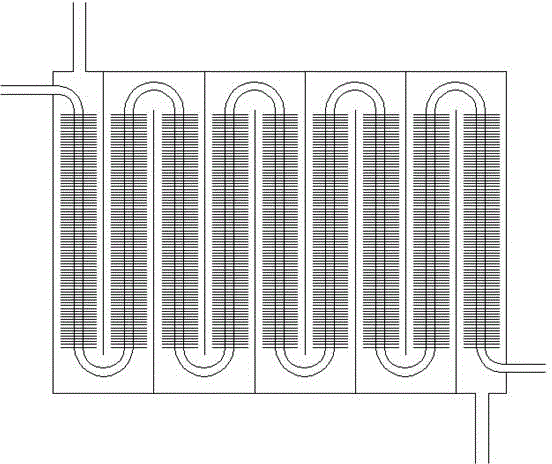

Heat exchange system with water quality detecting function

InactiveCN103528426AEasy to backwashEfficient backwashFlush cleaningHeat exchange apparatusWater qualityWastewater

The invention discloses a heat exchange system with a water quality detecting function. The heat exchange system comprises a cold water inlet pipe (5), a hot water outlet pipe (6), a waste water inlet pipe (7), a waste water outlet pipe (8), a nozzle (25), an upper heat exchange trough (1) and a lower heat exchange trough (2). An upper heat exchanger (3) and a lower heat exchanger (4) are respectively arranged in the upper heat exchange trough (1) and the lower heat exchange trough (2). The hot water outlet pipe (6) is provided with a heater (13), and a detector (15) is arranged in the lower heat exchange trough (2) and used for detecting water quality. A collector plate (16) is arranged on the upper portion of the upper heat exchange trough (1), and a detachable filter screen (17) is arranged in the lower heat exchange trough (2). The heat exchange system solves the technical problem that dirt is prone to accumulating in the heat exchangers and cannot be automatically cleaned.

Owner:江阴市赛英电子股份有限公司

A membrane bioreactor

ActiveCN104192994BAct as backwash cleaningReduce engineering costsSustainable biological treatmentBiological water/sewage treatmentWater productionMembrane surface

The invention discloses a membrane bioreactor which comprises a membrane assembly and a gas-water separation device, wherein the membrane assembly can be arranged in a mud-water mixed solution; the membrane assembly comprises a filter membrane and a water production inner cavity which is formed by the filter membrane; the water production inner cavity is communicated with the gas-water separation device through a water production pipe; the gas-liquid separation device comprises a piston barrel and a piston which is arranged in the piston barrel and used for dividing the inner cavity of the piston barrel into a front cavity and a rear cavity; a check valve which is capable of communicating from the front cavity to the rear cavity is arranged on the piston; the water production pipe is communicated with the front cavity of the piston barrel; and a water outlet pipe which is externally connected with a water production pump and a gas supply pipe which is externally connected with a gas source are communicated with the rear cavity of the piston barrel. According to the membrane bioreactor, the gas-water separation device is arranged and the gas source is used as a power source of the backwashing, so that large-scale equipment such as a backwashing water pump is not used and thus the engineering cost and the water charge per ton are reduced. Practices prove that the rise of pressure is faster than that of the backwashing water pump, so that the membrane surface can be more effectively cleaned, the processing effect is good and the unit energy consumption is low.

Owner:CITIC ENVIROTECH GUANGZHOU CO LTD +1

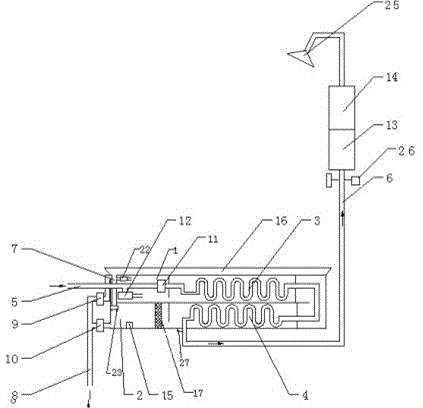

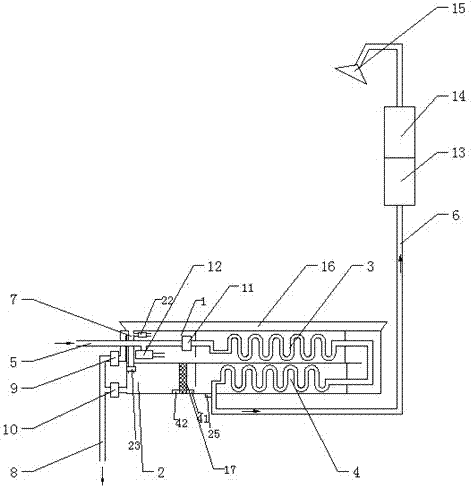

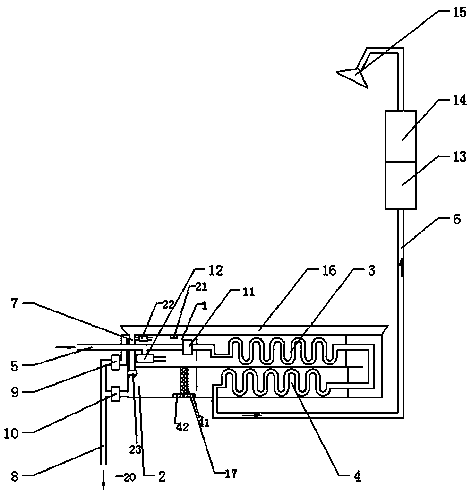

Water heater heat exchange system with flow velocity and water flooding detecting function

InactiveCN103528397AEasy to backwashEfficient backwashStationary conduit assembliesFlush cleaningWater floodingWastewater

The invention discloses a water heater heat exchange system with a flow velocity and water flooding detecting function. The water heater heat exchange system comprises a cold water inlet pipe (5), a hot water outlet pipe (6), a waste water inlet pipe (7), a waste water outlet pipe (8), a nozzle (25), an upper heat exchange trough (1) and a lower heat exchange trough (2). An upper heat exchanger (3) and a lower heat exchanger (4) are respectively arranged in the upper heat exchange trough (1) and the lower heat exchange trough (2). The hot water outlet pipe (6) is provided with a heater (13), a detector (15) is arranged in the lower heat exchange trough (2) and used for detecting water flow velocity, and a water flooding sensor (21) is arranged at the top of the upper heat exchange trough (1) and connected with a controller (14). The water heater heat exchange system solves the technical problem that dirt is prone to accumulating in the heat exchangers and cannot be automatically cleaned.

Owner:江阴市赛英电子股份有限公司

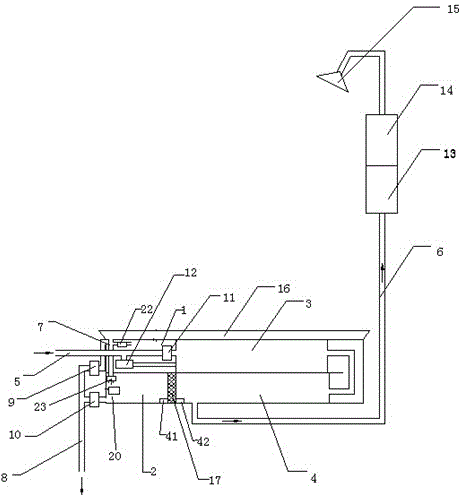

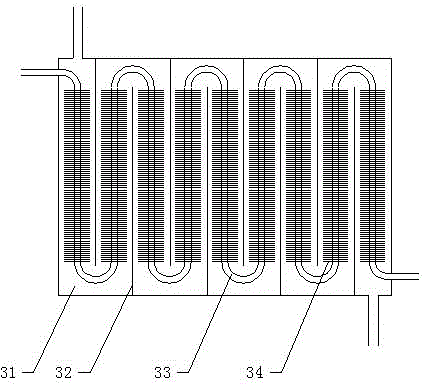

Water heater heat exchange system with water pressure and temperature detecting function

ActiveCN103528400AEasy to backwashEfficient backwashStationary tubular conduit assembliesFlush cleaningPore water pressureEngineering

The invention discloses a water heater heat exchange system with a water pressure and temperature detecting function. The water heater heat exchange system comprises a cold water inlet pipe (5), a hot water outlet pipe (6), a waste water inlet pipe (7), a waste water outlet pipe (8), a nozzle (15), an upper heat exchange trough (1) and a lower heat exchange trough (2). An upper heat exchange device (3) and a lower heat exchange device (4) are respectively arranged in the upper heat exchange trough (1) and the lower heat exchange trough (2), a detachable filter screen (17) is arranged in the lower heat exchange trough (2), a first pressure sensor (42) and a second pressure sensor (41) are respectively arranged on the left side and the right side of the filter screen (17) and are respectively connected with a controller (14), and the controller (14) comprises a comparing module (143) respectively connected with a setting module (144), the first pressure sensor (42), the second pressure sensor (41) and a waste water temperature sensor (20).

Owner:安徽宇测线缆质检技术有限公司

Preparation method of gap-variable adsorption material with porous ceramic as matrix

The invention discloses a preparation method of a gap-variable adsorption material taking porous ceramic as a matrix, and belongs to the field of ceramic adsorption materials. Porous ceramic is used as a matrix, a phase change layer and a heat-resistant outer coating film are formed on the surface of the matrix, and the heat-resistant outer coating film with a high melting point wraps the outer side of the phase change layer with a low melting point, thereby manufacturing the creative adsorption material having the gap-variable function. When a heat flow (hot gas or hot water) is used for backwashing the novel adsorption material, the phase change layer is heated and melted and is coated between the porous ceramic and the heat-resistant outer coating film in a fluid form, so that the heat-resistant outer coating film generates a continuous dynamic fluctuation process under the washing force of the heat flow; that is, the size and the shape of pores are changed, through the dynamic fluctuation process of the heat-resistant outer coating film, the heat-resistant outer coating film is more fully contacted with a heat flow, and meanwhile, loosening and falling of impurities on the surface of the heat-resistant outer coating film are also promoted, so that a high-efficiency and high-effect backwashing process is realized.

Owner:张宇

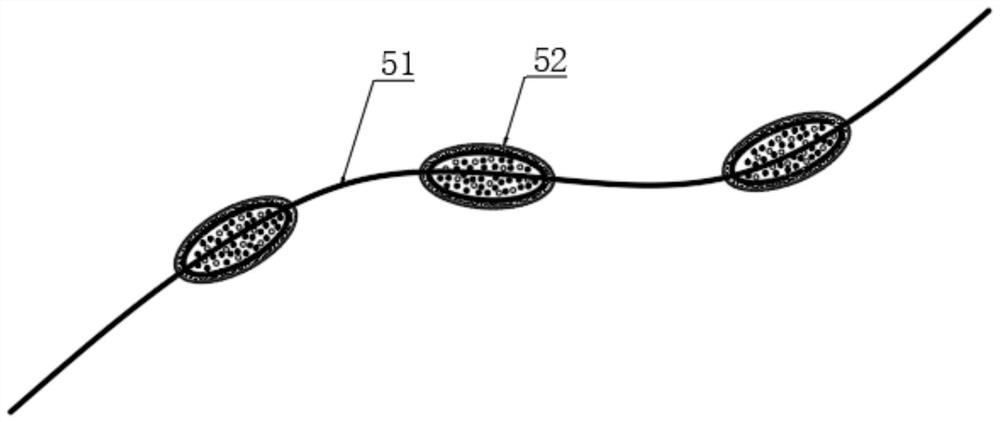

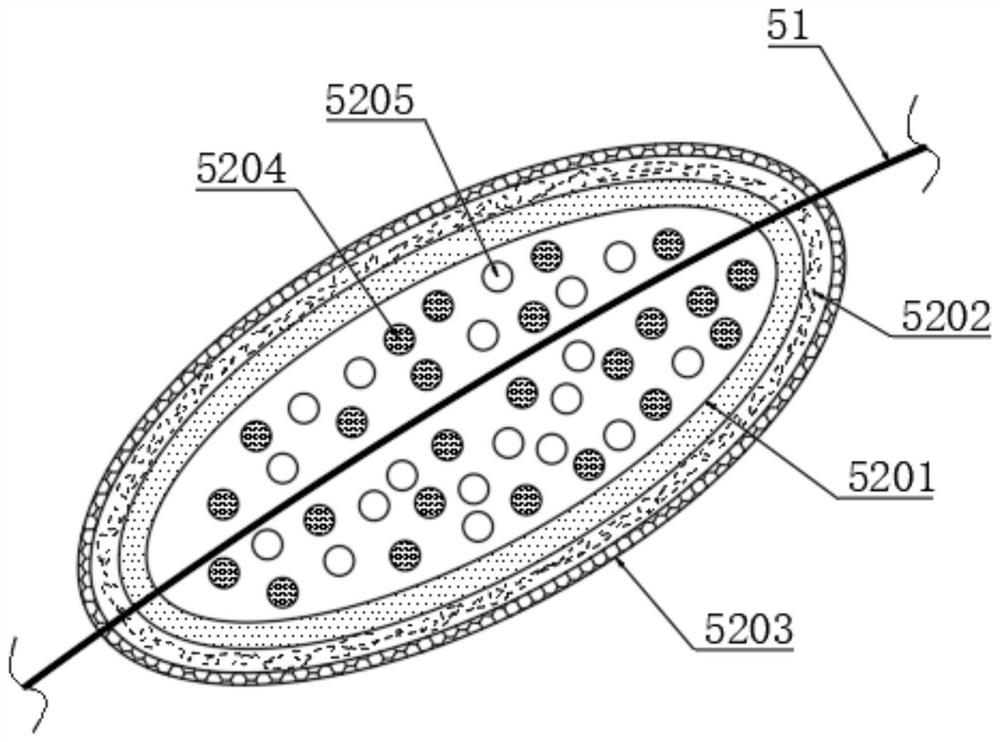

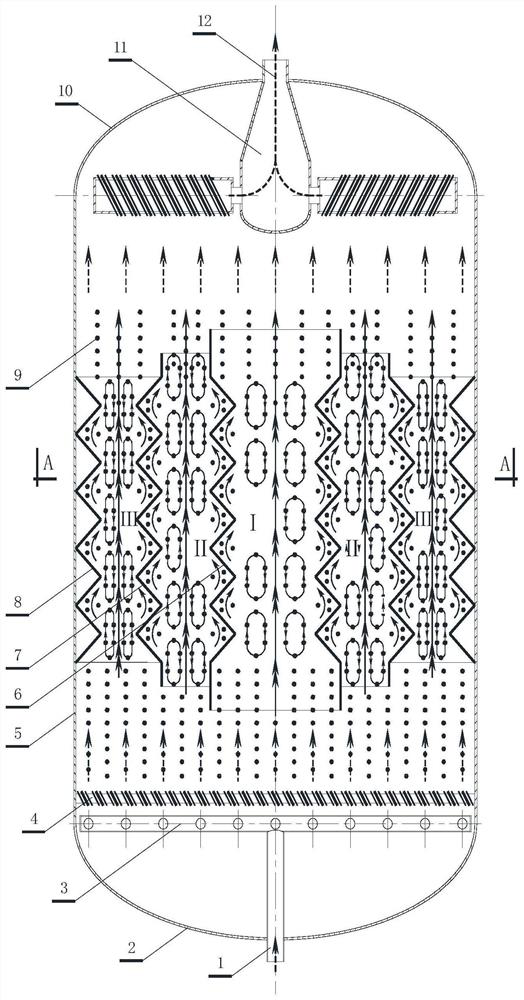

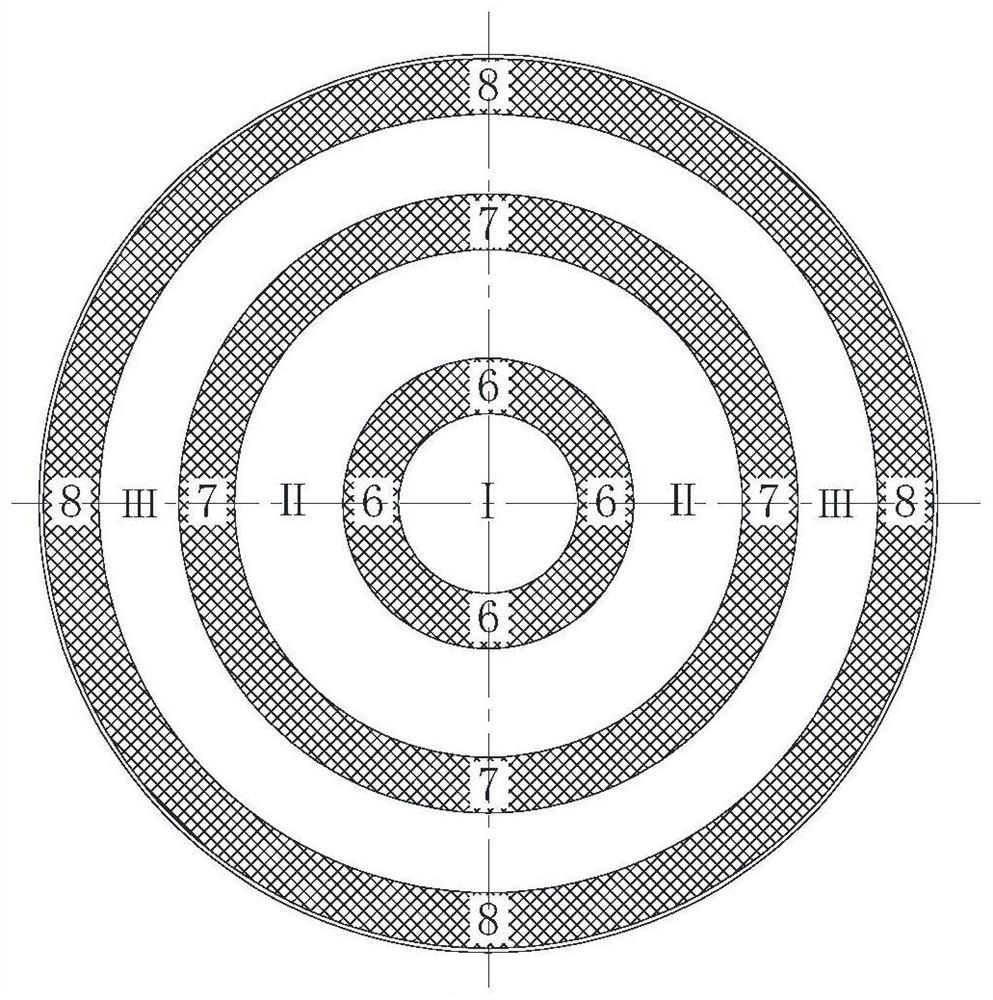

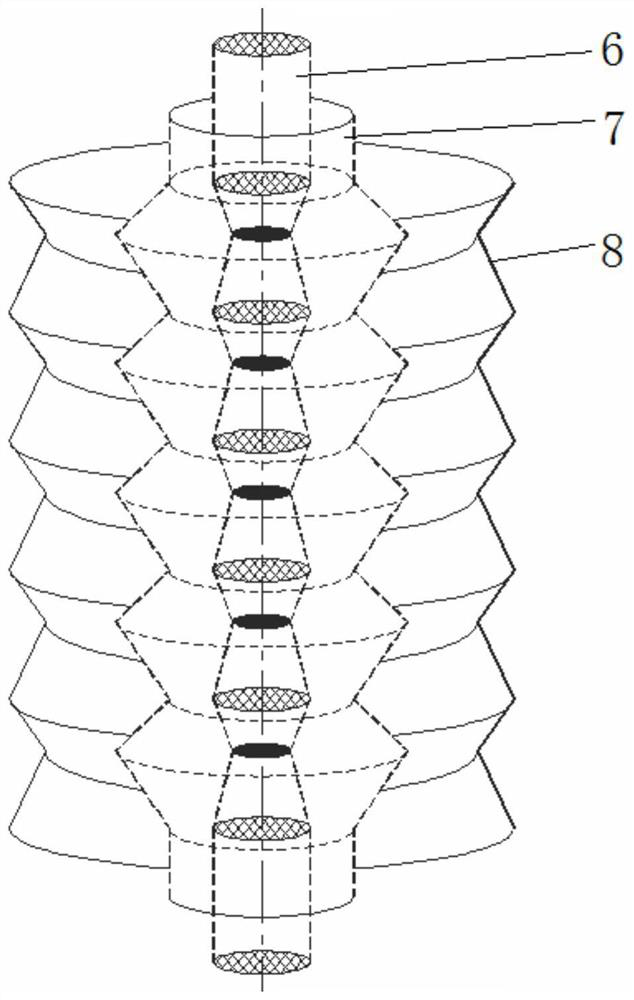

Multi-stage hydraulic self-pulse backwashing mechanism, fine filter and backwashing method

ActiveCN113101707BEfficient backwashIncrease collisionLoose filtering material filtersGravity filtersWater flowProcess engineering

The invention discloses a multi-stage hydraulic self-pulse backwashing mechanism, a fine filter and a backwashing method, wherein the backwashing mechanism is designed with a multi-stage dumbbell-shaped cylinder variable cross-section structure, which produces a multi-stage hydraulic self-pulse backwashing effect , strengthen the collision between the filter material particles in the filter bed and the shearing effect of the water flow, and realize the efficient backwashing of the filter bed, thus effectively solving the problem that the fine filter cannot be effectively backwashed due to the use of smaller filter materials and deeper filter beds. The problem.

Owner:NORTHEAST GASOLINEEUM UNIV +1

A recoilable heat exchange system with flow rate detection and temperature detection

ActiveCN103542530BEasy to backwashEfficient backwashFluid heatersFlush cleaningWater channelEngineering

The invention discloses a back-flushable type heat exchange system having flow velocity and temperature detecting functions. The back-flushable type heat exchange system comprises a cold water inlet pipe (5), a hot water outlet pipe (6), a waste water inlet pipe (7), a waste water outlet pipe (8), a spraying head (25), an upper heat exchange water channel (1) and a lower heat exchange water channel (2), wherein an upper heat exchange device (3) and a lower heat exchange device (4) are respectively arranged in the upper heat exchange water channel (1) and the lower heat exchange water channel (2). A heater (13) is further arranged on the hot water outlet pipe (6), and a detector (15) is arranged in the lower heat exchange water channel (2) and used for detecting flow velocity. The detector (15) is connected with a controller (14). The controller (14) comprises a comparison module (143) connected with a setting module (144), the detector (15) and a temperature sensor (27) respectively. The technical problem that stains easily accumulates inside the heat exchange devices and cannot be automatically cleaned is solved.

Owner:江阴戴勒姆动力设备有限公司

A heat exchange system with flow rate detection

ActiveCN103542741BEasy to backwashEfficient backwashStationary tubular conduit assembliesFlush cleaningThermodynamicsWastewater

Owner:蚌埠尚维知识产权运营有限公司

A heat exchange system with water quality detection

InactiveCN103528426BEasy to backwashEfficient backwashHeat exchange apparatusFlush cleaningWastewaterWater quality

The invention discloses a heat exchange system with a water quality detecting function. The heat exchange system comprises a cold water inlet pipe (5), a hot water outlet pipe (6), a waste water inlet pipe (7), a waste water outlet pipe (8), a nozzle (25), an upper heat exchange trough (1) and a lower heat exchange trough (2). An upper heat exchanger (3) and a lower heat exchanger (4) are respectively arranged in the upper heat exchange trough (1) and the lower heat exchange trough (2). The hot water outlet pipe (6) is provided with a heater (13), and a detector (15) is arranged in the lower heat exchange trough (2) and used for detecting water quality. A collector plate (16) is arranged on the upper portion of the upper heat exchange trough (1), and a detachable filter screen (17) is arranged in the lower heat exchange trough (2). The heat exchange system solves the technical problem that dirt is prone to accumulating in the heat exchangers and cannot be automatically cleaned.

Owner:江阴市赛英电子股份有限公司

Backflushing type heat exchange system with water pressure and temperature detecting function

InactiveCN103528403BEasy to backwashEfficient backwashCorrosion preventionStationary tubular conduit assembliesWastewaterPore water pressure

The invention discloses a backflushing type heat exchange system with a water pressure and temperature detecting function. The backflushing type heat exchange system comprises a cold water inlet pipe (5), a hot water outlet pipe (6), a waste water inlet pipe (7), a waste water outlet pipe (8), a nozzle (15), an upper heat exchange trough (1) and a lower heat exchange trough (2). An upper heat exchange device (3) and a lower heat exchange device (4) are respectively arranged in the upper heat exchange trough (1) and the lower heat exchange trough (2), a detachable filter screen (17) is arranged in the lower heat exchange trough (2), a first pressure sensor (42) and a second pressure sensor (41) are arranged on two sides of the filter screen (17) and respectively connected with a controller (14), and the controller (14) comprises a comparing module (143) respectively connected with a setting module (144), the first pressure sensor (42), the second pressure sensor (41) and a temperature sensor (25). The backflushing type heat exchange system solves the technical problem that dirt is prone to accumulating in the heat exchangers and cannot be automatically cleaned.

Owner:许东雪 +2

Water heater heat exchange system having water quality and temperature detecting functions

InactiveCN103542743AEasy to backwashStrong decontamination abilityStationary tubular conduit assembliesFlush cleaningWater qualityThermal water

The invention discloses a water heater heat exchange system having water quality and temperature detecting functions. The water heater heat exchange system comprises a cold water inlet pipe (5), a hot water outlet pipe (6), a waste water inlet pipe (7), a waste water outlet pipe (8), a spraying head (25), an upper heat exchange water channel (1) and a lower heat exchange water channel (2), wherein an upper heat exchange device (3) and a lower heat exchange device (4) are respectively arranged in the upper heat exchange water channel (1) and the lower heat exchange water channel (2). A heater (13) is further arranged on the hot water outlet pipe (6), and a detector (15) is arranged in the lower heat exchange water channel (2) and used for detecting water quality. The detector (15) is further connected with a controller (14). The controller (14) comprises a comparison module (143) connected with a setting module (144), the detector (15) and a waste water temperature sensor (20) respectively. The technical problem that stains easily accumulates inside the heat exchange devices and cannot be automatically cleaned is solved.

Owner:GUANGZHOU VOCATIONAL COLLEGE OF SCI & TECH

A heat exchange system with water pressure detection

InactiveCN103542740BEasy to backwashEfficient backwashStationary tubular conduit assembliesHeat exchange apparatusWater channelEngineering

The invention discloses a heat exchange system having a water pressure detecting function. The heat exchange system comprises a cold water inlet pipe (5), a hot water outlet pipe (6), a waste water inlet pipe (7), a waste water outlet pipe (8), a spraying head (25), an upper heat exchange water channel (1) and a lower heat exchange water channel (2), wherein an upper heat exchange device (3) and a lower heat exchange device (4) are respectively arranged in the upper heat exchange water channel (1) and the lower heat exchange water channel (2). A heater (13) is further arranged on the hot water outlet pipe (6), and a detachable filter screen (17) is further arranged in the lower heat exchange water channel (2). The left side and the right side of the filter screen (17) are respectively provided with a first pressure sensor (42) and a second pressure sensor (41). The technical problem that stains easily accumulates inside the heat exchange devices and cannot be automatically cleaned is solved.

Owner:江阴市赛英电子股份有限公司

Water heater heat exchange system with water pressure and water flooding detection function

ActiveCN103528398BEasy to backwashEfficient backwashStationary tubular conduit assembliesHeat exchange apparatusEngineeringMechanical engineering

The invention discloses a water heater heat exchange system with a water pressure and water flooding detection function. The water heater heat exchange system comprises a cold water inlet pipe (5), a hot water outlet pipe (6), a waste water inlet pipe (7), a waste water outlet pipe (8), a nozzle (15), an upper heat exchange trough (1) and a lower heat exchange trough (2). An upper heat exchanger (3) and a lower heat exchanger (4) are respectively arranged in the upper heat exchange trough (1) and the lower heat exchange trough (2), a water flooding sensor (21) is arranged at the top of the upper heat exchange trough (1) and connected with a controller (14), a detachable filter screen (17) is arranged in the lower heat exchange trough, and a first pressure sensor (42) and a second pressure sensor (41) are respectively arranged on the left side and the right side of the filter screen (17). The water heater heat exchange system solves the technical problem that dirt is prone to accumulating in the heat exchangers and cannot be automatically cleaned.

Owner:北京亚之捷动力科技有限公司

A water heater heat exchange system with water quality detection and temperature detection

InactiveCN103542743BEasy to backwashEfficient backwashStationary tubular conduit assembliesFlush cleaningWater channelWater quality

The invention discloses a water heater heat exchange system having water quality and temperature detecting functions. The water heater heat exchange system comprises a cold water inlet pipe (5), a hot water outlet pipe (6), a waste water inlet pipe (7), a waste water outlet pipe (8), a spraying head (25), an upper heat exchange water channel (1) and a lower heat exchange water channel (2), wherein an upper heat exchange device (3) and a lower heat exchange device (4) are respectively arranged in the upper heat exchange water channel (1) and the lower heat exchange water channel (2). A heater (13) is further arranged on the hot water outlet pipe (6), and a detector (15) is arranged in the lower heat exchange water channel (2) and used for detecting water quality. The detector (15) is further connected with a controller (14). The controller (14) comprises a comparison module (143) connected with a setting module (144), the detector (15) and a waste water temperature sensor (20) respectively. The technical problem that stains easily accumulates inside the heat exchange devices and cannot be automatically cleaned is solved.

Owner:GUANGZHOU VOCATIONAL COLLEGE OF SCI & TECH

A water heater heat exchange system with flow rate detection and water full detection

InactiveCN103528397BEasy to backwashEfficient backwashStationary conduit assembliesFlush cleaningWater floodingWastewater

The invention discloses a water heater heat exchange system with a flow velocity and water flooding detecting function. The water heater heat exchange system comprises a cold water inlet pipe (5), a hot water outlet pipe (6), a waste water inlet pipe (7), a waste water outlet pipe (8), a nozzle (25), an upper heat exchange trough (1) and a lower heat exchange trough (2). An upper heat exchanger (3) and a lower heat exchanger (4) are respectively arranged in the upper heat exchange trough (1) and the lower heat exchange trough (2). The hot water outlet pipe (6) is provided with a heater (13), a detector (15) is arranged in the lower heat exchange trough (2) and used for detecting water flow velocity, and a water flooding sensor (21) is arranged at the top of the upper heat exchange trough (1) and connected with a controller (14). The water heater heat exchange system solves the technical problem that dirt is prone to accumulating in the heat exchangers and cannot be automatically cleaned.

Owner:江阴市赛英电子股份有限公司

Water heater heat exchange system with water pressure and temperature detecting function

ActiveCN103528400BEasy to backwashEfficient backwashStationary tubular conduit assembliesFlush cleaningPore water pressureEngineering

The invention discloses a water heater heat exchange system with a water pressure and temperature detecting function. The water heater heat exchange system comprises a cold water inlet pipe (5), a hot water outlet pipe (6), a waste water inlet pipe (7), a waste water outlet pipe (8), a nozzle (15), an upper heat exchange trough (1) and a lower heat exchange trough (2). An upper heat exchange device (3) and a lower heat exchange device (4) are respectively arranged in the upper heat exchange trough (1) and the lower heat exchange trough (2), a detachable filter screen (17) is arranged in the lower heat exchange trough (2), a first pressure sensor (42) and a second pressure sensor (41) are respectively arranged on the left side and the right side of the filter screen (17) and are respectively connected with a controller (14), and the controller (14) comprises a comparing module (143) respectively connected with a setting module (144), the first pressure sensor (42), the second pressure sensor (41) and a waste water temperature sensor (20).

Owner:安徽宇测线缆质检技术有限公司

A kind of pulse backwashing deep bed filtering device and method

ActiveCN104208928BAlleviate the momentary shockEasy to desorbLoose filtering material filtersGravity filtersWater savingFrequency changer

The invention discloses a pulse backwashing deep bed filter device and a method, and belongs to the technical field of automatic control. A set of device may be provided with 1, 2.....n pulse backwashing deep bed filters; the pulse backwashing deep bed filter comprises a casing, a water collection mechanism arranged on the lower part of the casing and a connecting tube thereof, a water distributing mechanism arranged on the upper part of the casing and a connecting tube thereof, a filter material cushion layer arranged on the lower part of the casing, a filter material arranged in the middle part of the casing, and a filter material height detection device arranged on the upper part of the casing; a backwashing pump is a centrifugal pump, the rotating speed of an arranged motor can be regulated in variable frequency; a flow detection device is arranged on a main backwashing pipeline of a backwashing pump outlet; a control cabinet is provided with a PLC (programmable logic controller), and also provided with a frequency converter for regulating the rotating speed of the backwashing pump; the flow detection device and the filter material height detection device are provided with detection signal output ends which are connected with signal acquisition ends of the PLC. The effect of the pulse backwashing deep bed filter device is that: water-saving high-efficiency cleaning of a filtering layer can be performed by used of backwash water producing flow fluctuation.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

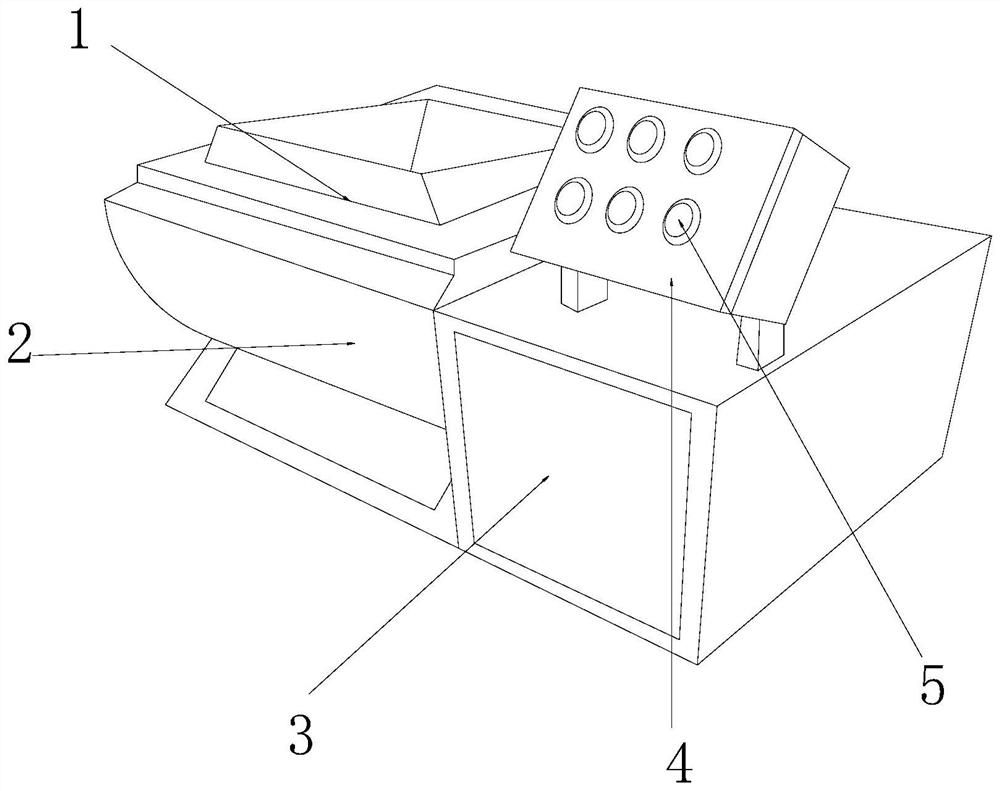

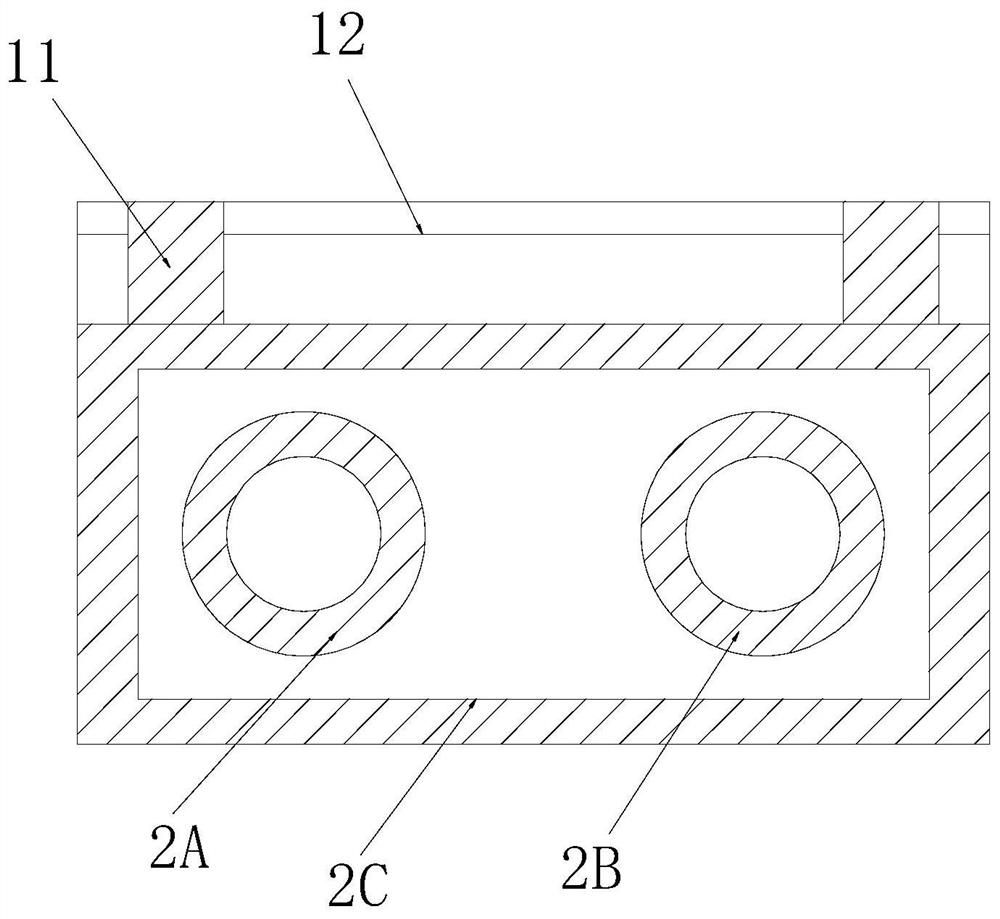

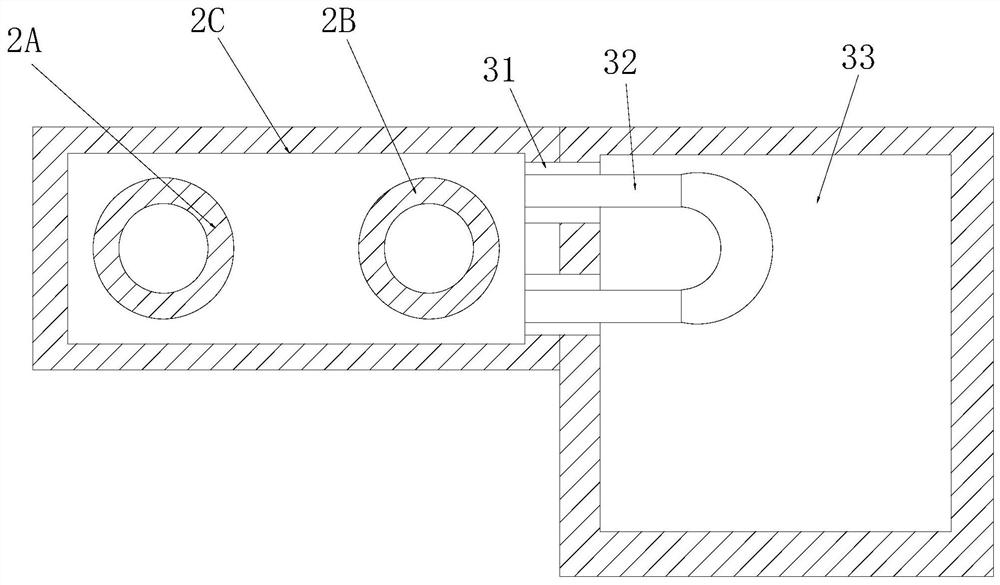

Cleaning device for intelligent fruit processing

InactiveCN112790401AImprove mobilityIncrease flexibilityFood treatmentPreservativeAgricultural engineering

The invention discloses a cleaning device for intelligent fruit processing. The cleaning device structurally comprises a feeding frame opening, a horizontal double-roller cleaning groove, a storage box groove, an electric control operation table and a round button key seat. According to the invention, the horizontal double-roller cleaning groove is matched with the storage box groove, and a rack wheel brush friction cleaning operation effect is formed through a short paddle barrel of a roller brush in a horizontal groove body, so preservative and pesticide thickness on the surfaces of fruits such as apples can be effectively cleaned and wiped, and the cleanliness of cleaning is higher; follow-up side net cover screen drums convey and overturn materials, so it is guaranteed that the fruits are conveyed through a baffling bend pipe one by one so as to realize efficient backwashing, and the automatic cleaning effect of the baffling bend pipe is improved; and conveying of the baffling bend pipe is matched with communication of double grooves, so efficient subsequent discharging is guaranteed, and fruit eating health is improved.

Owner:黄淑珠

A water heater heat exchange system with flow rate detection and temperature detection

InactiveCN103542529BEasy to backwashEfficient backwashFluid heatersFlush cleaningWater channelWastewater

Owner:山东华宇智慧教育科技发展股份有限公司

Backflushing type heat exchange system with water quality and temperature detecting function

ActiveCN103528401BEasy to backwashEfficient backwashCorrosion preventionStationary tubular conduit assembliesWastewaterThermal water

The invention discloses a backflushing type heat exchange system with a water quality and temperature detecting function. The backflushing type heat exchange system comprises a cold water inlet pipe (5), a hot water outlet pipe (6), a waste water inlet pipe (7), a waste water outlet pipe (8), a nozzle (25), an upper heat exchange trough (1) and a lower heat exchange trough (2). An upper heat exchanger (3) and a lower heat exchanger (4) are respectively arranged in the upper heat exchange trough (1) and the lower heat exchange trough 92). The hot water outlet pipe (6) is provided with a heater (13), a detector (15) is arranged in the lower heat exchange trough (2) and used for detecting water quality and is connected with a controller (14), and the controller (14) comprises a comparing module (143) respectively connected with a setting module (144), the detector (15) and a temperature sensor (27). The backflushing type heat exchange system solves the technical problem that dirt is prone to accumulating in the heat exchangers and cannot be automatically cleaned.

Owner:安徽宇测线缆质检技术有限公司

Water heater heat exchange system with water quality and water flooding detecting function

ActiveCN103528399BEasy to backwashEfficient backwashStationary tubular conduit assembliesHeat exchange apparatusWater floodingWater quality

The invention discloses a water heater heat exchange system with a water quality and water flooding detecting function. The water heater heat exchange system comprises a cold water inlet pipe (5), a hot water outlet pipe (6), a waste water inlet pipe (7), a waste water outlet pipe (8), a nozzle (25), an upper heat exchange trough (1) and a lower heat exchange trough (2). An upper heat exchanger (3) and a lower heat exchanger (4) are respectively arranged in the upper heat exchange trough (1) and the lower heat exchange trough (2). The hot water outlet pipe (6) is provided with a heater (13), a detector (15) is arranged in the lower heat exchange trough (2) and used for detecting water quality, and a water flooding sensor (21) is arranged at the top of the upper heat exchange trough (1) and connected with a controller (14). The water heater heat exchange system solves the technical problem that dirt is prone to accumulating in the heat exchangers and cannot be automatically cleaned.

Owner:安徽宇测线缆质检技术有限公司

Water heater heat exchange system with water quality and water flooding detecting function

ActiveCN103528399AEasy to backwashEfficient backwashStationary tubular conduit assembliesFlush cleaningWater floodingWastewater

The invention discloses a water heater heat exchange system with a water quality and water flooding detecting function. The water heater heat exchange system comprises a cold water inlet pipe (5), a hot water outlet pipe (6), a waste water inlet pipe (7), a waste water outlet pipe (8), a nozzle (25), an upper heat exchange trough (1) and a lower heat exchange trough (2). An upper heat exchanger (3) and a lower heat exchanger (4) are respectively arranged in the upper heat exchange trough (1) and the lower heat exchange trough (2). The hot water outlet pipe (6) is provided with a heater (13), a detector (15) is arranged in the lower heat exchange trough (2) and used for detecting water quality, and a water flooding sensor (21) is arranged at the top of the upper heat exchange trough (1) and connected with a controller (14). The water heater heat exchange system solves the technical problem that dirt is prone to accumulating in the heat exchangers and cannot be automatically cleaned.

Owner:安徽宇测线缆质检技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com