Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Avoid high speed crashes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

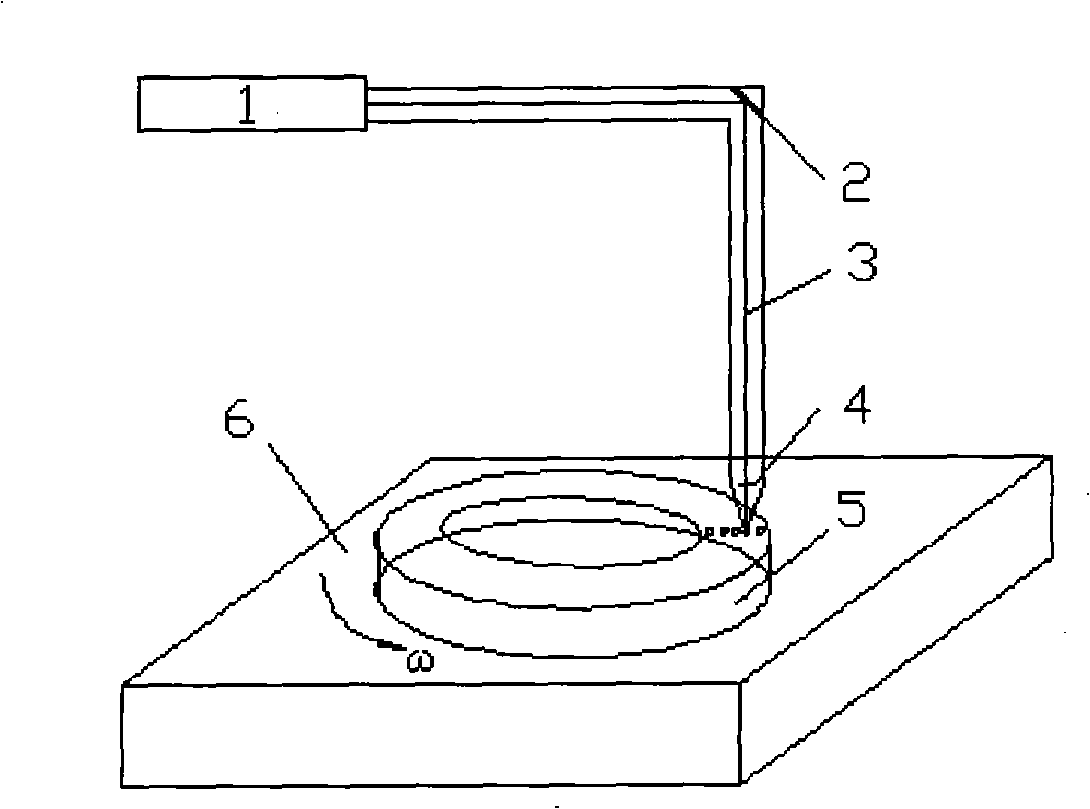

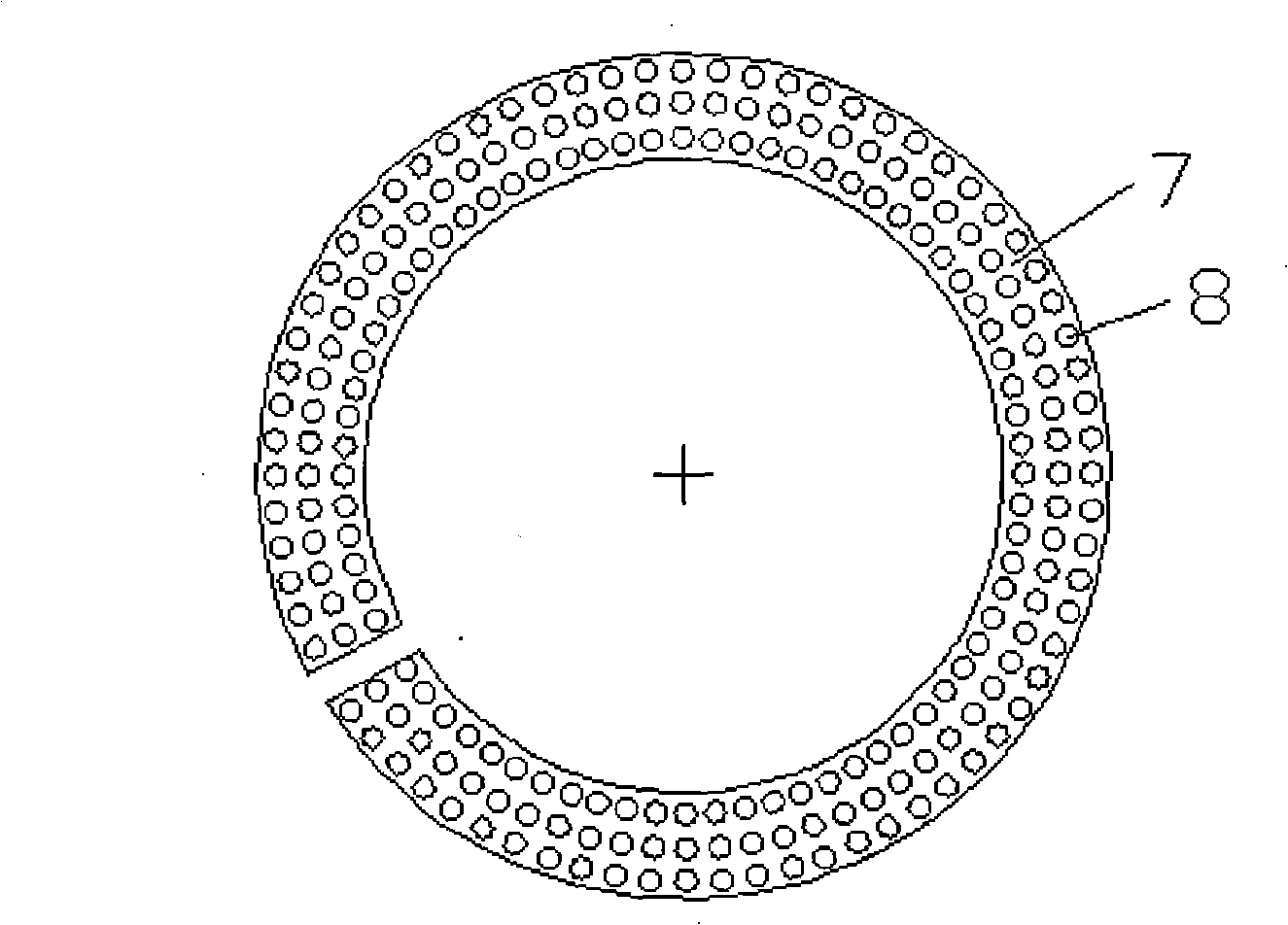

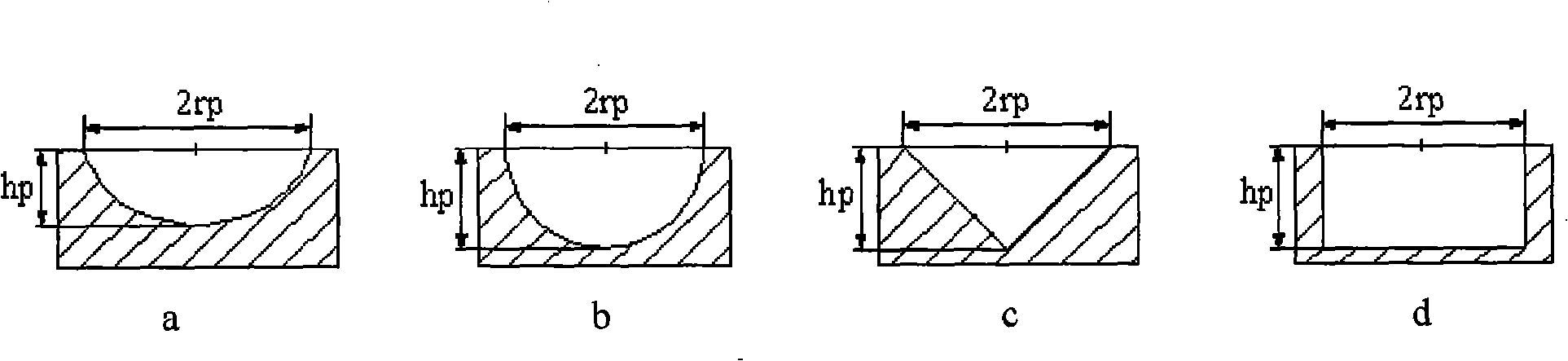

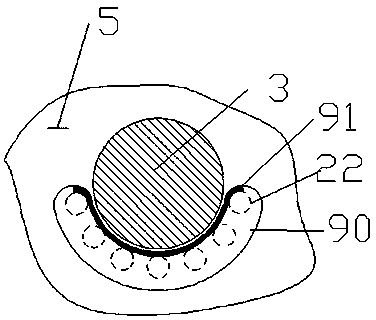

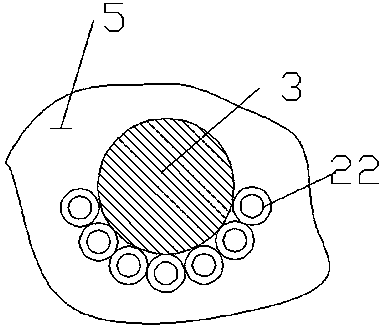

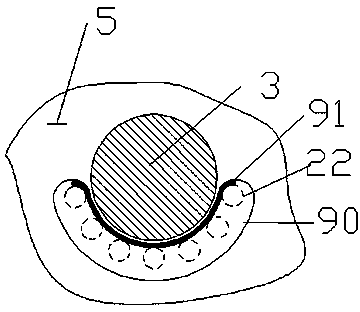

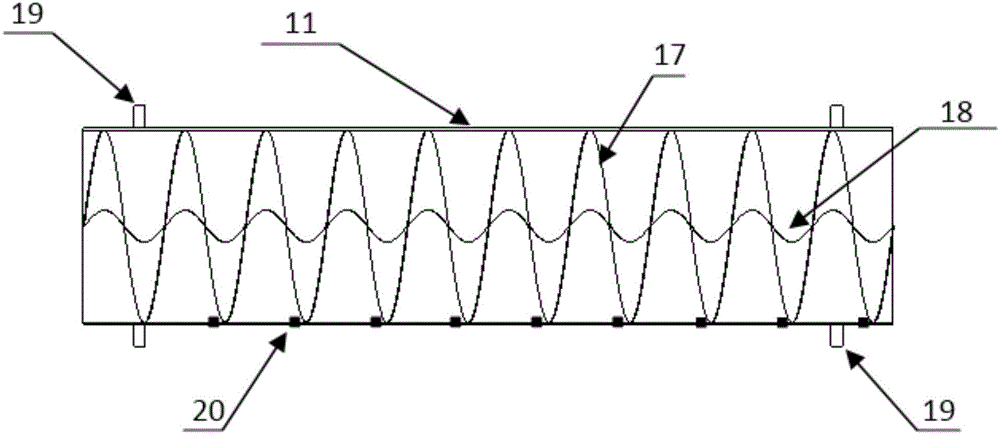

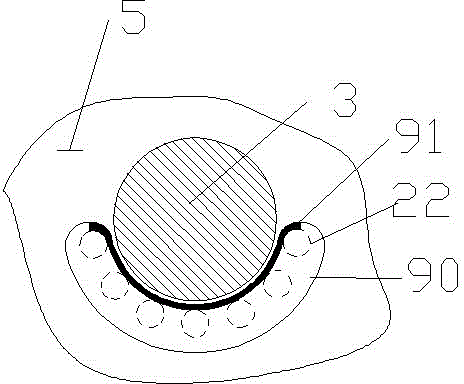

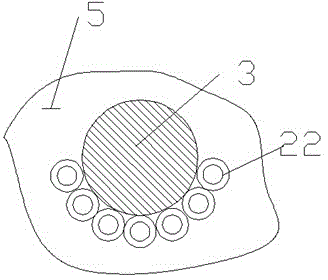

Laser surface modelling engine piston ring and preparation method thereof

InactiveCN101344048AHigh hardnessEnhanced wear resistance and anti-wear performancePiston ringsMachines/enginesPiston ringWear particle

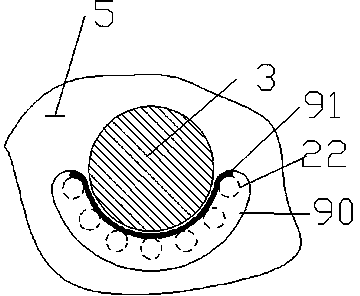

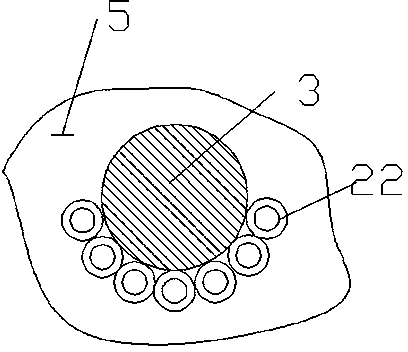

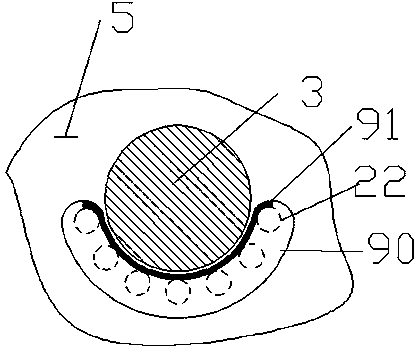

The invention relates to a piston ring of a laser micro-modeling engine and a manufacturing method, in particular to carrying out laser micro-modeling on the upper end surface and the lower end surface of the piston ring; a metallographical organization which has the hardness of HV800-900, is distributed uniformly, consists of micro-pits and is a micro-geometrical structure is obtained after the upper end surface and the lower end surface of the piston ring of the engine are processed by the laser micro-modeling, wherein, the geometric parameters of the micro-geometrical structure are that the radius of the pit is that rp is equal to 20 to 50Mum, the depth of the pit is that hp is equal to 2 to 8Mum, the area occupancy of the pit is that Sp is equal to 5 percent to 15 percent and the distance of the pit is that L is equal to 90 to 230Mum. The invention has the advantages that after the upper end surface and the lower end surface of the piston ring are processed by the laser micro-modeling, the metallographical organization occurs changing, the hardness is improved and the wearing resistance is enhanced; the micro-pits of the upper end surface and the lower end surface of the piston ring store lubricant and wearing particles, improves lubrication and reduces the wearing; the extrusion effect of a lubricating oil film of the pit reduces the break of the piston ring.

Owner:JIANGSU UNIV

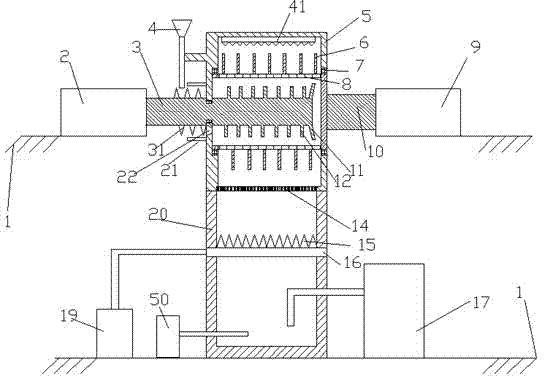

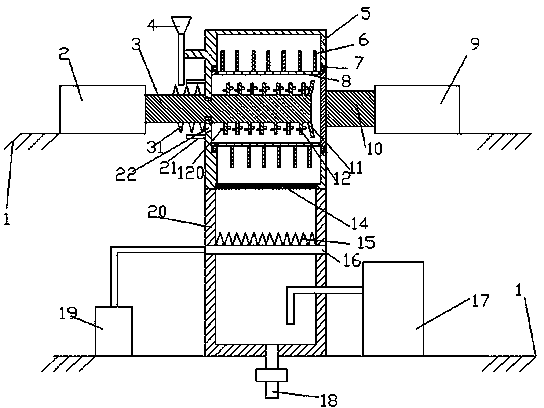

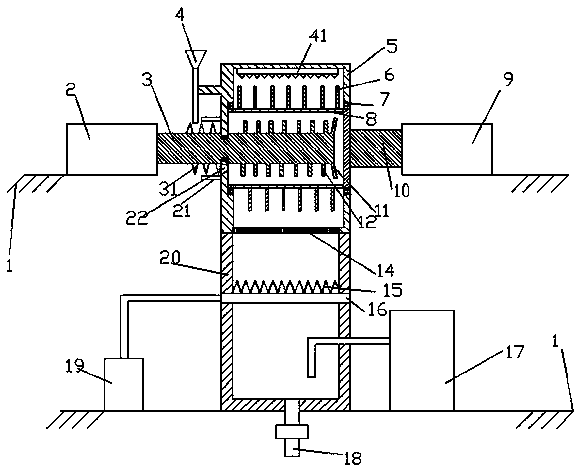

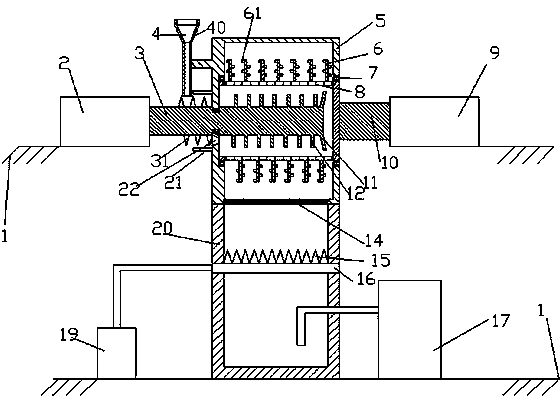

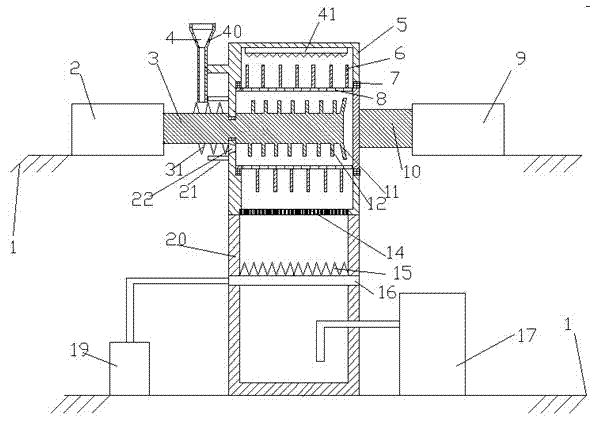

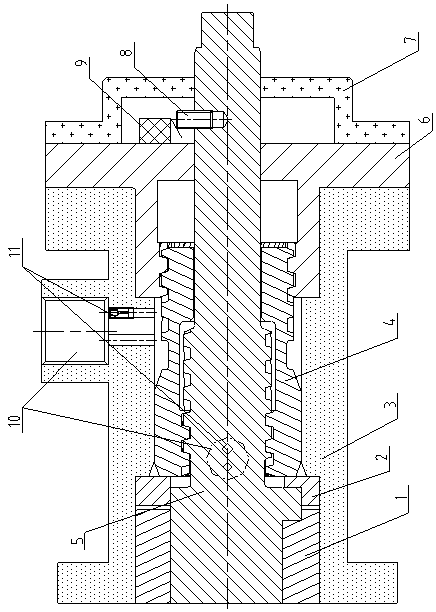

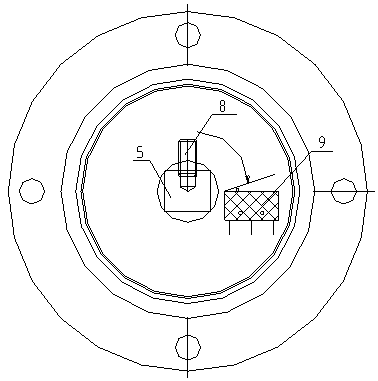

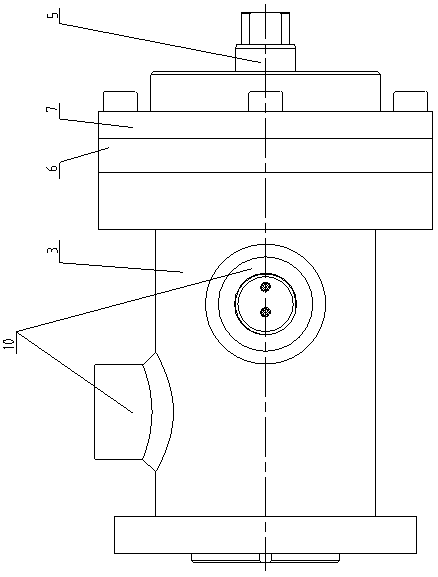

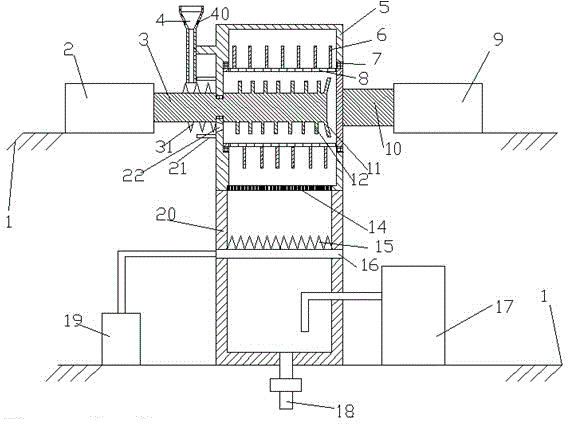

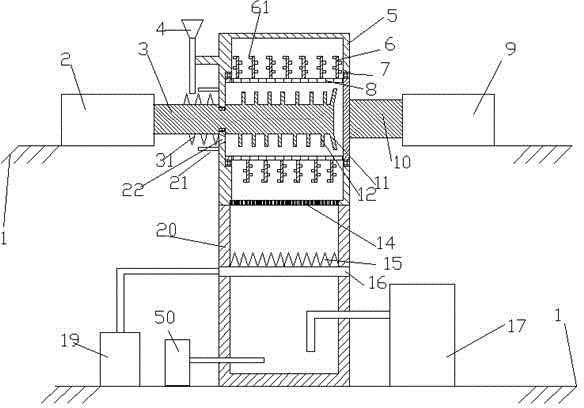

Gas-liquid pressurization cylinder

ActiveCN103362882AAvoid mixingAchieve positioningFluid-pressure convertersHydraulic cylinderEngineering

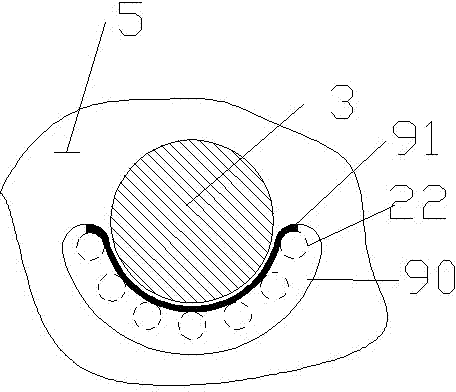

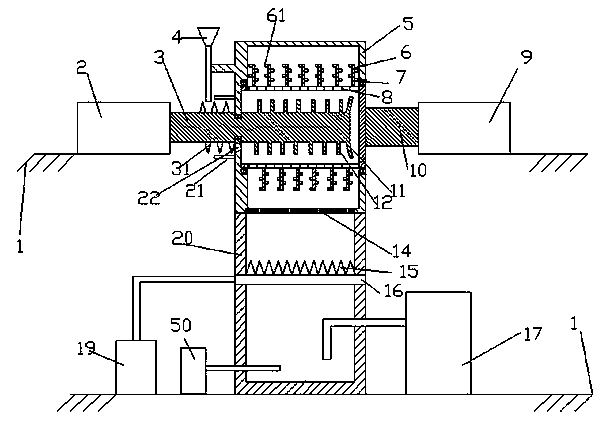

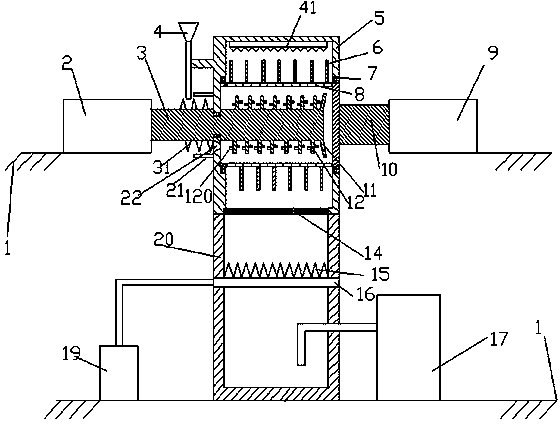

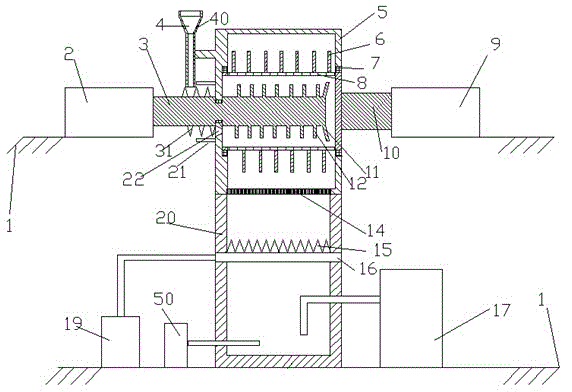

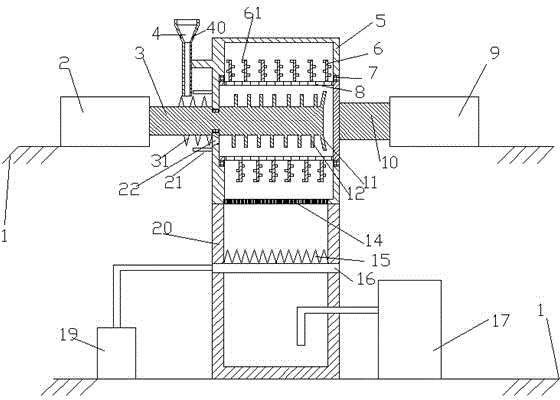

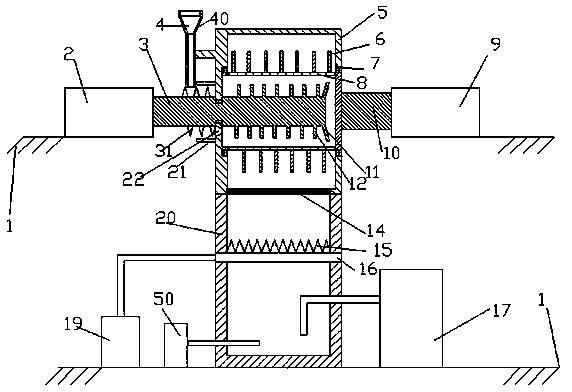

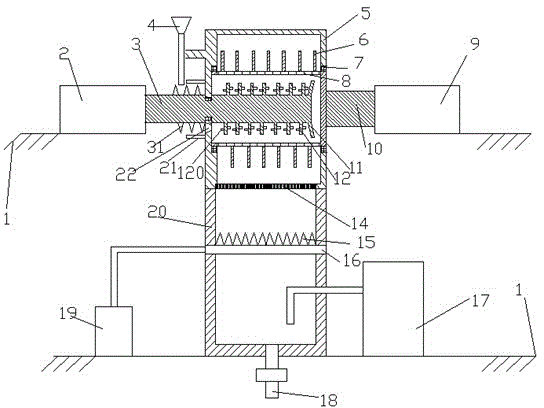

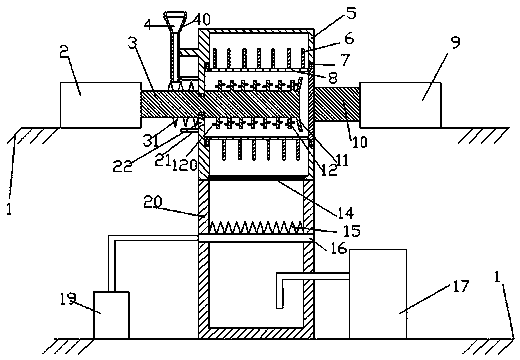

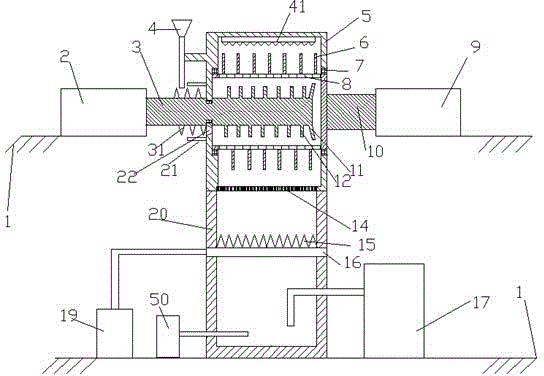

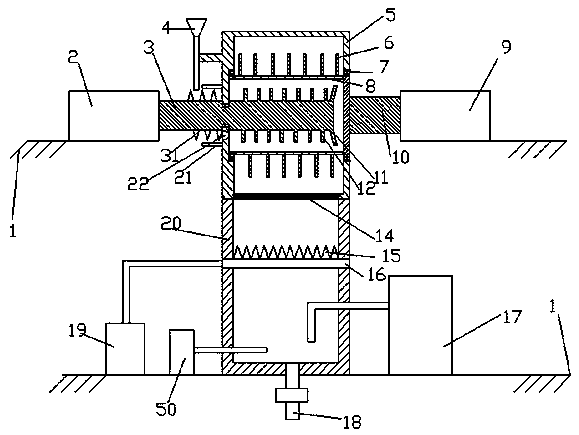

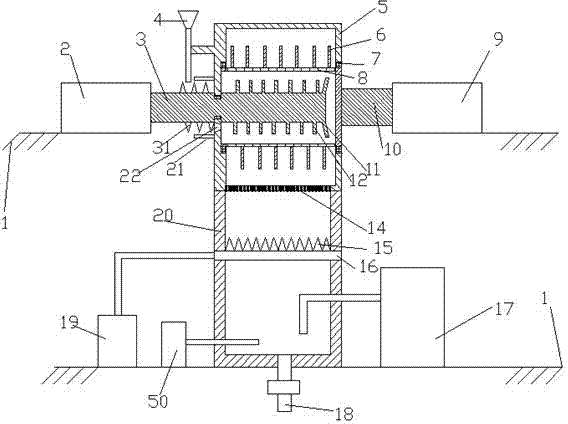

The invention discloses a gas-liquid pressurization cylinder. The gas-liquid pressurization cylinder is formed by the fact that a gas pressure cylinder body and a hydraulic cylinder body are in series connection through a middle cover with a middle hole and are separated into a pressurization gas cavity, a pre-pressing gas cavity, a pre-pressing oil storage cavity, a pressurization oil cavity and a stroke returning gas cavity through an upper end cover with a gas guide pipe, a pressurization piston with a hollow pressurization rod, a gas separation piston, the middle cover with the hole, a working piston and a lower end cover. The pressurization gas cavity, the pre-pressing gas cavity and the stroke returning gas cavity are respectively communicated with an exterior gas circuit through respective connectors, and the working processes of the pre-pressing stroke, the pressurization stroke and the reset stroke can be achieved through the control over the gas circuit. Compared with an existing gas-liquid pressurization cylinder, wherein the existing gas-liquid pressurization cylinder is provided with three or more cylinder bodies, and the cylinder bodies are in parallel connection or in serial connection, the gas-liquid pressurization cylinder has the advantages of being exquisite in structure, convenient to machine and high in use efficiency of a gas source. In addition, the design of the structure of conducting reasonable guiding and preventing rotation is added on an output working piston rod of the cylinder, and the installation and application of subsequent use are simplified.

Owner:俞祖文

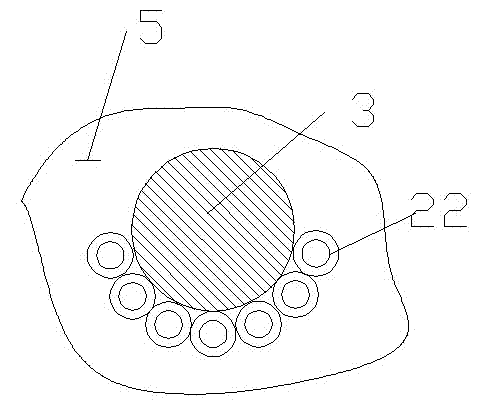

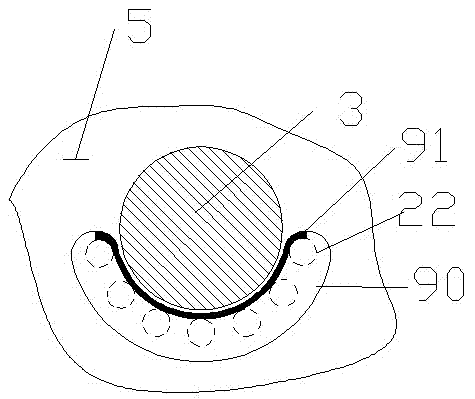

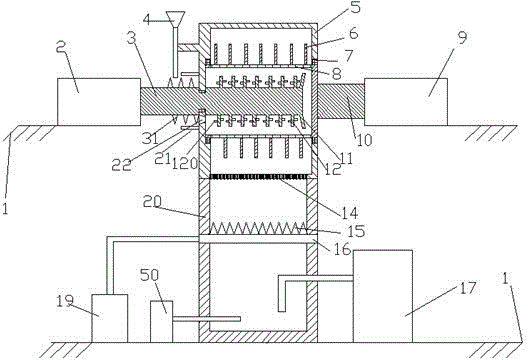

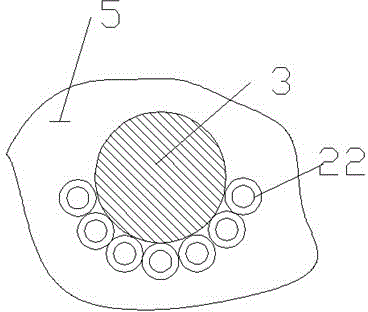

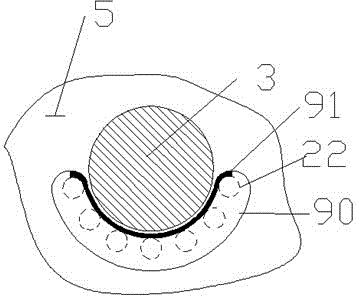

Nut protein extraction device with blowing strip and blowing stirring device

InactiveCN103789196AAvoid churnAvoid lossBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringGrinding teeth

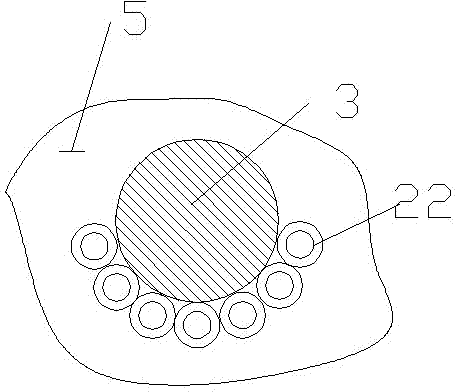

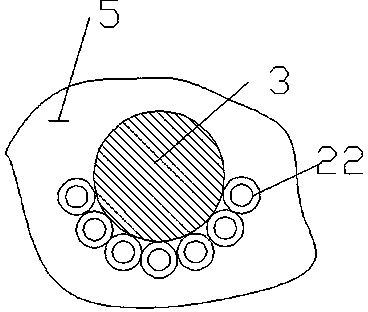

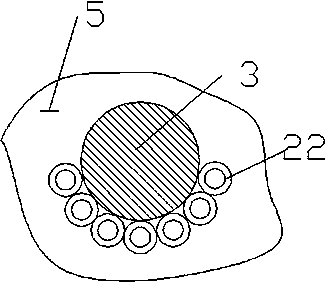

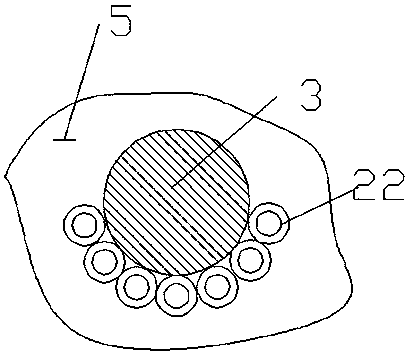

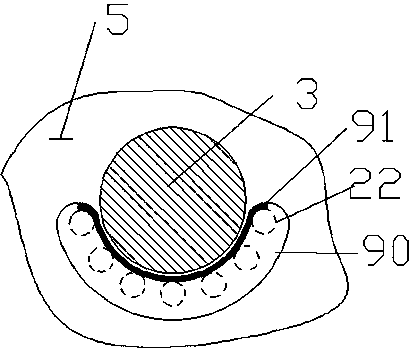

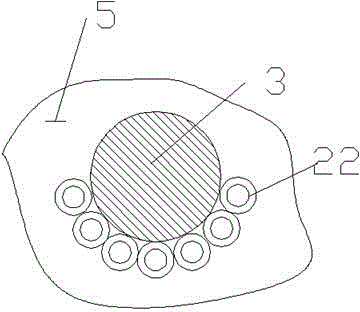

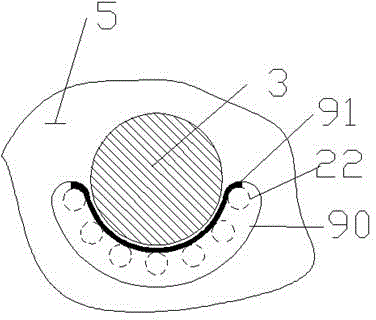

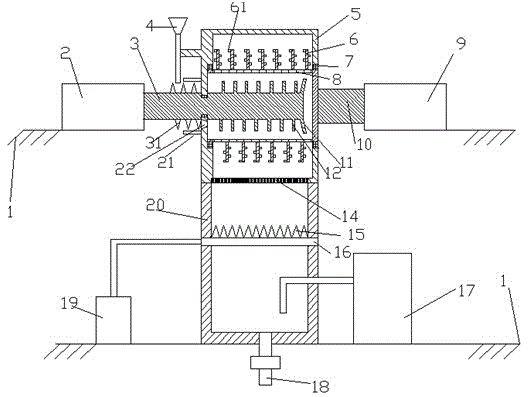

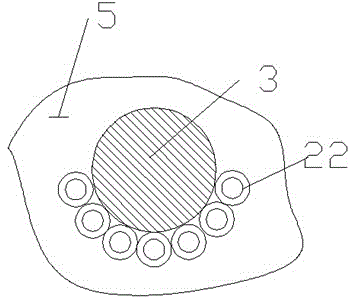

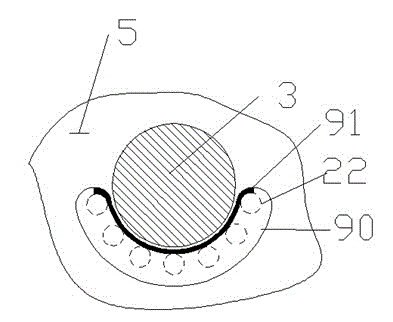

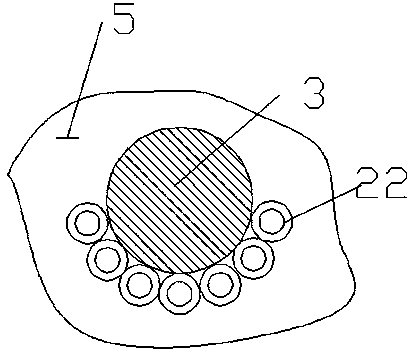

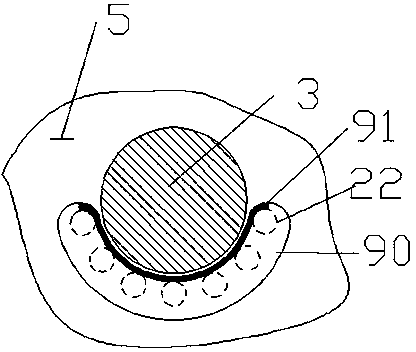

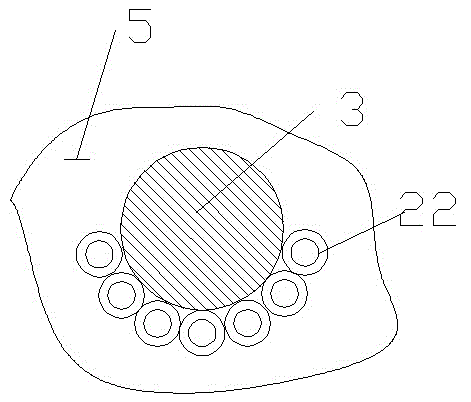

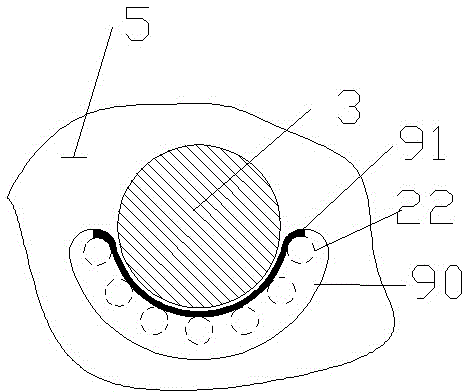

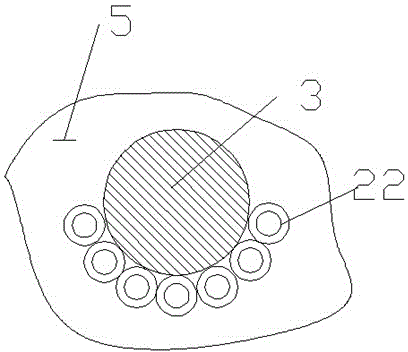

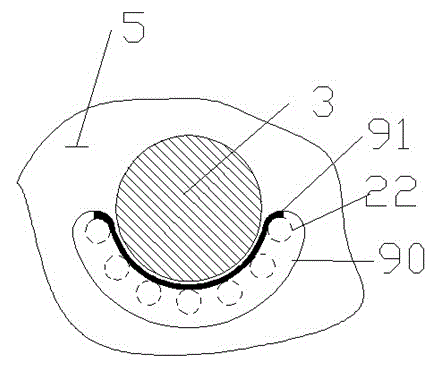

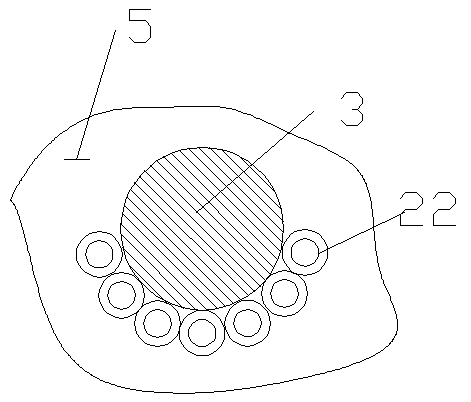

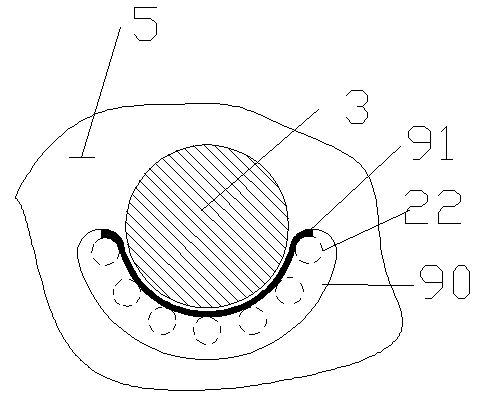

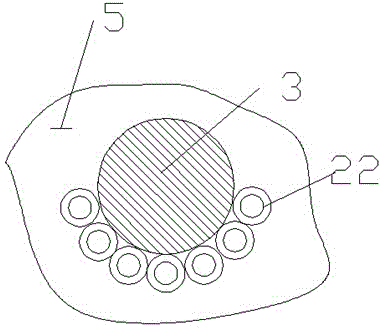

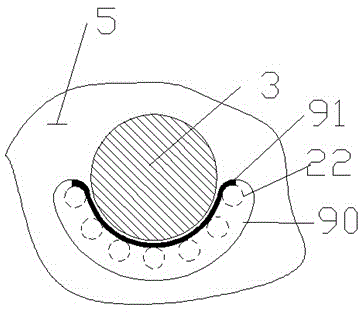

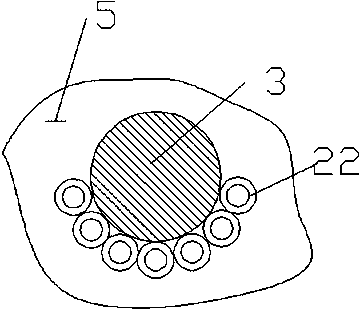

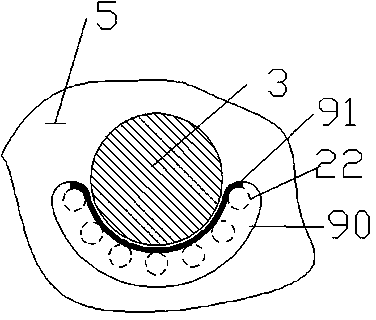

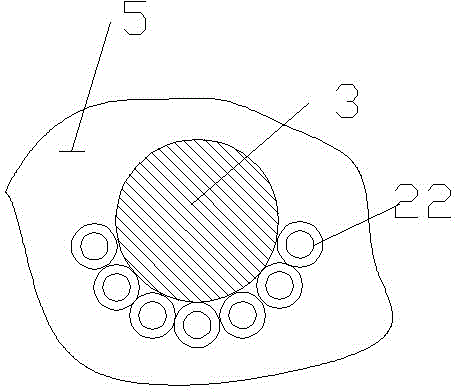

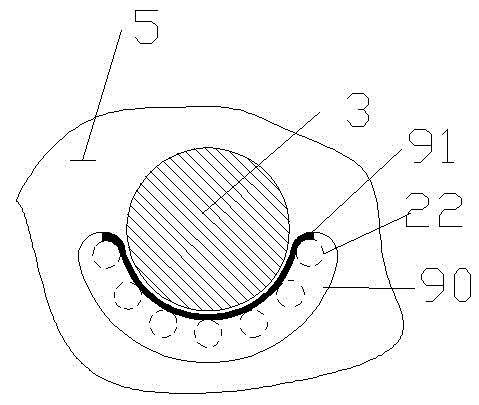

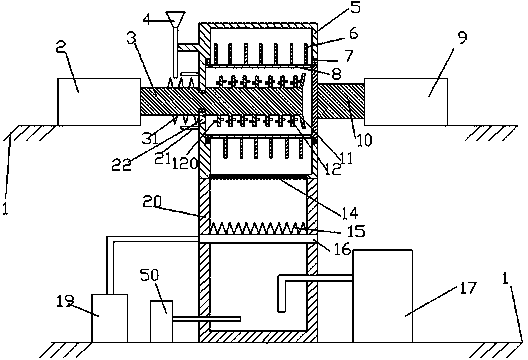

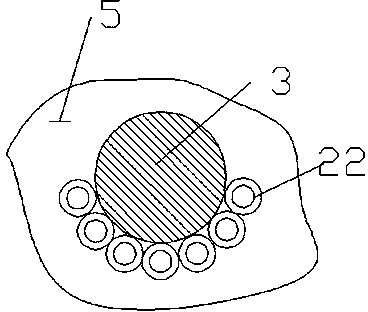

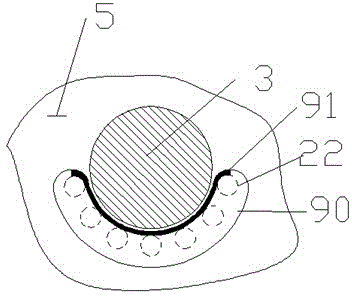

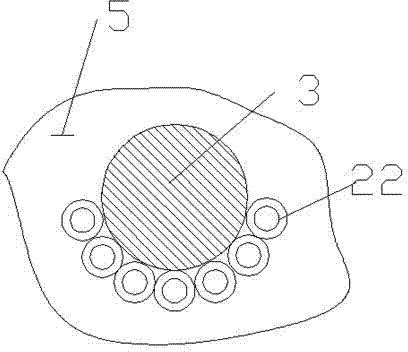

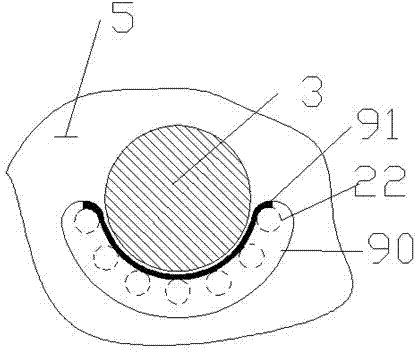

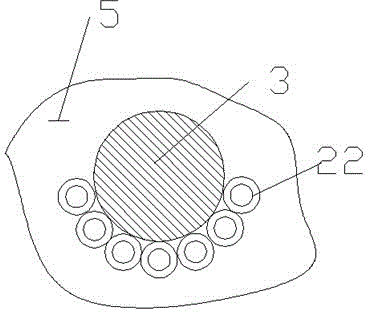

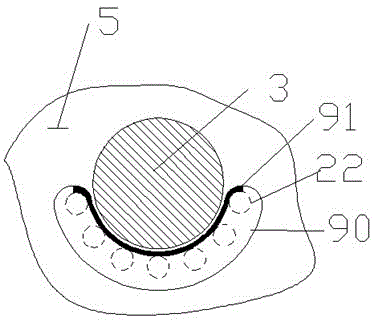

The invention provides a nut protein extraction device with a blowing strip and a blowing stirring device, which comprises a grinding module and an enzymolysis module, wherein the grinding module comprises a first-level grinding component, a second-level grinding component and a grinding module shell (5); the first-level grinding component comprises a first-level grinding motor (2); the first-level grinding motor (2) is in power connection with a first-level grinding main shaft (3); the first-level grinding main shaft (3) stretches into a grinding chamber of the grinding module shell (5) through a left through hole in the left side of the grinding module shell (5) and is in rotatable fit with the left through hole through a bearing component; first-level grinding teeth (12) are distributed on the part, stretching into the grinding chamber, of the first-level grinding main shaft.

Owner:南通海永科技创意园有限公司

Nut protein extracting device with secondary teeth and gas blowing stirring device

ActiveCN103749938AAvoid churnAvoid lossProtein composition from vegetable seedsEngineeringNut Proteins

The invention provides a nut protein extracting device with secondary teeth and a gas blowing stirring device. The nut protein extracting device comprises a smashing module and an enzymolysis module, wherein the smashing module comprises a first-stage smashing part, a second-stage smashing part and a smashing module shell (5); the first-stage smashing part comprises a first-stage smashing motor (2) which is connected with a first-stage main smashing shaft (3) through power; the first-stage main smashing shaft (3) extends into a smashing chamber of the smashing module shell (5) through a left through hole in the left side of the smashing module shell (5); the first-stage main smashing shaft (3) is rotatably matched with the left through hole through a bearing part; first-stage smashing teeth (12) are distributed on the part, extending into the smashing chamber, of the first-stage main smashing shaft.

Owner:广东康必健医疗科技有限公司

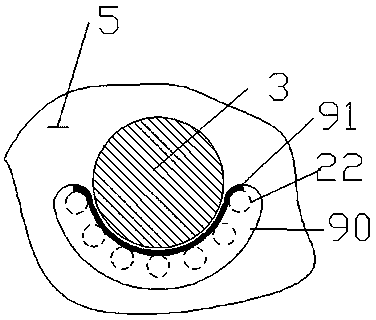

Nut protein extracting device with output tube and primary auxiliary teeth

InactiveCN103756878AAvoid churnAvoid lossBioreactor/fermenter combinationsBiological substance pretreatmentsPulp and paper industryGrinding teeth

The invention provides a nut protein extracting device with an output tube and primary auxiliary teeth. The nut protein extracting device comprises a grinding module and an enzymolysis module, wherein the grinding module comprises a primary grinding part, a secondary grinding part and a grinding module shell (5); the primary grinding part comprises a primary grinding motor (2) which is connected with a primary grinding main shaft (3) by power; the primary grinding main shaft (3) extends into a grinding chamber of the grinding module shell (5) via a left through hole on the left of the grinding module shell (5); the primary grinding main shaft (3) is rotatablely matched with the left through hole via a bearing part; primary grinding teeth (12) are distributed on the part, extending into the grinding chamber, of the primary grinding main shaft.

Owner:徐学铖

Nut protein extraction device with output pipe and air blowing strip

ActiveCN103740583AAvoid churnAvoid lossBioreactor/fermenter combinationsBiological substance pretreatmentsEnzymatic hydrolysisEngineering

The invention provides a nut protein extraction device with an output pipe and an air blowing strip. The nut protein extraction device comprises a grinding module and an enzymatic hydrolysis module, wherein the grinding module comprises a primary grinding part, a secondary grinding part and a grinding module shell (5); the primary grinding part comprises a primary grinding motor (2); the primary grinding motor (2) is connected with a primary grinding main shaft (3) through power; the primary grinding main shaft (3) extends into a grinding chamber of the grinding module shell (5) through a left through hole in the left side of the grinding module shell (5) and is rotatably matched with the left through hole through a bearing part; primary grinding teeth (12) are distributed on a part, extending into the grinding chamber, of the primary grinding main shaft,.

Owner:江苏古沙农业科技发展有限公司

Nut protein extraction device with two-level subsidiary teeth and feeding sensor

InactiveCN103756876AAvoid churnAvoid lossBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringNut Proteins

The invention provides a nut protein extraction device with two-level subsidiary teeth and feeding sensor. The nut protein extraction device comprises a smashing module and an enzymolysis module, wherein the smashing module comprises a first-level smashing part, a second-level smashing part and a smashing module shell (5); the first-level smashing part comprises a first-level smashing motor (2), the first-level smashing motor (2) is in power connection with a first-level smashing main shaft (3), and the first-level smashing main shaft (3) stretches into a smashing chamber of the smashing module shell (5) through a left through hole formed in the left side of the smashing module shell (5); the first-level smashing main shaft (3) is rotatablely matched with the left through hole through a bearing part, and first-level smashing teeth (12) are distributed on a part, which stretches into the smashing chamber, of the first-level smashing main shaft.

Owner:GUANGDONG MEIYAN HYDROPOWER CO LTD

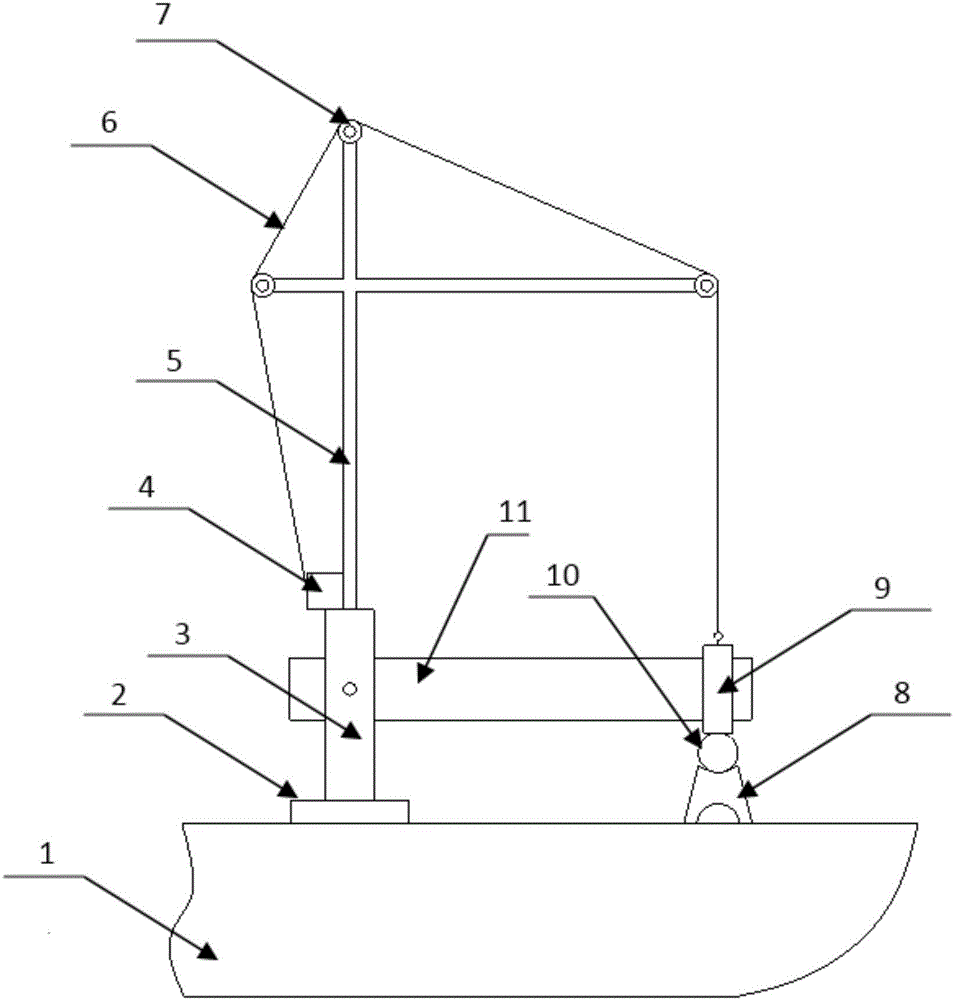

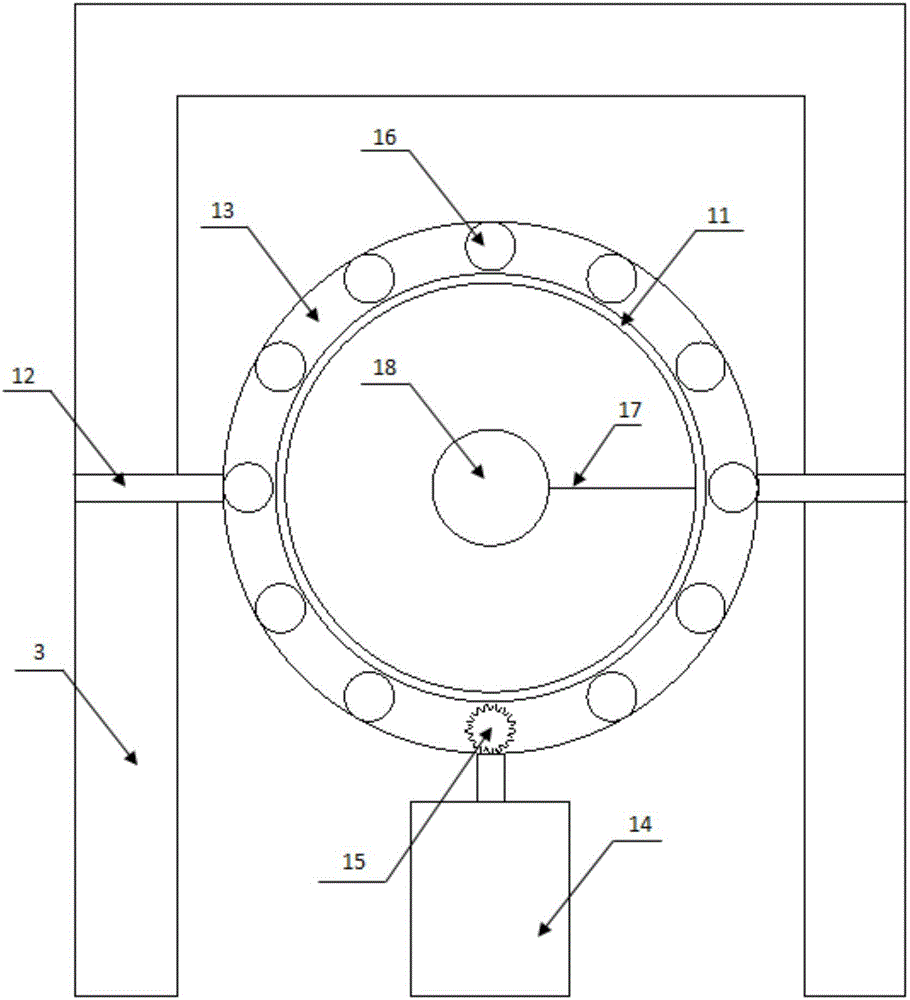

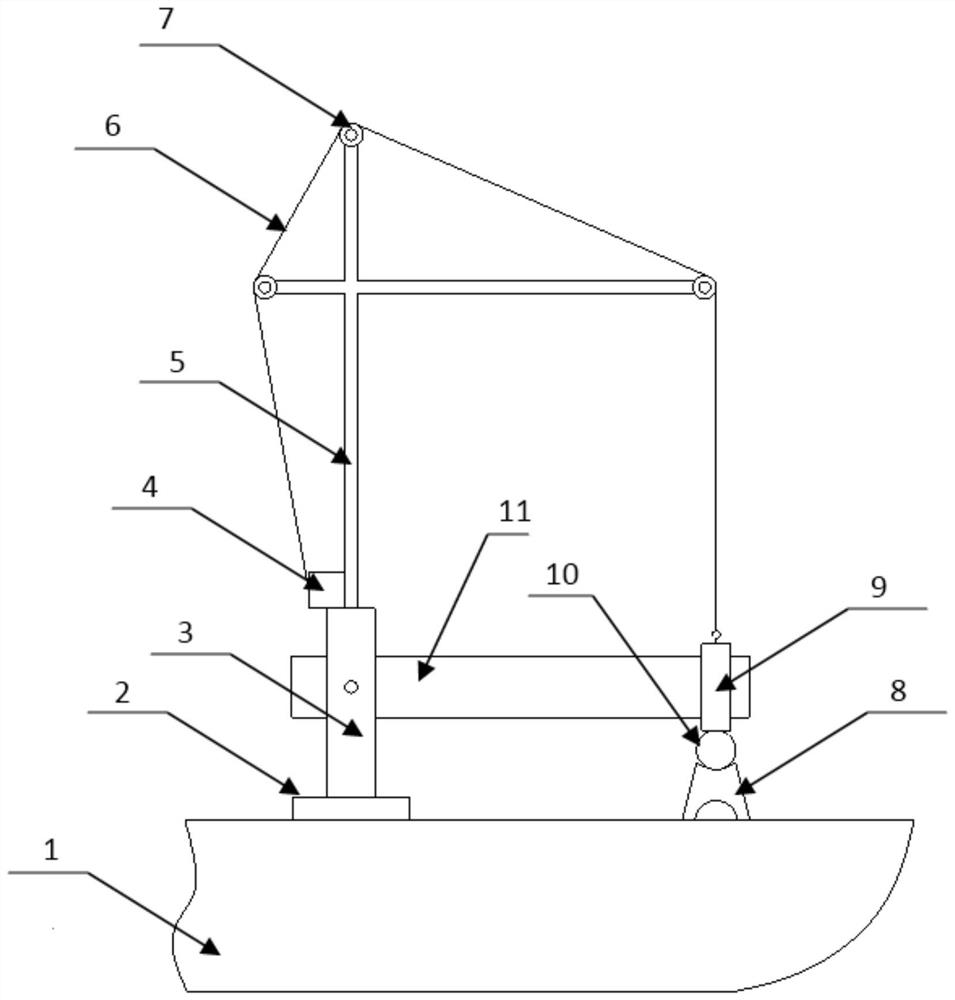

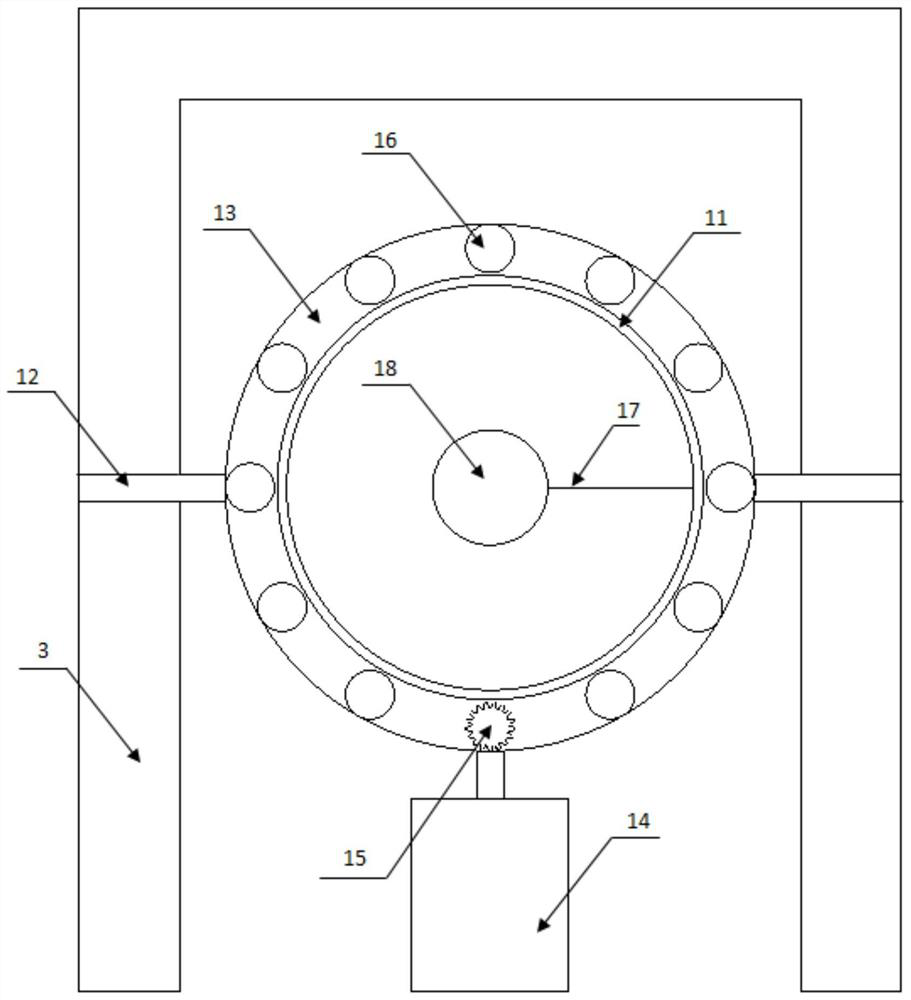

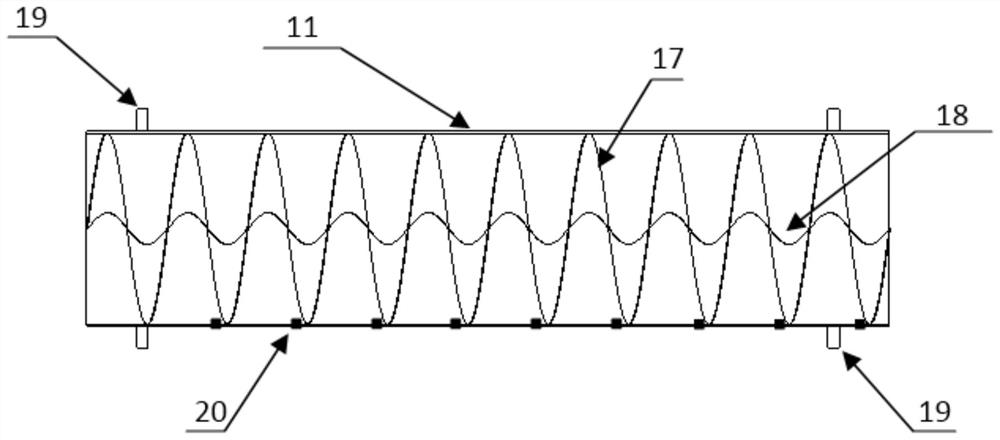

In-roller guide vane push type fish capture set device

The invention discloses an in-roller guide vane push type fish capture set device. A rotary base and a clamping seat are installed on a hull; the lower end of an n-shaped base frame is fixed to the rotary base, a hanger is mounted at the top end of the n-shaped base frame, and a fixed pulley is mounted at the top end of the hanger; the left end of the roller is restrained by a roller power hoop, and the roller power hoop is mounted in the middle of the n-shaped base frame through rotating shafts; the right end of the roller is restrained by a roller driven hoop, and a positioning floater is fixed under the roller driven hoop and placed on the clamping seat; a hoist motor is fixed over the n-shaped base frame, a steel cable is driven by the hoist motor and passes the fixed pulley, and the tail end of the steel cable is connected with the roller driven hoop. The device is simple in structure, low in cost, high in fish capture efficiency, low in driving power and low in fish breakage.

Owner:SOUTH CHINA AGRI UNIV

Nut protein extraction device with air blowing strip and feeding sensor

The invention provides a nut protein extraction device with an air blowing strip and a feeding sensor. The nut protein extraction device comprises a grinding module and an enzymatic hydrolysis module, wherein the grinding module comprises a primary grinding part, a secondary grinding part and a grinding module shell (5); the primary grinding part comprises a primary grinding motor (2); the primary grinding motor (2) is connected with a primary grinding main shaft (3) through power; the primary grinding main shaft (3) extends into a grinding chamber of the grinding module shell (5) through a left through hole in the left side of the grinding module shell (5) and is rotatably matched with the left through hole through a bearing part; primary grinding teeth (12) are distributed on a part, extending into the grinding chamber, of the primary grinding main shaft.

Owner:南通江海港建设工程有限公司

A complete set of fish collection device for pushing type of guide vane in drum

The invention discloses a complete set of fish collecting device with guide vanes in the drum. A rotating base and a clamping seat are installed on the hull; the lower end of the inverted U-shaped base frame is fixed on the rotating base, and the top of the inverted U-shaped base frame is installed There is a hanger, and a fixed pulley is installed on the top of the hanger; the left end of the drum is constrained by the drum power clamp, and the drum power clamp is installed in the middle of the inverted U-shaped base frame through the rotating shaft; the right end of the drum is constrained by the drum driven clamp, A positioning float is fixed under the driven clamp of the drum, and the positioning float is placed on the deck; the hoisting motor is fixed above the inverted U-shaped base frame, and the steel cable is driven by the hoisting motor and passes through the fixed pulley. The roller driven clamp is connected. The device of the invention has the advantages of simple structure, low cost, high fish collecting efficiency, low driving power and low fish loss rate.

Owner:SOUTH CHINA AGRI UNIV

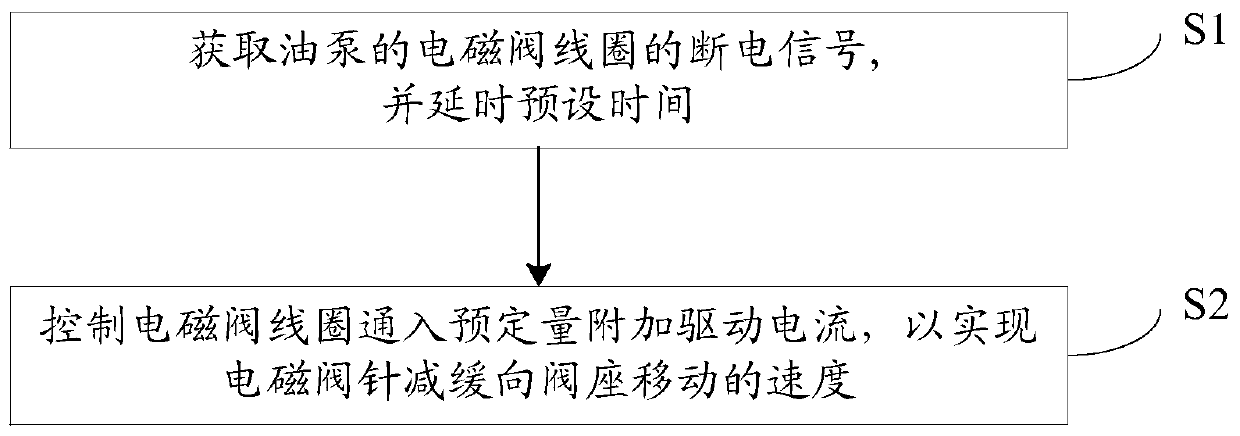

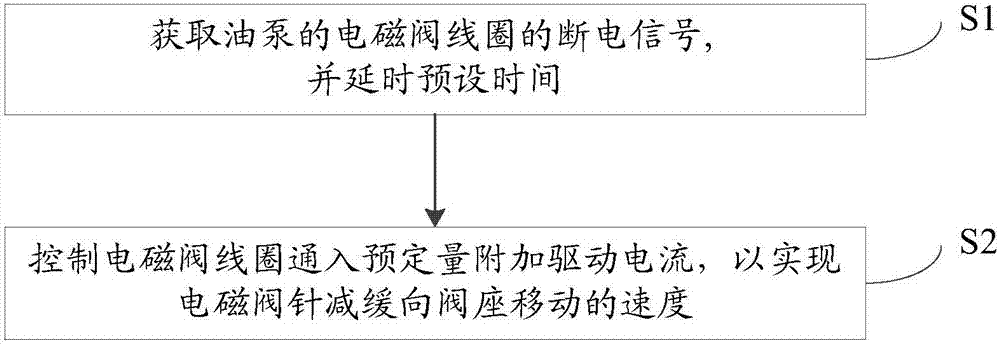

Method for reducing noise of oil pump, oil pump and engine

ActiveCN107489569BReduce impact forceReduce impactPositive displacement pump componentsLiquid fuel feedersSolenoid valveEngineering

The invention discloses a method for reducing oil pump noise. The method comprises the following steps that a power-off signal of an electromagnetic valve coil of an oil pump is obtained, and after the preset time is delayed, the additional force used for reducing the moving speed of an electromagnetic valve needle to a valve seat is exerted on the electromagnetic valve needle of the oil pump; and after the preset time of power-off of the electromagnetic valve coil, the additional force reducing the moving speed of the electromagnetic valve needle is exerted on the valve needle, so that the speed of seating of the electromagnetic valve needle can be reduced in order to reduce the impact strength of the electromagnetic valve needle and the valve seat and reduce the possibility of vibration caused by impact of the electromagnetic valve needle and the valve seat. On the one hand, by reducing impact and vibration, the stability of the oil pump is improved, the noise of the oil pump is reduced, and the NVH performance of a vehicle is improved; On the other hand, the moving speed of the electromagnetic valve needle is reduced, high-speed impact of the electromagnetic valve needle and the valve seat is avoided, the service life of the electromagnetic valve needle is prolonged, and equipment production materials are saved. The invention further discloses an oil pump for realizing the method and an engine comprising the oil pump.

Owner:BEIQI FOTON MOTOR CO LTD

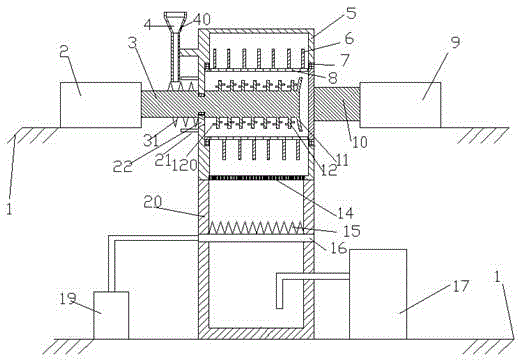

Swing hydraulic cylinder with damping function

PendingCN110836290AReduce trafficSlow downOperating means/releasing devices for valvesFluid-pressure actuatorsHydraulic cylinderGear wheel

The invention relates to the field of hydraulic machinery, and provides a swing hydraulic cylinder with a damping function. A hydraulic oil entering through a hydraulic oil inlet pushes a piston gearsleeve to reciprocate linearly, the piston gear sleeve and a rear gland are meshed through a spiral gear, the rear gland is fixed, the piston gear sleeve is also rotated in a spiral direction in the moving process, and the piston gear sleeve is meshed with an outer helical gear of an output shaft through an inner helical gear, so that the output shaft generates reciprocating rotary motion; a hydraulic oil inlet and a hydraulic oil outlet are each provided with two channels, the two channels are separated by a certain distance, and one channel is provided with a damping structure; and an oil cavity of the piston gear sleeve is a conical surface, the conical surface structure of the piston gear sleeve gradually seals the first channel of the hydraulic oil outlet in the process of running theend point, and hydraulic oil flows out only in the channel with the damping structure at the rear. According to the swing hydraulic cylinder, the opening and closing requirements of a flap valve canbe well met, the working reliability of the flap valve is improved, the transient noise of a valve opening and closing is reduced, and the valve closing signal is reliably output.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

Nut protein extraction device with primary auxiliary teeth and feeding sensor

InactiveCN103756879BAvoid churnAvoid lossBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringNut Proteins

The invention provides a nut protein extraction device with primary auxiliary teeth and a feeding sensor. The nut protein extraction device comprises a crushing module and an enzymolysis module, wherein the crushing module comprises a primary crushing component, a secondary crushing component and a crushing module shell (5), the primary crushing component comprises a primary crushing motor (2) which is in power connection with a primary crushing main shaft (3), the primary crushing main shaft (3) extends into the crushing chamber of the crushing module shell (5) through a left through hole formed at the left side of the crushing module shell (5), the primary crushing main shaft (3) is in rotatable fit with the left through hole through a bearing component, and primary crushing teeth (12) are distributed on the part, extending into the crushing chamber, of the primary crushing main shaft.

Owner:江苏快乐宝贝种植有限公司

Nut Protein Extraction Apparatus with Output Tube and Secondary Accessory Teeth

InactiveCN103756881BAvoid churnAvoid lossBioreactor/fermenter combinationsBiological substance pretreatmentsNut ProteinsAerospace engineering

The invention provides a nut protein extraction device with an output pipe and secondary auxiliary teeth. The nut protein extraction device comprises a crushing module and an enzymolysis module, wherein the crushing module comprises a primary crushing component, a secondary crushing component and a crushing module shell (5), the primary crushing component comprises a primary crushing motor (2) which is in power connection with a primary crushing main shaft (3), the primary crushing main shaft (3) extends into the crushing chamber of the crushing module shell (5) through a left through hole formed at the left side of the crushing module shell (5), the primary crushing main shaft (3) is in rotatable fit with the left through hole through a bearing component, and primary crushing teeth (12) are distributed on the part, extending into the crushing chamber, of the primary crushing main shaft.

Owner:王良源

Nut protein extracting device with blowing strip and primary assistant teeth

ActiveCN103756884BAvoid churnAvoid lossBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringNut Proteins

The invention provides a nut protein extracting device with a blowing strip and primary assistant teeth. The device comprises a smashing module and an enzymolysis module, wherein the smashing module comprises a primary smashing part, a secondary smashing part and a smashing module shell (5); the primary smashing part comprises a primary smashing motor (2); the primary smashing motor (2) is in power connection with a primary smashing main shaft (3); the primary smashing main shaft (3) extends to a smashing chamber of the smashing module shell (5) through a left through hole at left side of the smashing module shell (5); the primary smashing main shaft (3) is rotatably cooperated with the left through hole through a bearing part; primary smashing teeth (12) are distributed on the part, extending to the smashing chamber, of the primary smashing main shaft.

Owner:启东斯单珂工具制造有限公司

Nut protein extractor with feed sensor and blowing stirrer

ActiveCN103756875BAvoid churnAvoid lossBioreactor/fermenter combinationsBiological substance pretreatmentsEgg whiteAerospace engineering

The invention provides a nut protein extractor with a feed sensor and a blowing stirring device, which comprises a pulverization module and an enzymolysis module, wherein the pulverization module comprises a primary pulverization part, a secondary pulverization part and a pulverization module shell (5); the primary pulverization part comprises a primary pulverization motor (2) which is connected with a primary pulverization main shaft (3) through power; the primary pulverization main shaft (3) extends into a pulverization chamber of the pulverization module shell (5) through a left through hole on the left side of the pulverization module shell (5); the primary pulverization main shaft (3) is rotatablely matched with the left through hole through a bearing part; and primary pulverization teeth (12) are distributed on the part of the primary pulverization main shaft extending into the pulverization chamber.

Owner:启东和安无纺材料有限公司

Nut protein extraction device with two-level subsidiary teeth and feeding sensor

InactiveCN103756876BAvoid churnAvoid lossBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringNut Proteins

The invention provides a nut protein extraction device with two-level subsidiary teeth and feeding sensor. The nut protein extraction device comprises a smashing module and an enzymolysis module, wherein the smashing module comprises a first-level smashing part, a second-level smashing part and a smashing module shell (5); the first-level smashing part comprises a first-level smashing motor (2), the first-level smashing motor (2) is in power connection with a first-level smashing main shaft (3), and the first-level smashing main shaft (3) stretches into a smashing chamber of the smashing module shell (5) through a left through hole formed in the left side of the smashing module shell (5); the first-level smashing main shaft (3) is rotatablely matched with the left through hole through a bearing part, and first-level smashing teeth (12) are distributed on a part, which stretches into the smashing chamber, of the first-level smashing main shaft.

Owner:GUANGDONG MEIYAN HYDROPOWER CO LTD

Nut protein extractor with feed sensor and blowing stirrer

ActiveCN103756875AAvoid churnAvoid lossBioreactor/fermenter combinationsBiological substance pretreatmentsEgg whiteAerospace engineering

The invention provides a nut protein extractor with a feed sensor and a blowing stirring device, which comprises a pulverization module and an enzymolysis module, wherein the pulverization module comprises a primary pulverization part, a secondary pulverization part and a pulverization module shell (5); the primary pulverization part comprises a primary pulverization motor (2) which is connected with a primary pulverization main shaft (3) through power; the primary pulverization main shaft (3) extends into a pulverization chamber of the pulverization module shell (5) through a left through hole on the left side of the pulverization module shell (5); the primary pulverization main shaft (3) is rotatablely matched with the left through hole through a bearing part; and primary pulverization teeth (12) are distributed on the part of the primary pulverization main shaft extending into the pulverization chamber.

Owner:启东和安无纺材料有限公司

Nut protein extracting device with output tube and primary auxiliary teeth

InactiveCN103756878BAvoid churnAvoid lossBioreactor/fermenter combinationsBiological substance pretreatmentsComputer modulePulp and paper industry

Owner:徐学铖

Nut protein extraction device with primary auxiliary teeth and feeding sensor

InactiveCN103756879AAvoid churnAvoid lossBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringNut Proteins

The invention provides a nut protein extraction device with primary auxiliary teeth and a feeding sensor. The nut protein extraction device comprises a crushing module and an enzymolysis module, wherein the crushing module comprises a primary crushing component, a secondary crushing component and a crushing module shell (5), the primary crushing component comprises a primary crushing motor (2) which is in power connection with a primary crushing main shaft (3), the primary crushing main shaft (3) extends into the crushing chamber of the crushing module shell (5) through a left through hole formed at the left side of the crushing module shell (5), the primary crushing main shaft (3) is in rotatable fit with the left through hole through a bearing component, and primary crushing teeth (12) are distributed on the part, extending into the crushing chamber, of the primary crushing main shaft.

Owner:江苏快乐宝贝种植有限公司

Nut protein extraction device with blowing strip and blowing stirring device

InactiveCN103789196BAvoid churnAvoid lossBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringGrinding teeth

The invention provides a nut protein extraction device with a blowing strip and a blowing stirring device, which comprises a grinding module and an enzymolysis module, wherein the grinding module comprises a first-level grinding component, a second-level grinding component and a grinding module shell (5); the first-level grinding component comprises a first-level grinding motor (2); the first-level grinding motor (2) is in power connection with a first-level grinding main shaft (3); the first-level grinding main shaft (3) stretches into a grinding chamber of the grinding module shell (5) through a left through hole in the left side of the grinding module shell (5) and is in rotatable fit with the left through hole through a bearing component; first-level grinding teeth (12) are distributed on the part, stretching into the grinding chamber, of the first-level grinding main shaft.

Owner:南通海永科技创意园有限公司

Nut protein extraction device with first-stage secondary teeth and air blowing stirring device

The invention provides a nut protein extraction device with first-stage secondary teeth and an air blowing stirring device. The nut protein extraction device comprises a grinding module and an enzymatic hydrolysis module, wherein the grinding module comprises a primary grinding part, a secondary grinding part and a grinding module shell (5); the primary grinding part comprises a primary grinding motor (2); the primary grinding motor (2) is connected with a primary grinding main shaft (3) through power; the primary grinding main shaft (3) extends into a grinding chamber of the grinding module shell (5) through a left through hole in the left side of the grinding module shell (5) and is rotatably matched with the left through hole through a bearing part; primary grinding teeth (12) are distributed on a part, extending into the grinding chamber, of the primary grinding main shaft.

Owner:温州天龙机械科技有限公司

Nut protein extraction device with output pipe and gas blowing stirring device

InactiveCN103756883AAvoid churnAvoid lossBioreactor/fermenter combinationsBiological substance pretreatmentsEnzymatic hydrolysisEngineering

The invention provides a nut protein extraction device with an output pipe and a gas blowing stirring device. The nut protein extraction device comprises a crushing module and an enzymatic hydrolysis module, wherein the crushing module comprises a primary crushing part, a secondary crushing part and a crushing module shell (5), the primary crushing part comprises a primary crushing motor (2), the primary crushing motor (2) is dynamically connected with a primary crushing spindle (3), the primary crushing spindle (3) extends into a crushing cavity of the crushing module shell (5) through a left through hole formed in the left side of the crushing module shell (5) and is rotatably matched with the left through hole by virtue of a bearing part, and primary crushing teeth (12) are distributed on the part of the primary crushing spindle, extending into the crushing cavity.

Owner:南通海永科技创意园有限公司

Nut protein extraction device with first-stage auxiliary teeth and blowing and stirring device

The invention provides a nut protein extraction device with first-stage secondary teeth and an air blowing stirring device. The nut protein extraction device comprises a grinding module and an enzymatic hydrolysis module, wherein the grinding module comprises a primary grinding part, a secondary grinding part and a grinding module shell (5); the primary grinding part comprises a primary grinding motor (2); the primary grinding motor (2) is connected with a primary grinding main shaft (3) through power; the primary grinding main shaft (3) extends into a grinding chamber of the grinding module shell (5) through a left through hole in the left side of the grinding module shell (5) and is rotatably matched with the left through hole through a bearing part; primary grinding teeth (12) are distributed on a part, extending into the grinding chamber, of the primary grinding main shaft.

Owner:温州天龙机械科技有限公司

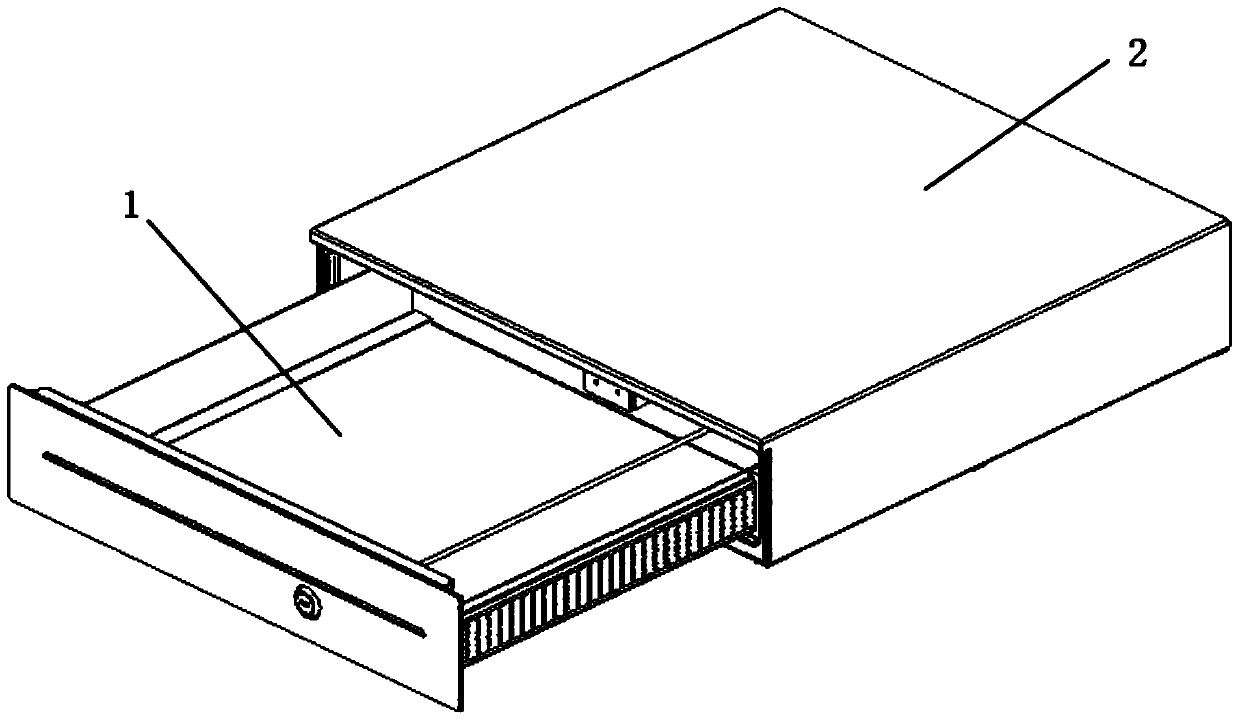

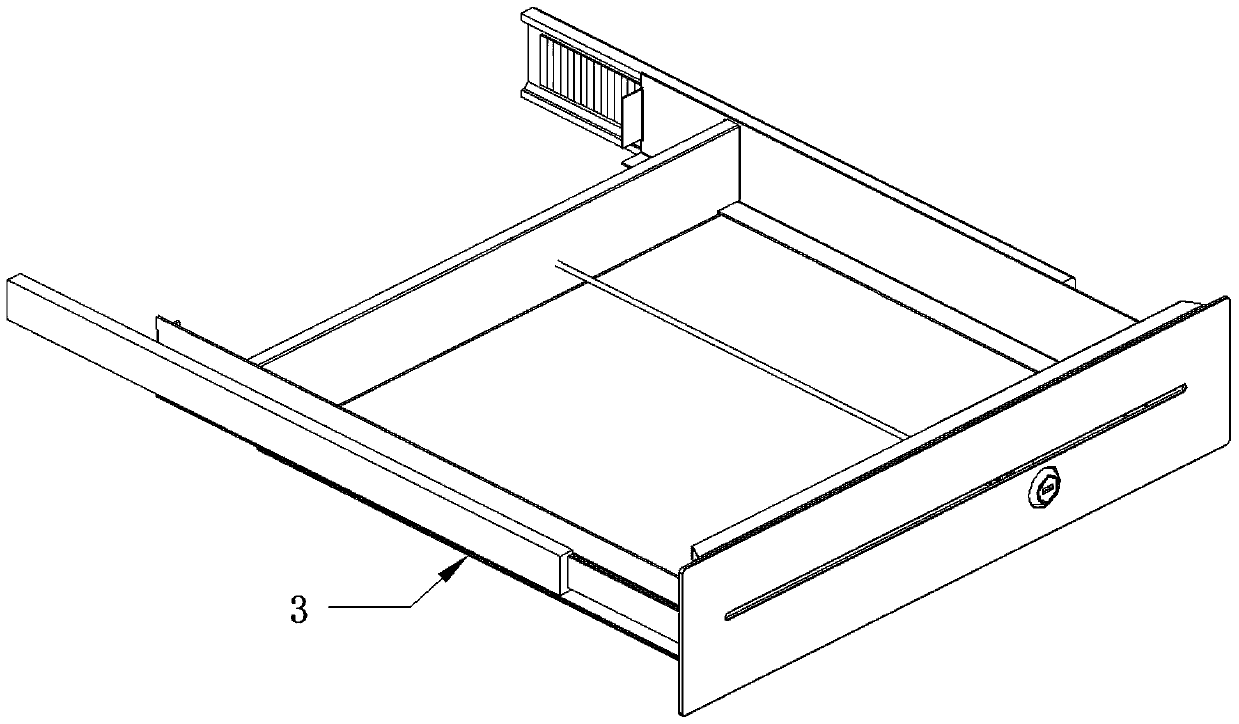

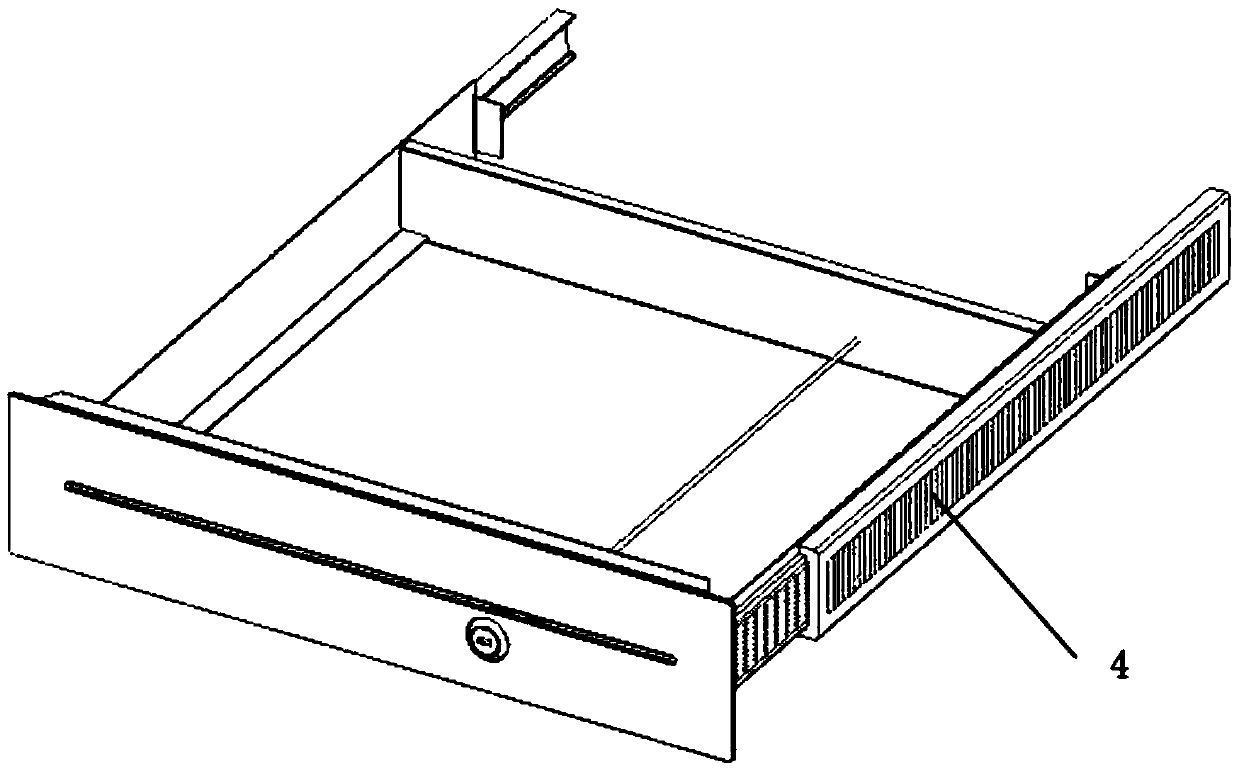

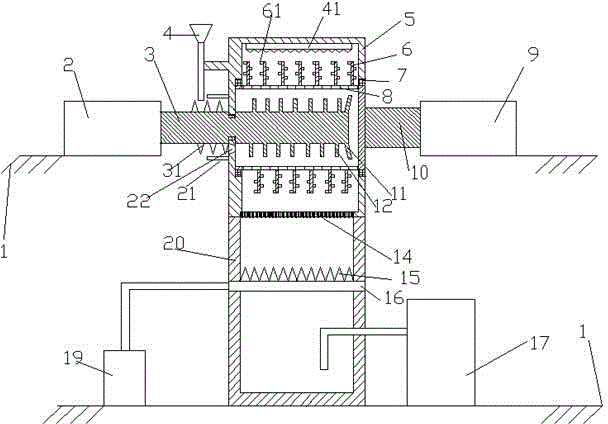

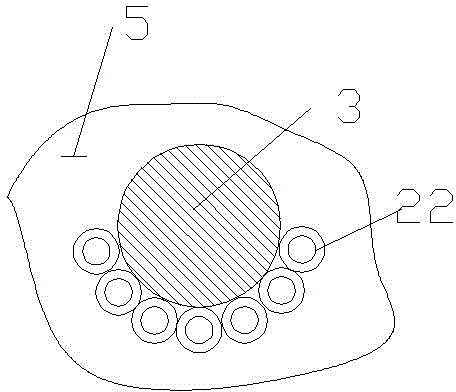

A magnetic levitation smart drawer and its operating method

The present invention is applicable to the field of living appliances, and provides a magnetic levitation smart drawer and its operating method. The drawer includes a drawer body and a box matching the drawer body. The joint part of the drawer body and the box body A guide rail for positioning and guiding is installed on one side, and a linear motor is installed on the other side, and the drawer also includes a power supply system connected to the linear motor. The present invention uses a linear motor as a power source, and the power supply system outputs alternating current to the linear motor. Driven by the linear motor, the drawer body slides inward or outward along the guide rail, and the linear motor exerts a more uniform force on the drawer body, and there is no energy failure. situation, there is basically no noise during use. The invention provides an intelligent drawer. The drawer body is in a state of constant control and self-adaptation to realize its smooth, quiet and fast reciprocating operation and effectively reduce noise.

Owner:深圳桑达银络科技有限公司

Nut protein extraction device provided with air blowing strips and secondary teeth

InactiveCN103756882BAvoid churnAvoid lossBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringNut Proteins

Owner:南通海永科技创意园有限公司

Method for reducing oil pump noise, oil pump and engine

ActiveCN107489569AReduce impact forceReduce the impactPositive displacement pump componentsLiquid fuel feedersEngineeringElectromagnetic valve

The invention discloses a method for reducing oil pump noise. The method comprises the following steps that a power-off signal of an electromagnetic valve coil of an oil pump is obtained, and after the preset time is delayed, the additional force used for reducing the moving speed of an electromagnetic valve needle to a valve seat is exerted on the electromagnetic valve needle of the oil pump; and after the preset time of power-off of the electromagnetic valve coil, the additional force reducing the moving speed of the electromagnetic valve needle is exerted on the valve needle, so that the speed of seating of the electromagnetic valve needle can be reduced in order to reduce the impact strength of the electromagnetic valve needle and the valve seat and reduce the possibility of vibration caused by impact of the electromagnetic valve needle and the valve seat. On the one hand, by reducing impact and vibration, the stability of the oil pump is improved, the noise of the oil pump is reduced, and the NVH performance of a vehicle is improved; On the other hand, the moving speed of the electromagnetic valve needle is reduced, high-speed impact of the electromagnetic valve needle and the valve seat is avoided, the service life of the electromagnetic valve needle is prolonged, and equipment production materials are saved. The invention further discloses an oil pump for realizing the method and an engine comprising the oil pump.

Owner:BEIQI FOTON MOTOR CO LTD

Nut protein extraction device with output pipe and feeding sensor

ActiveCN103756877BAvoid churnAvoid lossBioreactor/fermenter combinationsBiological substance pretreatmentsComputer moduleEngineering

The invention provides a nut protein extraction device with an output pipe and a feeding sensor. The nut protein extraction device comprises a crushing module and an enzymolysis module, wherein the crushing module comprises a primary crushing component, a secondary crushing component and a crushing module shell (5), the primary crushing component comprises a primary crushing motor (2) which is in power connection with a primary crushing main shaft (3), the primary crushing main shaft (3) extends into the crushing chamber of the crushing module shell (5) through a left through hole formed at the left side of the crushing module shell (5), the primary crushing main shaft (3) is in rotatable fit with the left through hole through a bearing component, and primary crushing teeth (12) are distributed on the part, extending into the crushing chamber, of the primary crushing main shaft.

Owner:启东斯单珂工具制造有限公司

Nut protein extraction device with output pipe and gas blowing stirring device

InactiveCN103756883BAvoid churnAvoid lossBioreactor/fermenter combinationsBiological substance pretreatmentsEnzymatic hydrolysisEngineering

The invention provides a nut protein extraction device with an output pipe and a gas blowing stirring device. The nut protein extraction device comprises a crushing module and an enzymatic hydrolysis module, wherein the crushing module comprises a primary crushing part, a secondary crushing part and a crushing module shell (5), the primary crushing part comprises a primary crushing motor (2), the primary crushing motor (2) is dynamically connected with a primary crushing spindle (3), the primary crushing spindle (3) extends into a crushing cavity of the crushing module shell (5) through a left through hole formed in the left side of the crushing module shell (5) and is rotatably matched with the left through hole by virtue of a bearing part, and primary crushing teeth (12) are distributed on the part of the primary crushing spindle, extending into the crushing cavity.

Owner:南通海永科技创意园有限公司

Nut protein extracting device with secondary teeth and gas blowing stirring device

ActiveCN103749938BAvoid churnAvoid lossBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringNut Proteins

The invention provides a nut protein extracting device with secondary teeth and a gas blowing stirring device. The nut protein extracting device comprises a smashing module and an enzymolysis module, wherein the smashing module comprises a first-stage smashing part, a second-stage smashing part and a smashing module shell (5); the first-stage smashing part comprises a first-stage smashing motor (2) which is connected with a first-stage main smashing shaft (3) through power; the first-stage main smashing shaft (3) extends into a smashing chamber of the smashing module shell (5) through a left through hole in the left side of the smashing module shell (5); the first-stage main smashing shaft (3) is rotatably matched with the left through hole through a bearing part; first-stage smashing teeth (12) are distributed on the part, extending into the smashing chamber, of the first-stage main smashing shaft.

Owner:广东康必健医疗科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com