Swing hydraulic cylinder with damping function

A swing hydraulic cylinder and functional technology, applied in the field of swing hydraulic cylinders, can solve the problems of impacting the valve body, loud noise, and large volume, and achieve the effects of avoiding high-speed impact, reducing impact force, and small cylinder volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiment is only one of the embodiments of the present invention, not all of them. .

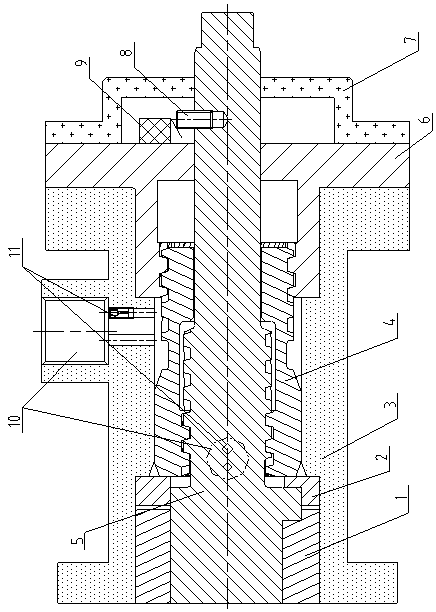

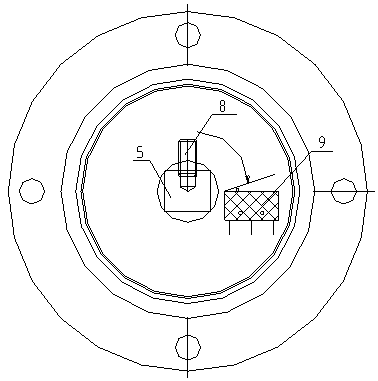

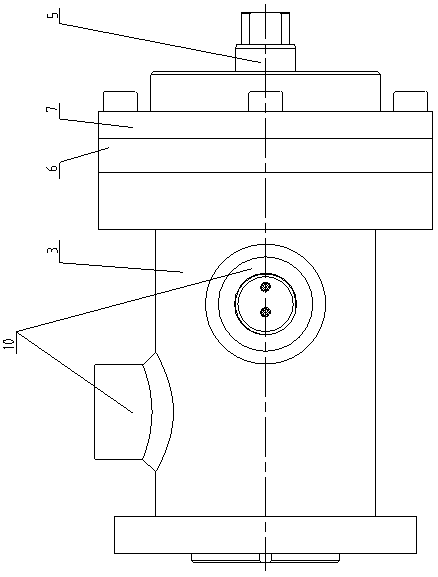

[0019] Such as Figure 1~3 As shown, a swing hydraulic cylinder with damping function includes piston gear sleeve 4, hydraulic cylinder body 3, output shaft 5, gasket 2, front gland 1, rear gland 6, hydraulic oil inlet, hydraulic oil outlet, Damping structure 11 and junction box 7.

[0020] The hydraulic cylinders are arranged with hydraulic oil inlets and hydraulic oil outlets in directions perpendicular to each other at 90 degrees. The hydraulic oil entering the hydraulic oil inlet pushes the piston gear sleeve 4 to reciprocate and linearly move. The piston gear sleeve 4 and the rear gland 6 are meshed through the helical gear, and the rear gland 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com