Solid-liquid separator structure with automatic backwash function

A solid-liquid separator and backwashing technology, which is applied in the direction of filtration separation, separation method, fixed filter element filter, etc., can solve the problems of filter element clogging, increase of enterprise operating costs, weakening, etc., to improve service efficiency and life, reduce The effect of maintaining manpower and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

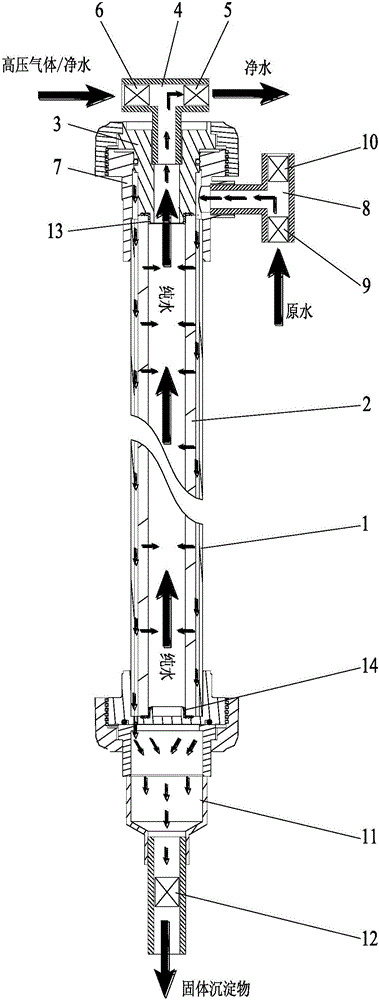

[0014] Such as figure 1 As shown, the present invention includes a pipe body 1 and a filter element 2, the filter element 2 is a microporous filter element, the filter element 2 is sleeved in the pipe body 1, and an annular cavity is formed between the outer wall of the filter element 2 and the inner wall of the pipe body 1; the upper end of the filter element 2 A water outlet seat 3 is connected, and the water outlet channel inside the water outlet seat 3 is connected with the axial channel inside the filter element 2. The upper end of the water outlet seat 3 is connected with a three-way pipe 4, and the first nozzle of the A three-way pipe 4 is connected to the water outlet seat. 3. The internal water outlet channel is connected. The second nozzle of A three-way pipe 4 is provided with A solenoid valve 5, the third nozzle of A three-way pipe 4 is provided with B solenoid valve 6, and the third nozzle of A three-way pipe 4 The nozzle is connected with a high-pressure air pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com