Nut protein extraction device with first-stage auxiliary teeth and blowing and stirring device

A nut protein and extraction device technology, which is applied in the field of plant protein extraction, can solve the problems of loss of nut and fruit nutrients, large impact force of nut particles, and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

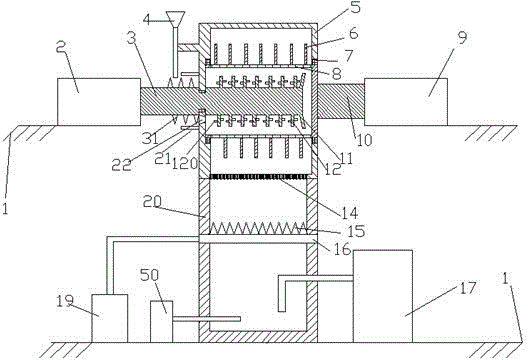

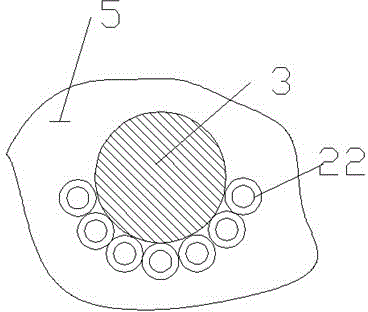

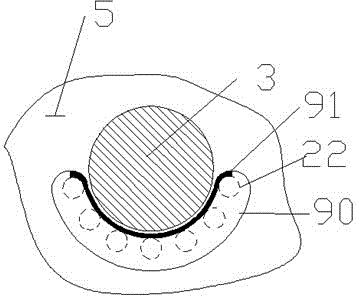

[0014] A nut protein extraction device with a first-stage auxiliary tooth and an air-blowing stirring device, including a crushing module and an enzymolysis module, wherein the crushing module includes a primary crushing component, a secondary crushing component and a crushing module shell 5, the The primary crushing component includes a primary crushing motor 2, and the primary crushing motor 2 is power-connected with a primary crushing main shaft 3, and the primary crushing main shaft 3 extends into the The crushing chamber of the crushing module shell 5, the primary crushing main shaft 3 is rotatably matched with the left through hole through a bearing component, and a part of the primary crushing main shaft extending into the crushing chamber is distributed with a Stage crushing teeth 12, said primary crushing teeth 12 comprising cylindrical portion crushing teeth extending along the radial direction of the cylindrical surface of said primary crushing main shaft and end por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com