Laser surface modelling engine piston ring and preparation method thereof

A technology for piston rings and engines, which is applied to piston rings, engine components, laser welding equipment, etc., can solve the problems of complex production process and equipment, high labor intensity of workers, and pollution of the environment, and achieves small thermal deformation, improved hardness, The effect of reducing the harm to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

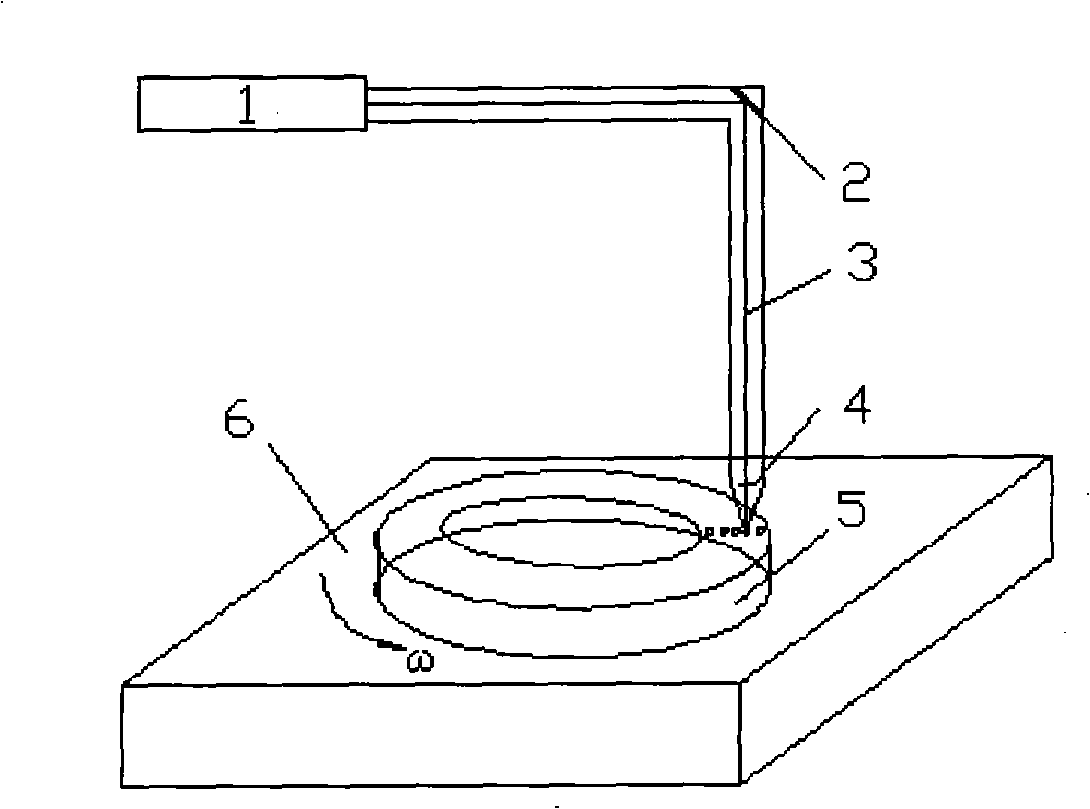

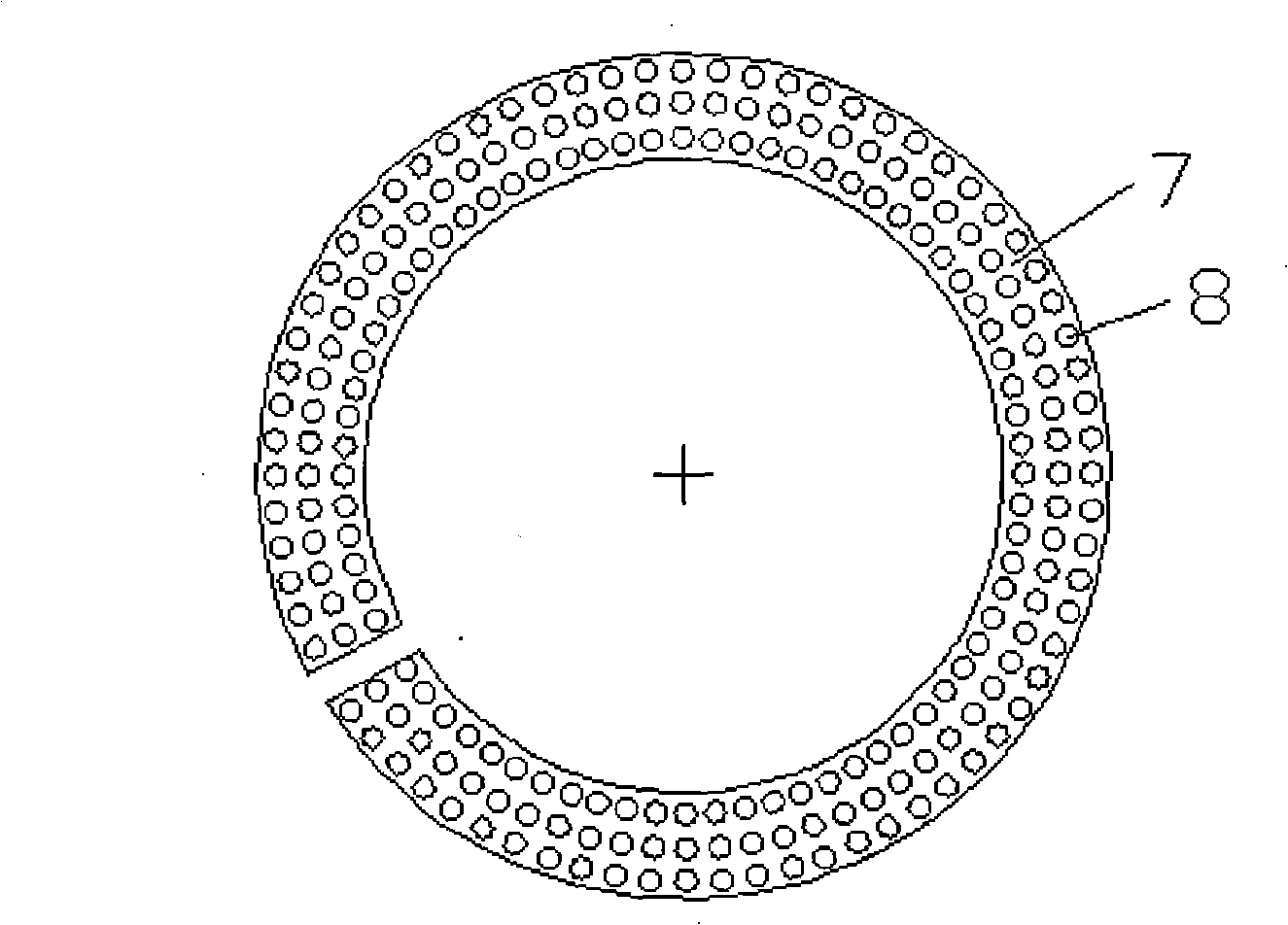

[0014] The specific implementation process of the present invention will be described below by taking the first gas ring of an automobile engine as an example.

[0015] The laser micromodeling equipment uses a diode-pumped Nd:YAG laser.

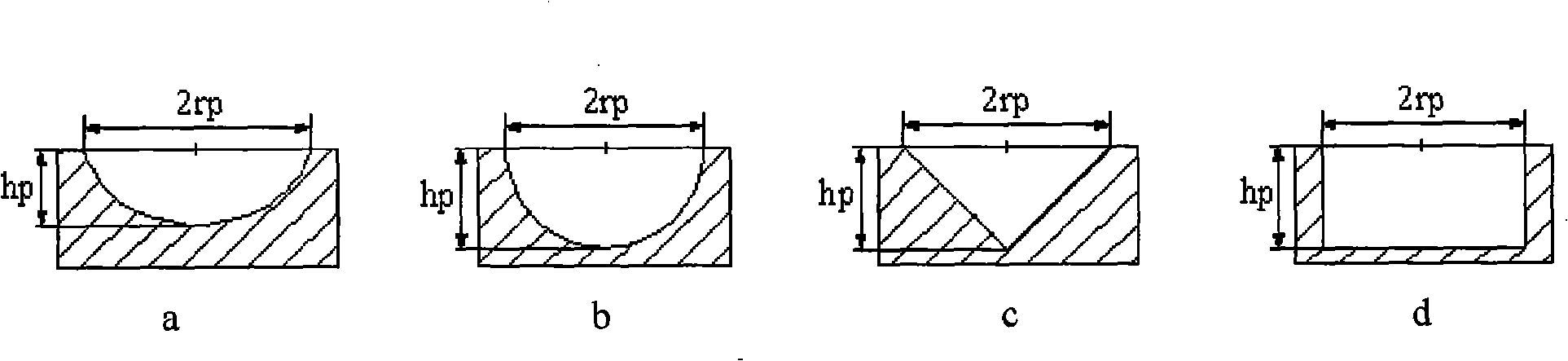

[0016] The embodiment of the present invention provides a method for preparing the upper and lower end faces of a laser micro-modeled piston ring, the steps of which are as follows:

[0017] Step 1: Provide a diode-pumped Nd:YAG laser whose basic parameters are: laser power 3W, Q-switched pulse frequency 1-50KHz, wavelength 532nm.

[0018] The second step: select a piston ring with a rectangular section of the engine, and its material is ductile cast iron.

[0019] Step 3: Drive the laser and adjust the laser power density to 10 5 -10 7 W / cm 2 , the pulse width is 30-50ns, the wavelength is 532nm, the pump current is 20.5A, and the pulse frequency is 7.8KHz. Input the size parameters of the piston ring, the rotating speed of the worktable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com