Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

154results about "Letterpress printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

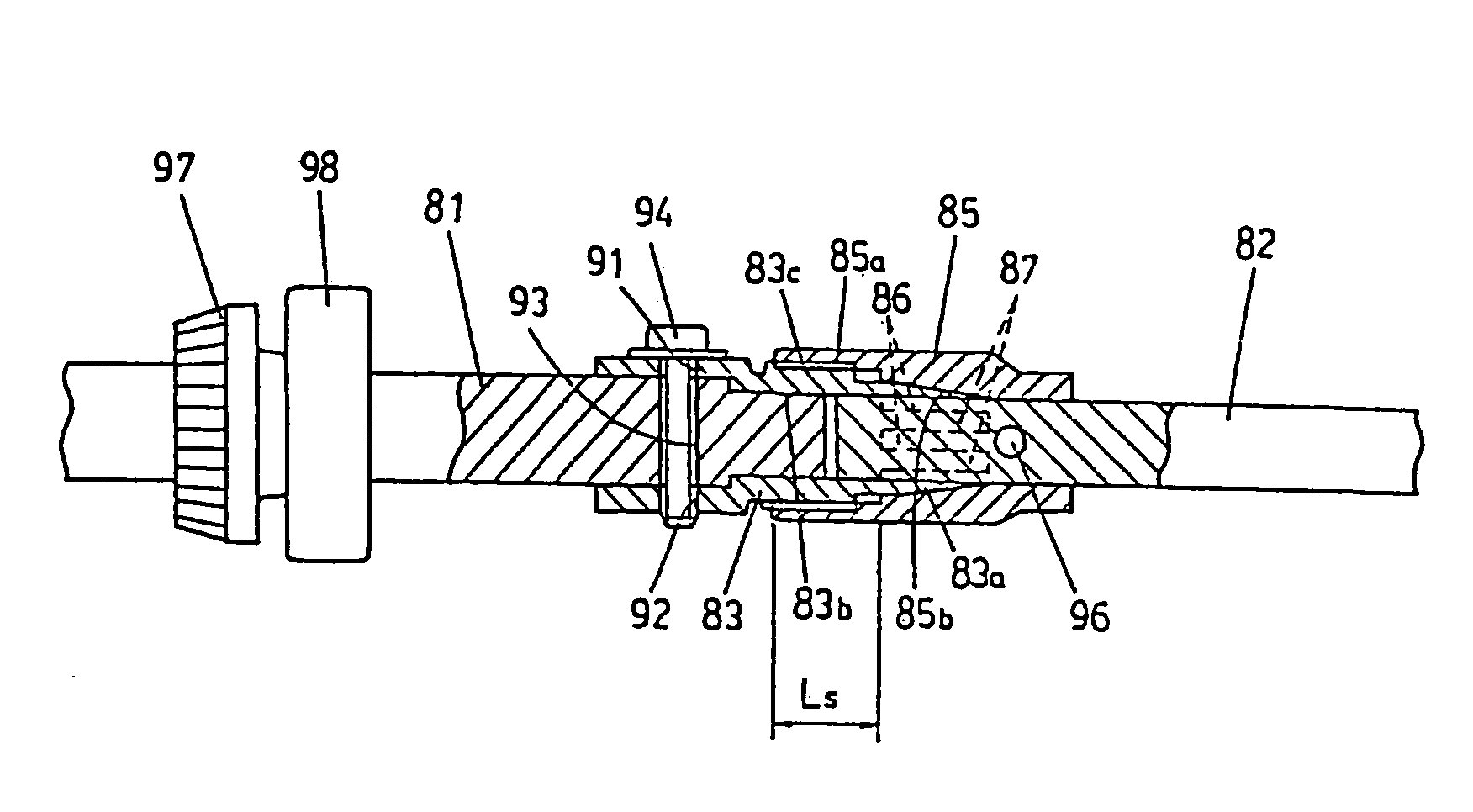

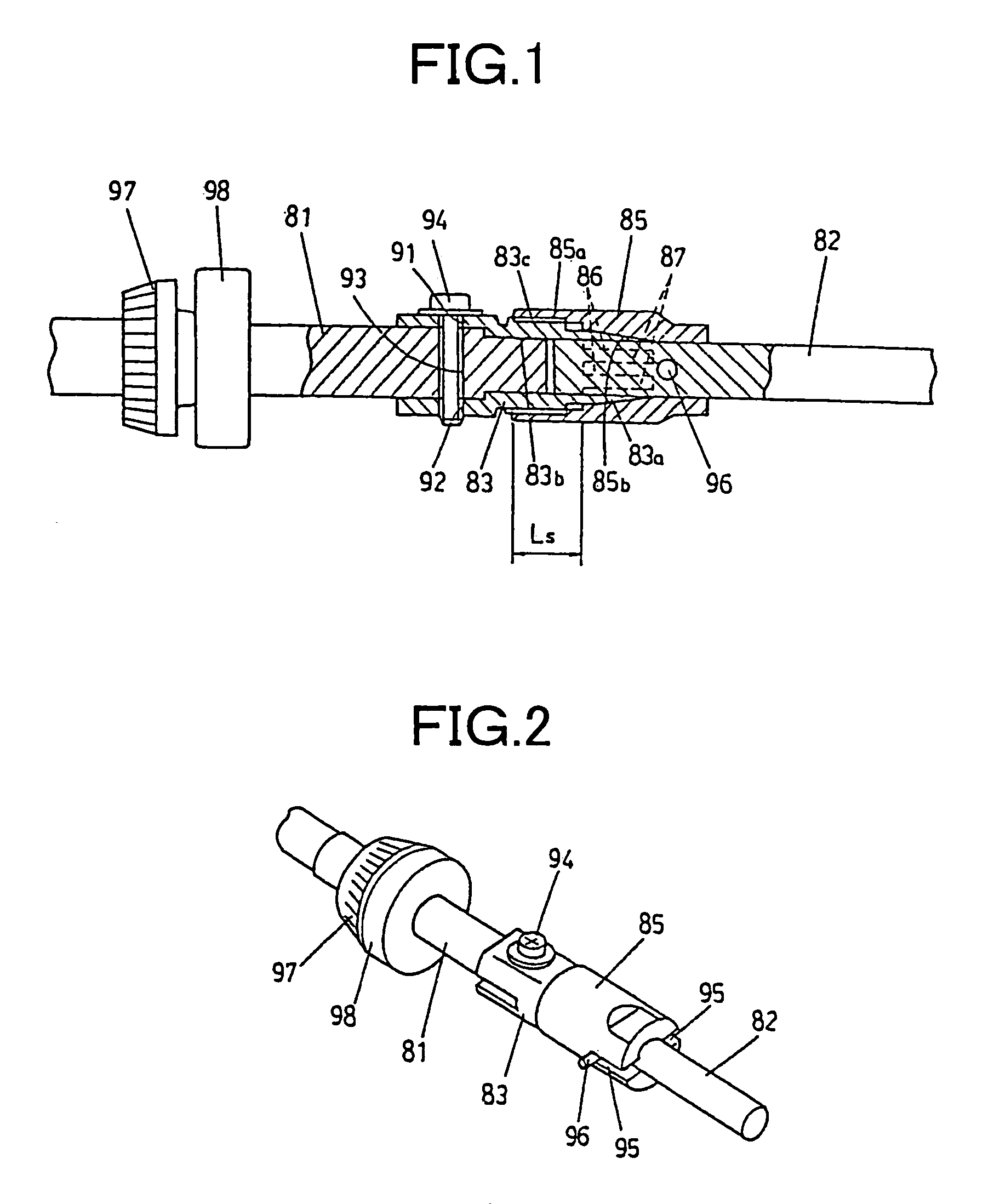

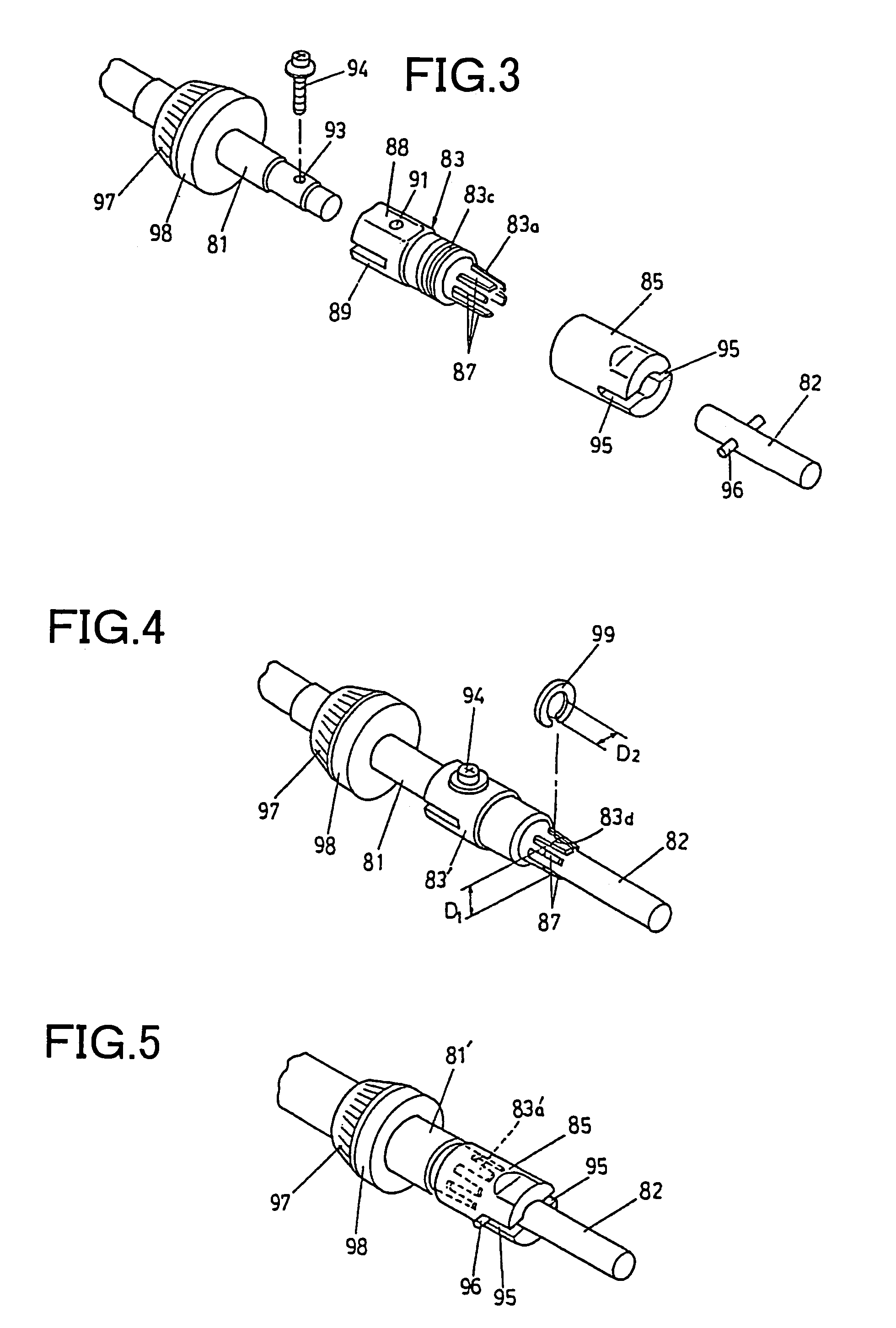

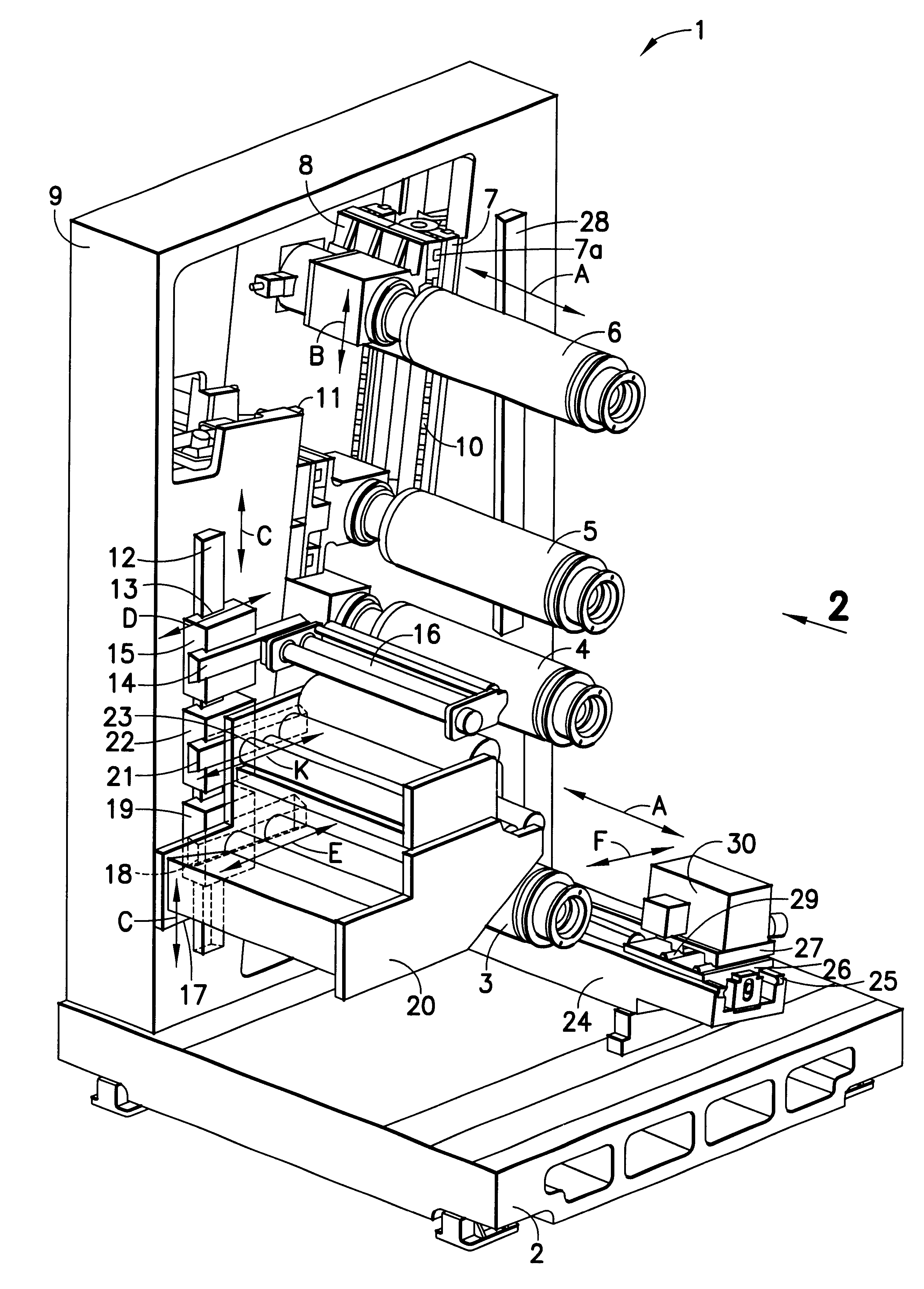

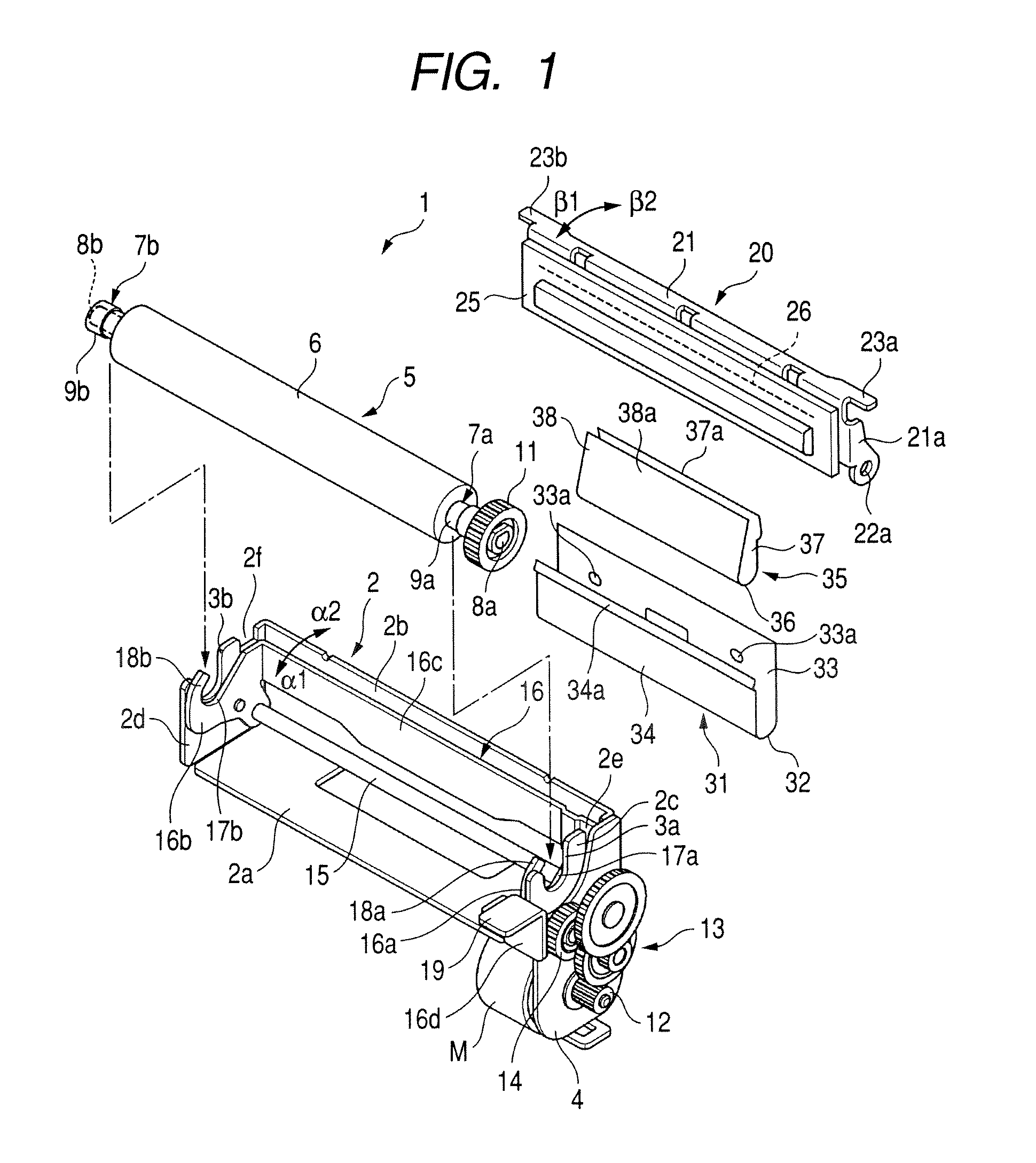

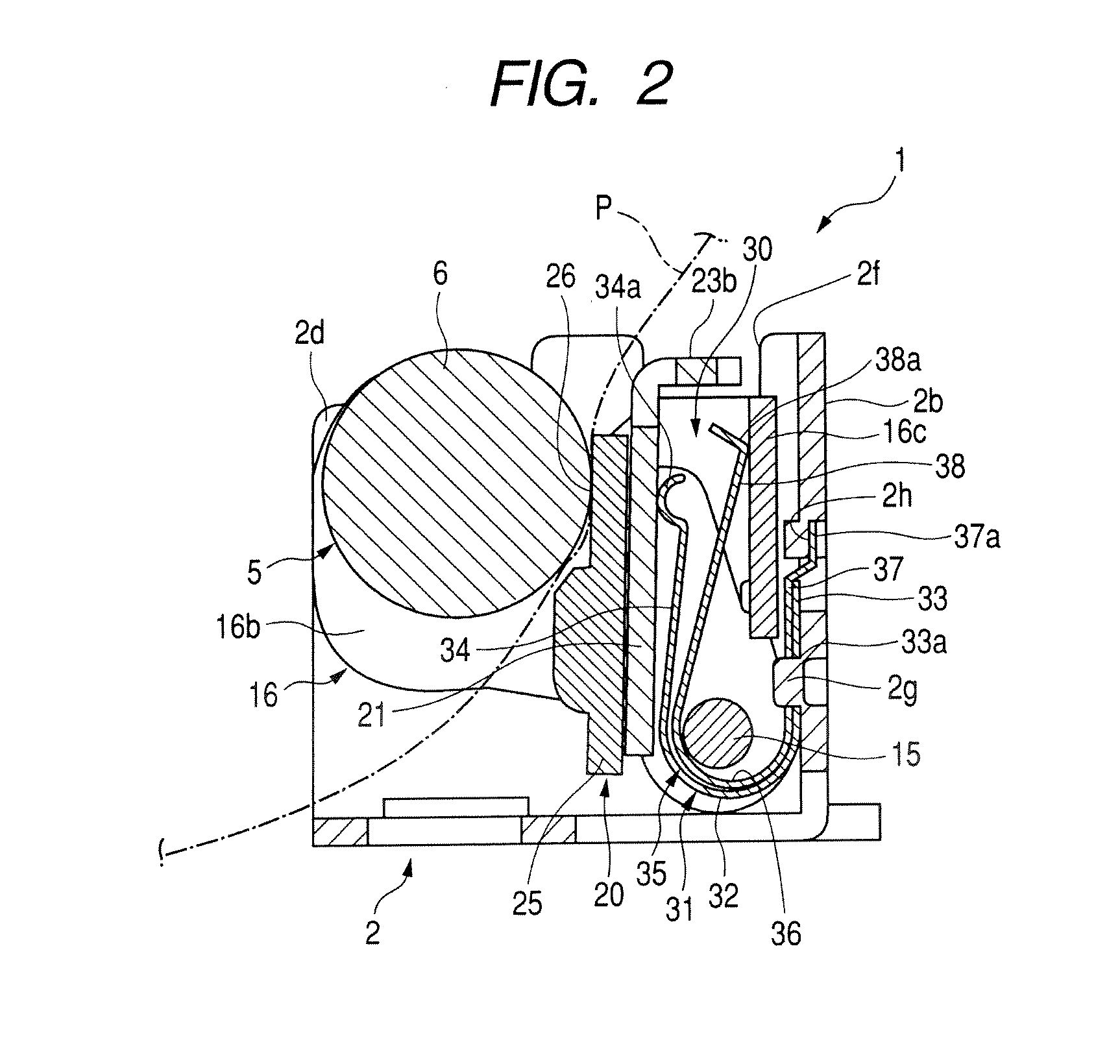

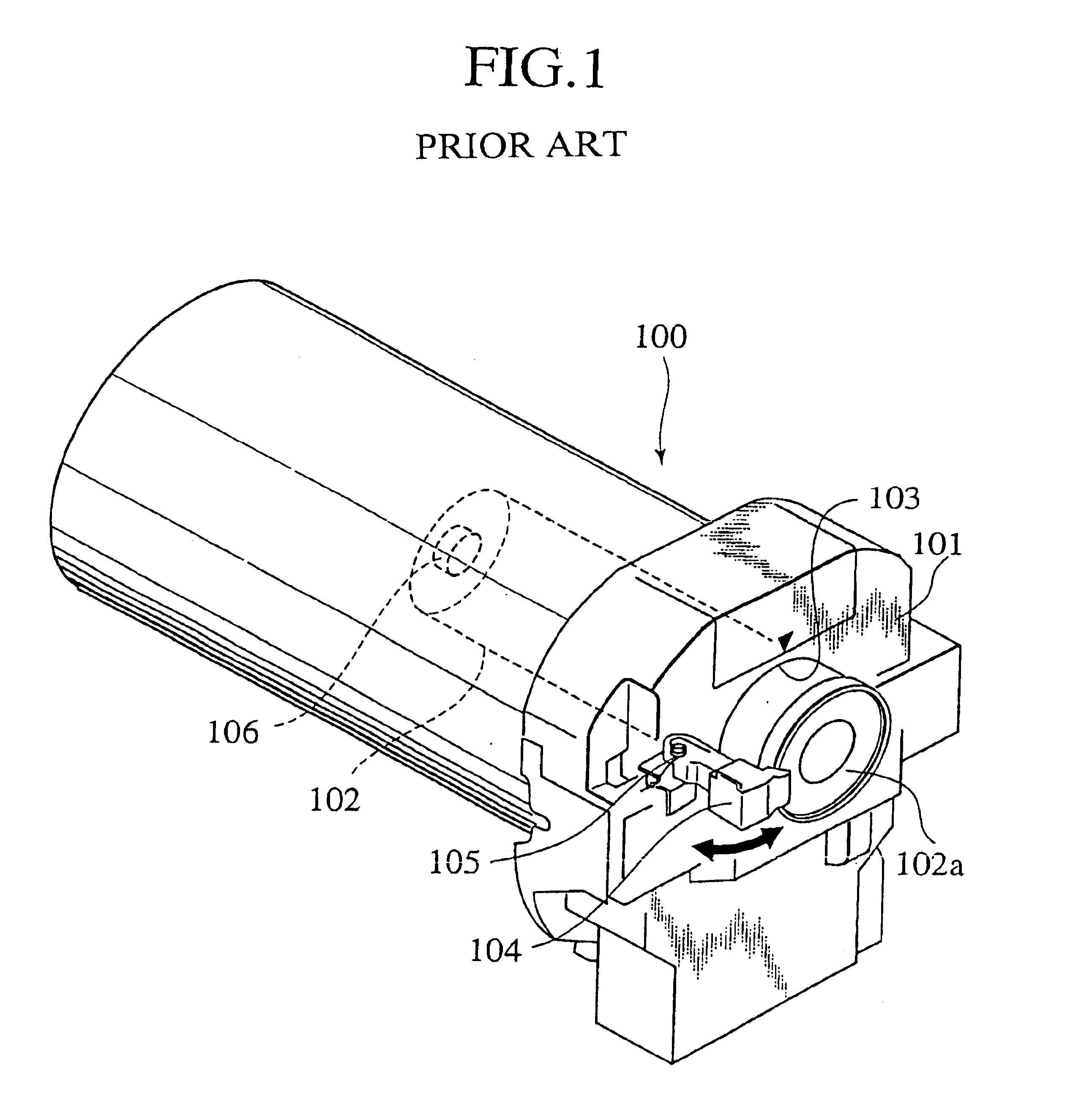

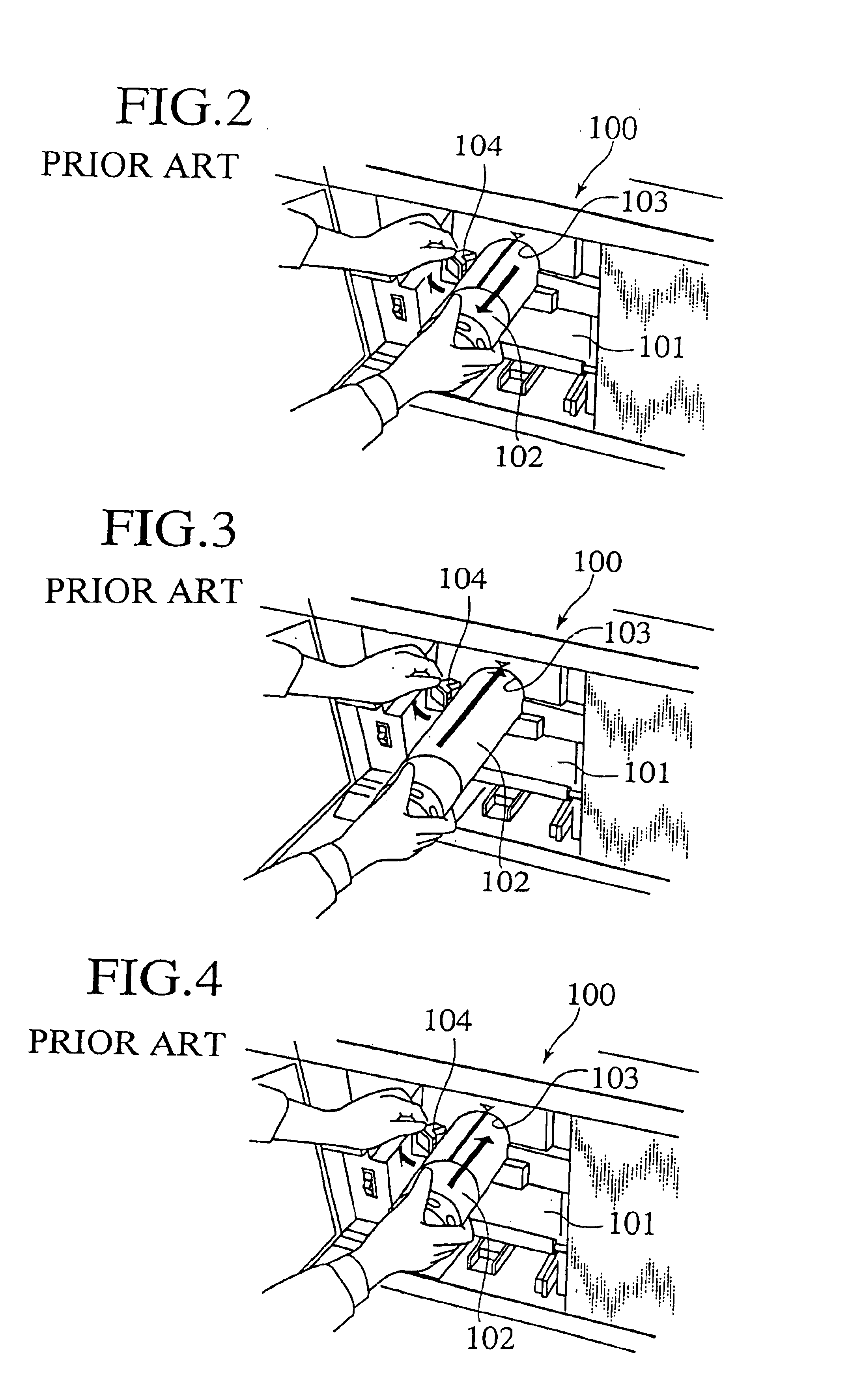

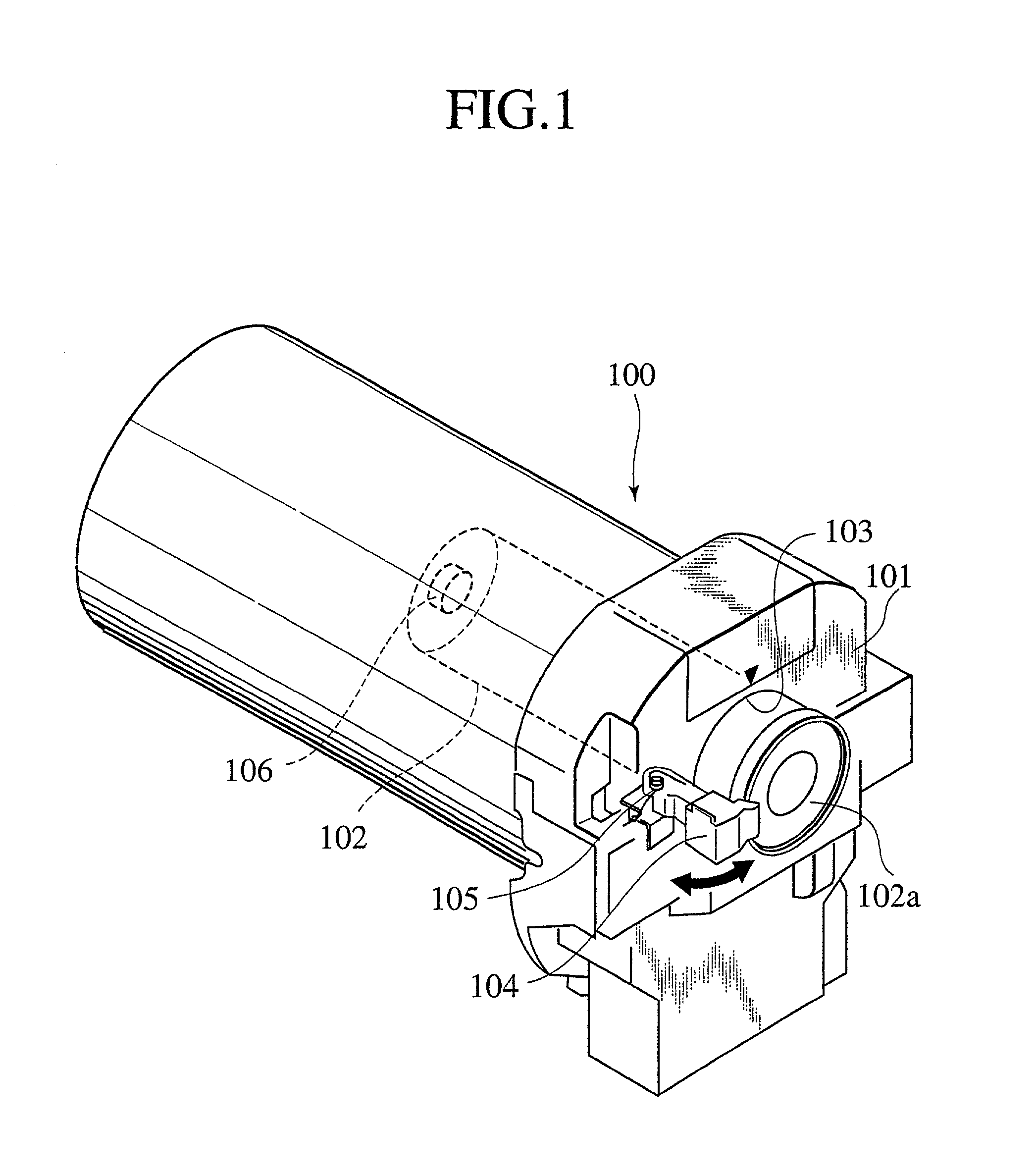

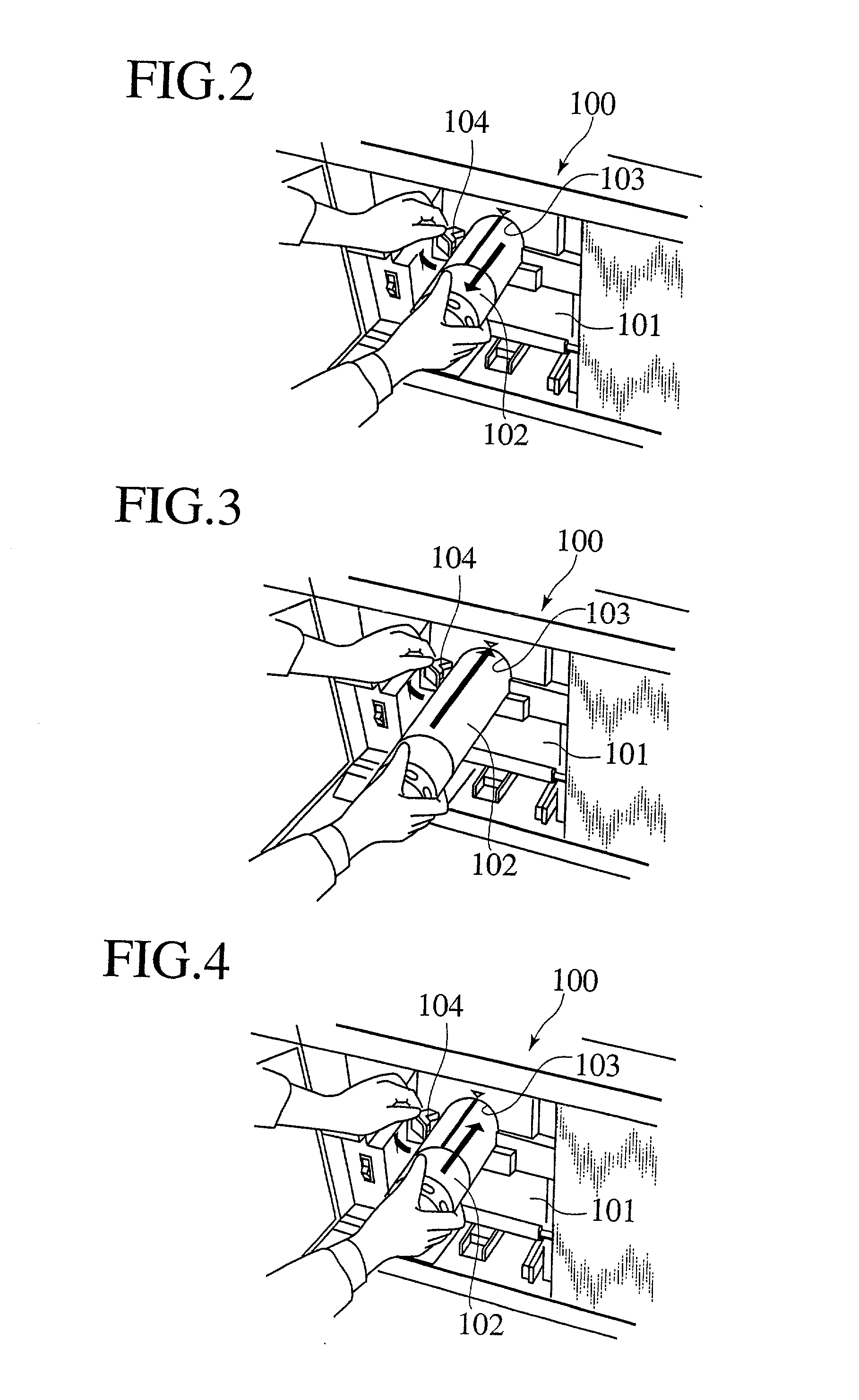

Device for and method of coupling shafts, image formation apparatus, process cartridge, and belt unit

A shaft coupling device for coupling a first shaft and a second shaft together includes a grip unit to be attached to the first shaft and including a grip portion configured to grip the second shaft, the grip portion having an end with notches of a length being parallel with an axial direction of the first shaft. The shaft coupling device also includes a grip force acting unit to be attached to the second shaft and configured to cause a grip force for gripping the second shaft to act on the grip portion by moving the grip portion in a radial direction of the second shaft.

Owner:RICOH KK

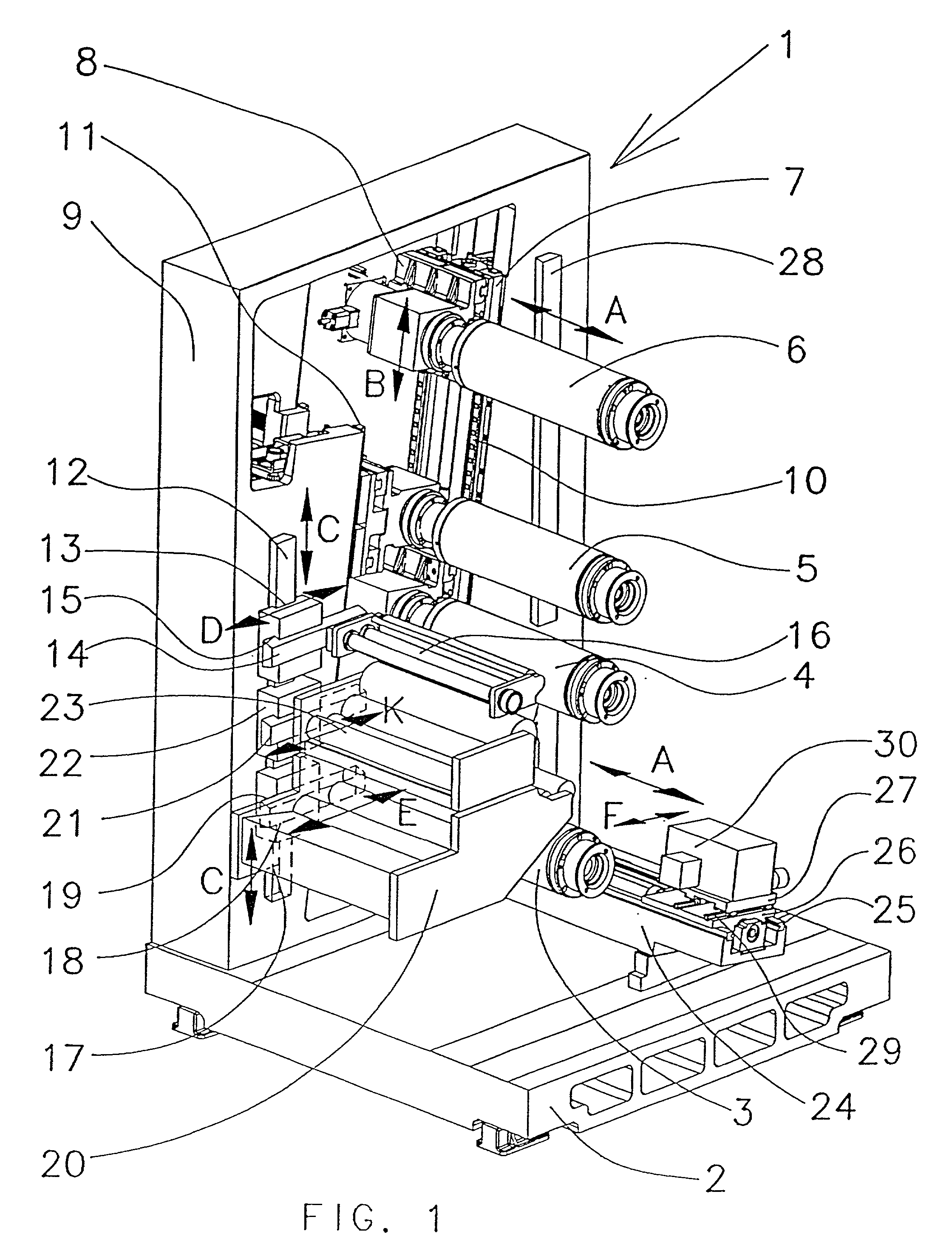

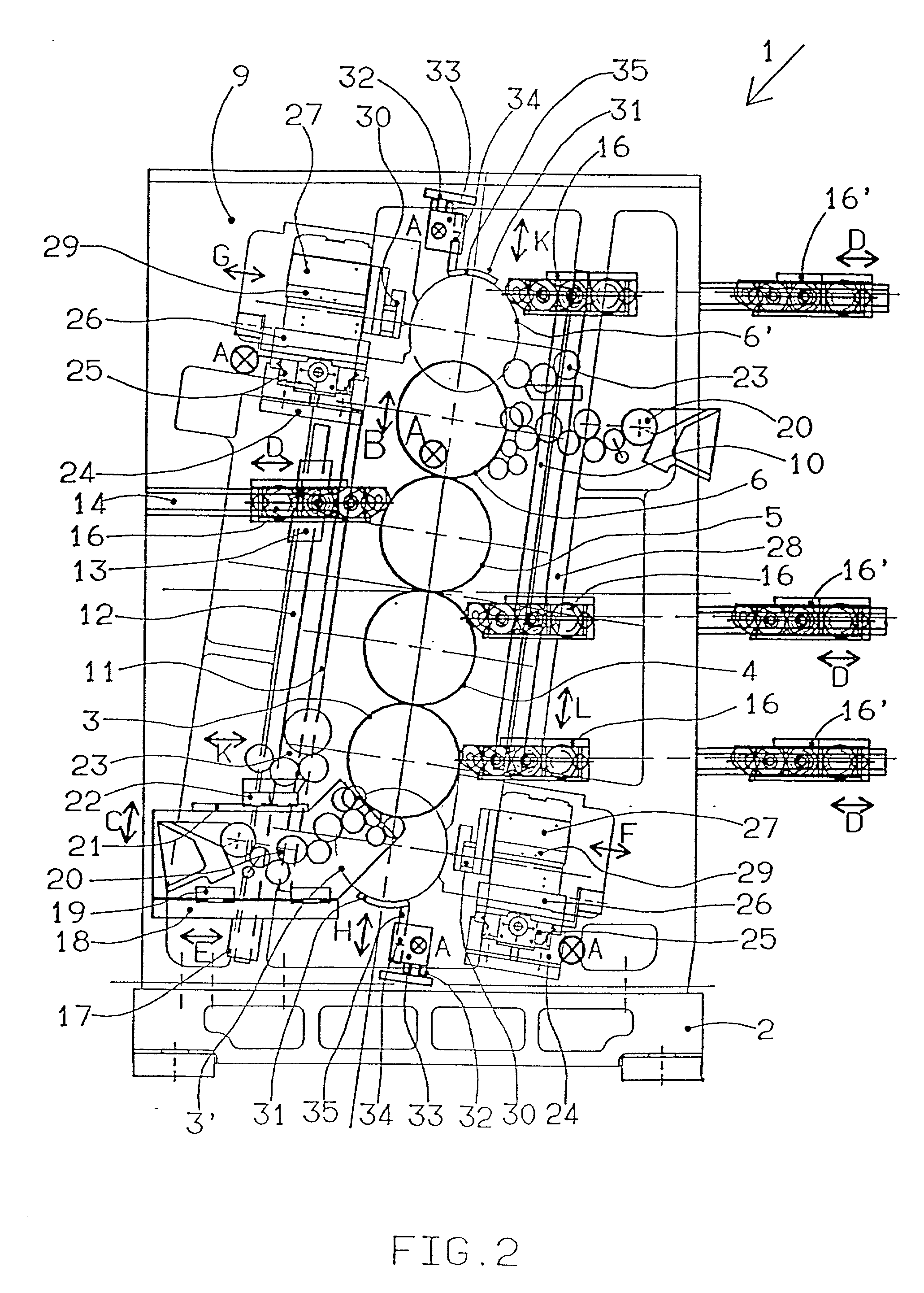

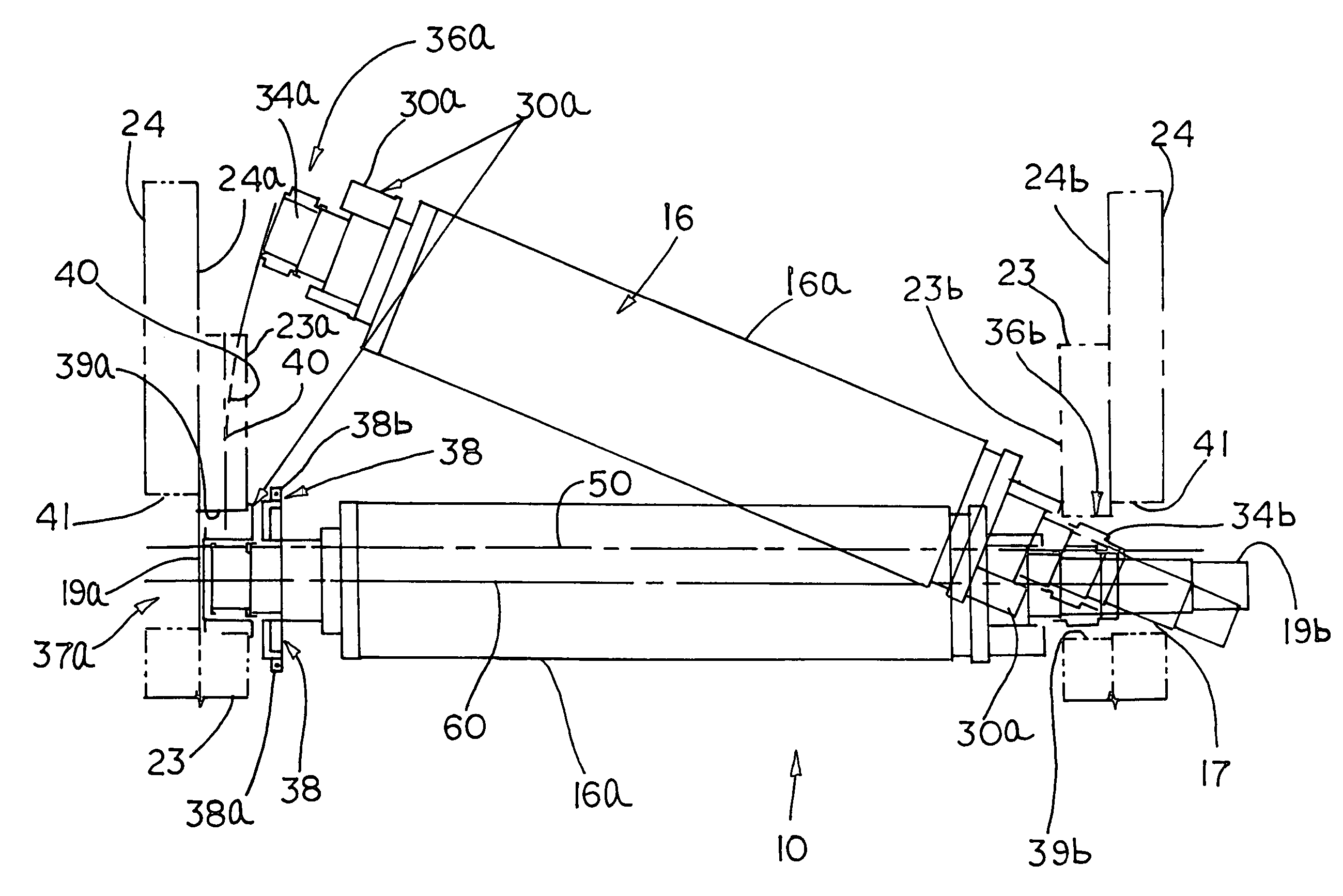

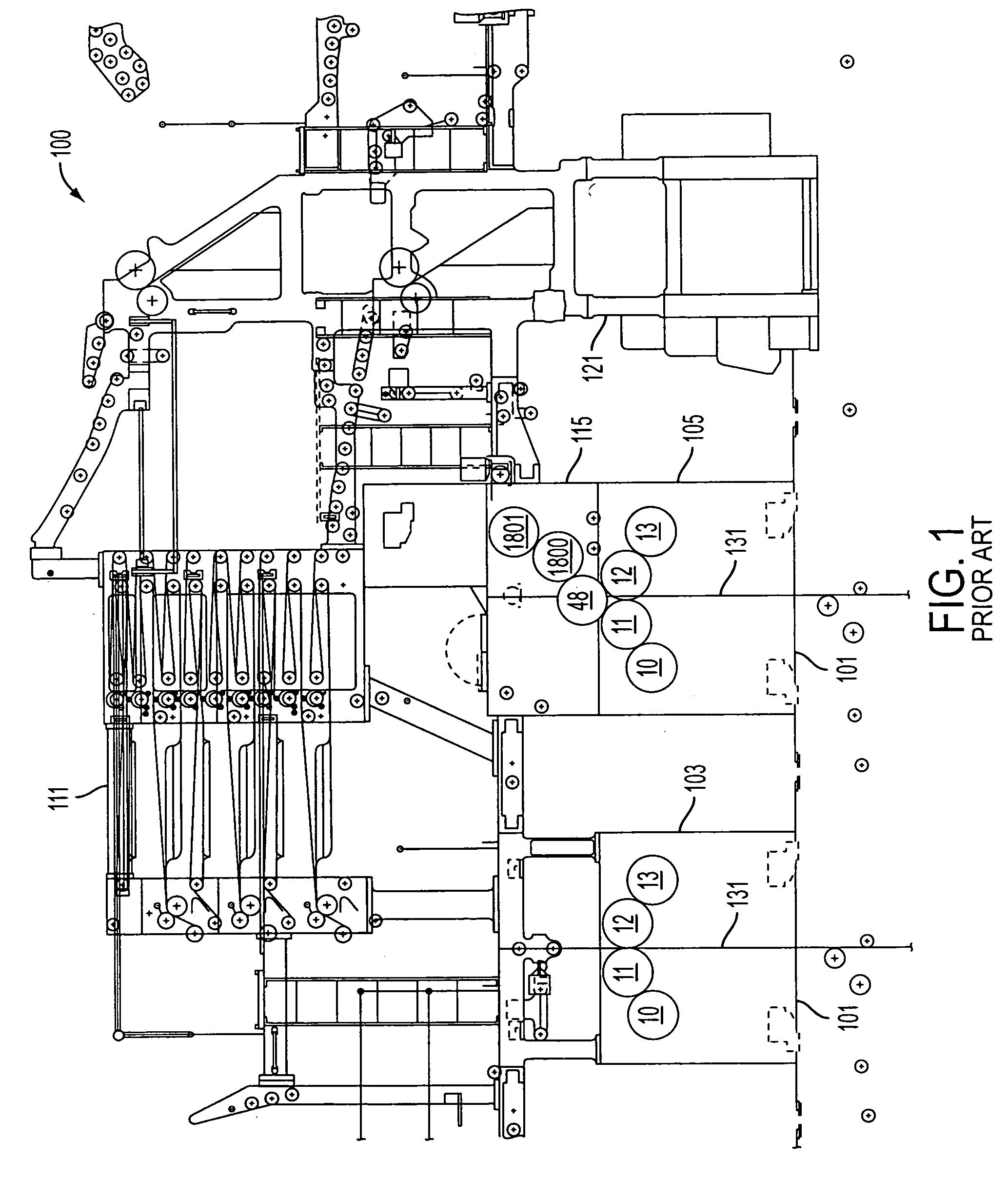

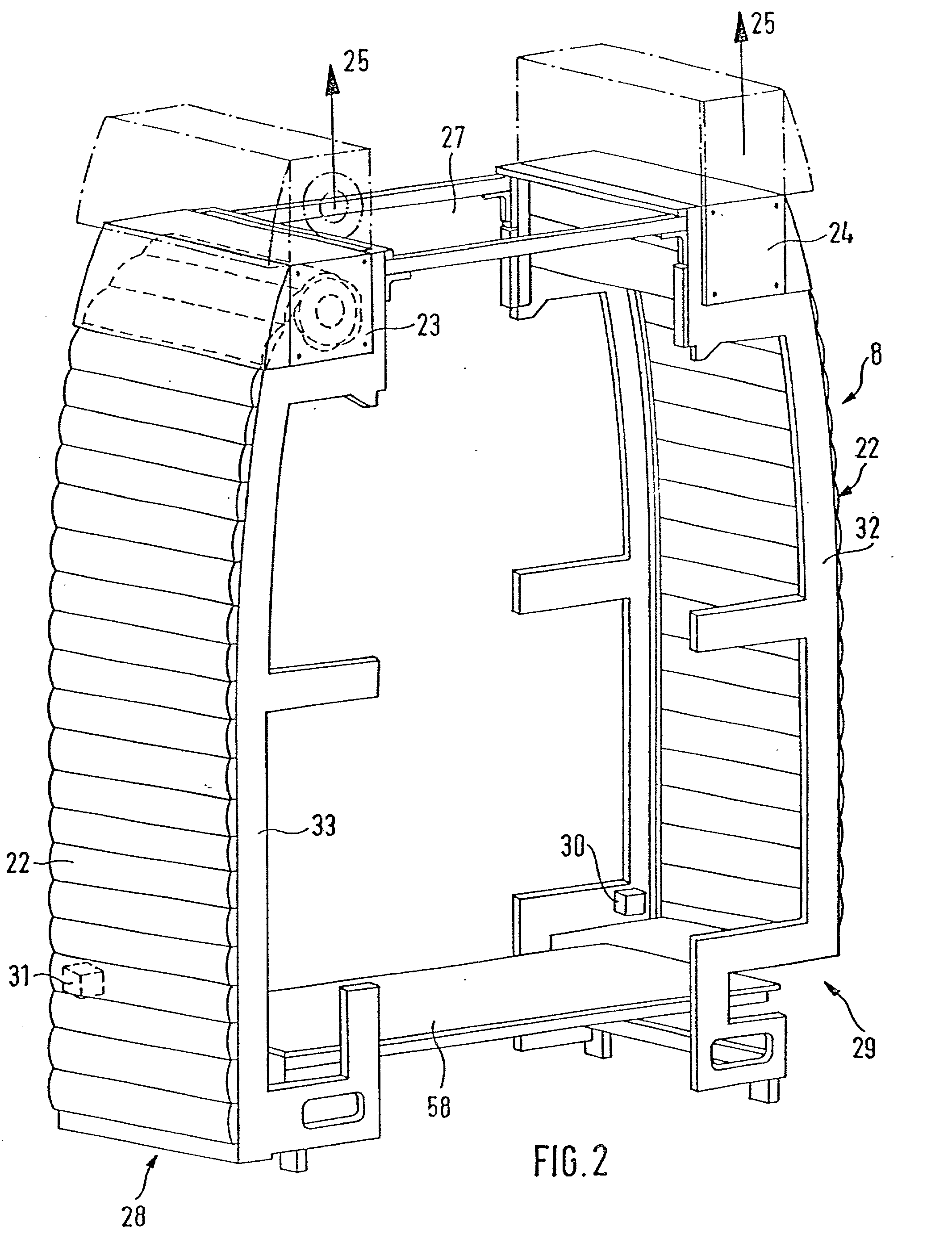

Printing unit

A printing unit for a web-fed rotary printing machine is provided having at least one carrying wall, a plurality of cylinders mounted on the carrying wall, a drive motor corresponding to each cylinder and a slide corresponding to each cylinder. Each slide carries its corresponding cylinder and receives the corresponding drive motor. A drive means is provided for driving the slides and a plurality of guide elements are mounted on the carrying wall and arranged laterally next to the adjacent end faces of the cylinders for guiding the slides along the wall. The guide elements are arranged opposite and parallel to one another on the carrying wall. Optionally, the carrying wall includes panels defining an orifice to allow cylinders, journals and sleeves of the printing machine of varying sizes to be changed readily.

Owner:MANROLANAD AG

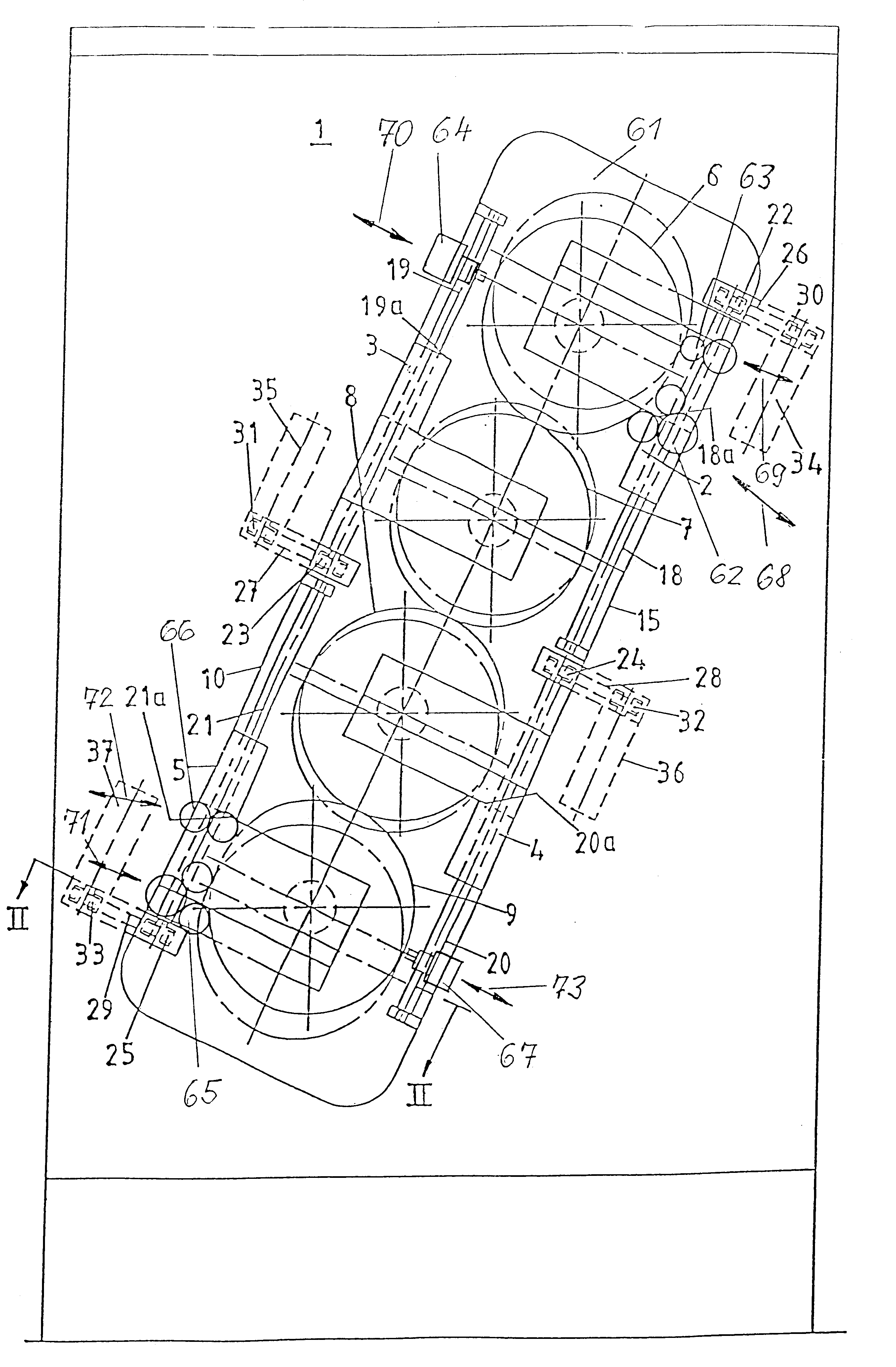

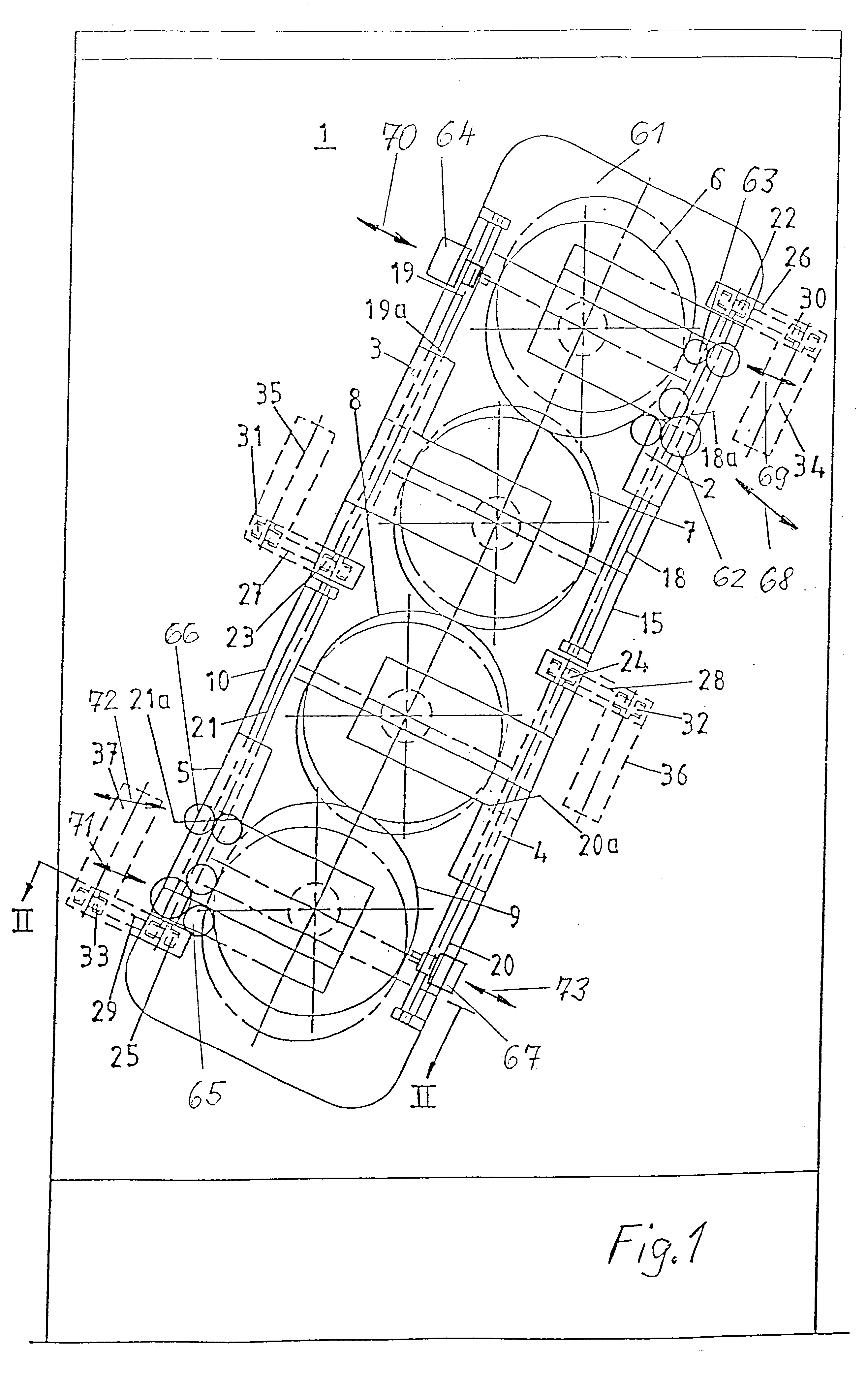

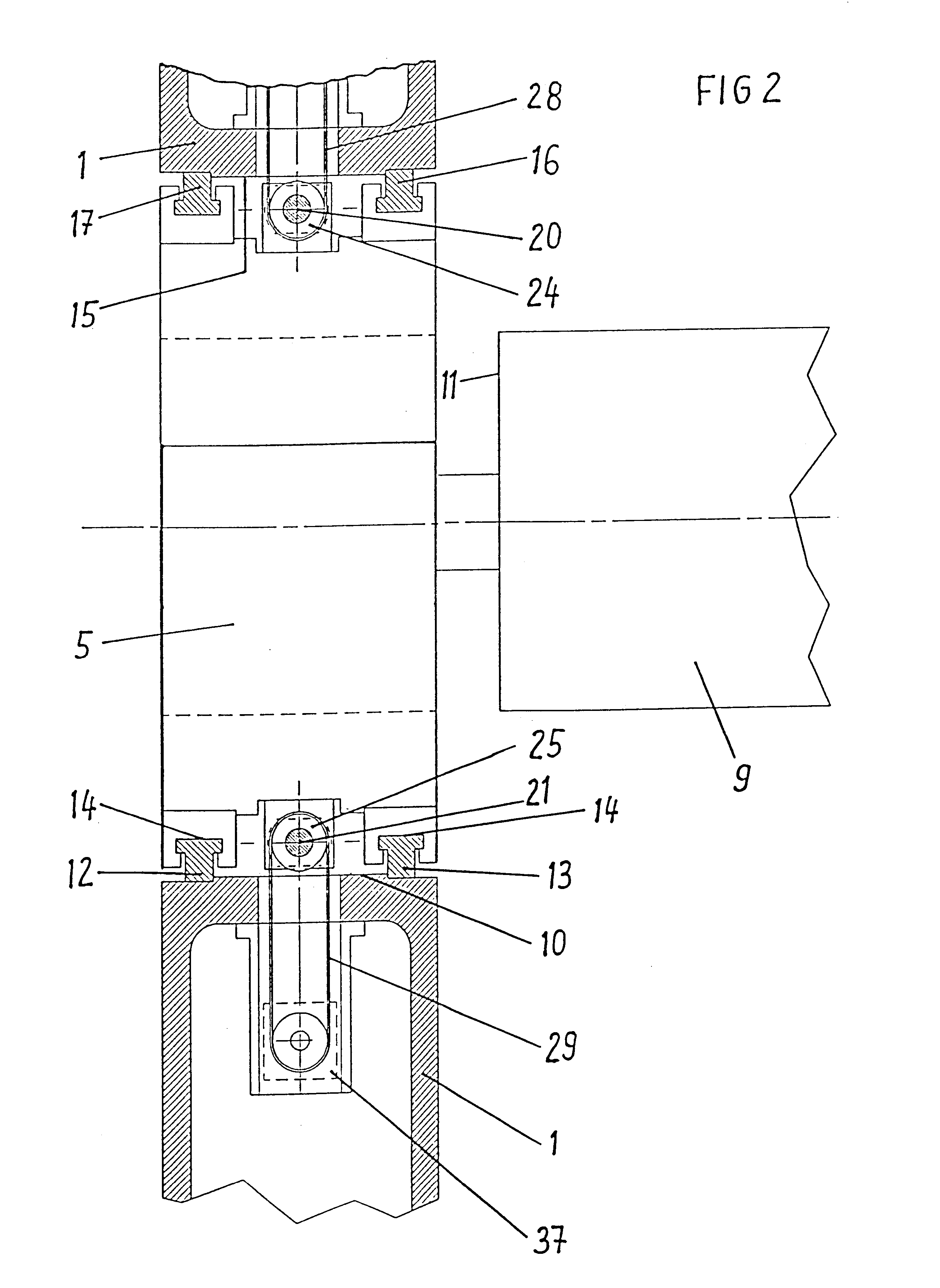

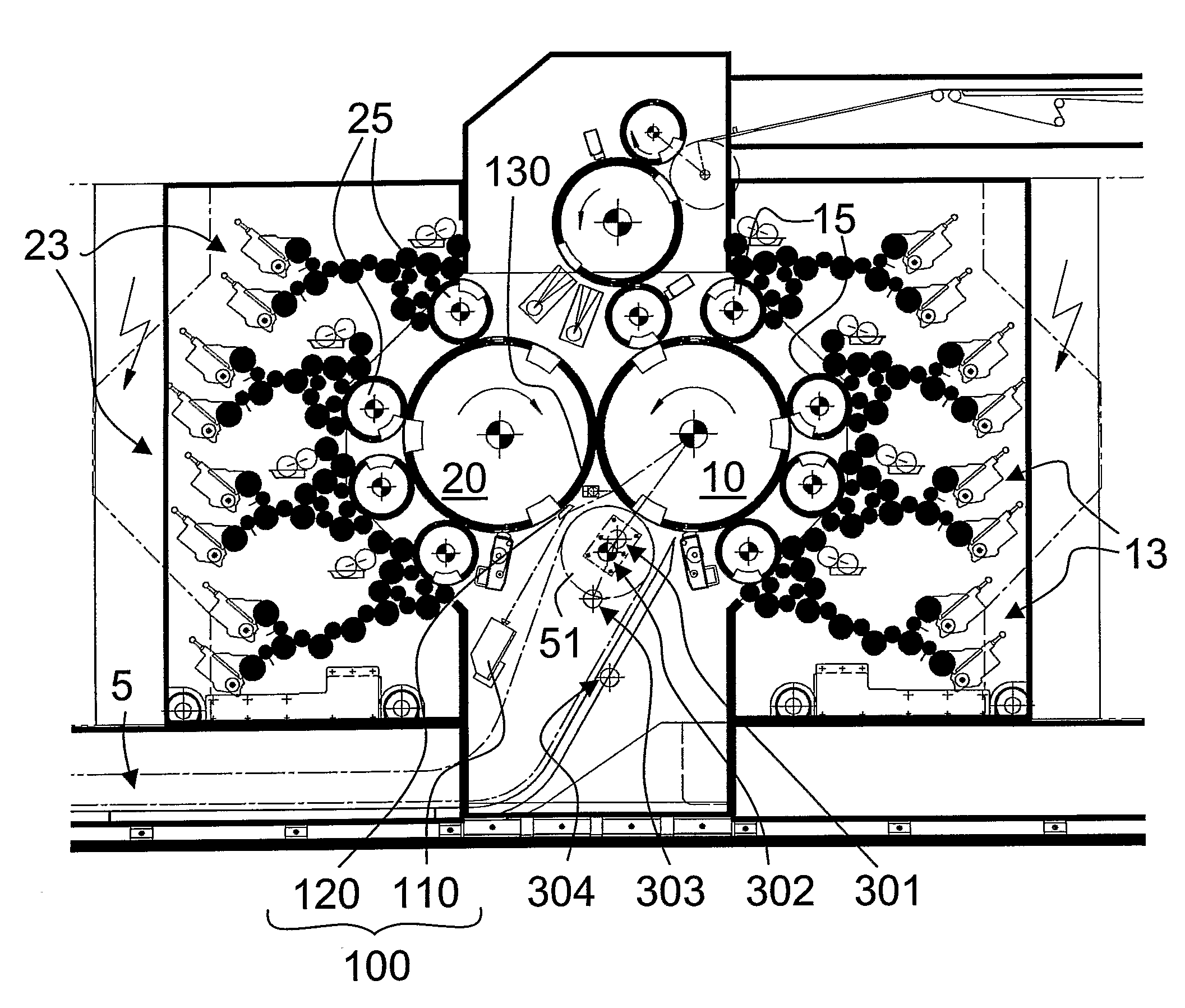

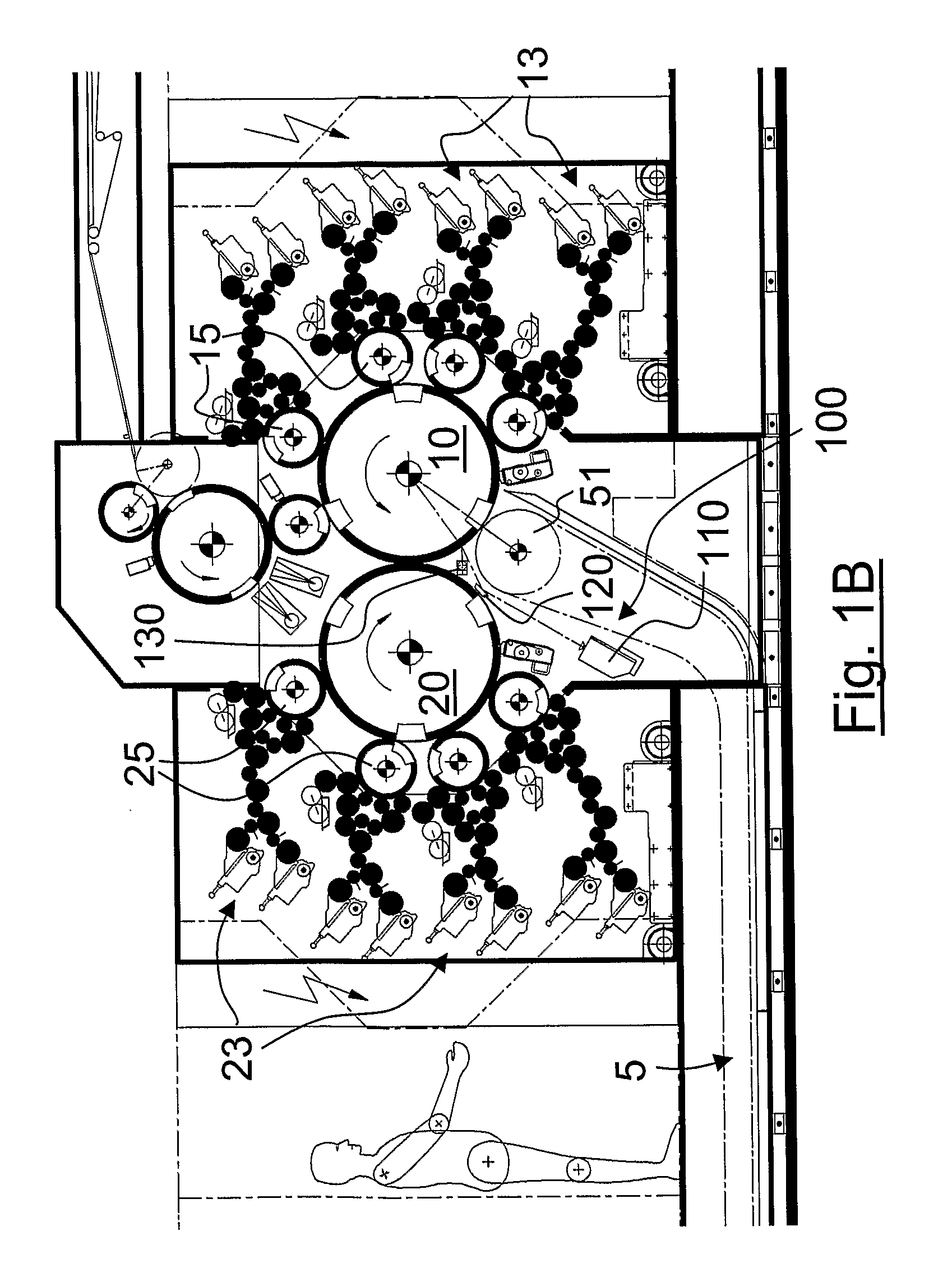

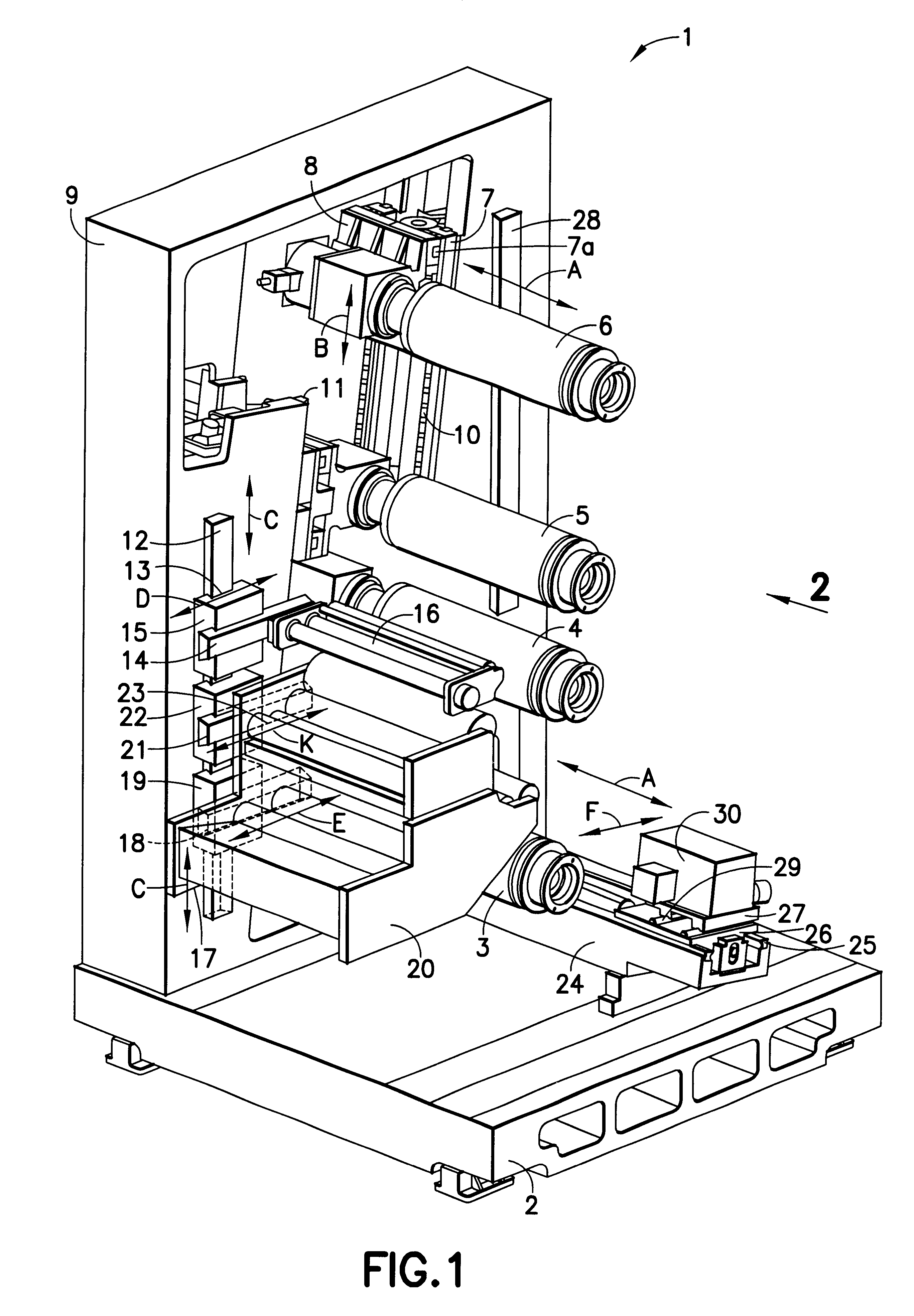

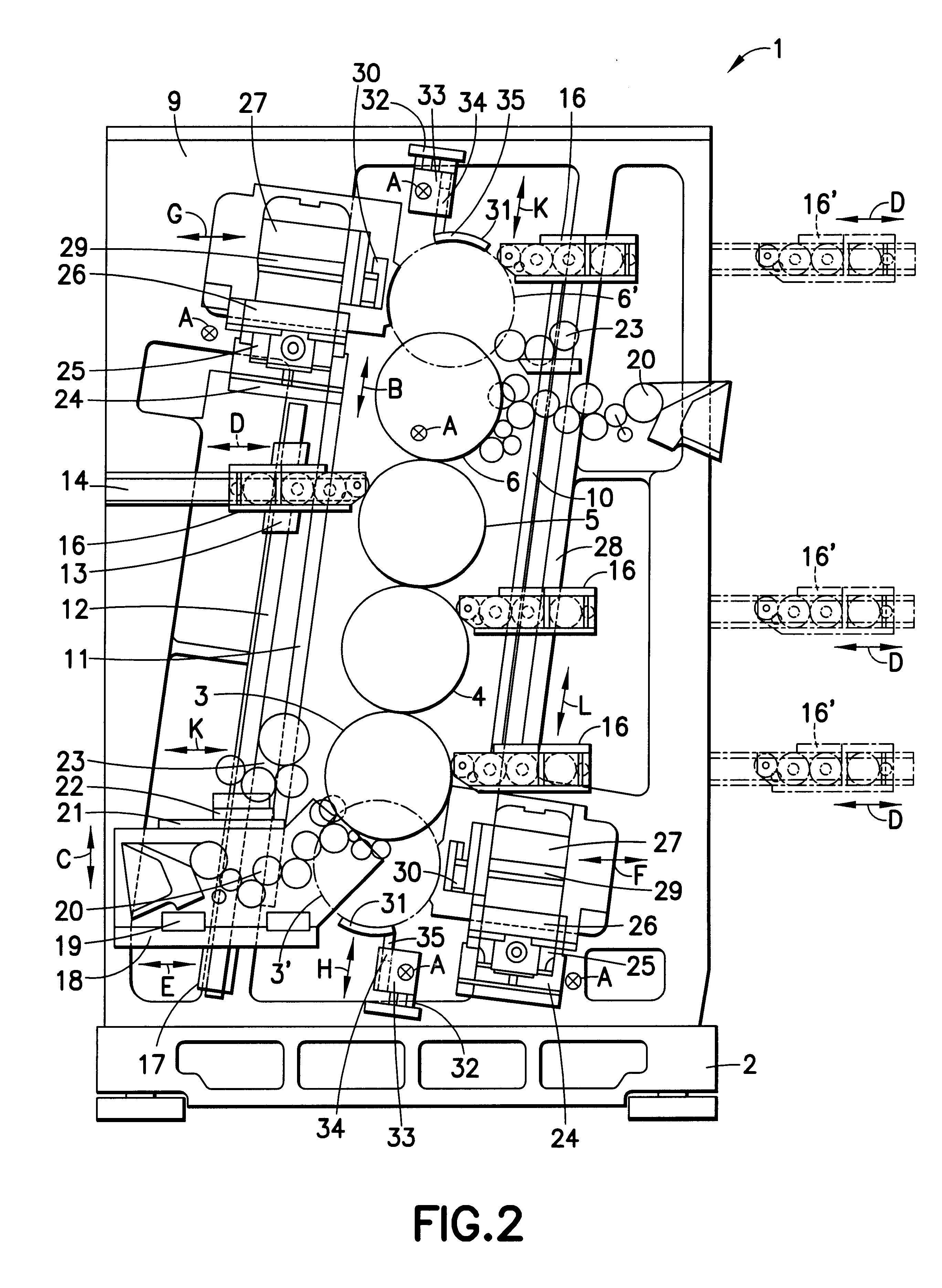

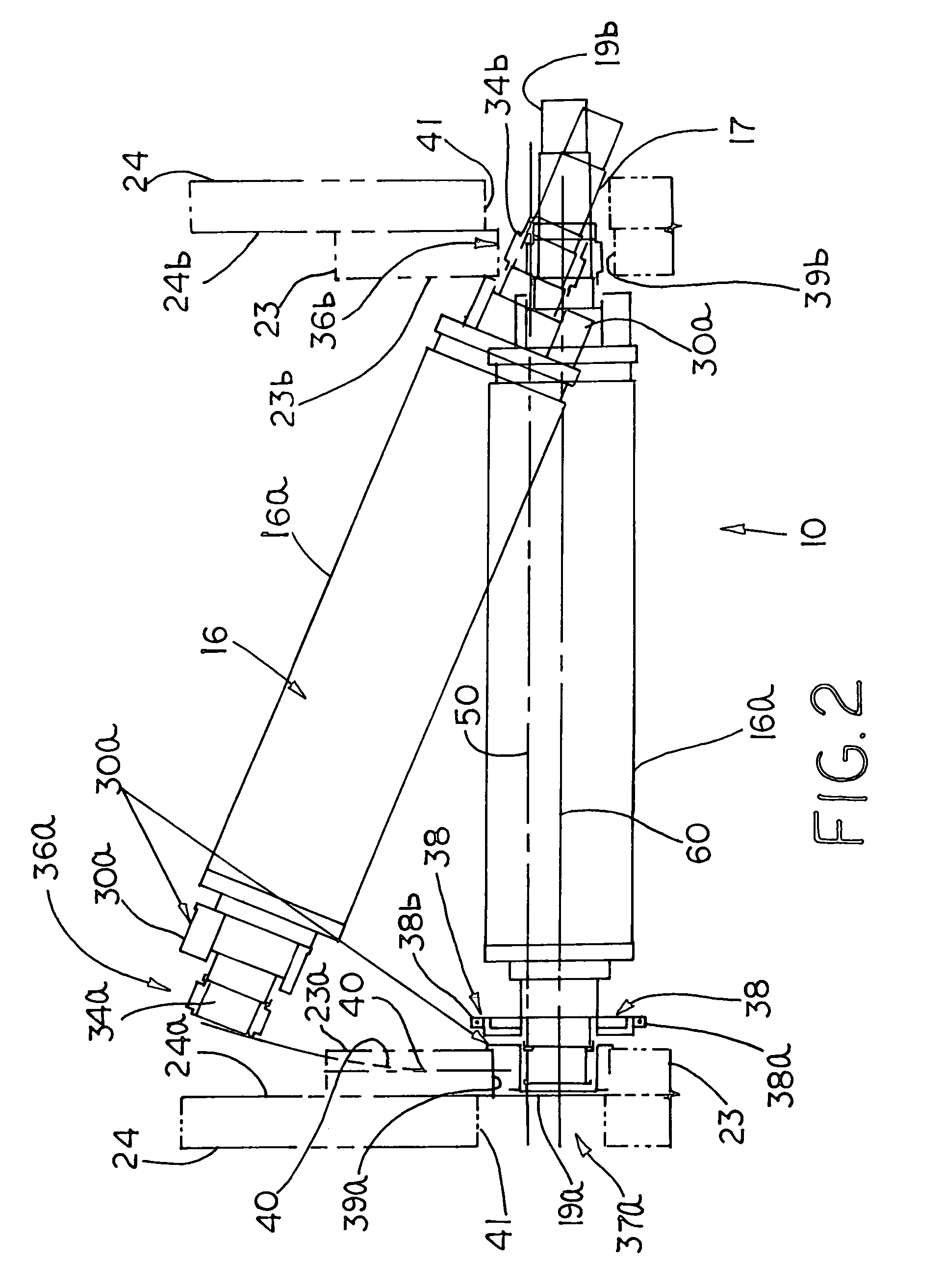

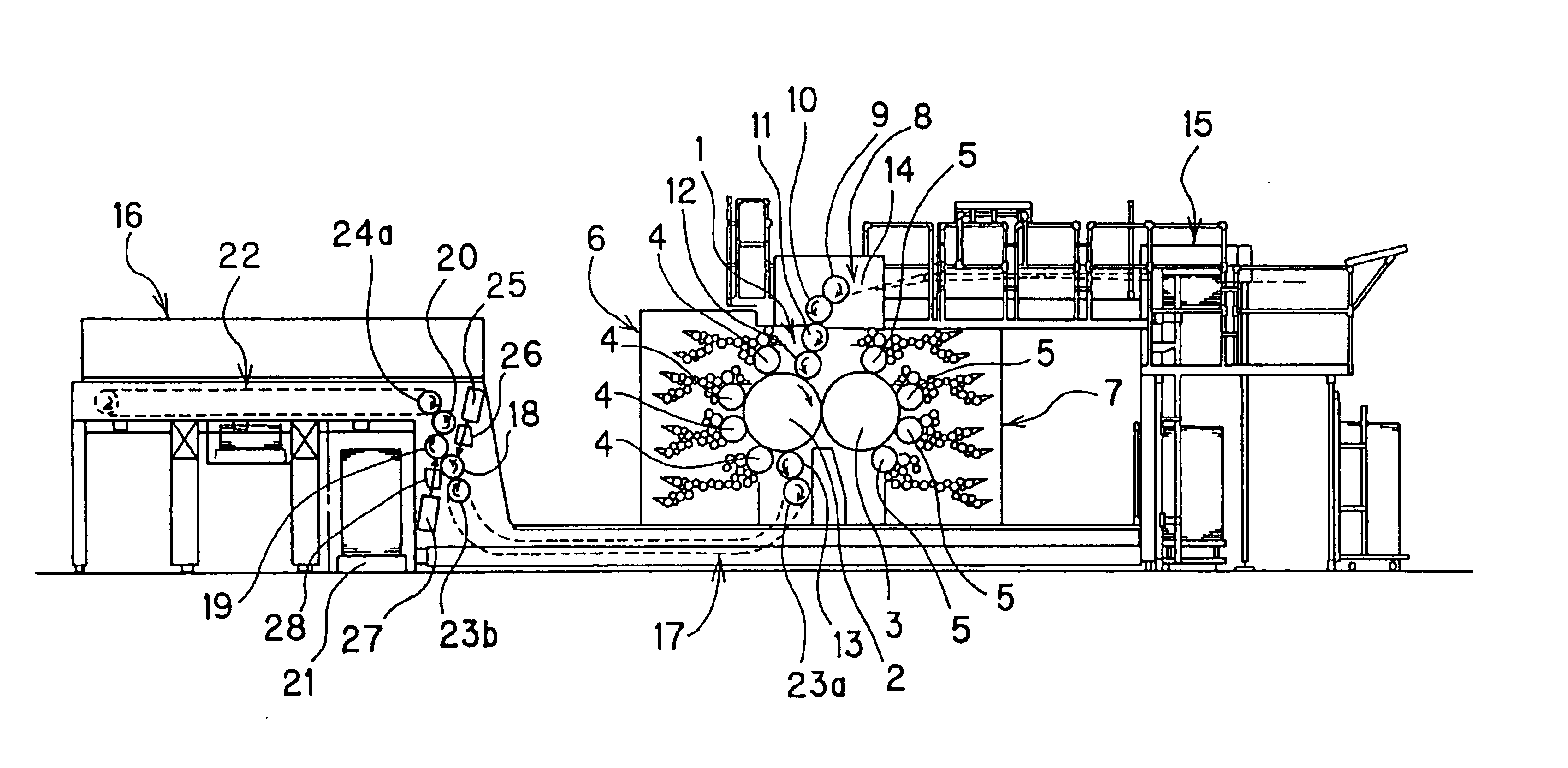

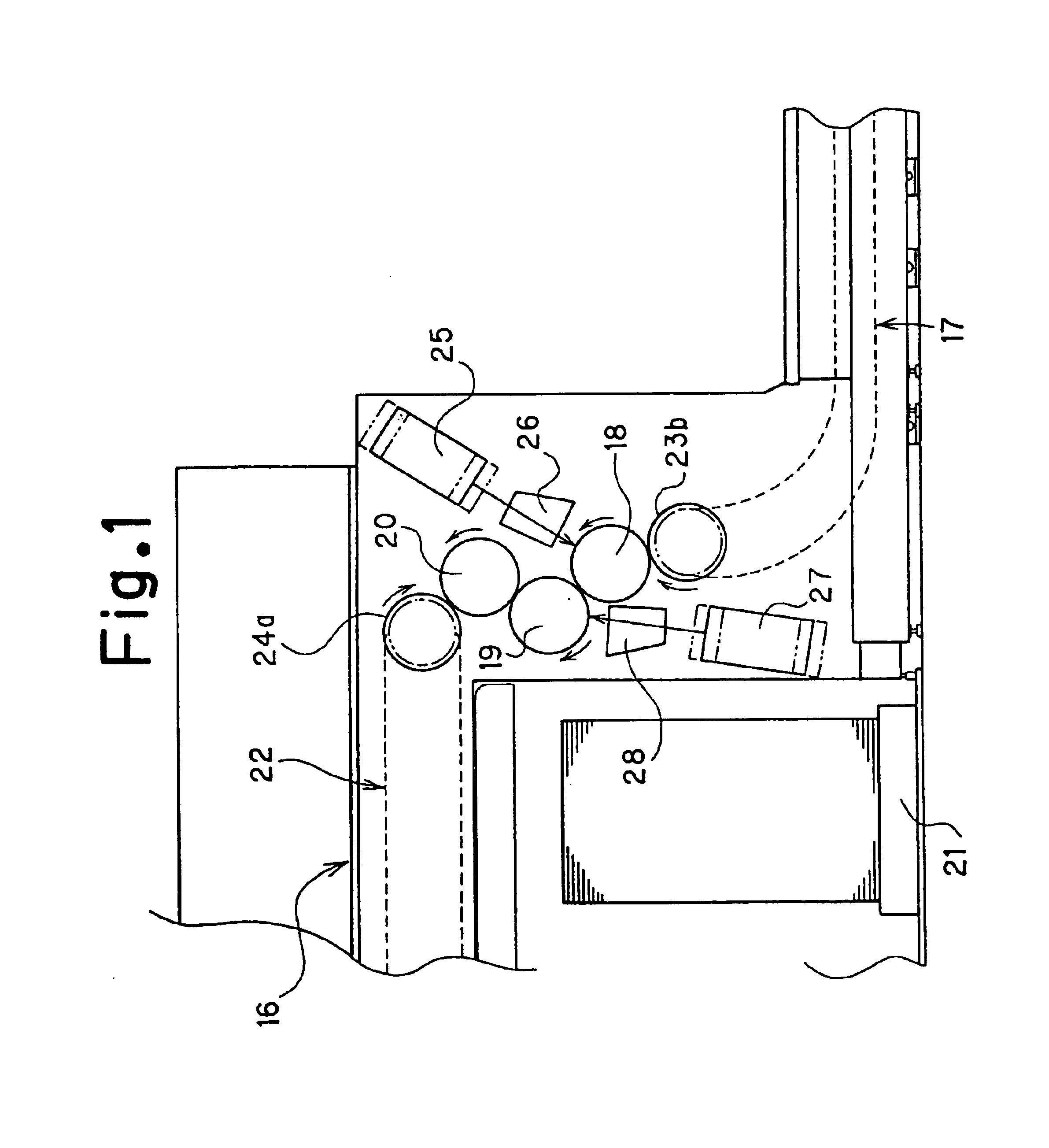

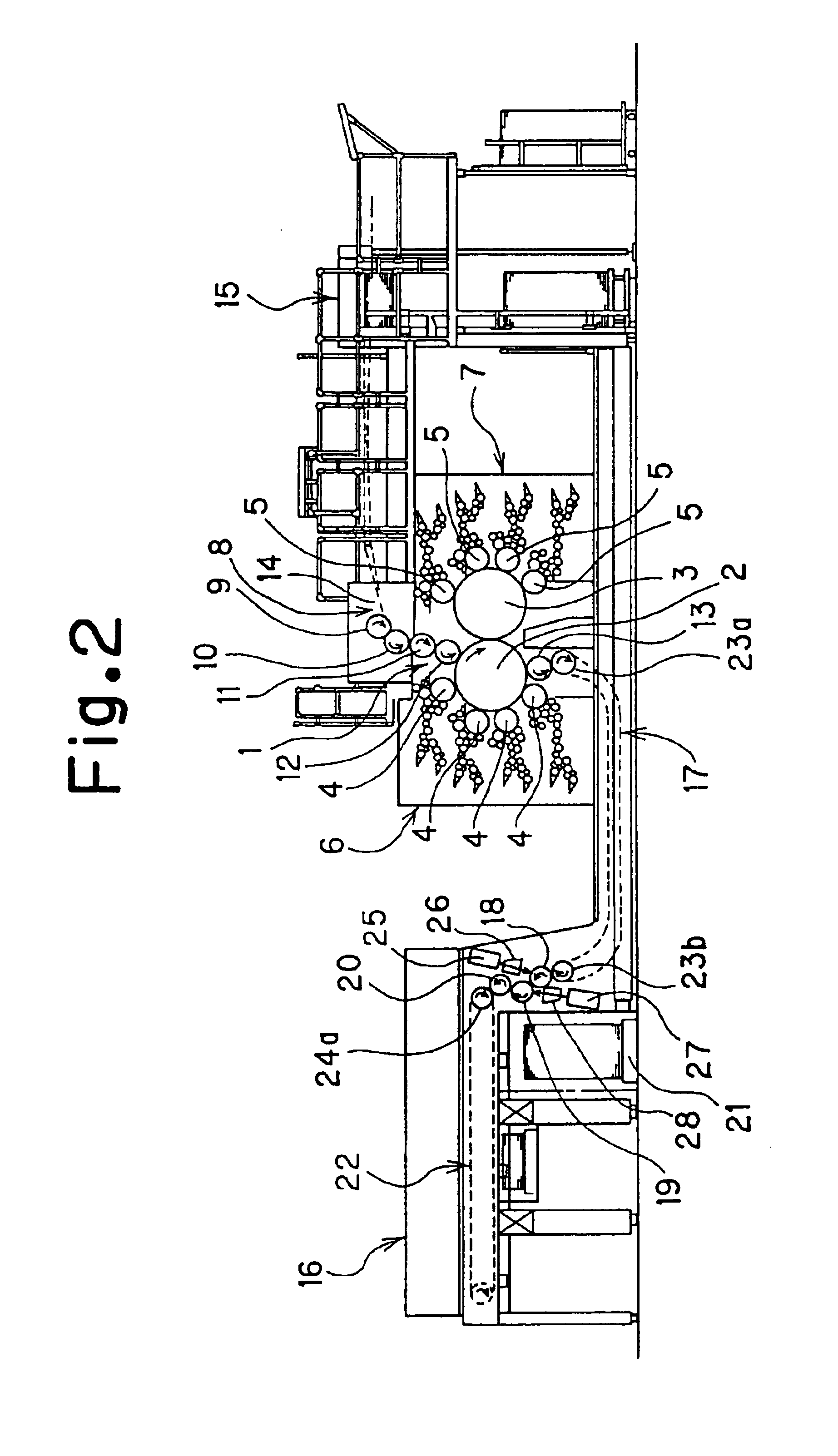

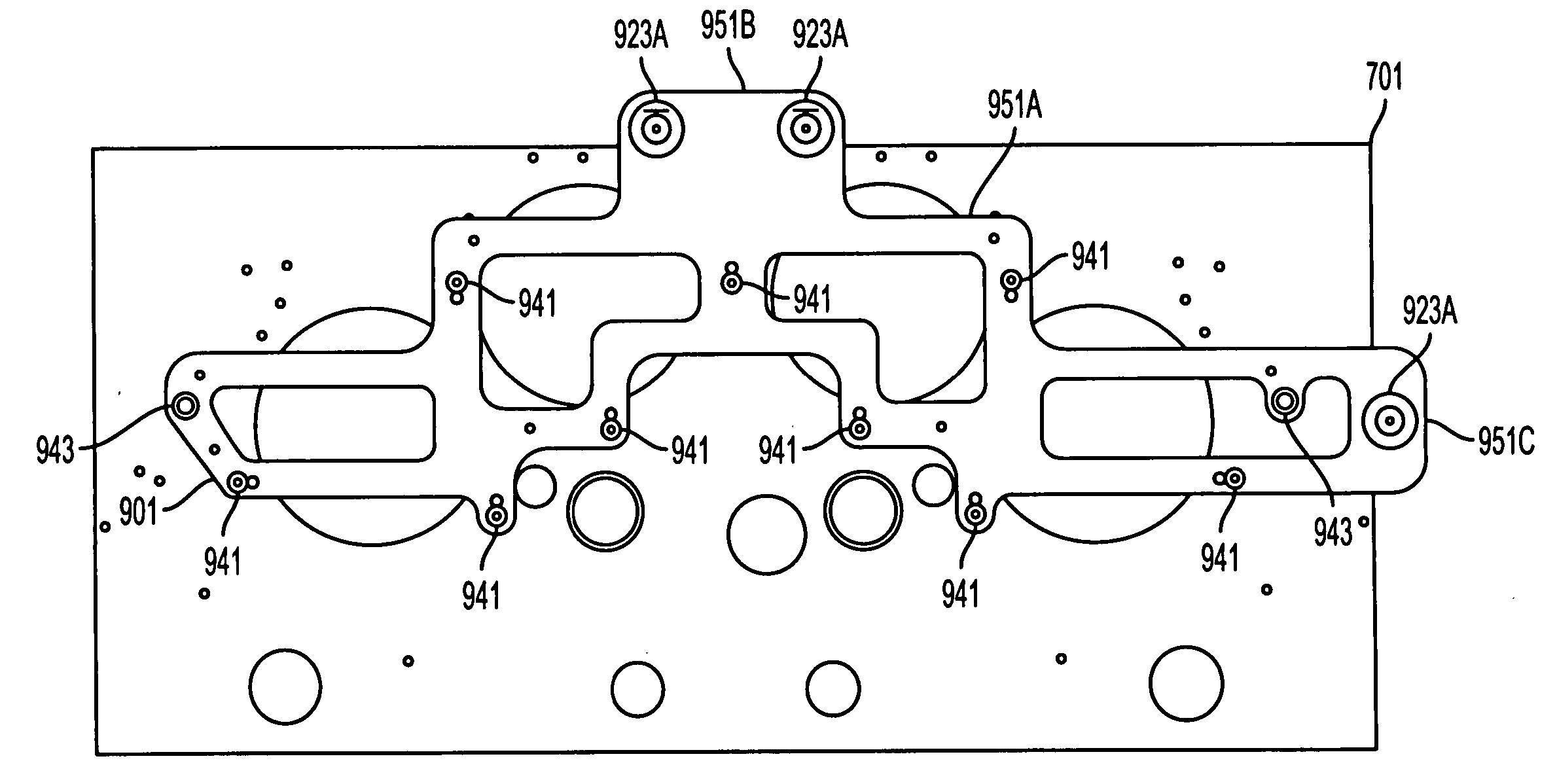

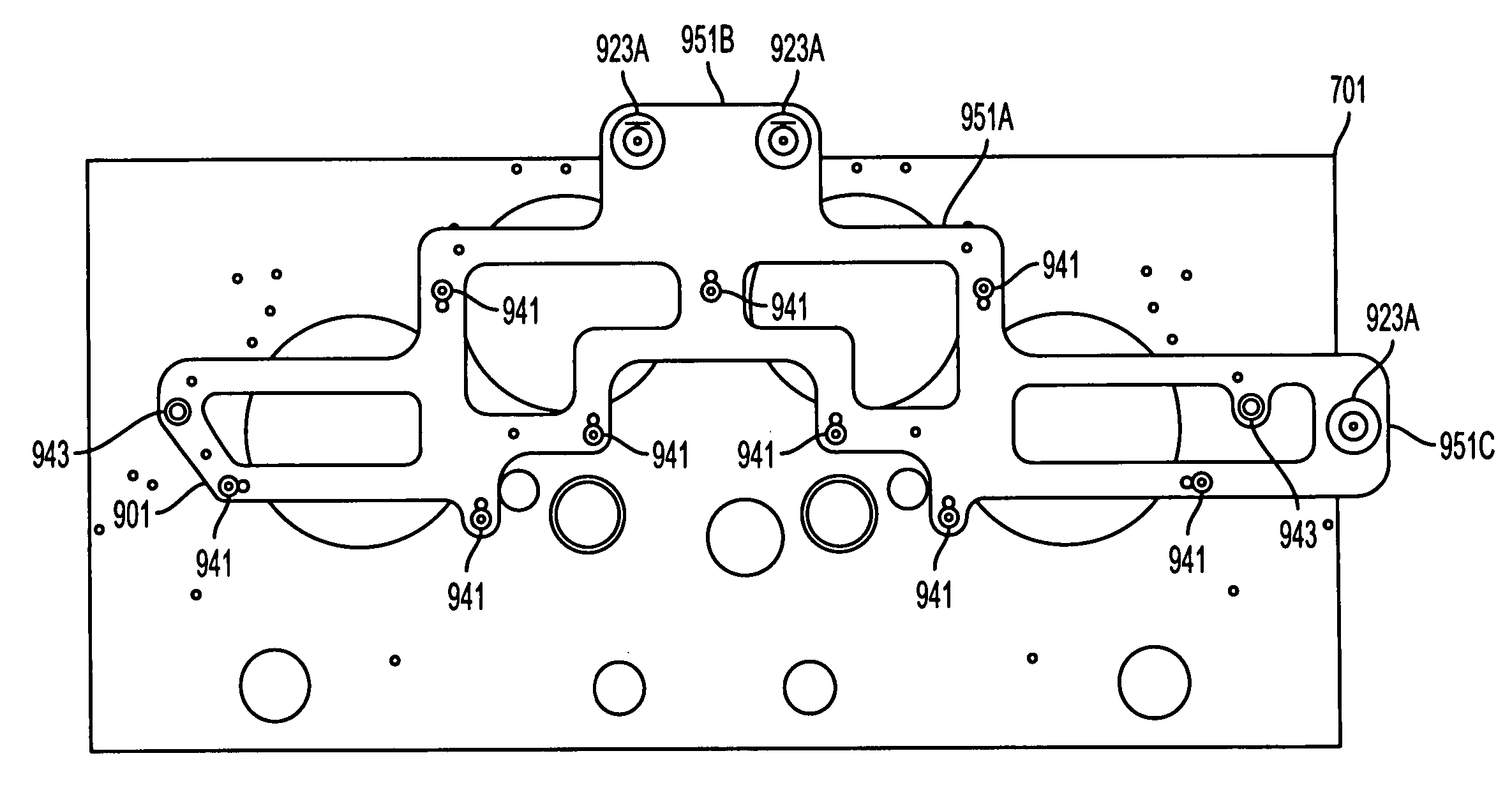

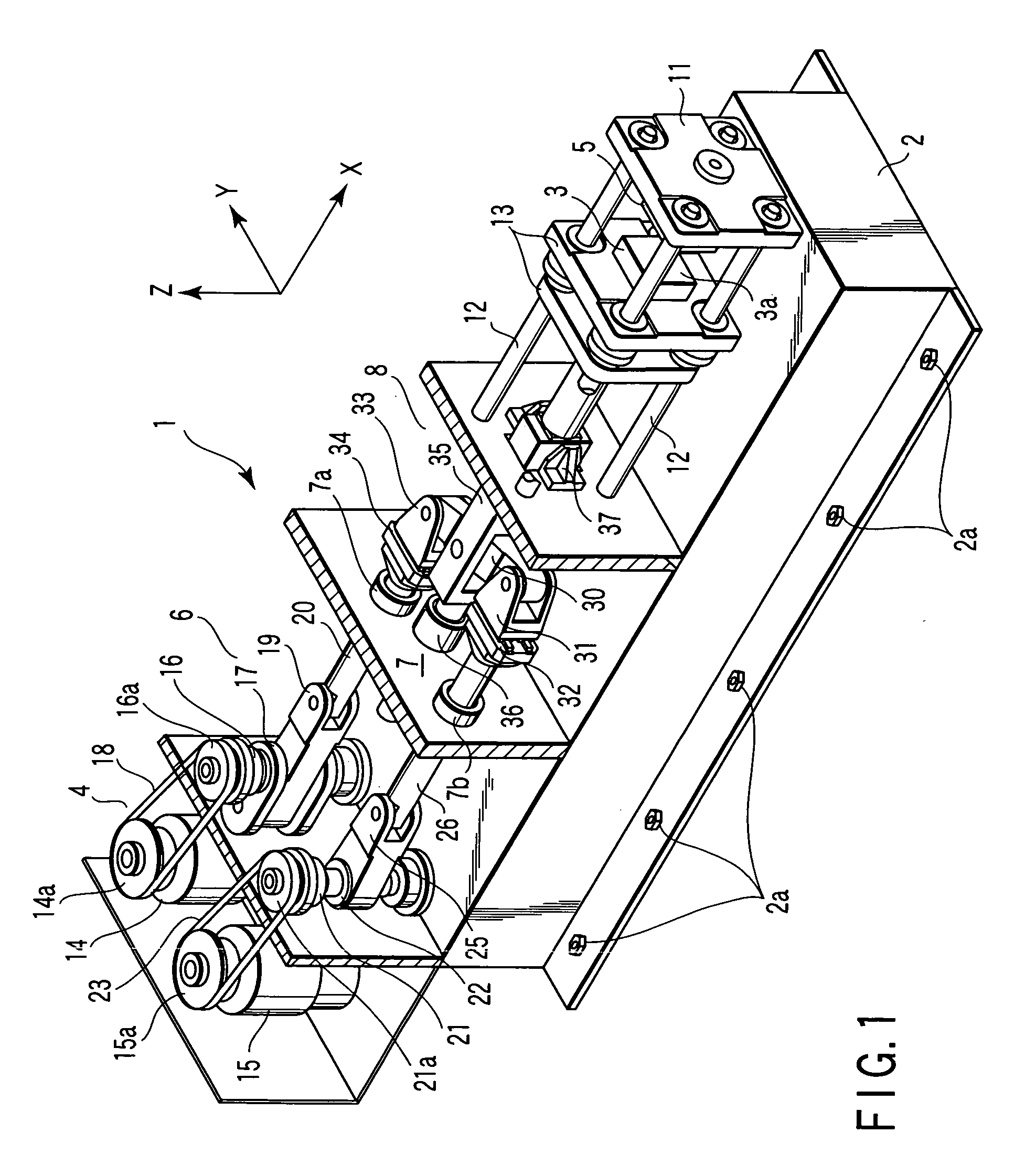

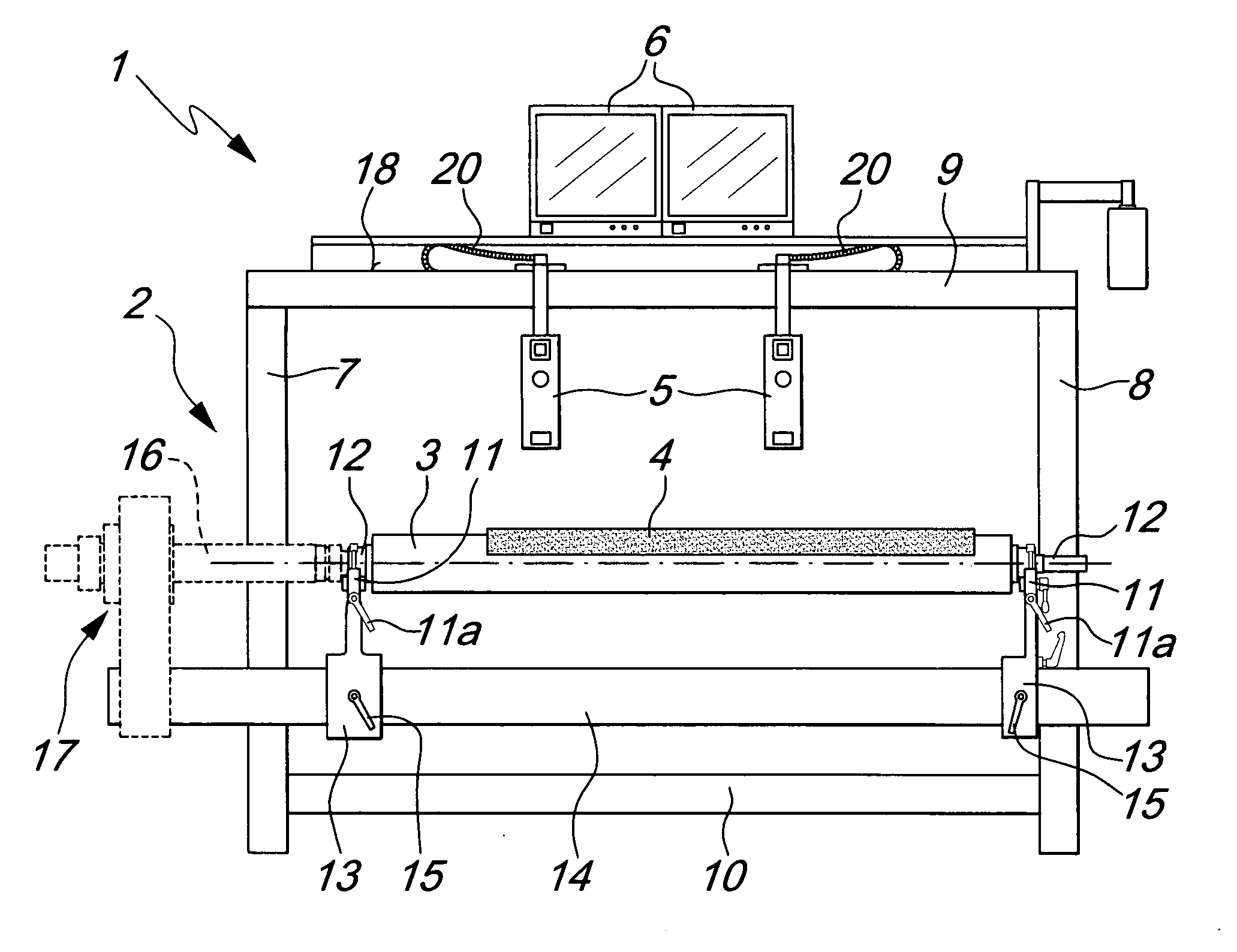

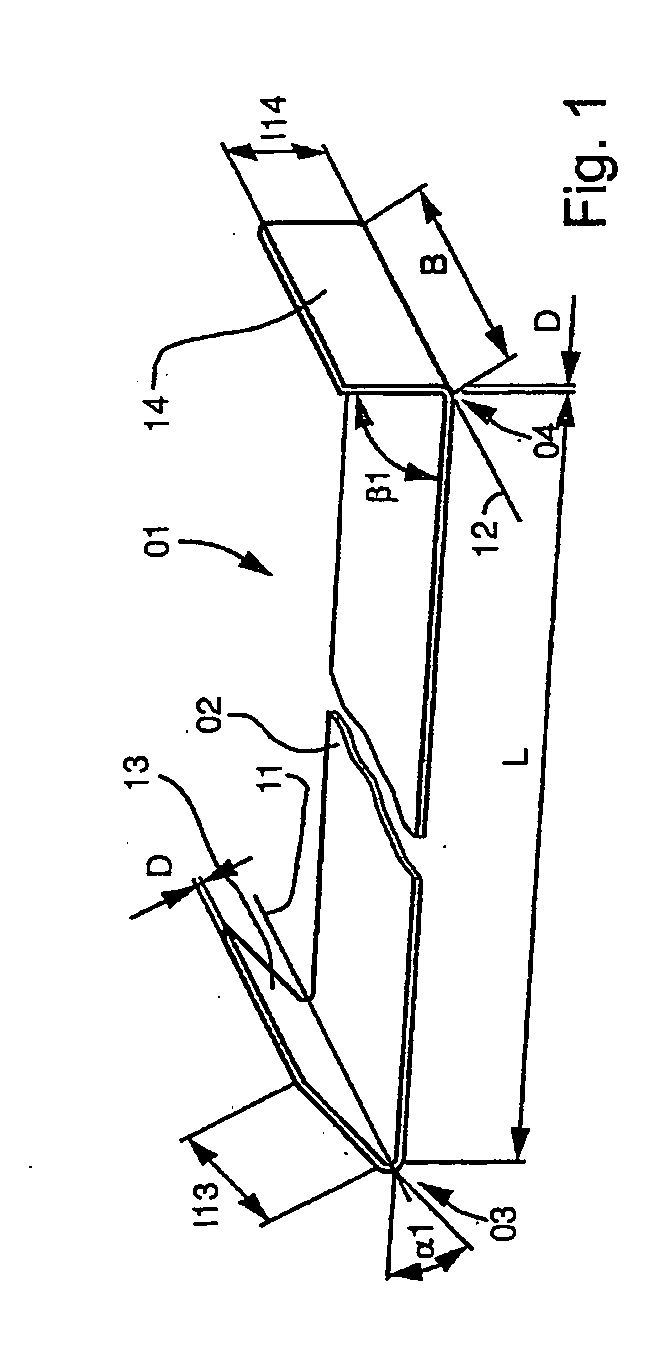

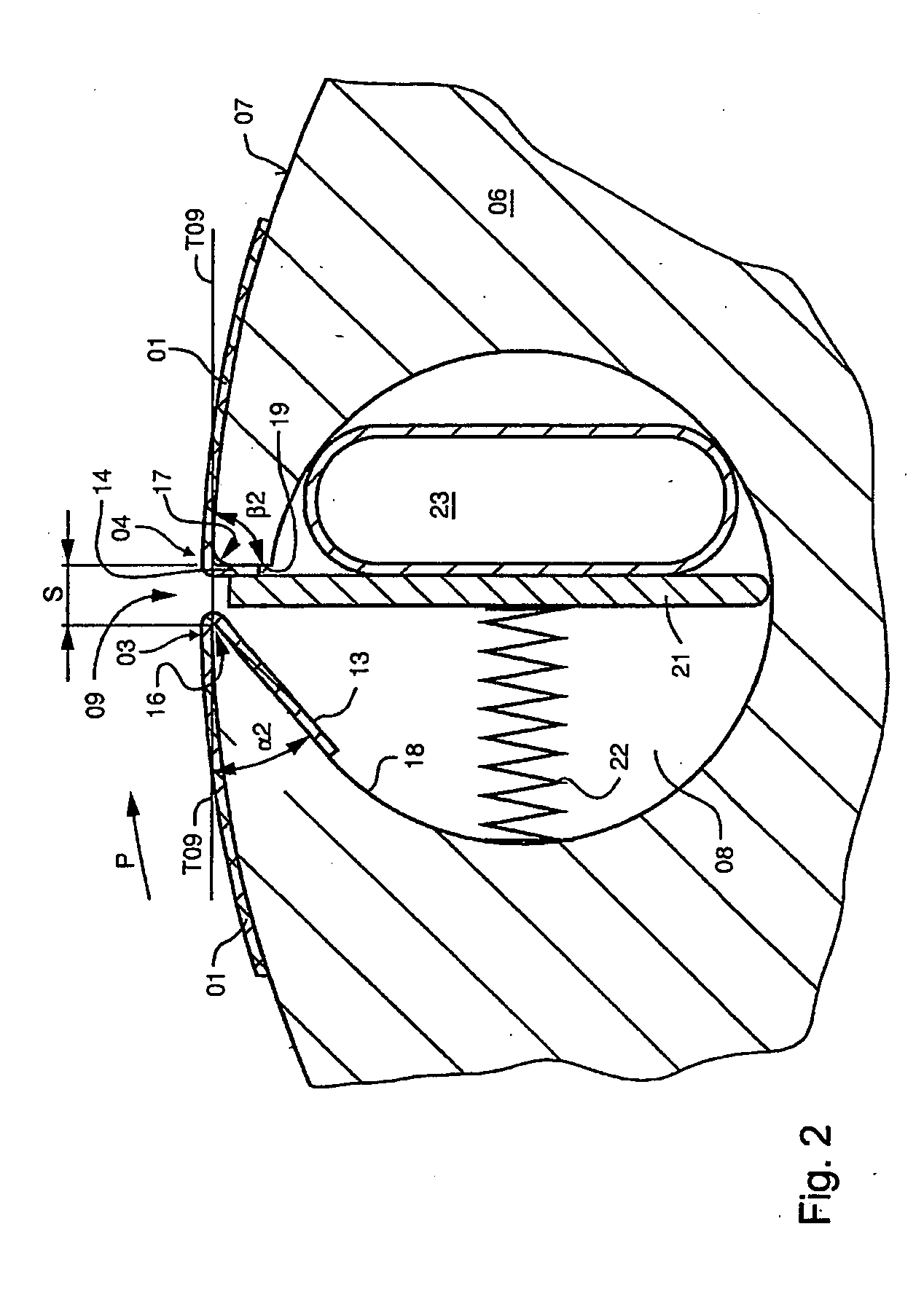

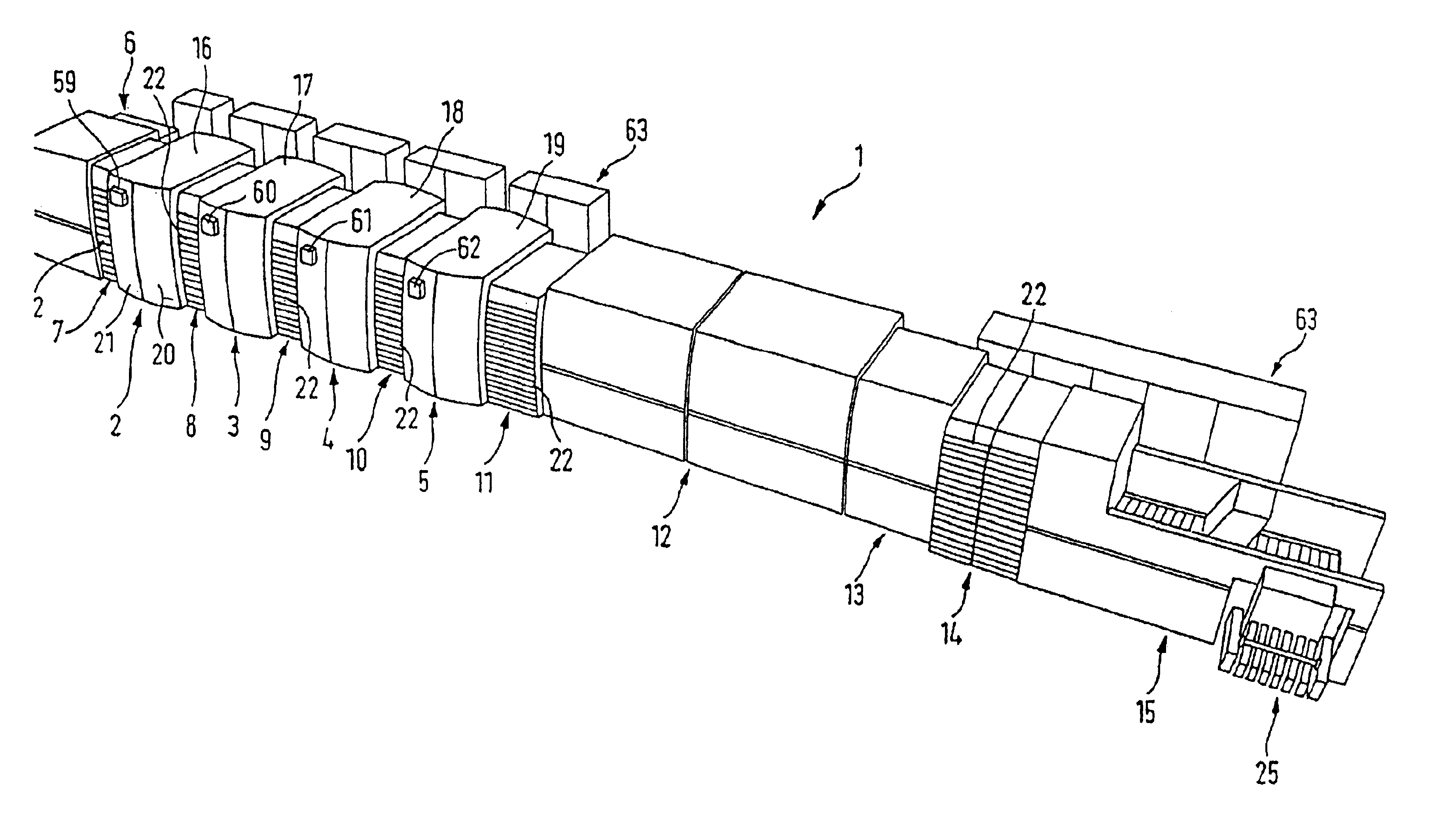

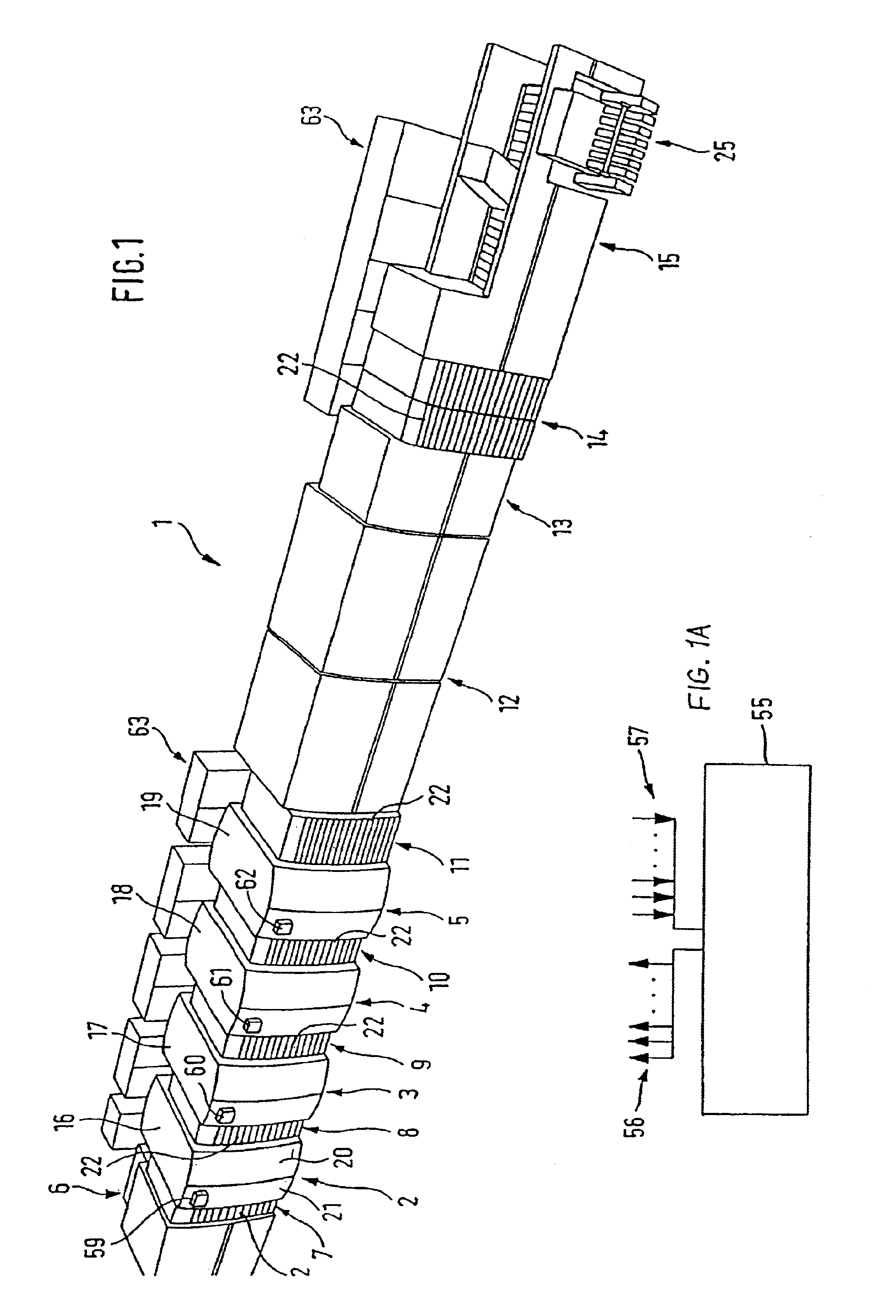

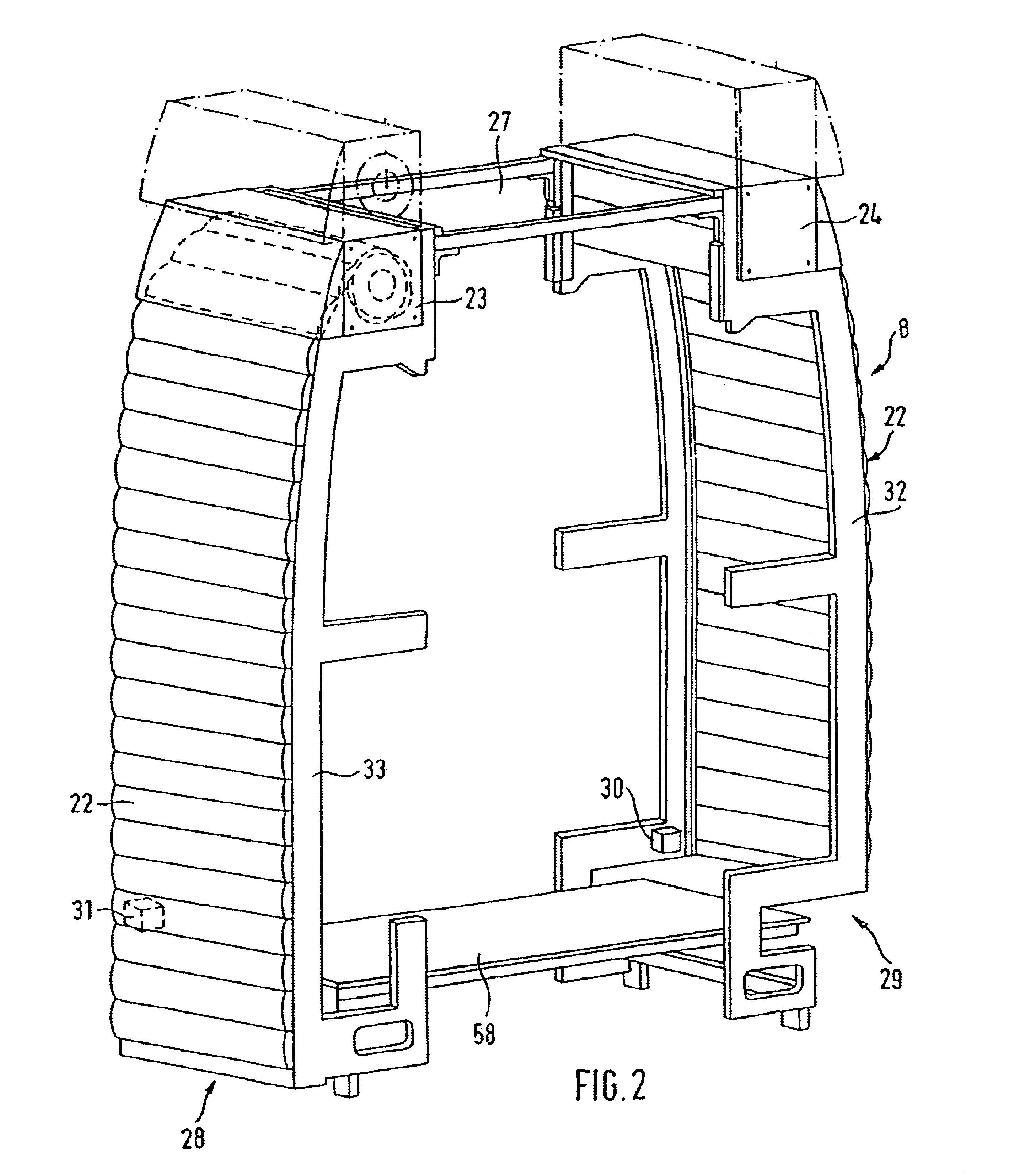

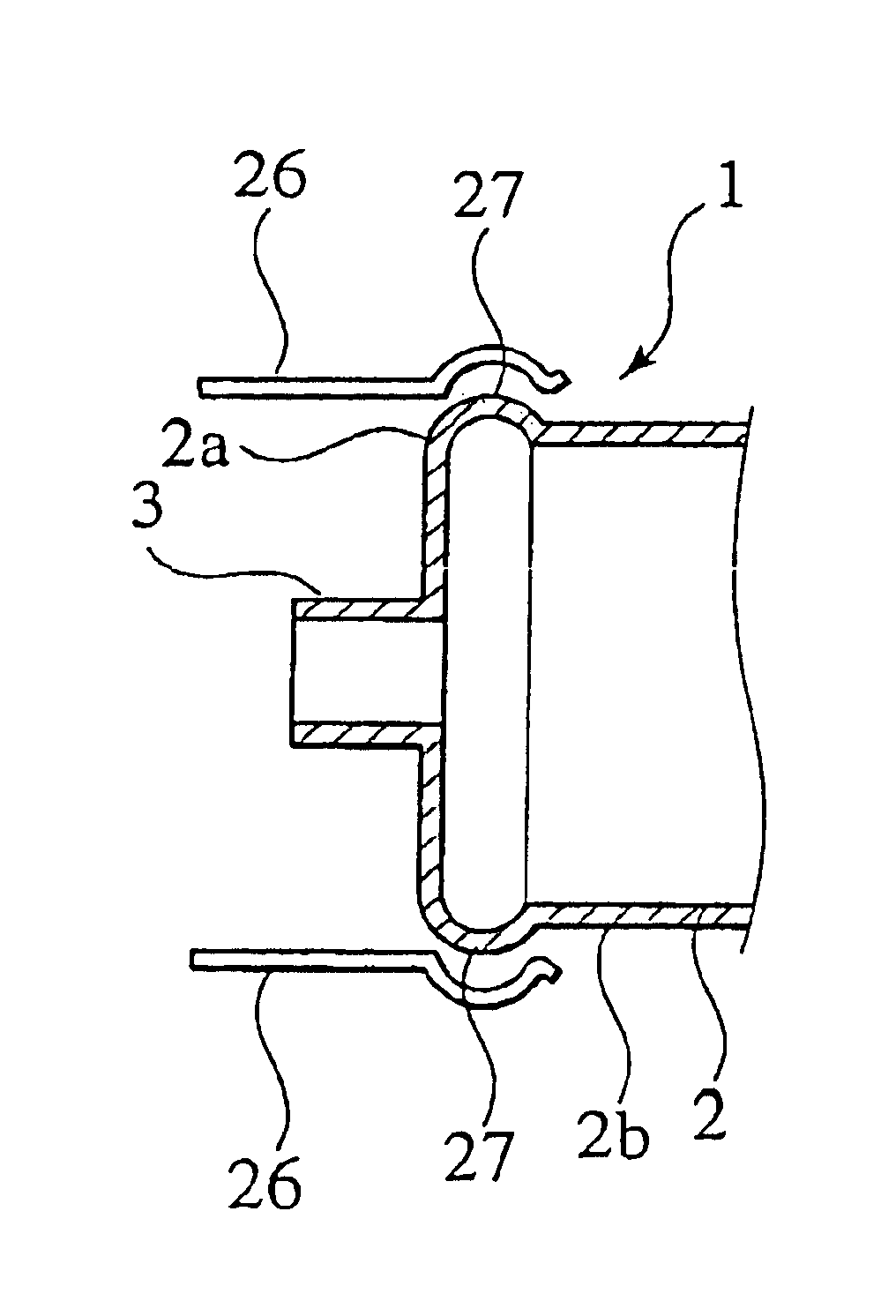

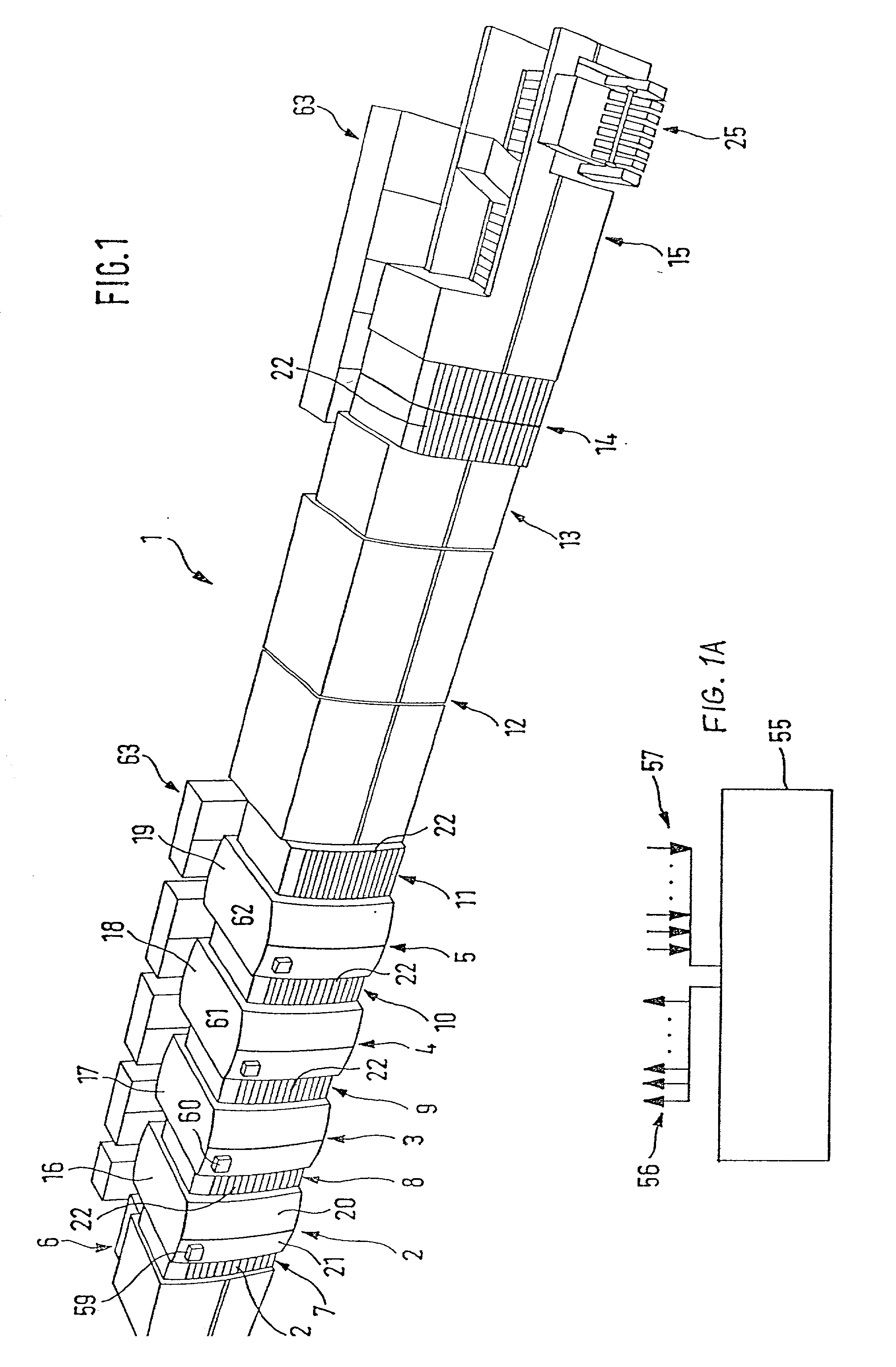

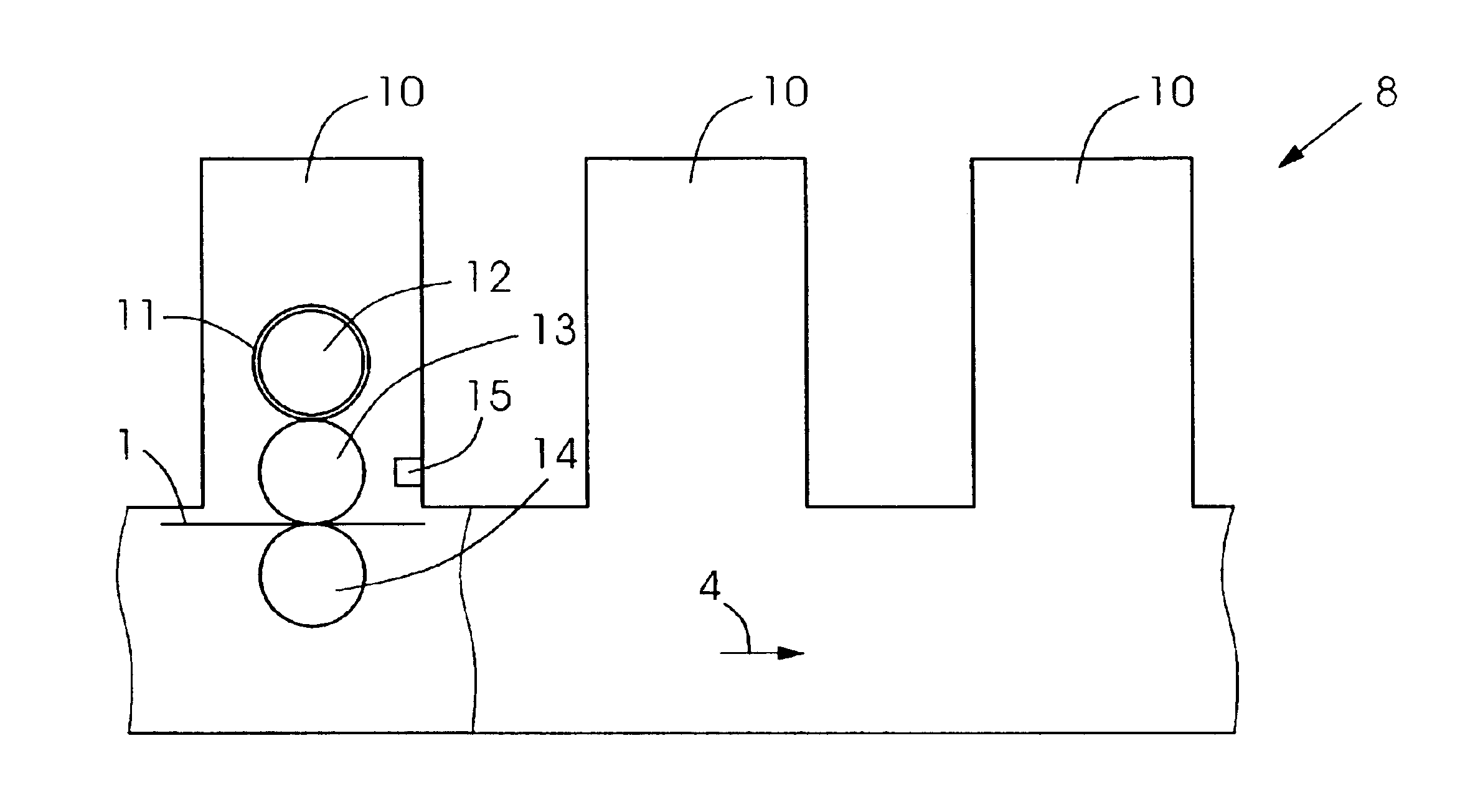

Printing unit for a rotary printing machine with cross slide

InactiveUS20010035104A1Long constructionEfficient introductionCylinder pressesAddressographsEngineeringPrinting press

Rotary printing machine with forme and impression cylinders for variable-format or variable-circumference printing and with service apparatus which are capable of being moved radially in relation to the printing-unit cylinders for throw-on or throw-off movements and in the axial direction of the cylinders or in the side-wall plane. The service apparatus and the printing-unit cylinders are arranged on cross slides which can each be moved in two directions relative to the printing-unit side wall.

Owner:MANROLANAD AG

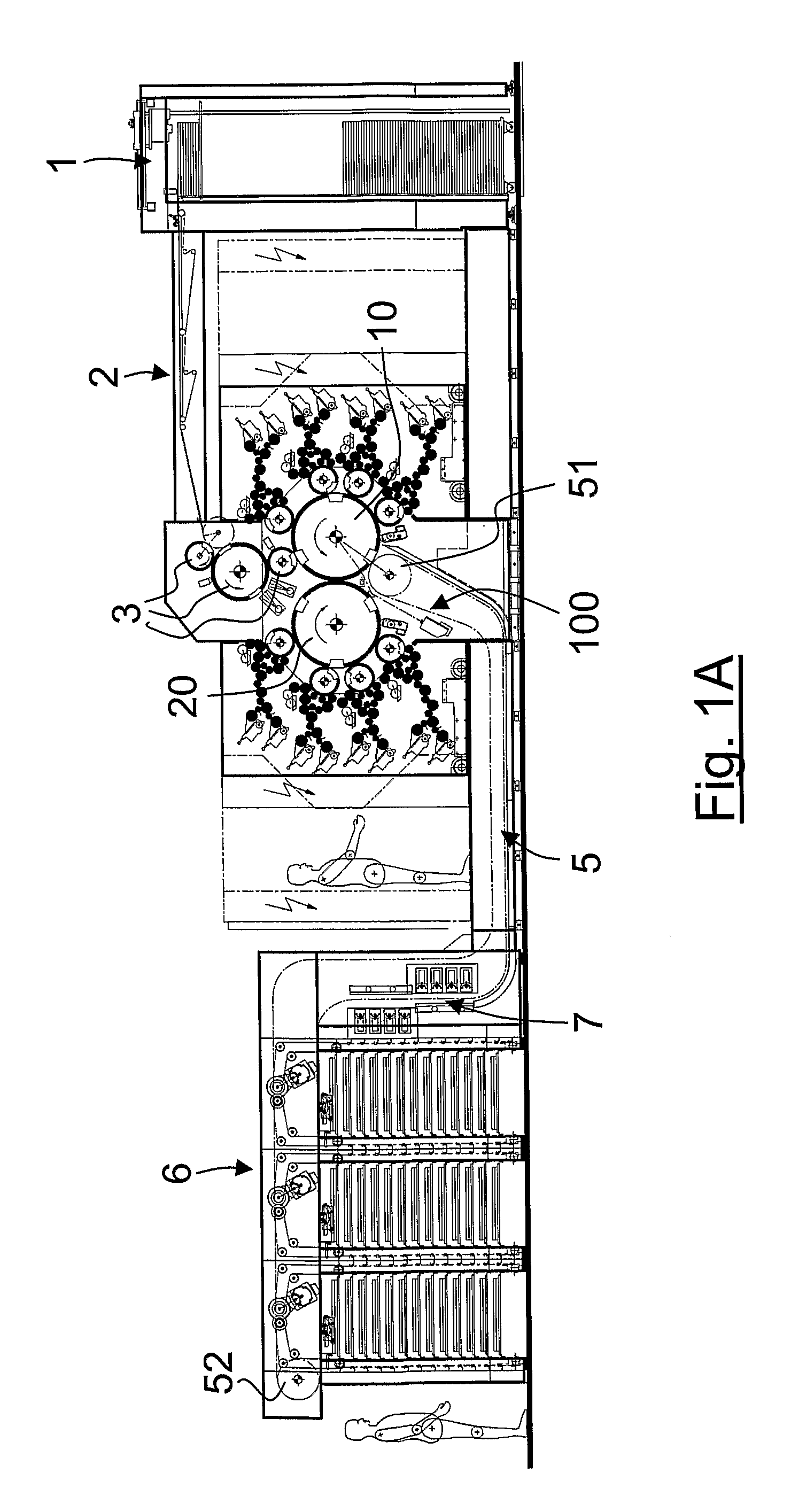

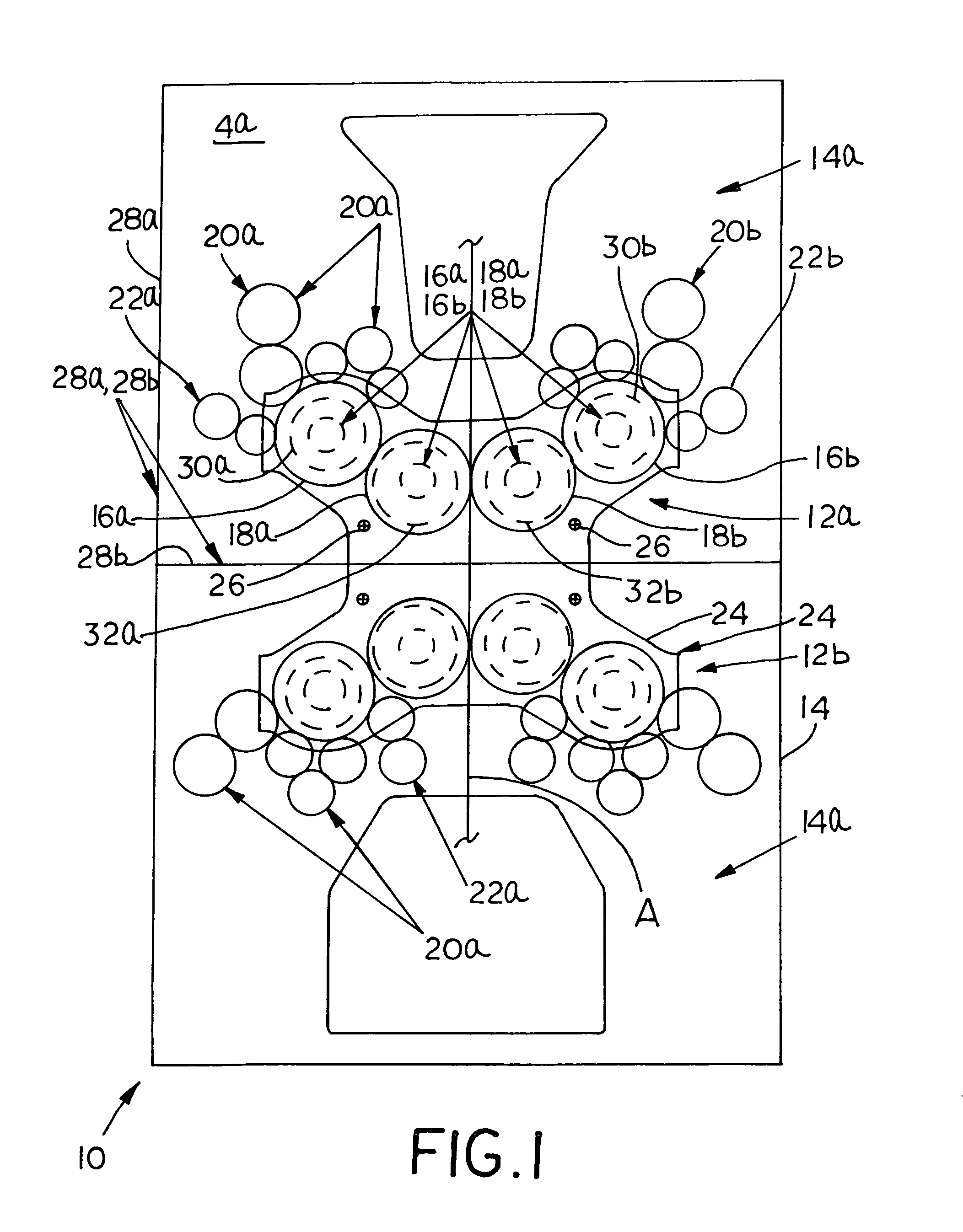

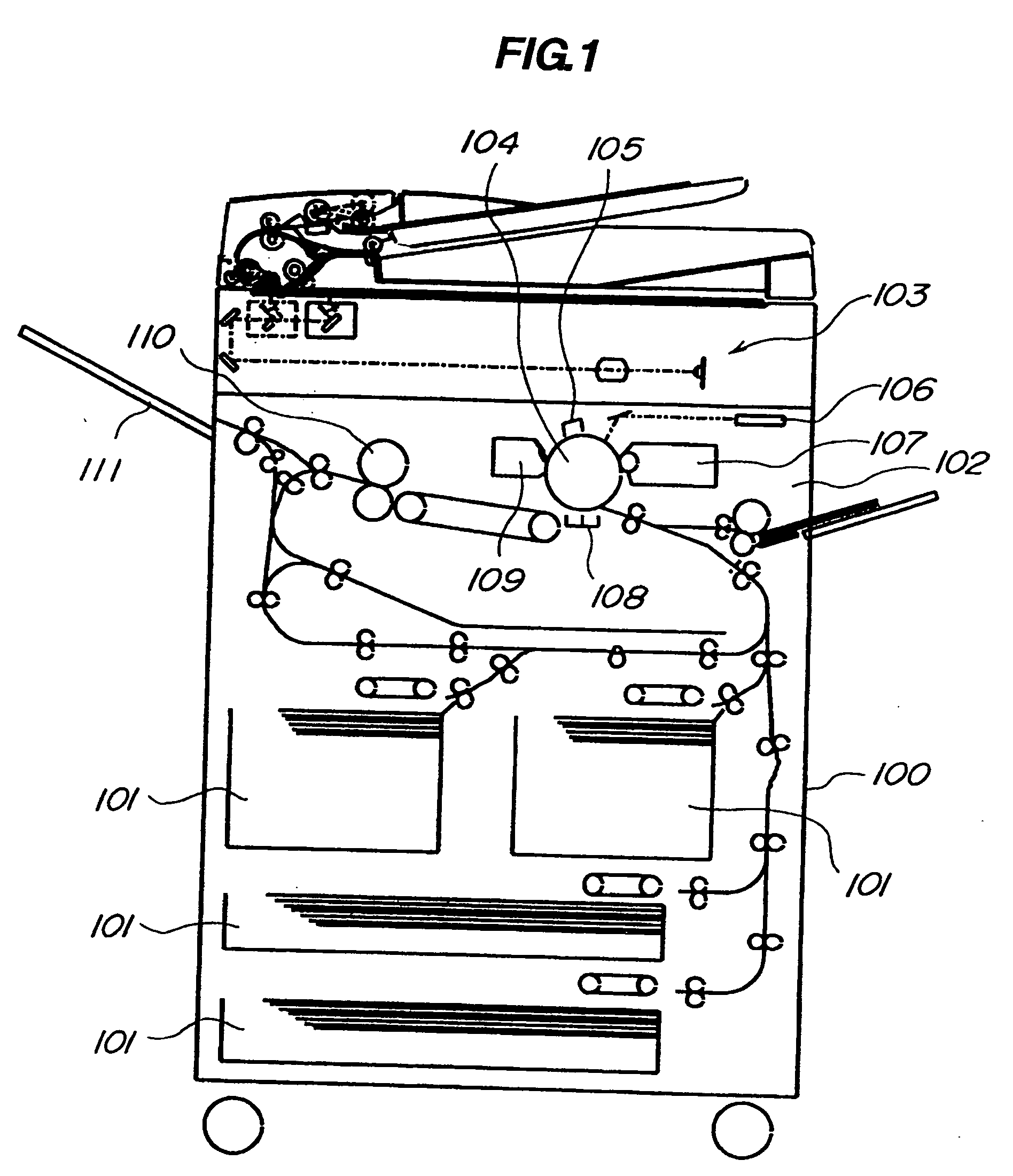

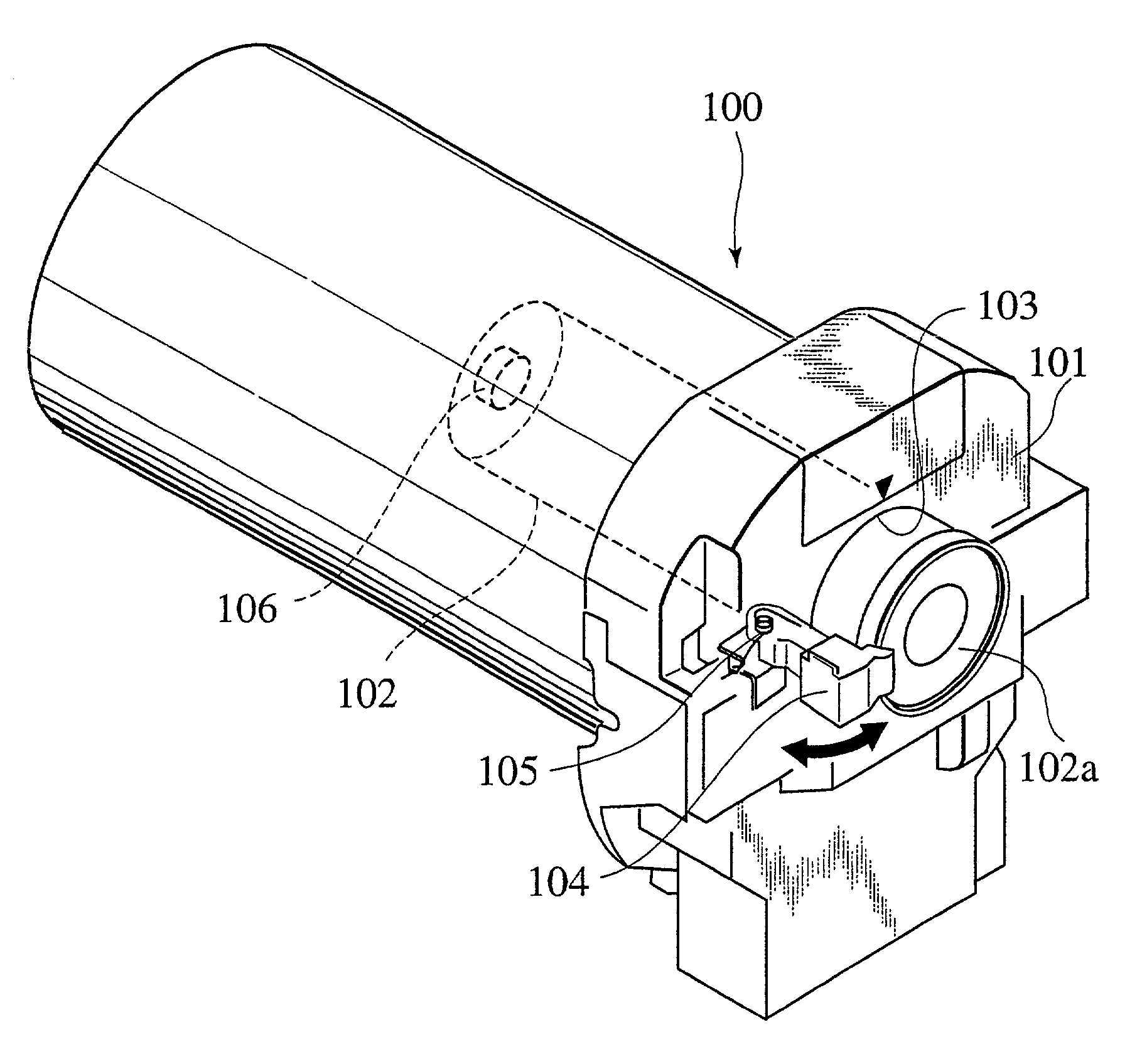

Inspection System for a Sheet-Fed Recto-Verso Printing Press

ActiveUS20090007807A1Increased complexityIncrease the lengthAddressographsLetterpress printingEngineeringPrinting press

There is described a sheet inspection system for a sheet-fed recto-verso printing press of the type comprising two printing cylinders (10, 20) for carrying out simultaneous recto-verso printing of the sheets, said sheet inspection system comprising at least a first inspection device (100) for taking an image of a first side of the printed sheets. The first inspection device (100) comprises a first line image sensor (110) for performing line-scanning image acquisition of the first side of the printed sheets, and the first inspection device (100) is disposed in such a way that the first line image sensor visually acquires an image of a printed sheet while the said printed sheet is still adhering onto the surface of a first one (10) of the two printing cylinders (10, 20) of the printing press and immediately before the said printed sheet is transferred to a chain gripper system (5) of the printing press. Also described is a printing press equipped with the inspection system.

Owner:KBA NOTASYS SA

Printing unit for a rotary printing machine with cross slide

InactiveUS6502509B2Long constructionEfficient introductionCylinder pressesAddressographsPrinting pressMechanical engineering

Rotary printing machine with forme and impression cylinders for variable-format or variable-circumference printing and with service apparatus which are capable of being moved radially in relation to the printing-unit cylinders for throw-on or throw-off movements and in the axial direction of the cylinders or in the side-wall plane. The service apparatus and the printing-unit cylinders are arranged on cross slides which can each be moved in two directions relative to the printing-unit side wall.

Owner:MANROLANAD AG

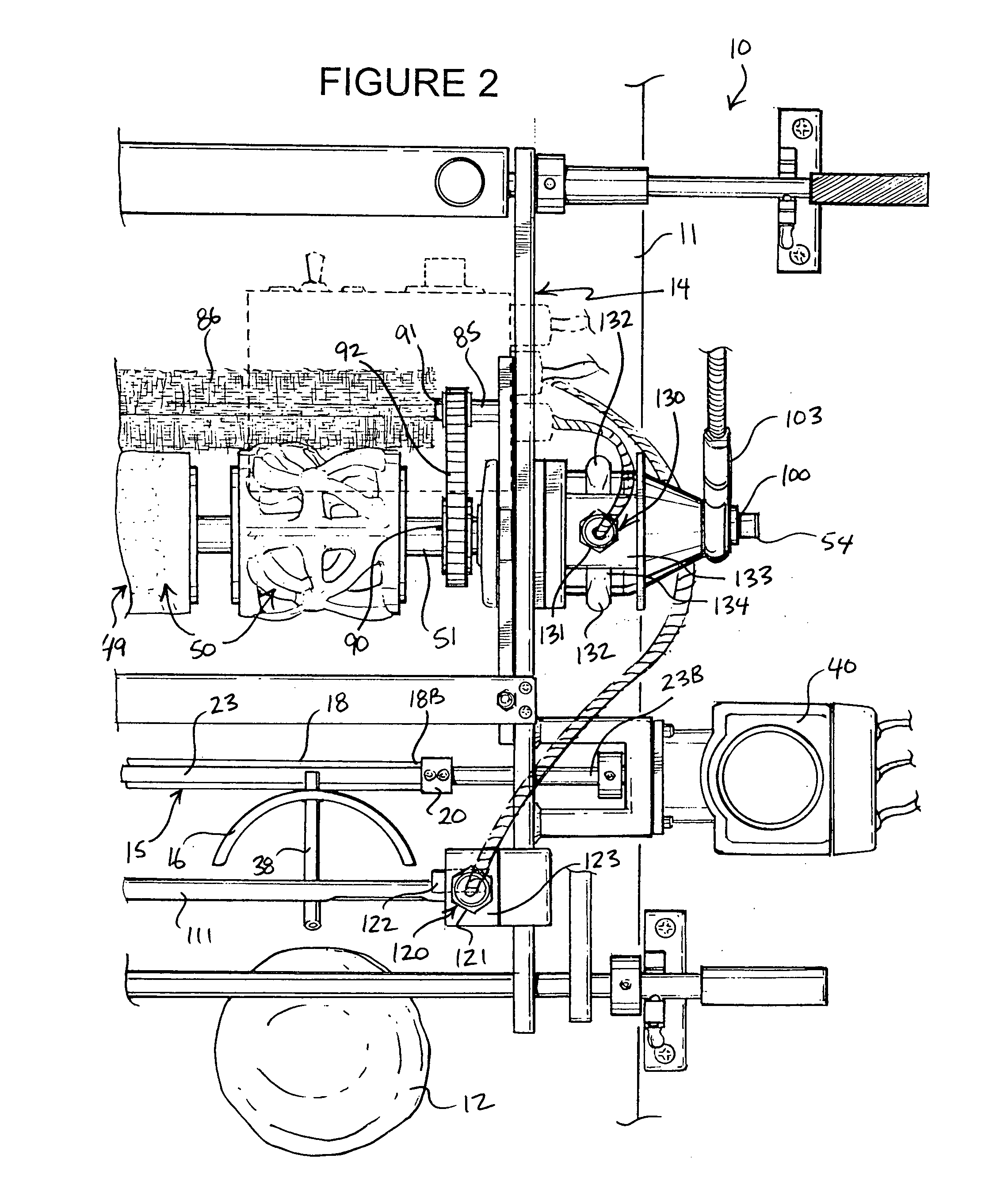

Method and apparatus for changing print length on a printing press

To modify an existing printing press from its original length / cut off to a different cut off, a sub-frame may be mounted on an existing frame of a printing press. The sub-frame permits the relocation of bearing supports for various printing cylinders, such as, for example, the plate cylinders and blanket cylinders. In addition to mounting the sub-frame on the existing frame, new plate and blanket cylinders having different sizes than the plate and blanket cylinders used in the existing printing press may be mounted in the sub-frame to provide different printing lengths / cut offs. Suitable sleeves, such as the eccentric mounting sleeves may be provided as necessary in order to mount the cylinders to the sub-frame.

Owner:SHANGHAI ELECTRICGROUP CORP

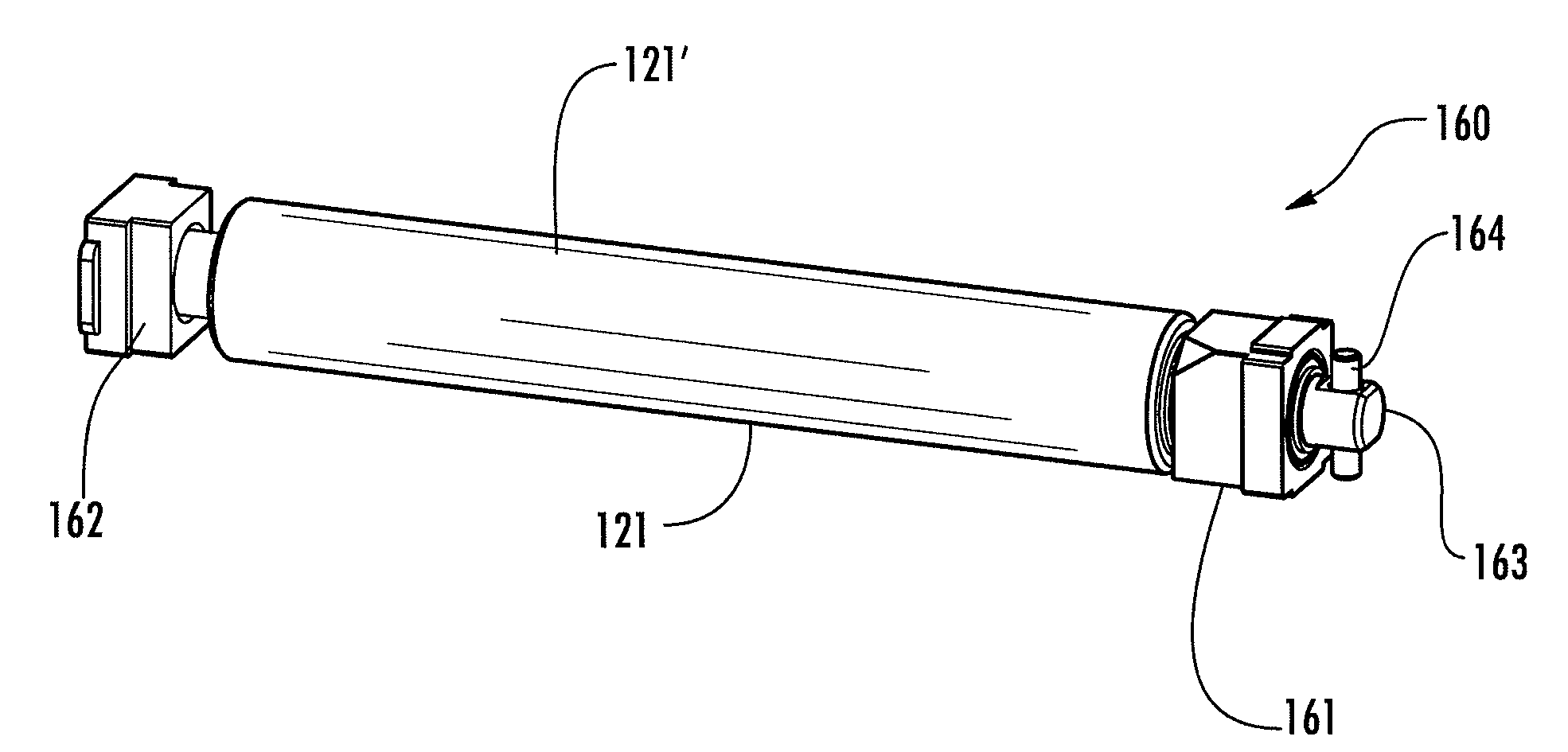

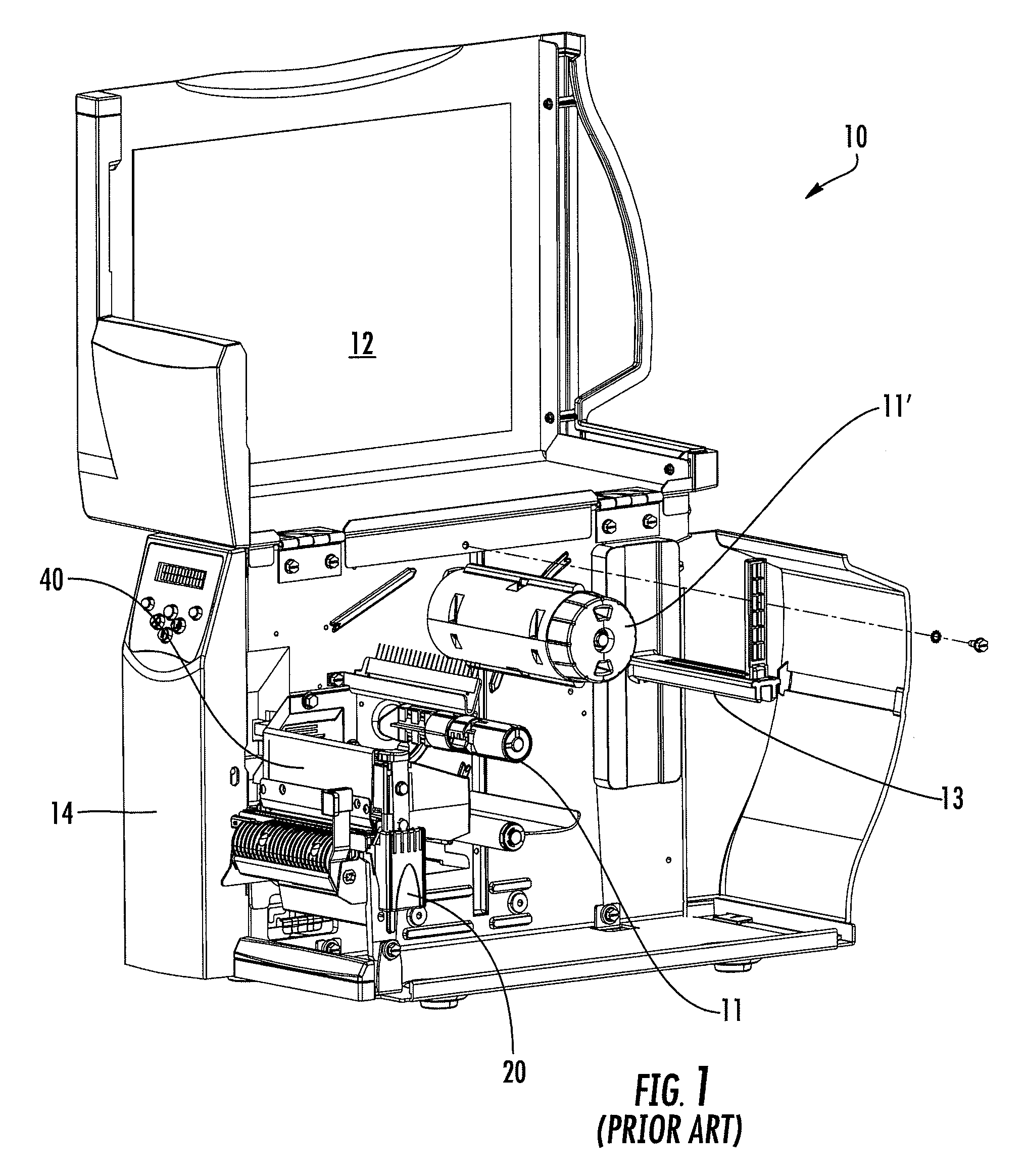

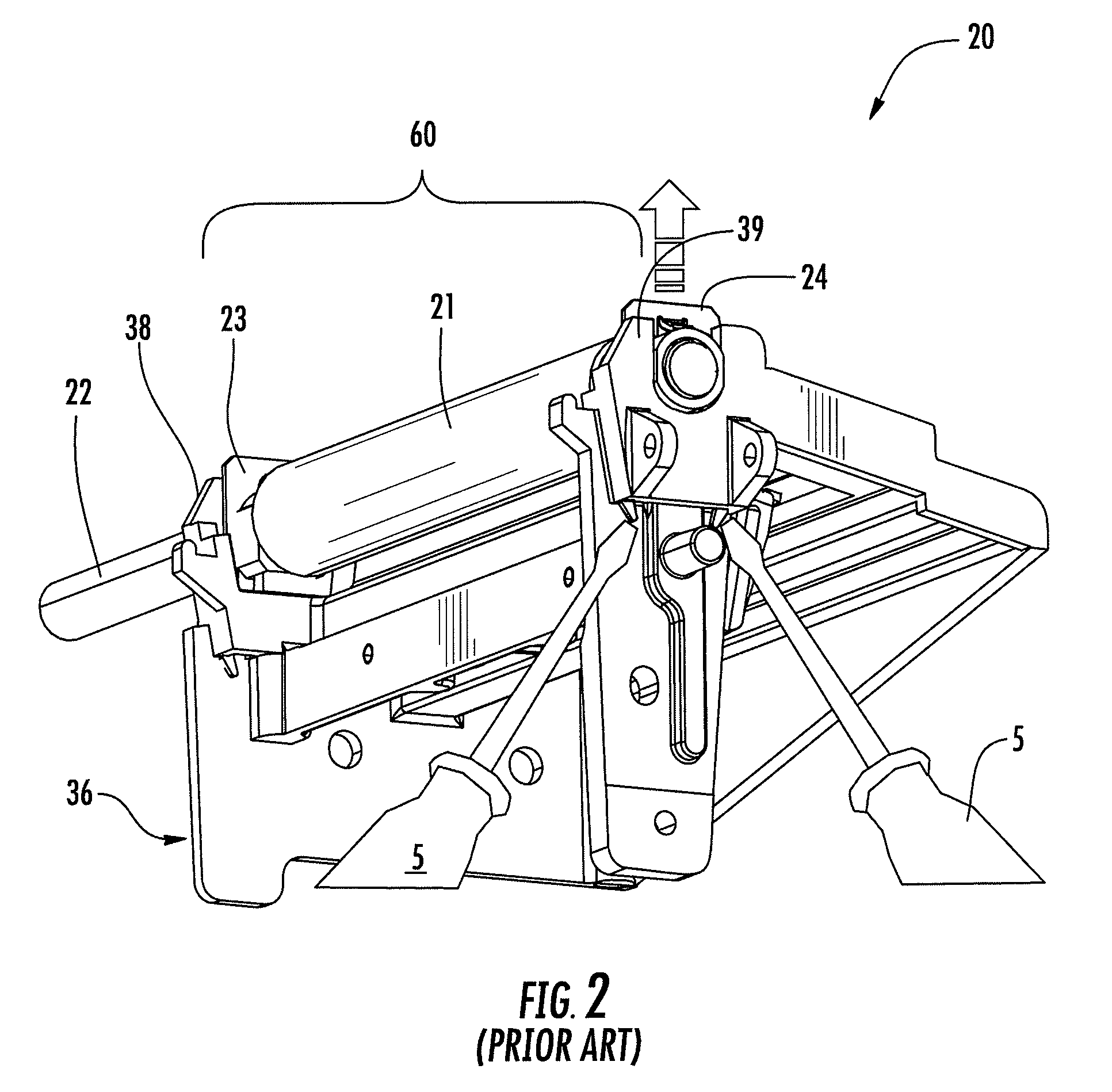

Platen assembly

ActiveUS20090038495A1Easy to replaceEasy alignmentAddressographsLetterpress printingEngineeringAssembly structure

A platen assembly for a printer comprised of a platen roller assembly and a housing assembly that is structured to rotatably support the platen roller assembly. More particularly, the present invention is directed to a platen roller assembly comprising a platen roller defining first and second ends; a locking pin extending from at least one of the first and second ends of the platen roller; a housing assembly adapted to rotatably support the platen roller; and a drive assembly structured to rotatably engage the locking pin extending from one end of the platen roller. In this regard, the present invention provides a platen roller assembly that is simple, easily alignable, and readily replaceable by a user.

Owner:ZEBRA TECH CORP

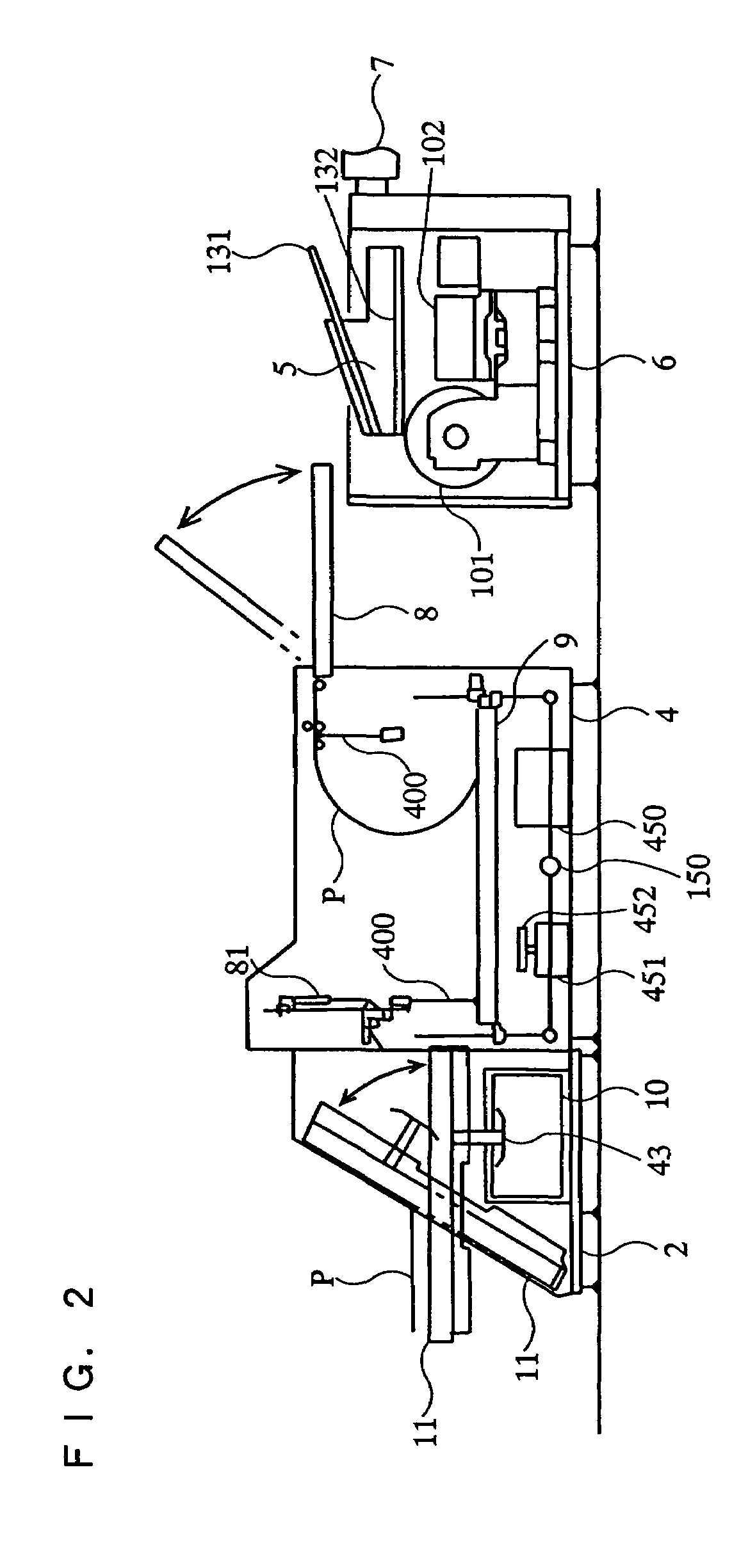

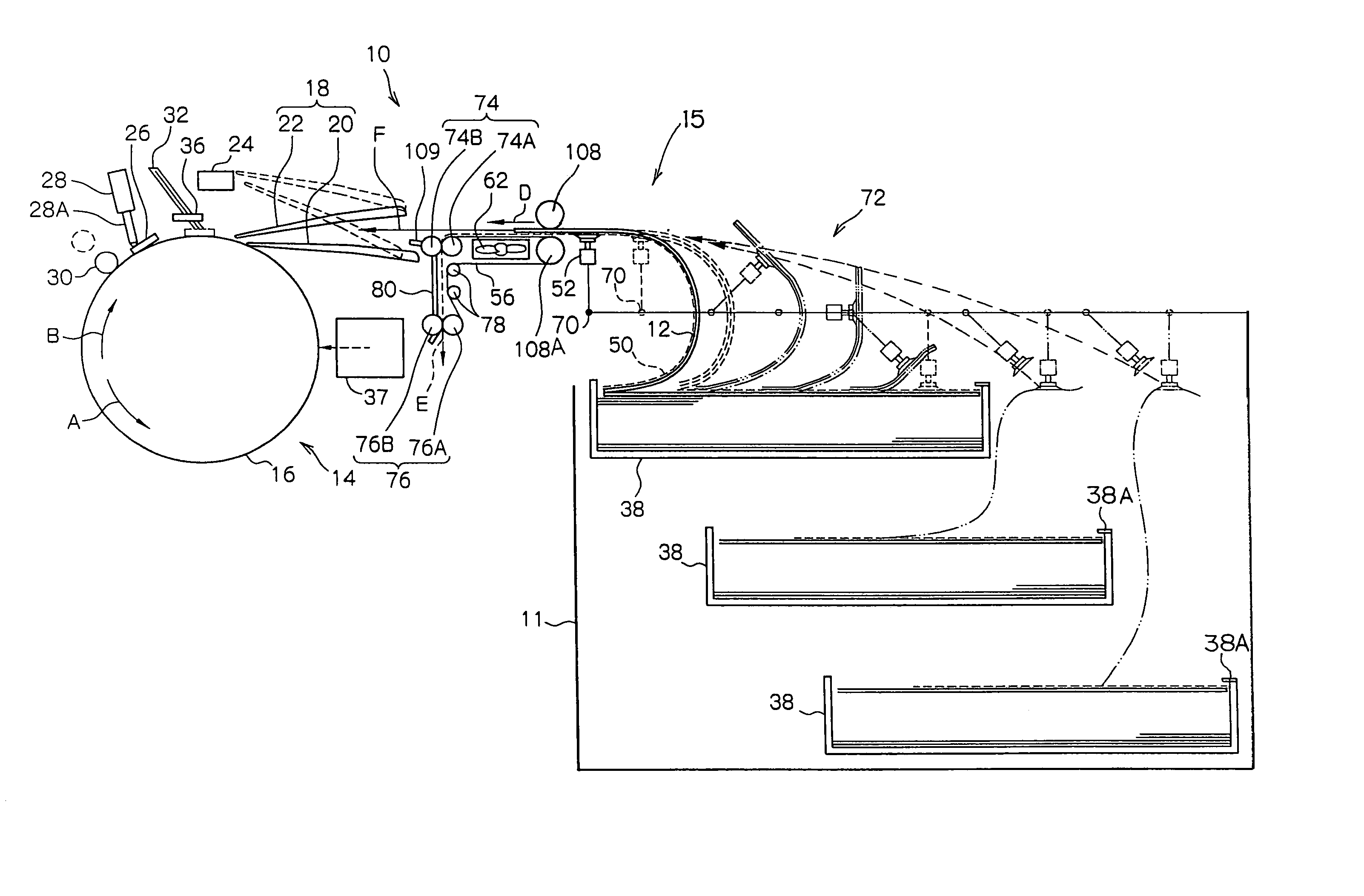

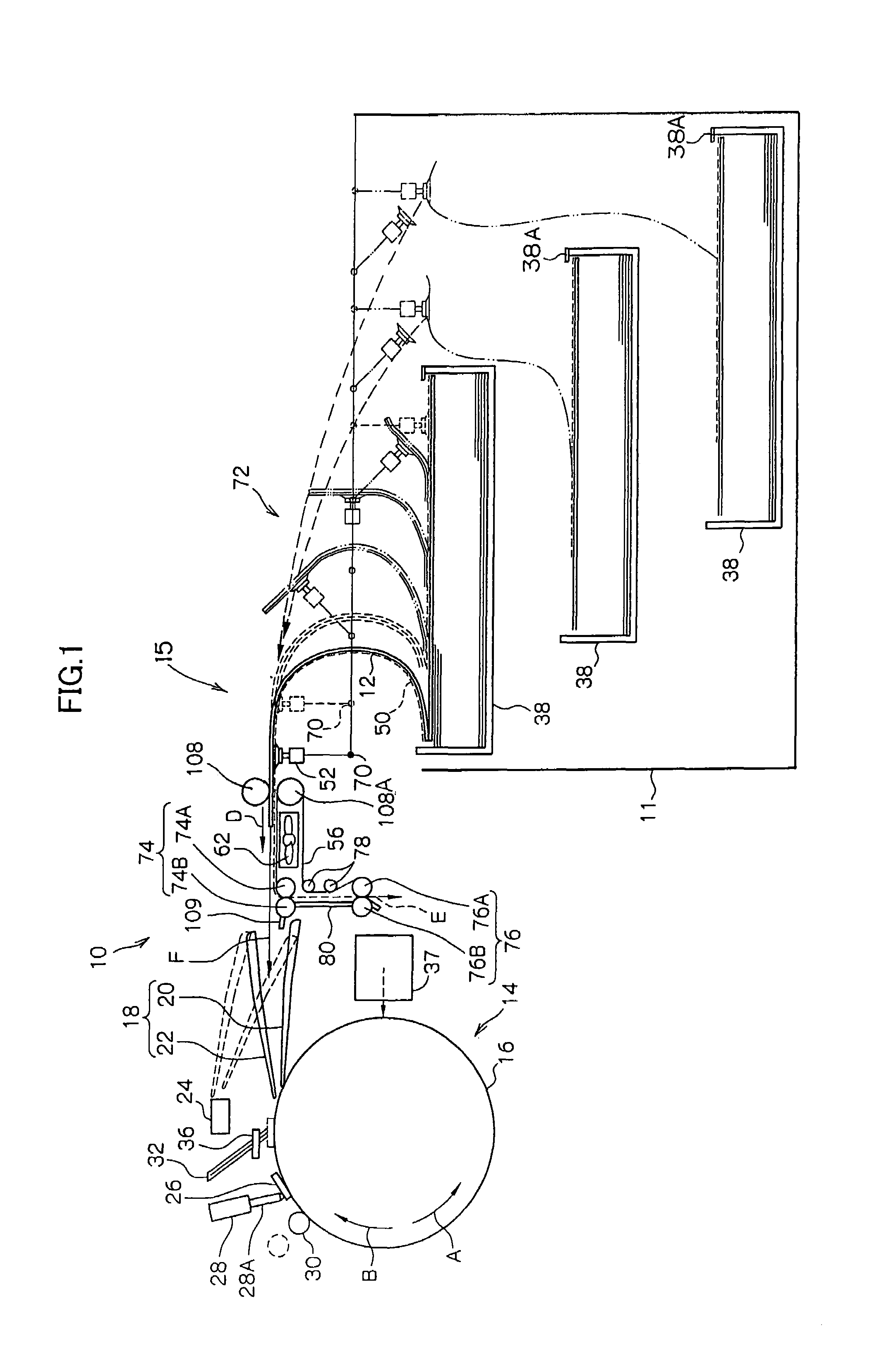

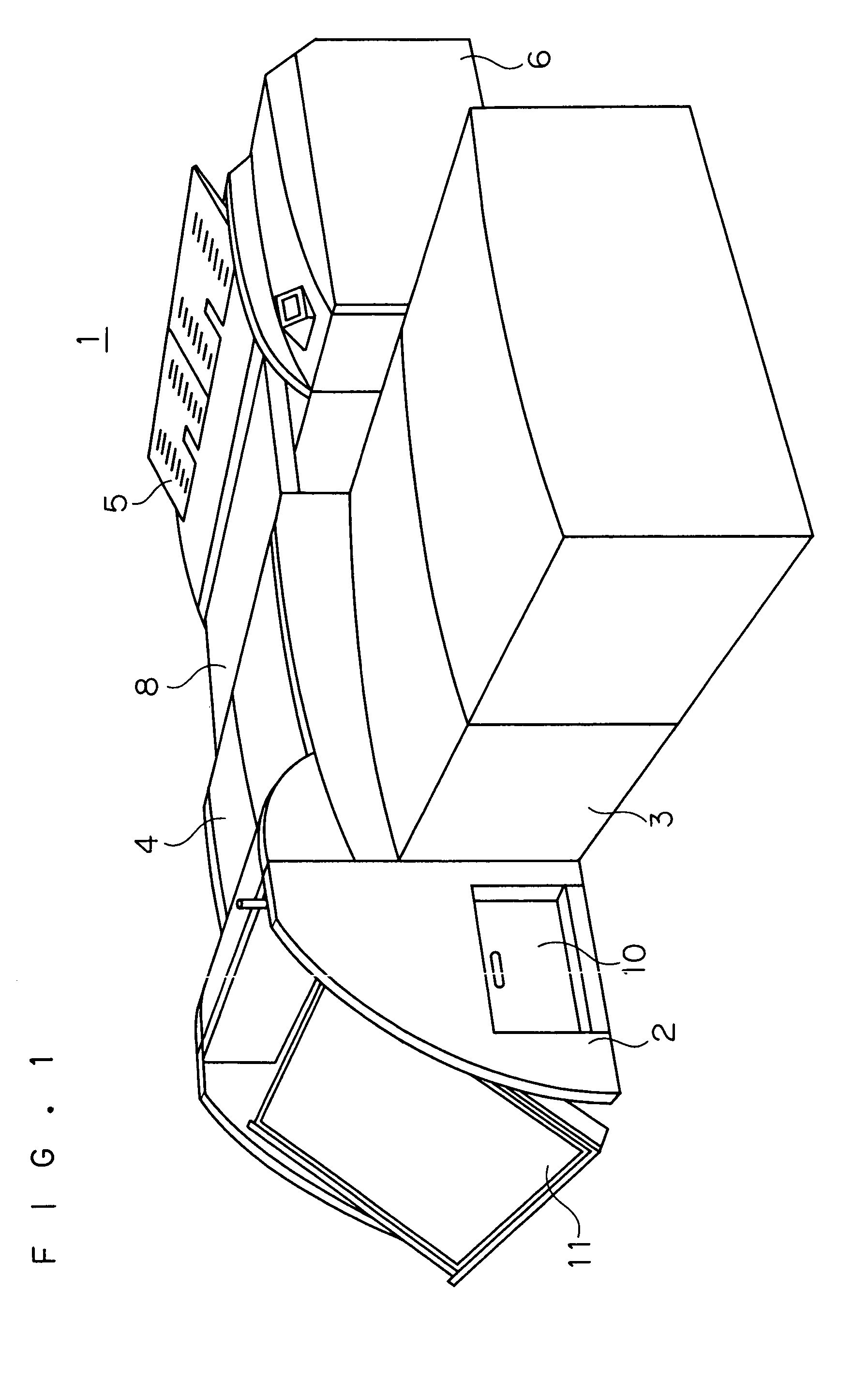

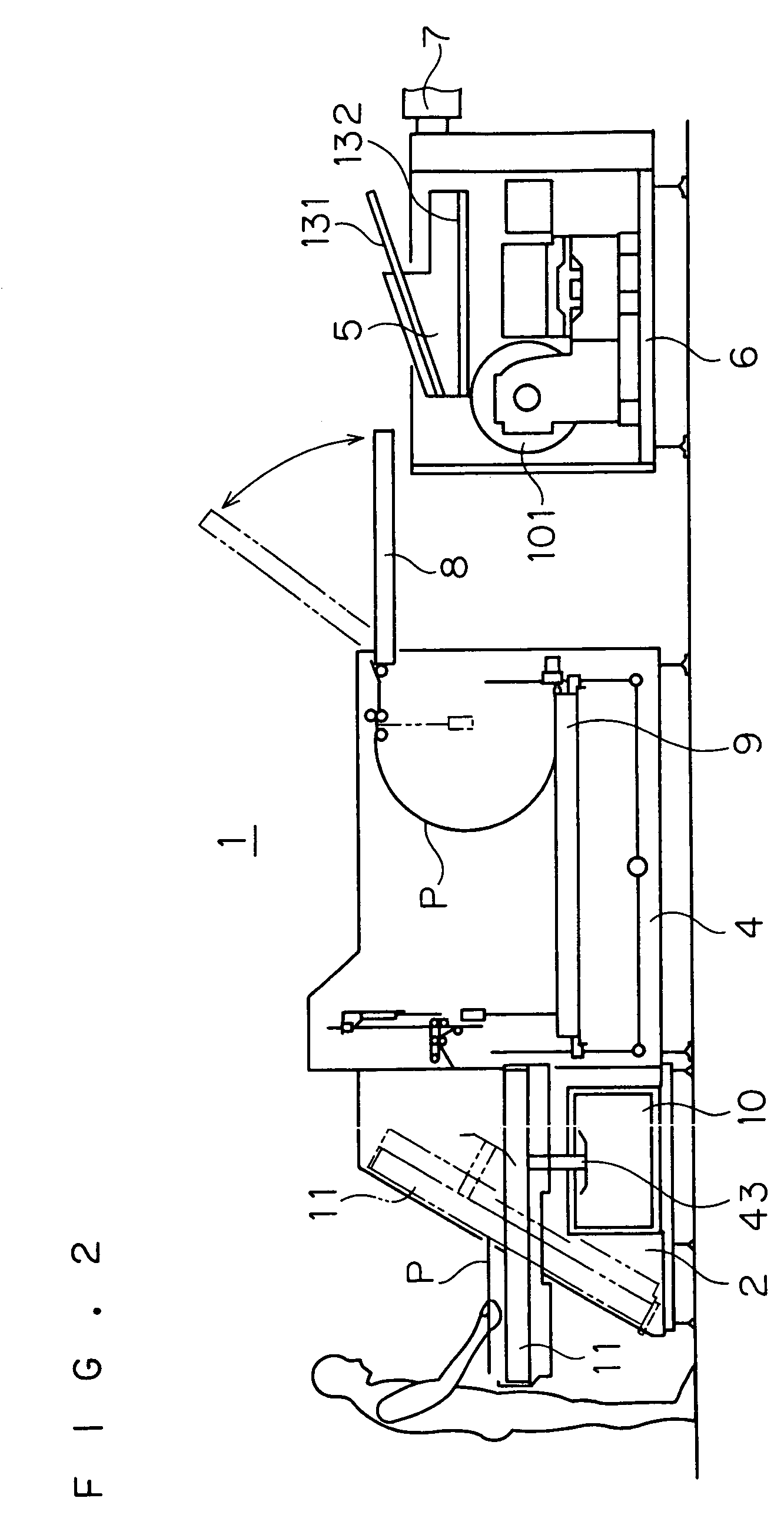

Quality inspection apparatus for double-sided printing machine

InactiveUS6883429B2Increasing installation space and overall machine lengthCylinder pressesAddressographsEngineeringMechanical engineering

A quality inspection apparatus for a double-sided printing machine which includes a rubber impression cylinder and a rubber cylinder; inking unite for supplying ink to the rubber impression cylinder and the rubber cylinder; and a transport mechanism for transporting the printed paper to a delivery unit. The transport mechanism includes first through third transport cylinders for transporting the paper from the first delivery chain, and a delivery chain for transporting the paper from the first through third transport cylinders. The quality inspection apparatus includes an inspection camera for detecting a status of printing on one face of the paper when transported by the first transport cylinder, and an inspection camera for detecting a status of printing on the other face of the paper when transported by the second transport cylinder.

Owner:KOMORI CORP

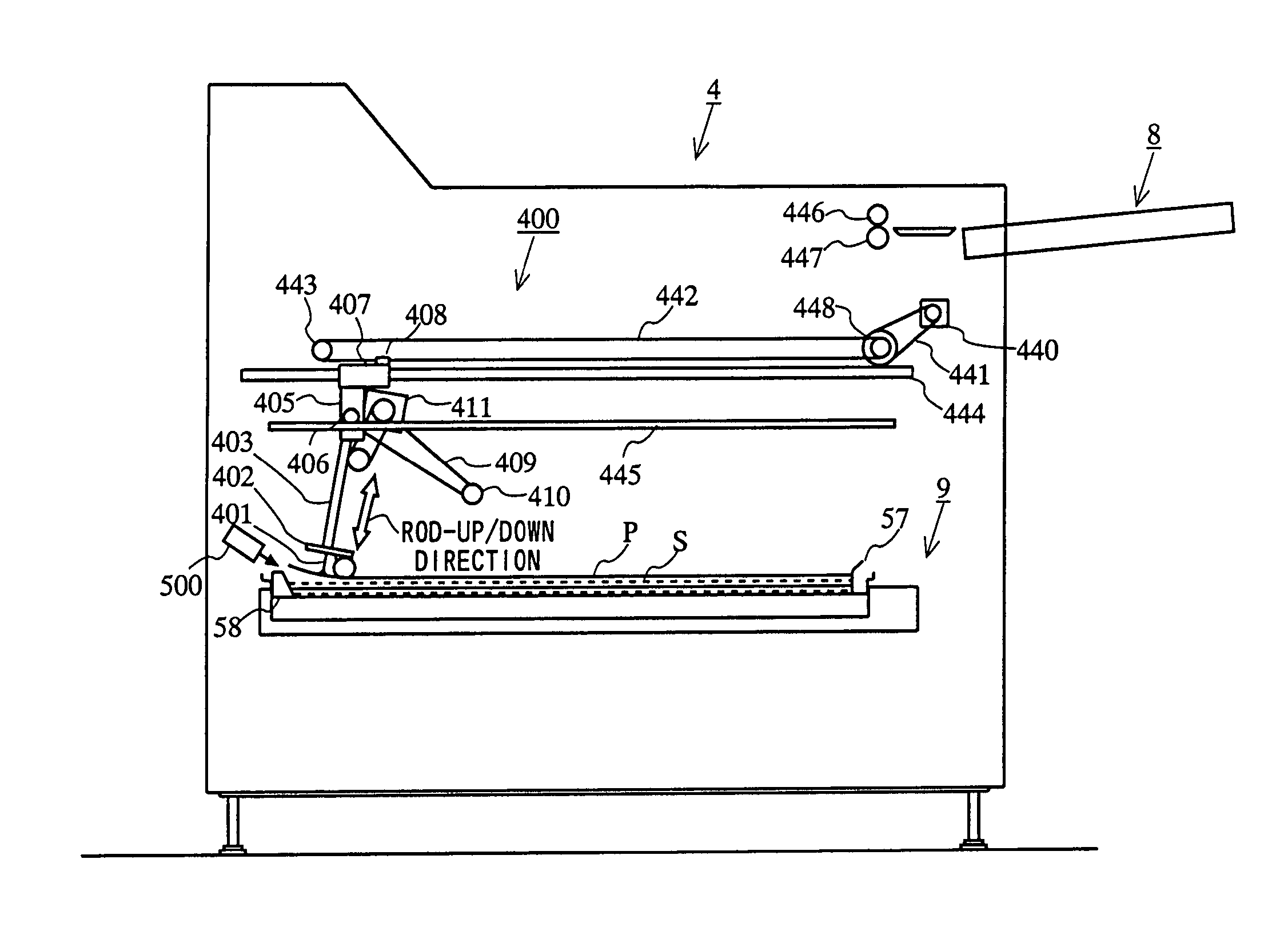

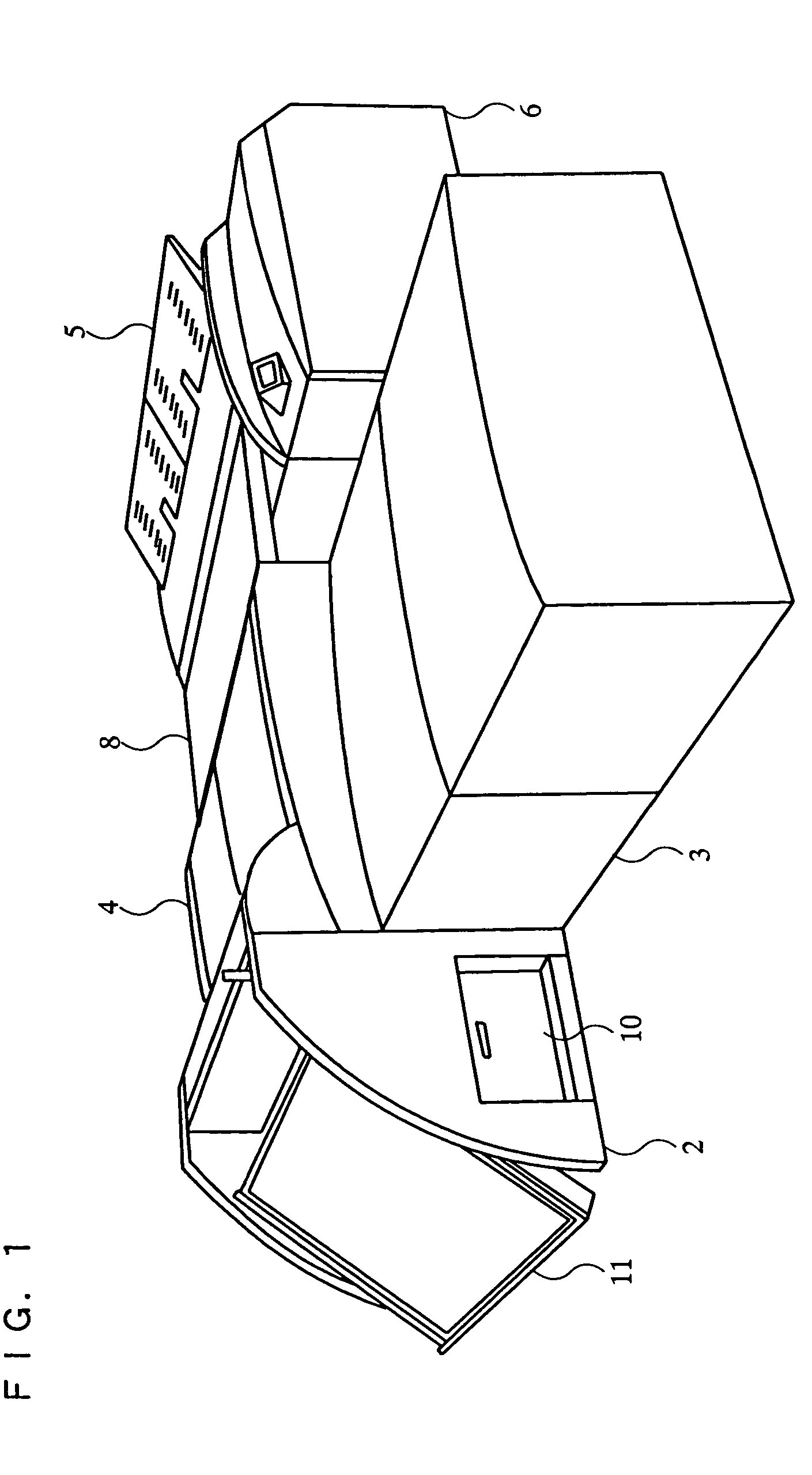

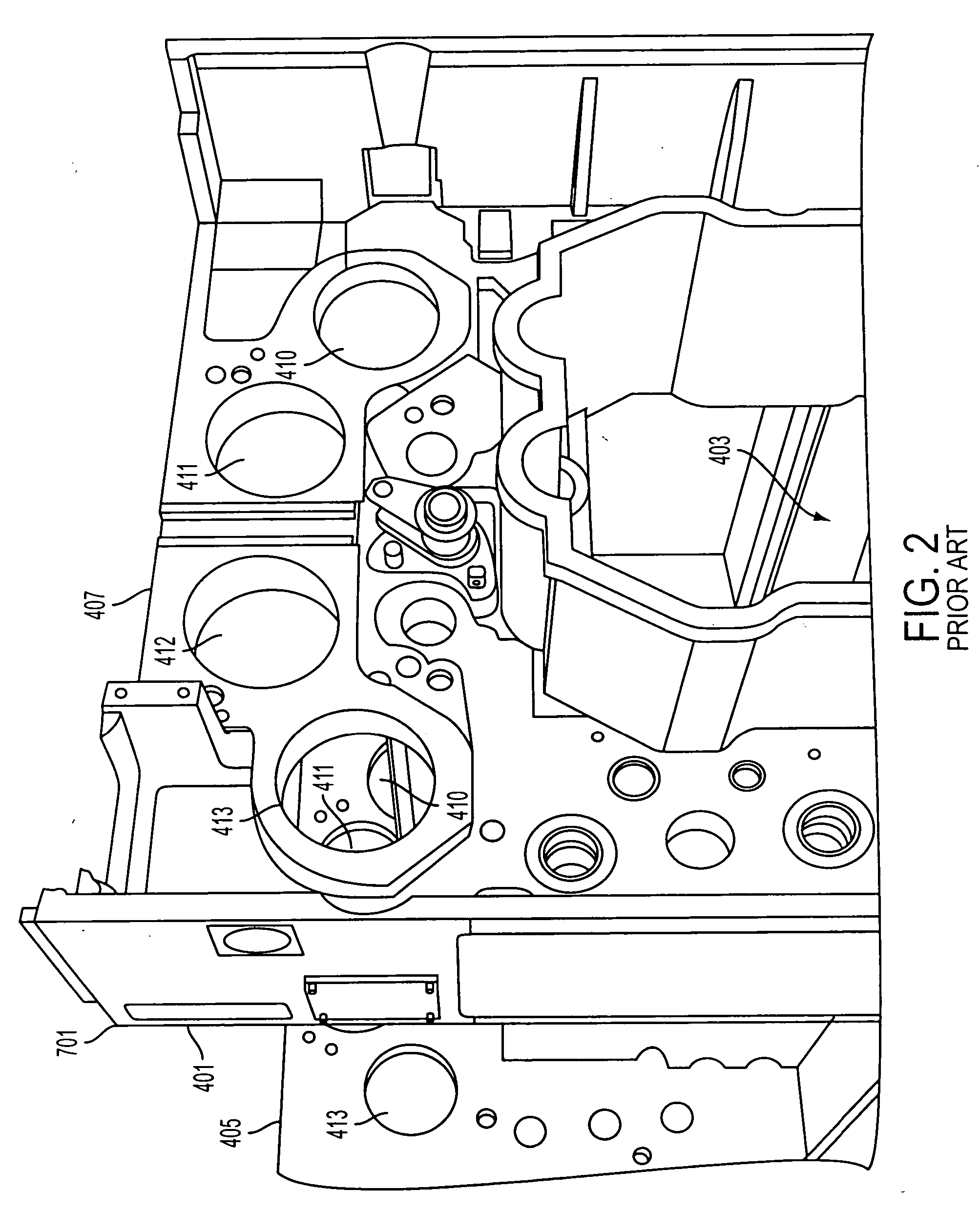

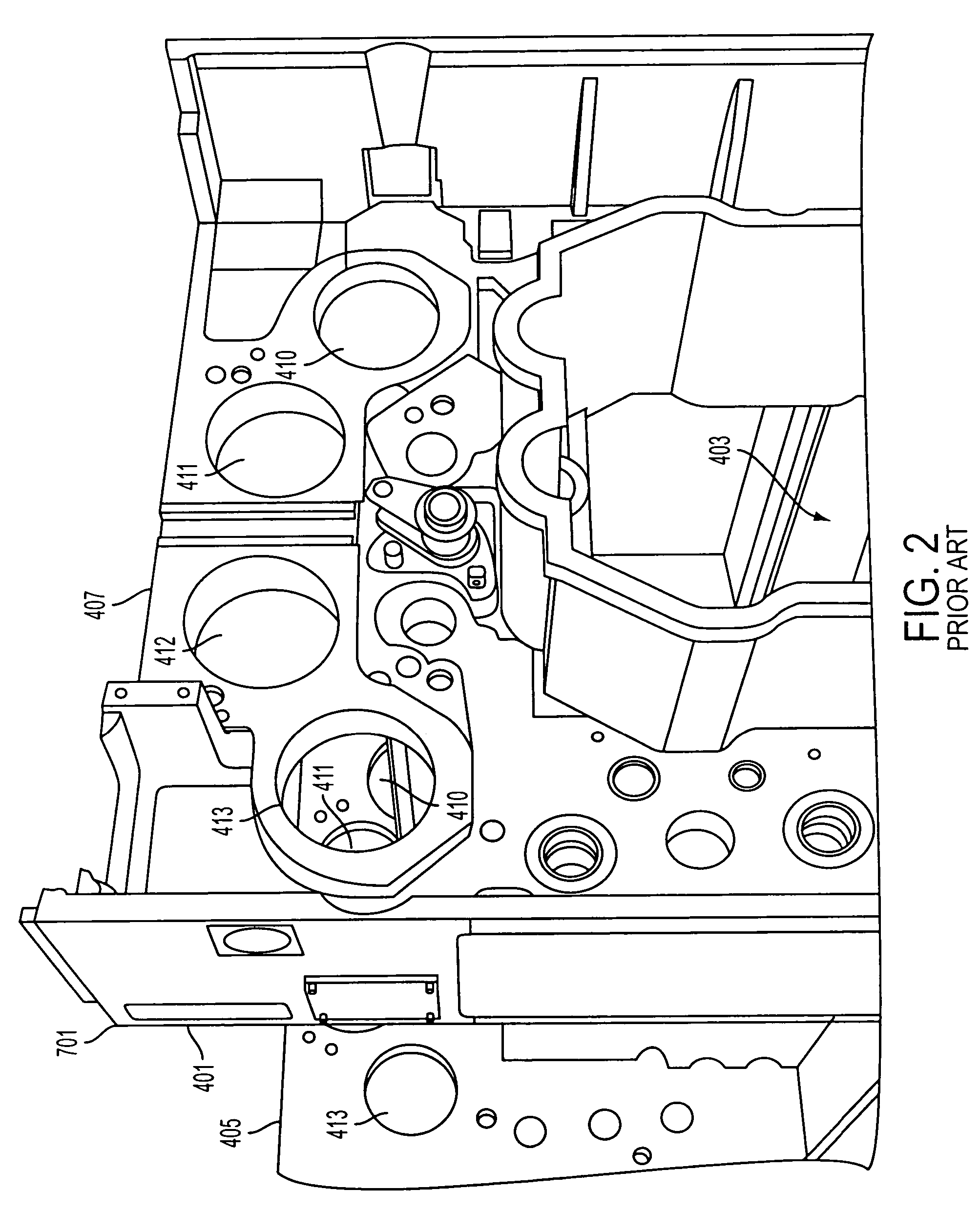

Plate supplying apparatus

InactiveUS6978716B2Preventing an image recording layer of a plate from being damagedReduce torqueAddressographsLetterpress printingSlip sheetEngineering

In the plate supplying apparatus of the present invention, various vibrations are provided to a plate secured via suction during a separating operation by causing pad rods 403 to repeat a slight ascent and a pause, and thereafter causing the pad rods 403 to make an abrupt descent, thereby reliably peeling off a slip sheet adhering to the back face of the plate. Further, vibration in the rod-up / down direction is provided to the plate during the separating operation, and the plate is not pushed hard. Thus, it is possible to prevent the plate from being damaged. A raising and lowering motor 52 is driven to lower the cassette 9. A separating operation for peeling off a slip sheet S adhering to the back face of the plate P is performed, and thereafter the plate P secured via suction is turned over and transferred.

Owner:DAINIPPON SCREEN MTG CO LTD

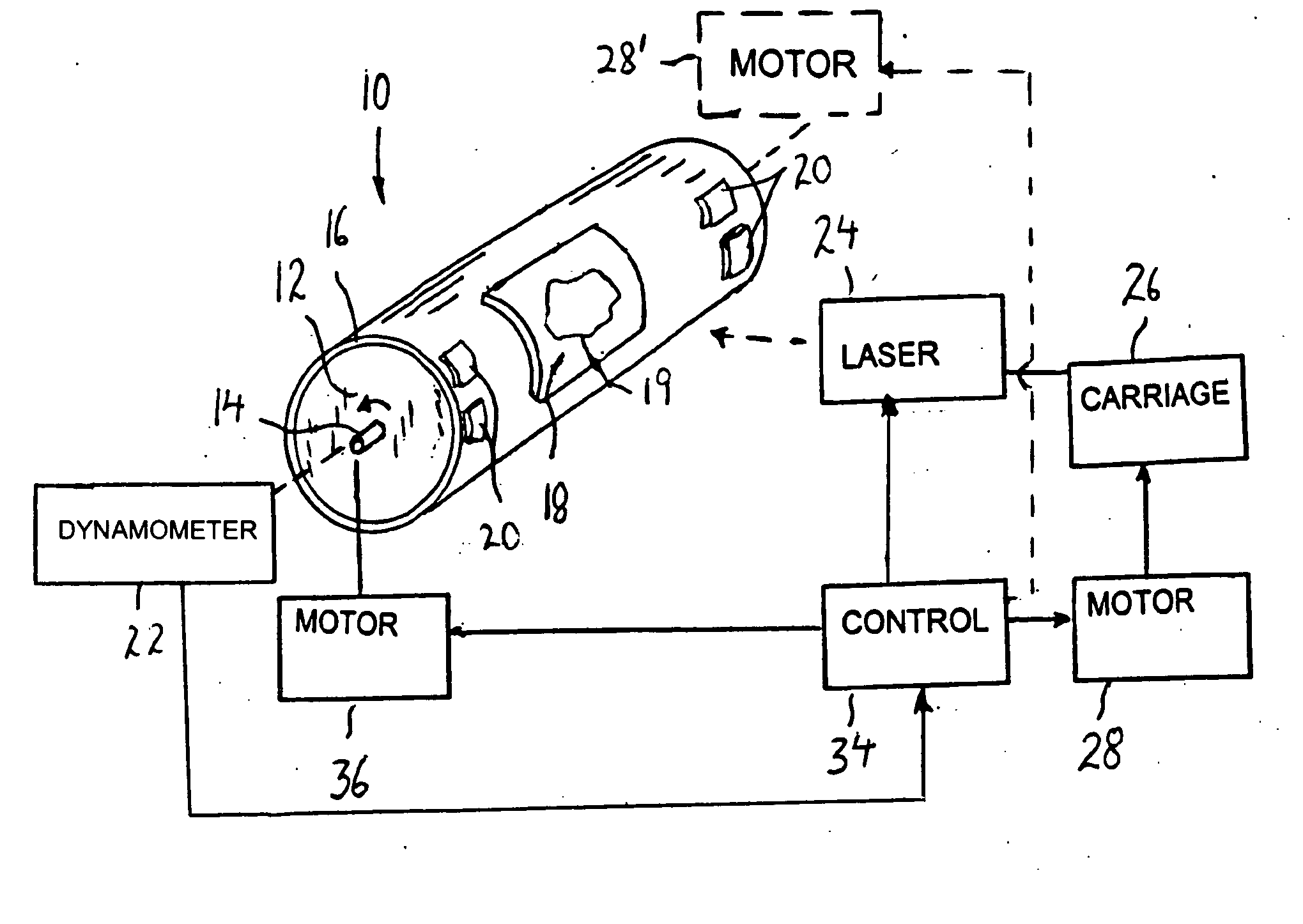

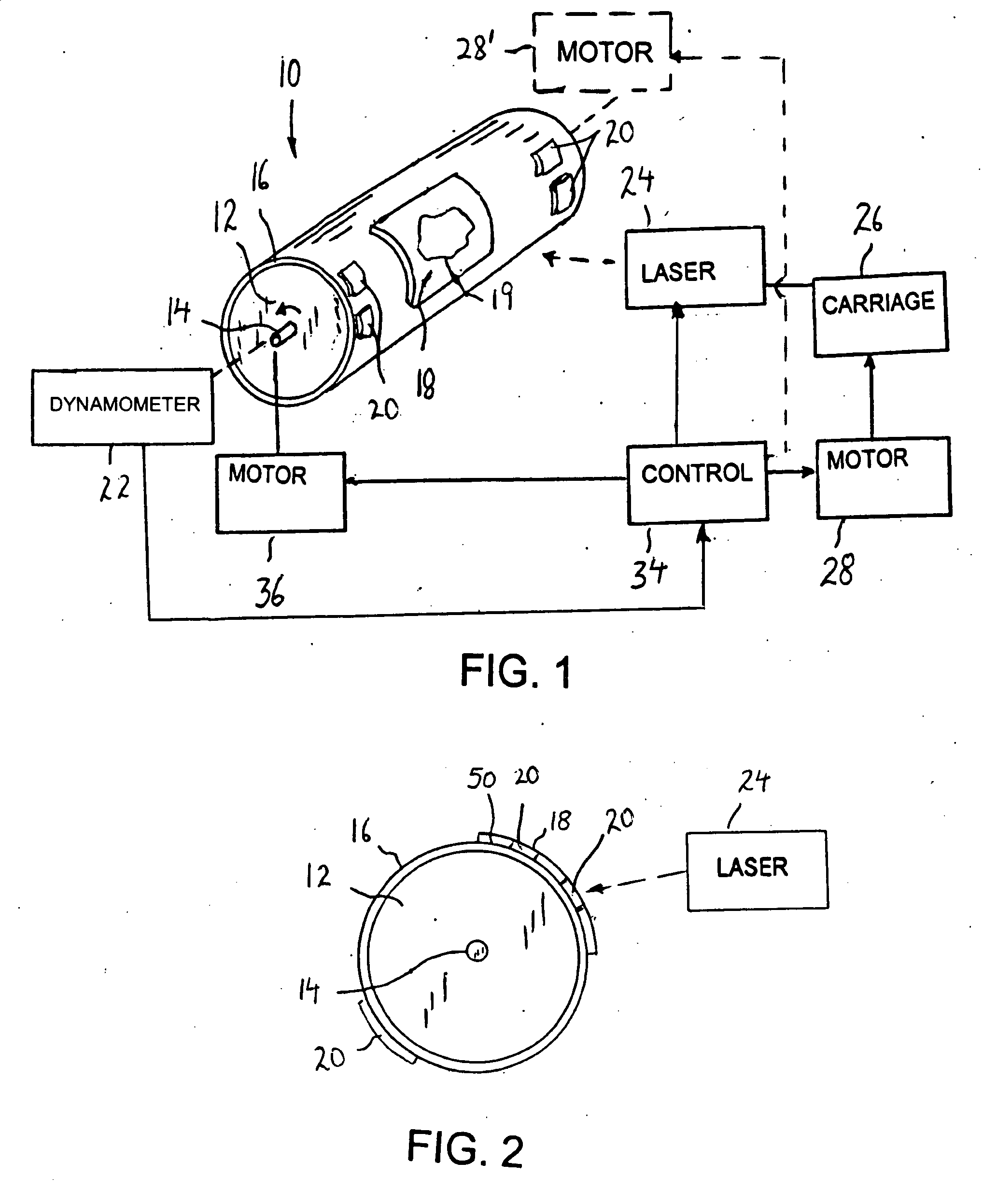

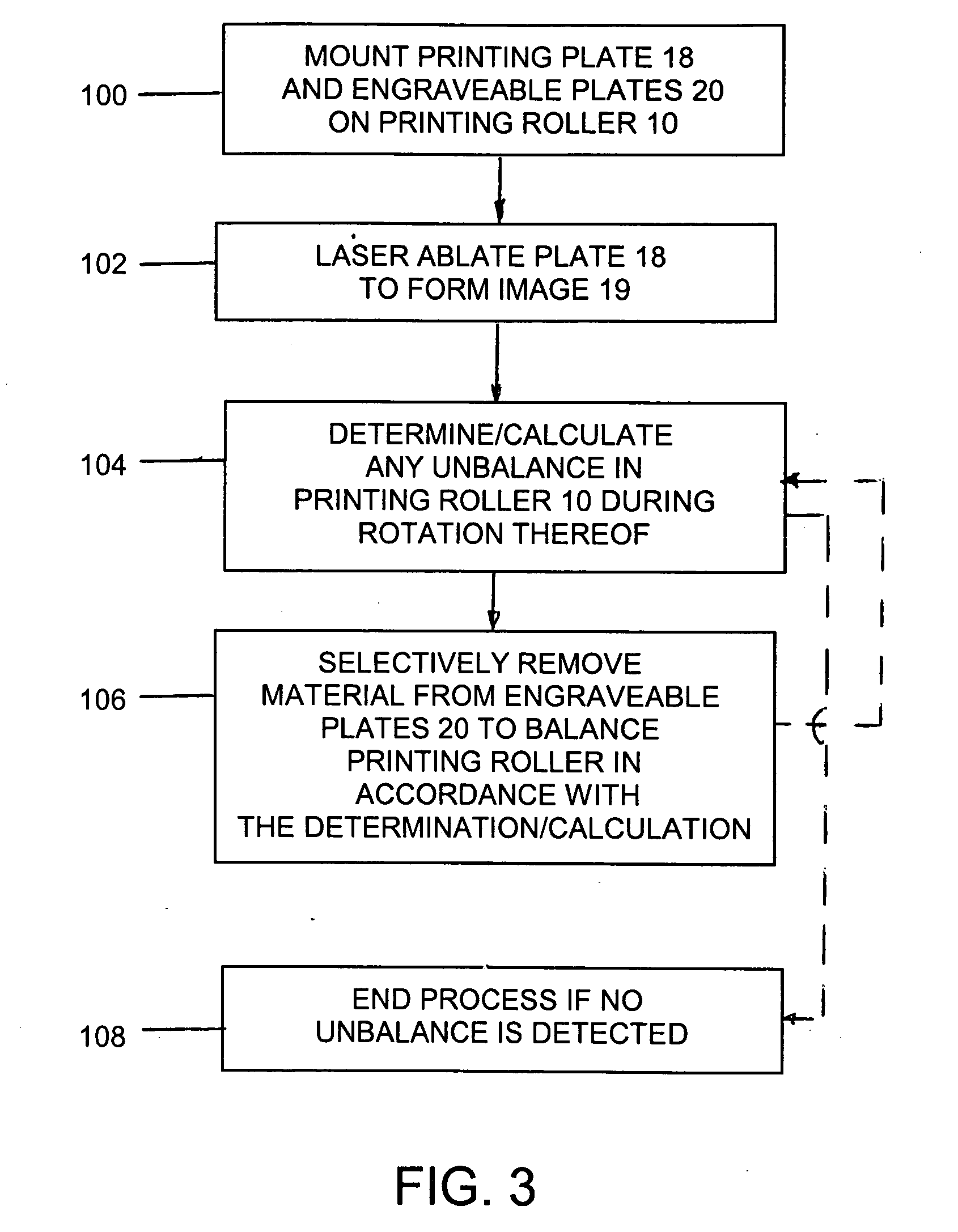

Apparatus and method for balancing a printing roller having an image producing area on its outer surface

InactiveUS20070095231A1Inexpensive and easy to useInexpensive and easy to and manufactureAddressographsLetterpress printingWeight adjustmentEngineering

Owner:VAN DENEND MARK E

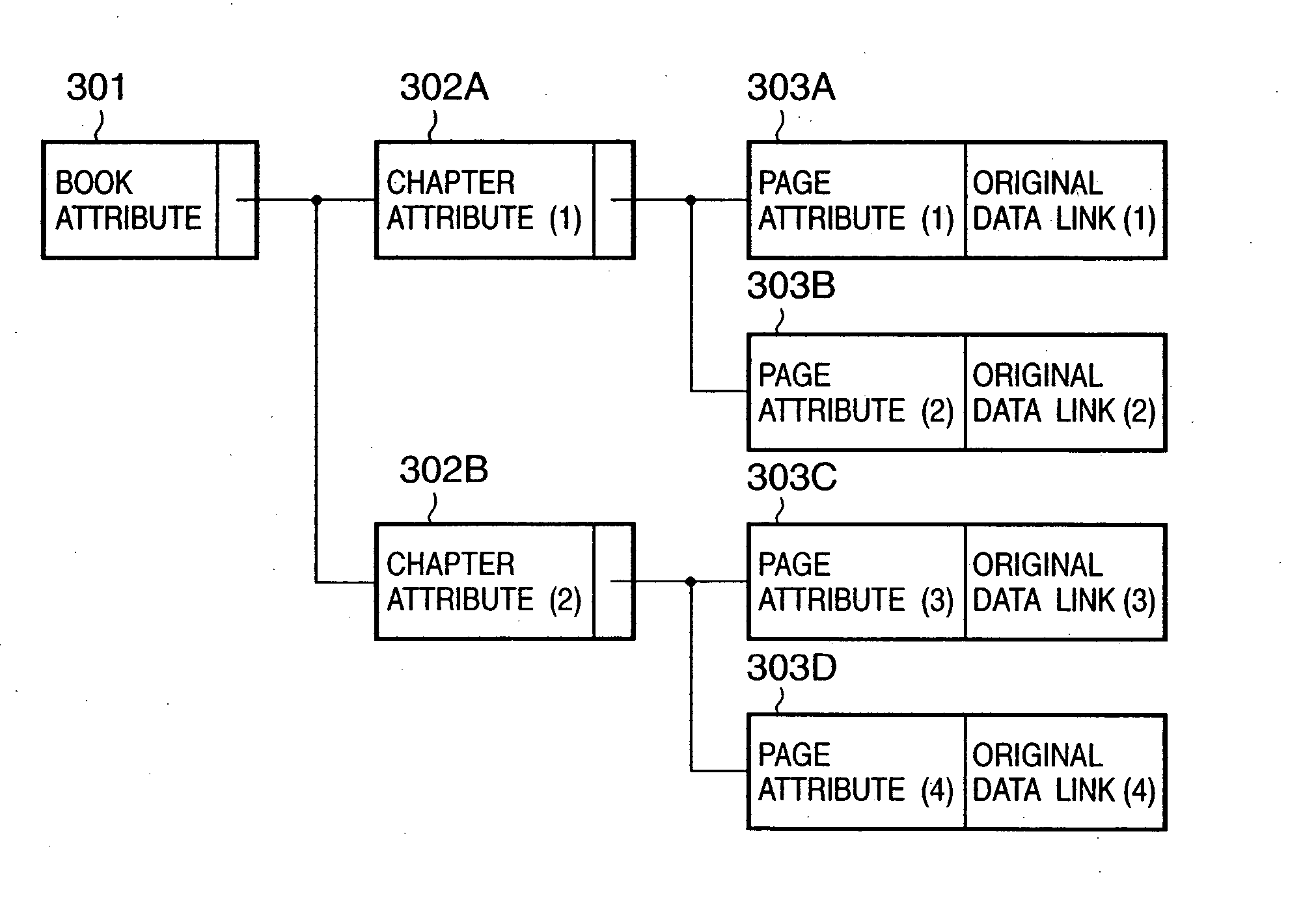

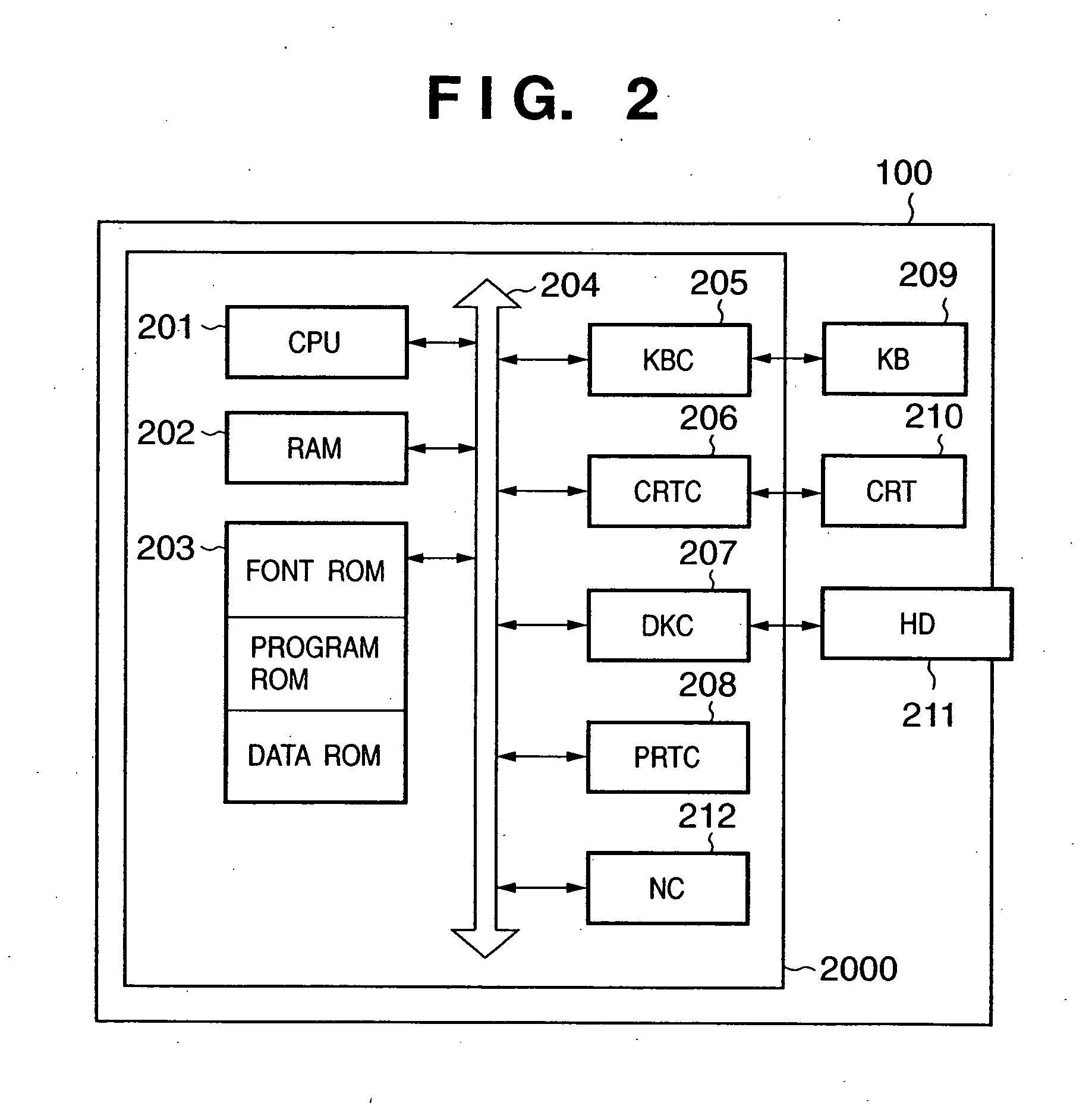

Document processing system, information processing apparatus, and setting methods therefor

ActiveUS20050128500A1Digitally marking record carriersLetterpress printingInformation processingComputer printing

When a user sets, from a user interface window using a bookbinding application, instructions of dividing a document into a plurality of parts and stapling each part of the document, a printer driver generates one job in which the staple attribute of a binder corresponding to each part is set to “ON” or “OFF”, and issues the job for a printer. With this operation, the user can perform staple designation to an arbitrary part of the document, and can realize a plurality of staple processes in one print job.

Owner:CANON KK

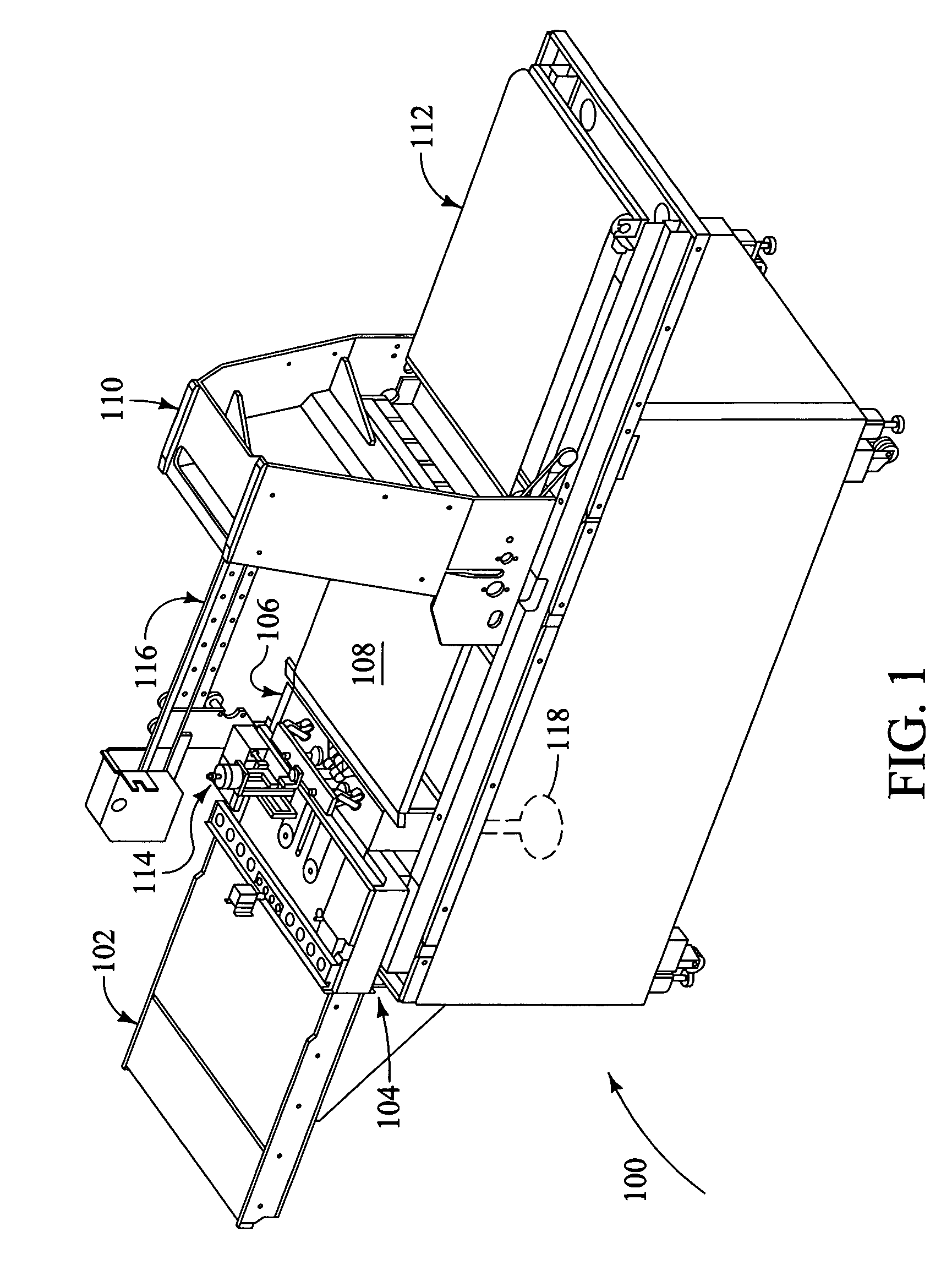

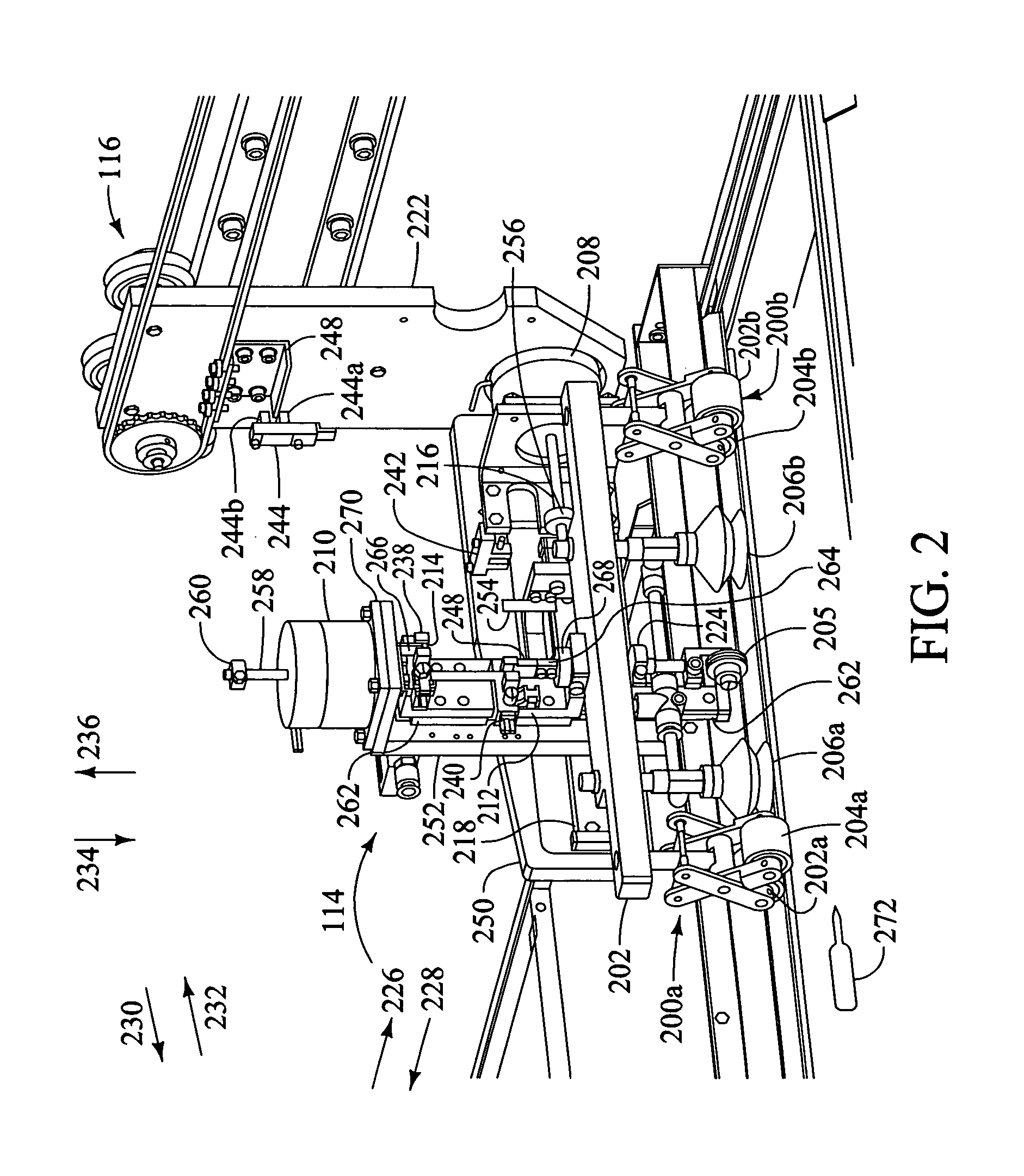

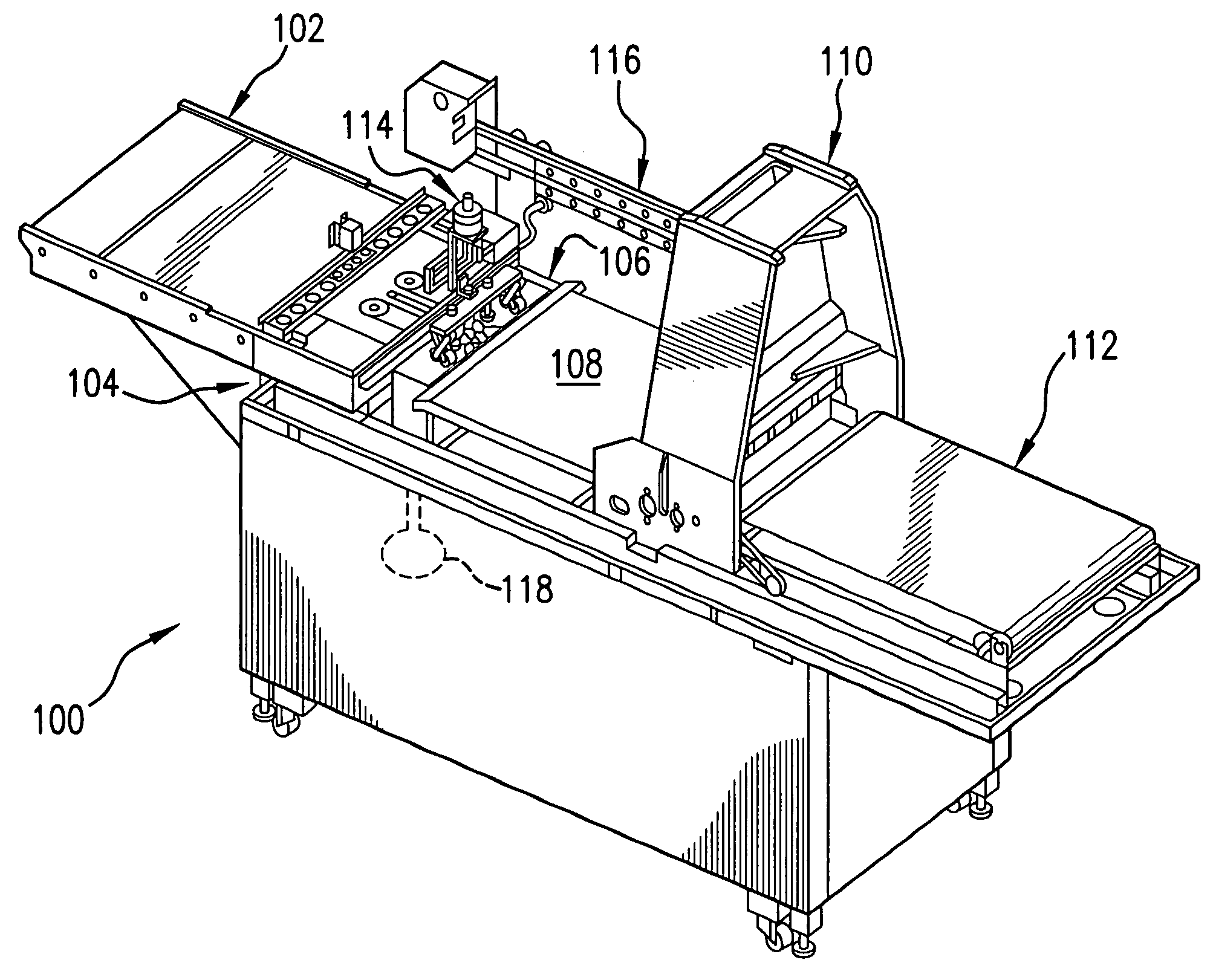

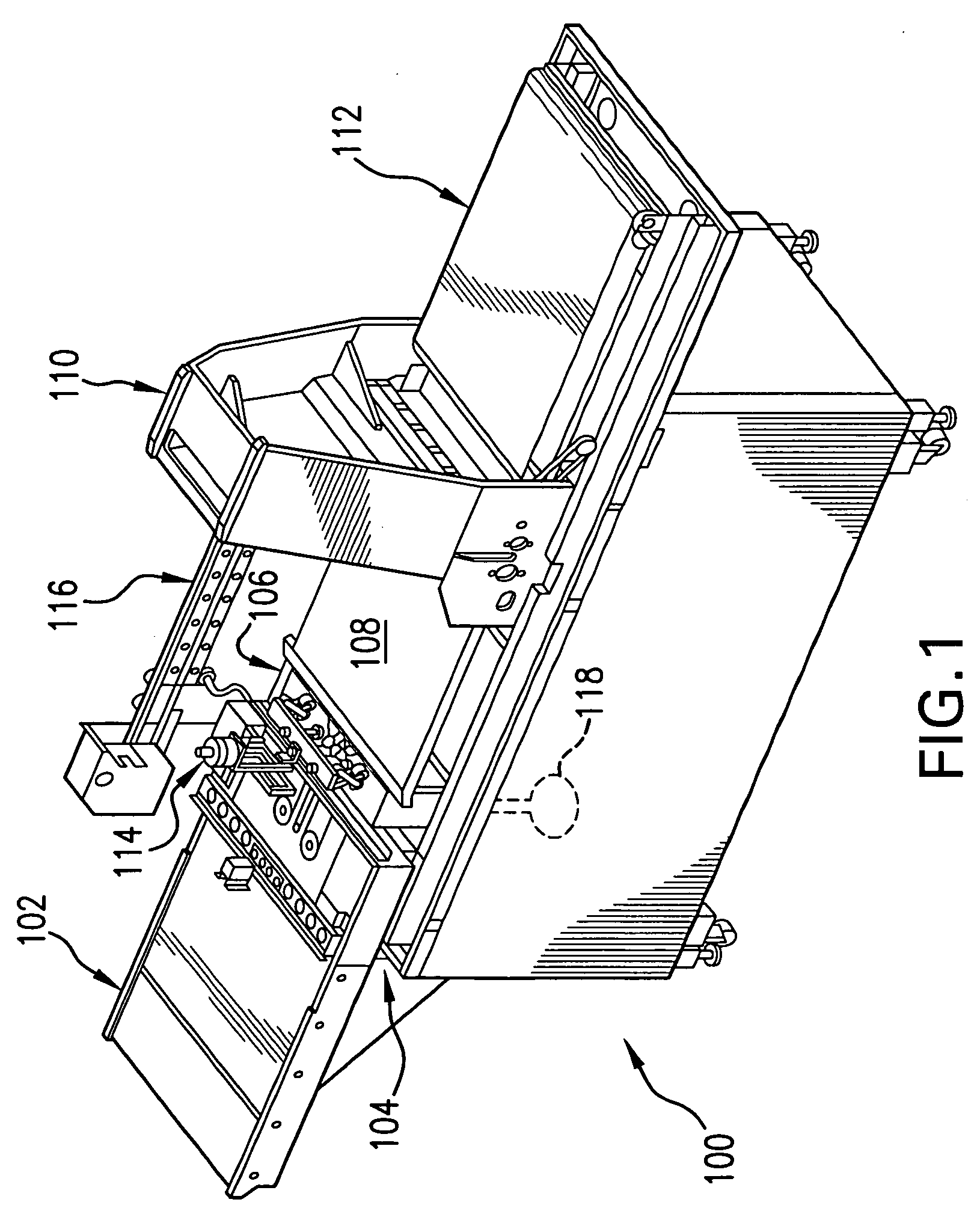

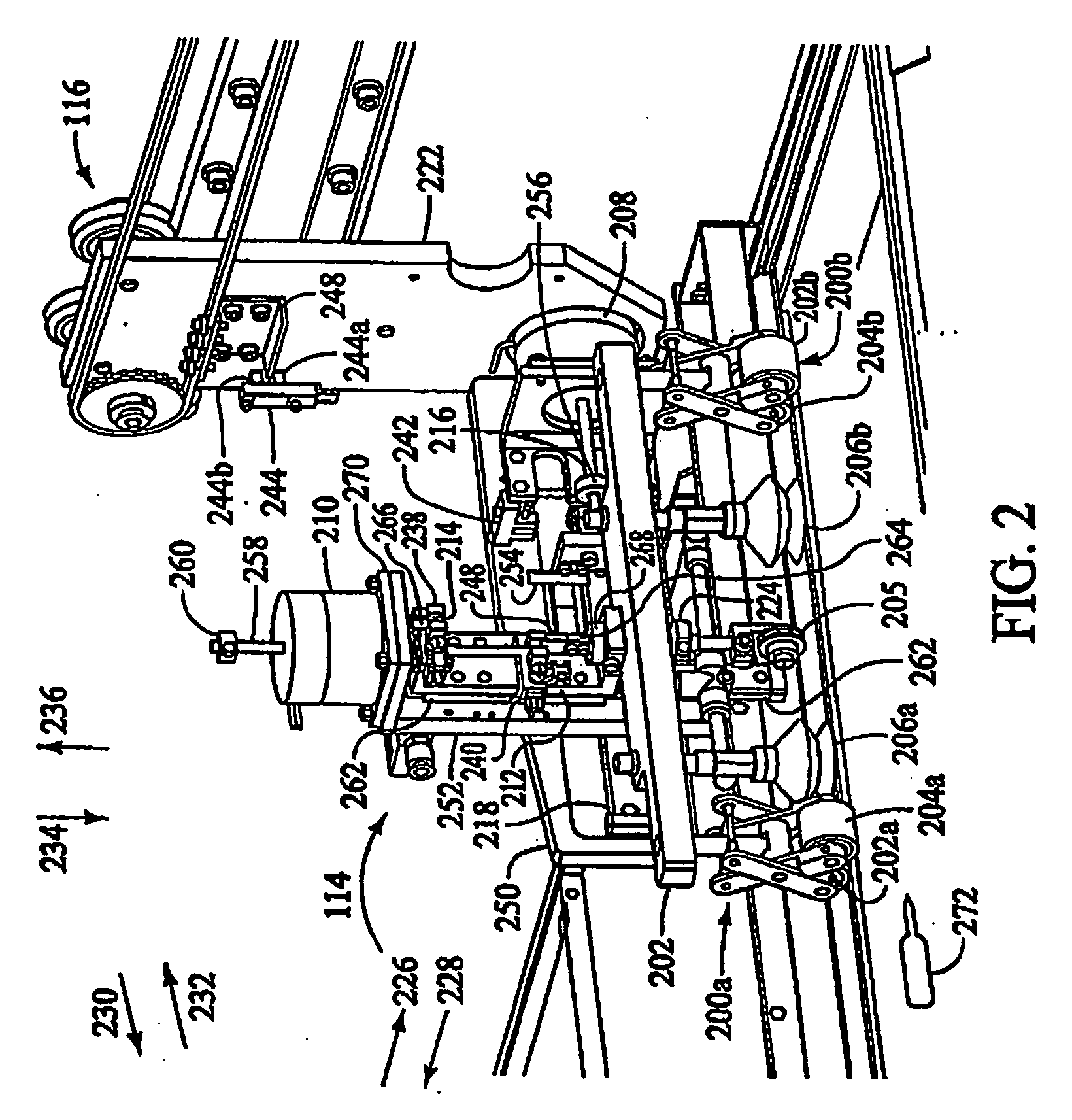

System and method for interleaf sheet and/or plate sheet removal and/or transport for use with a printing apparatus

InactiveUS7000541B2Minimize the numberSimple and low solutionAddressographsLetterpress printingComputer to plateImage system

The present invention relates generally to systems and methods that remove an interleaf sheet interposed between plate sheets from a material stack used, for example, in a computer-to-plate imaging system and / or environment. Embodiments of the system and method can also remove plate sheets from an interleaf sheet, and transport the plate sheet for subsequent imaging.

Owner:ECRM

Image recording material separating/removing device

An image recording material separating / removing device which, by using a single lift-out mechanism section, can lift image recording materials out from plural cassettes along simple loci of movement, and in which a space for providing and withdrawing the cassettes is kept as small as possible. In a cassette housing section, a plurality of cassettes are disposed one above another. Each cassette is offset in a horizontal direction. An amount of offset is set on the basis of a locus of movement of a printing plate at a time when the printing plate is sucked and held by suction cups and lifted up in a vertical direction. At least while the suction cups are moving in the vertical direction, the printing plate is not interfered with by cassettes thereabove, and an emulsion surface of the printing plate is not scratched. Space required for placement of the cassette housing section can be reduced. Moreover, because movement of the suction cups can be simplified, a control system can be simplified.

Owner:FUJIFILM HLDG CORP +1

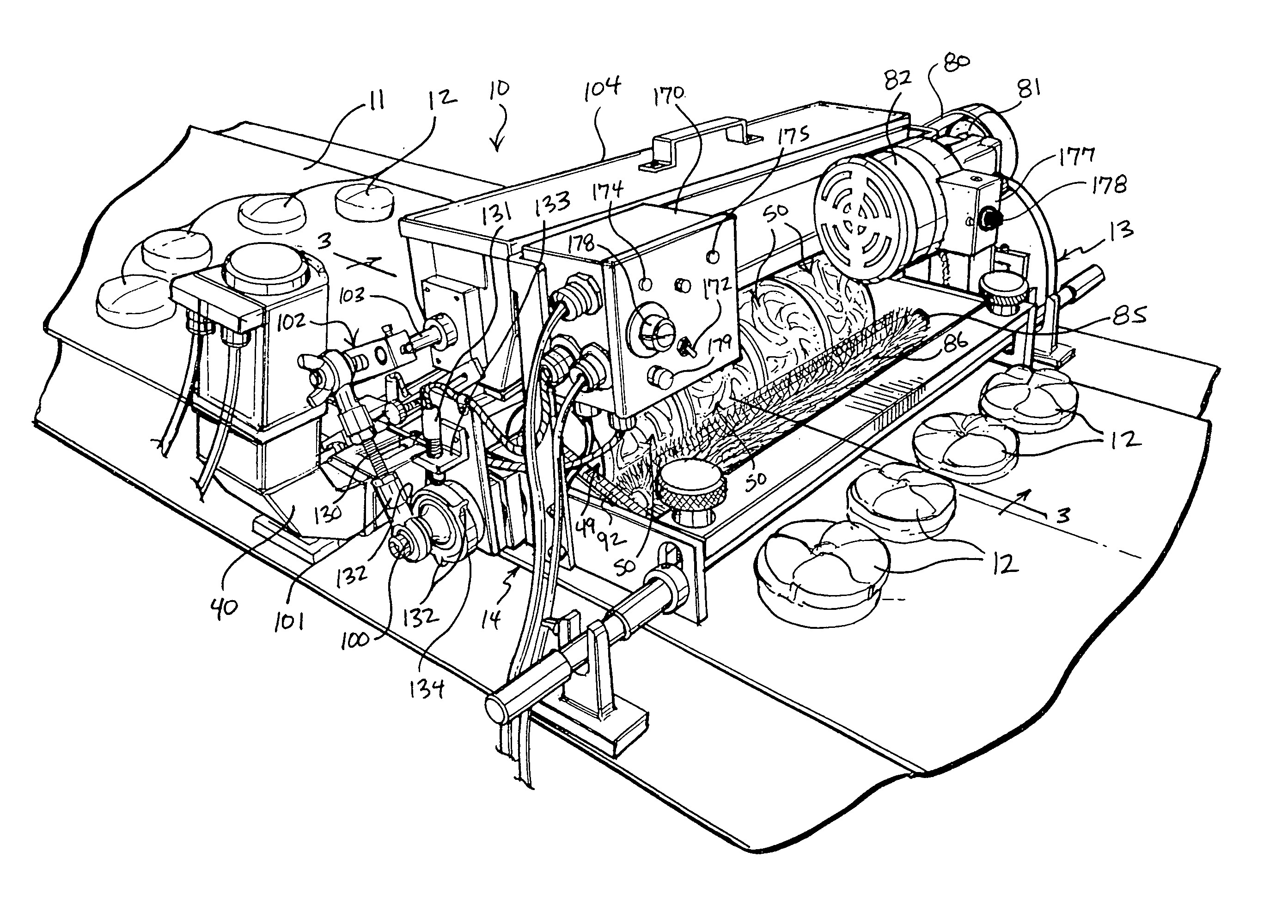

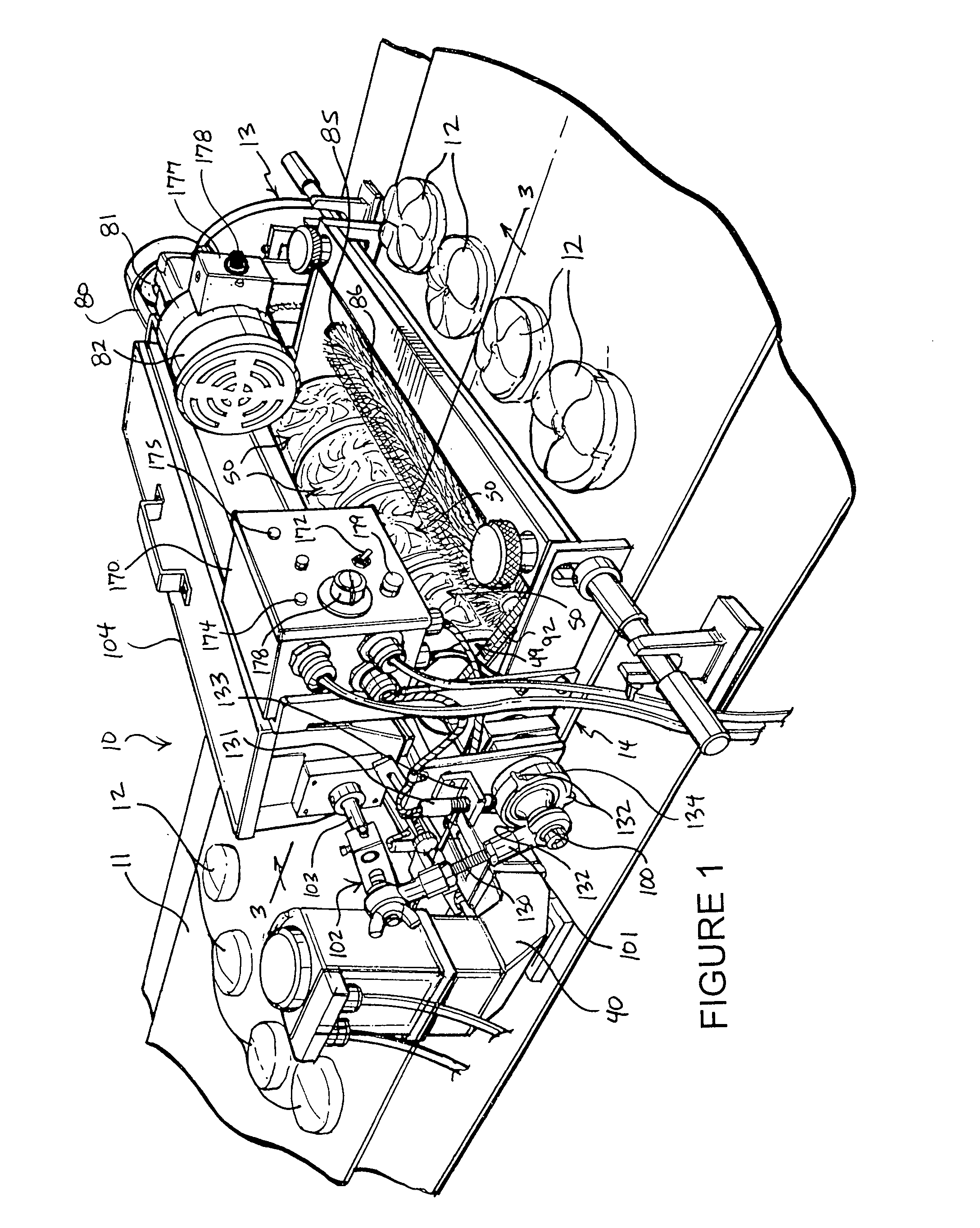

Systems and methods for newspaper press cut-off reduction

Systems and methods for modifying, altering, constructing, or retrofitting an existing newspaper press having a first cut-off length, to have a second cut-off length which is different from and generally less than the first. These systems and methods generally provide for the machining of new bore holes into the existing press unit frame. The new bore holes will generally completely encompass the old bore holes and allow for linear translation of the axes of rotation of the new cylinders relative to the positions of the axes for the old cylinders.

Owner:PRESSLINE SERVICES

Systems and methods for newspaper press cut-off reduction

Owner:PRESSLINE SERVICES

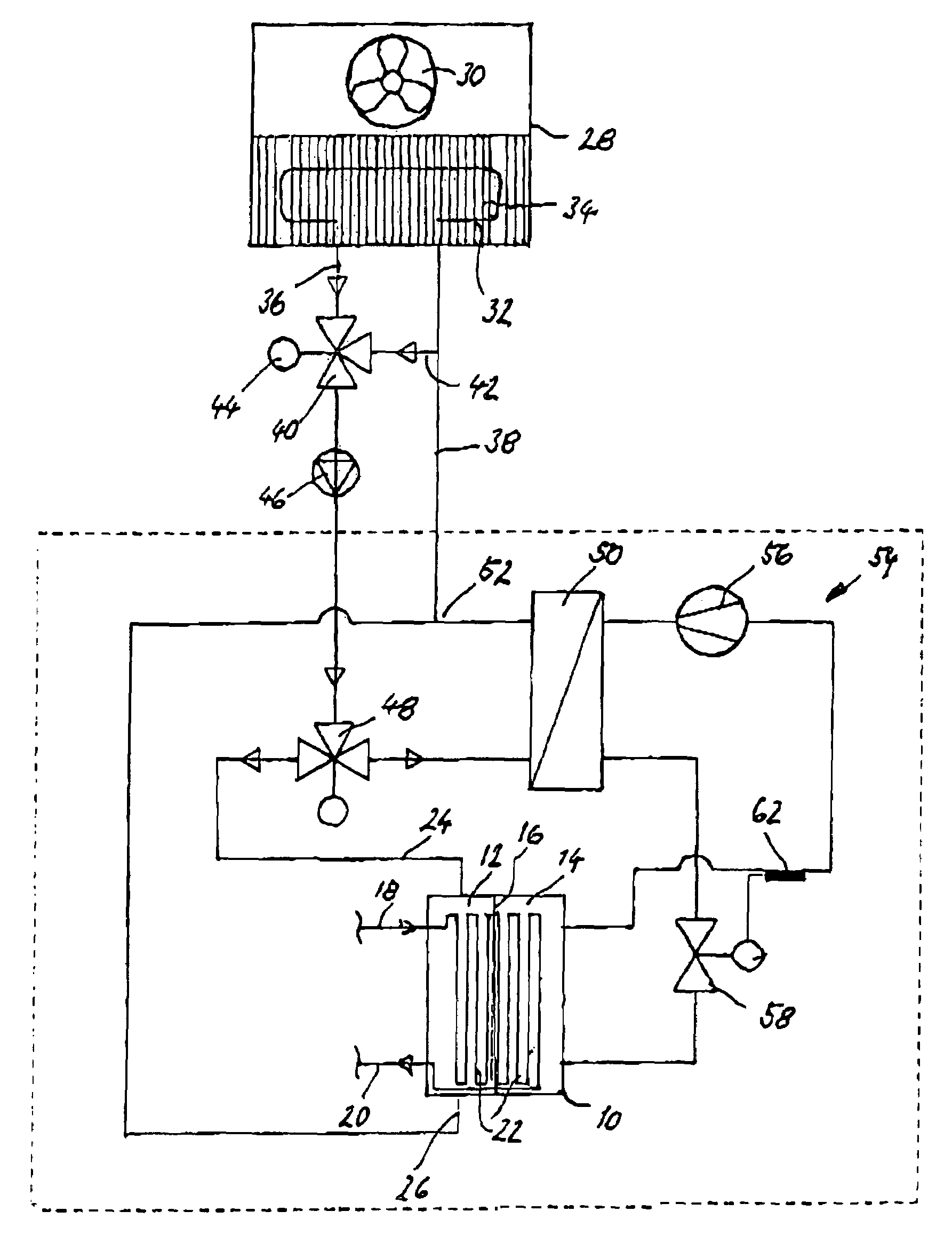

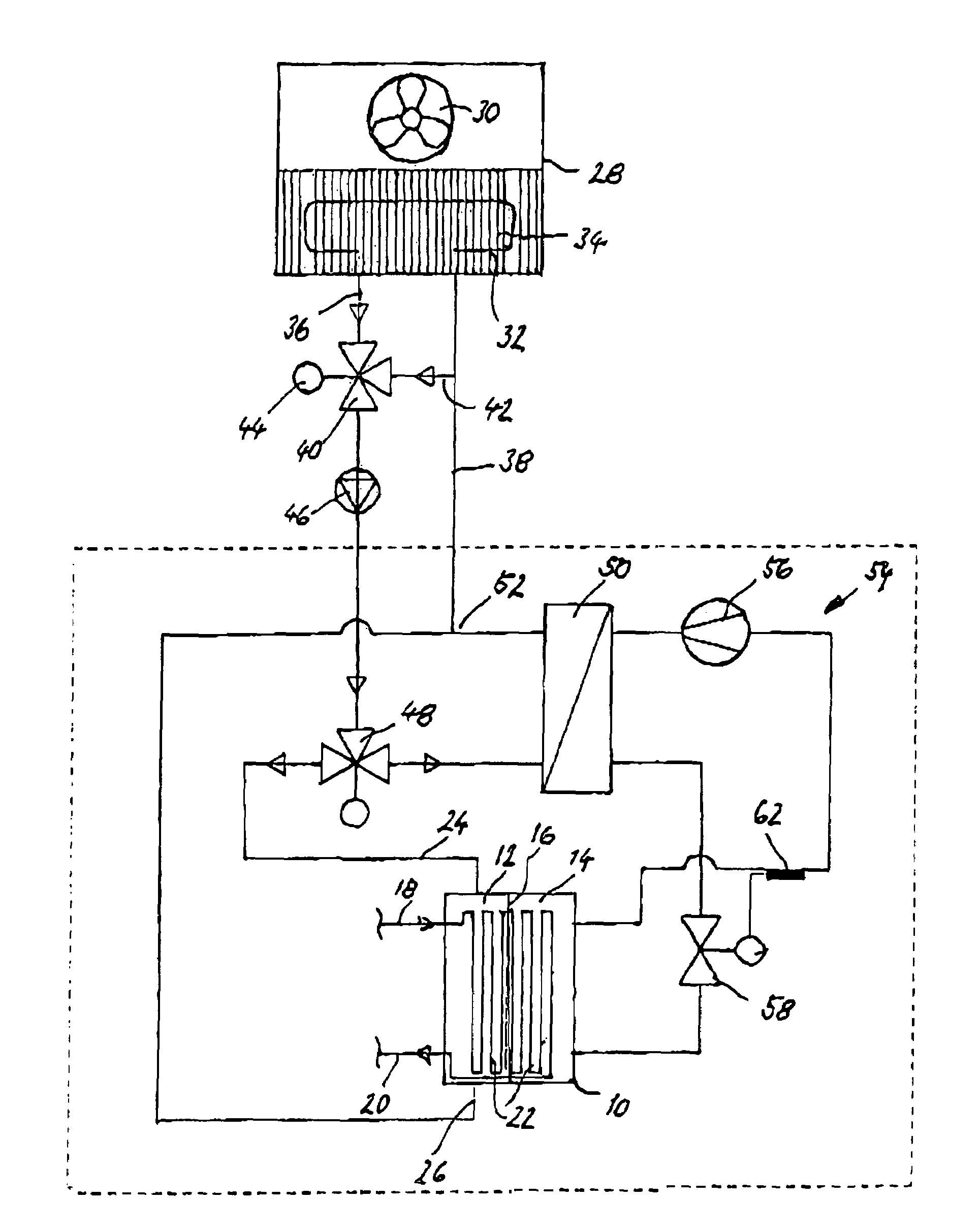

Tempering device for printing presses

InactiveUS7159518B2Effective tempering of temperingLess energyAddressographsLetterpress printingFree coolingProcess engineering

A tempering device for printing presses, includes a compression refrigerating plant with a condenser and an evaporator, in which a coolant circulates in a compression refrigerating path, and a free cooling path, in which a coolant circulates. A process water path circulates a coolant for either printing rollers or a fountain solution for offset printing. A heat exchanger arrangement cools the process water path with the help of the compression refrigerating plant and / or the free cooling path. The heat exchanger arrangement includes a three-media heat exchanger, in which heat is exchanged between the process water path and the compression refrigerating plant as well as the free cooling path.

Owner:TECHNOTRANS

System and method for interleaf sheet and/or plate sheet removal and/or transport for use with a printing apparatus

InactiveUS20060174790A1Easy to separateSimple actionAddressographsLetterpress printingComputer to plateEngineering

One or more embodiments of the present invention relate generally to systems and methods that remove an interleaf sheet interposed between plate sheets from a material stack used, for example, in a computer-to-plate imaging system and / or environment.

Owner:ECRM

Printer having detachably mounted platen roller

InactiveUS20110072995A1Narrow spaceSmall sizeAddressographsLetterpress printingEngineeringMechanical engineering

Owner:ALPS ALPINE CO LTD

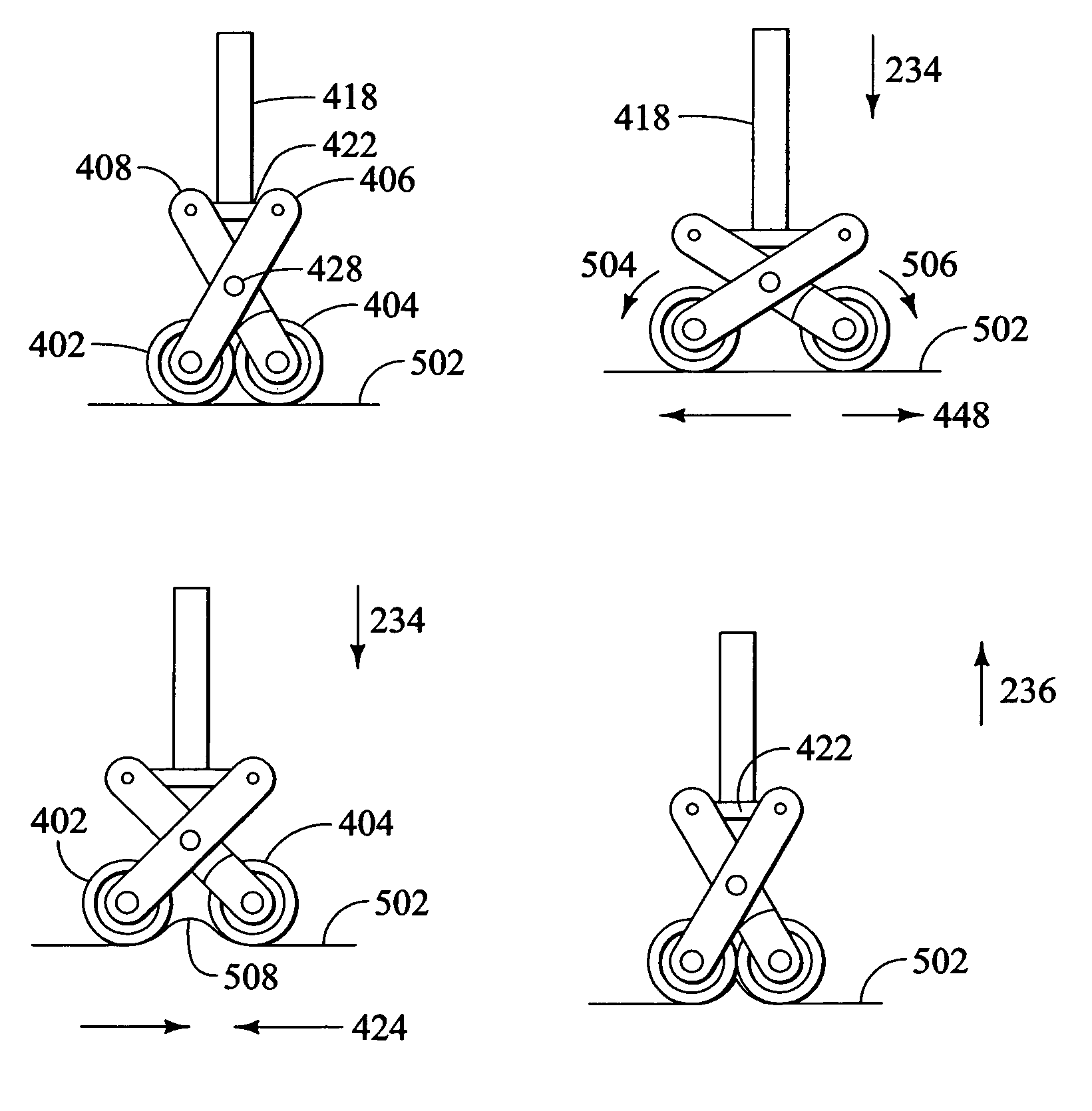

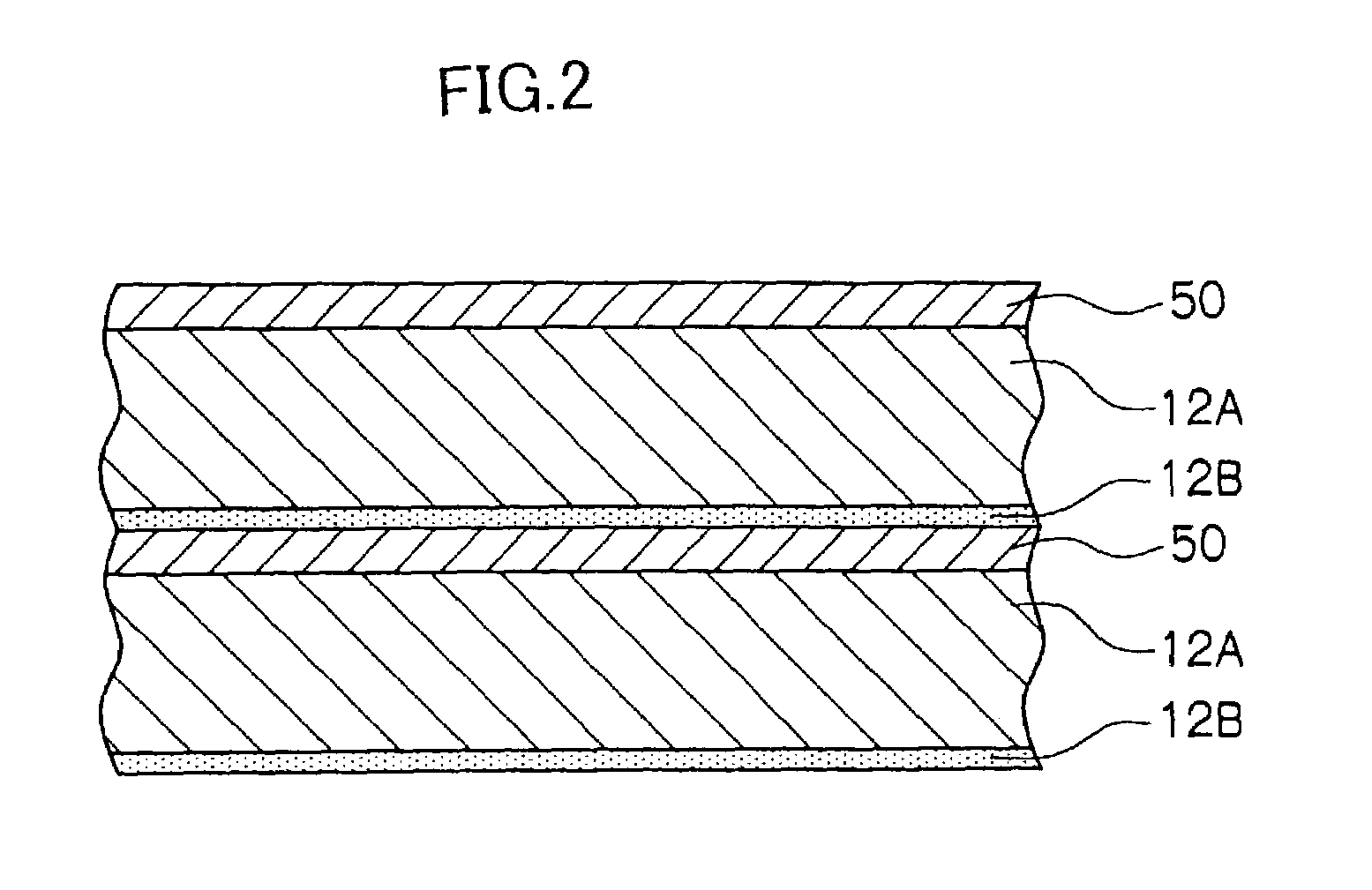

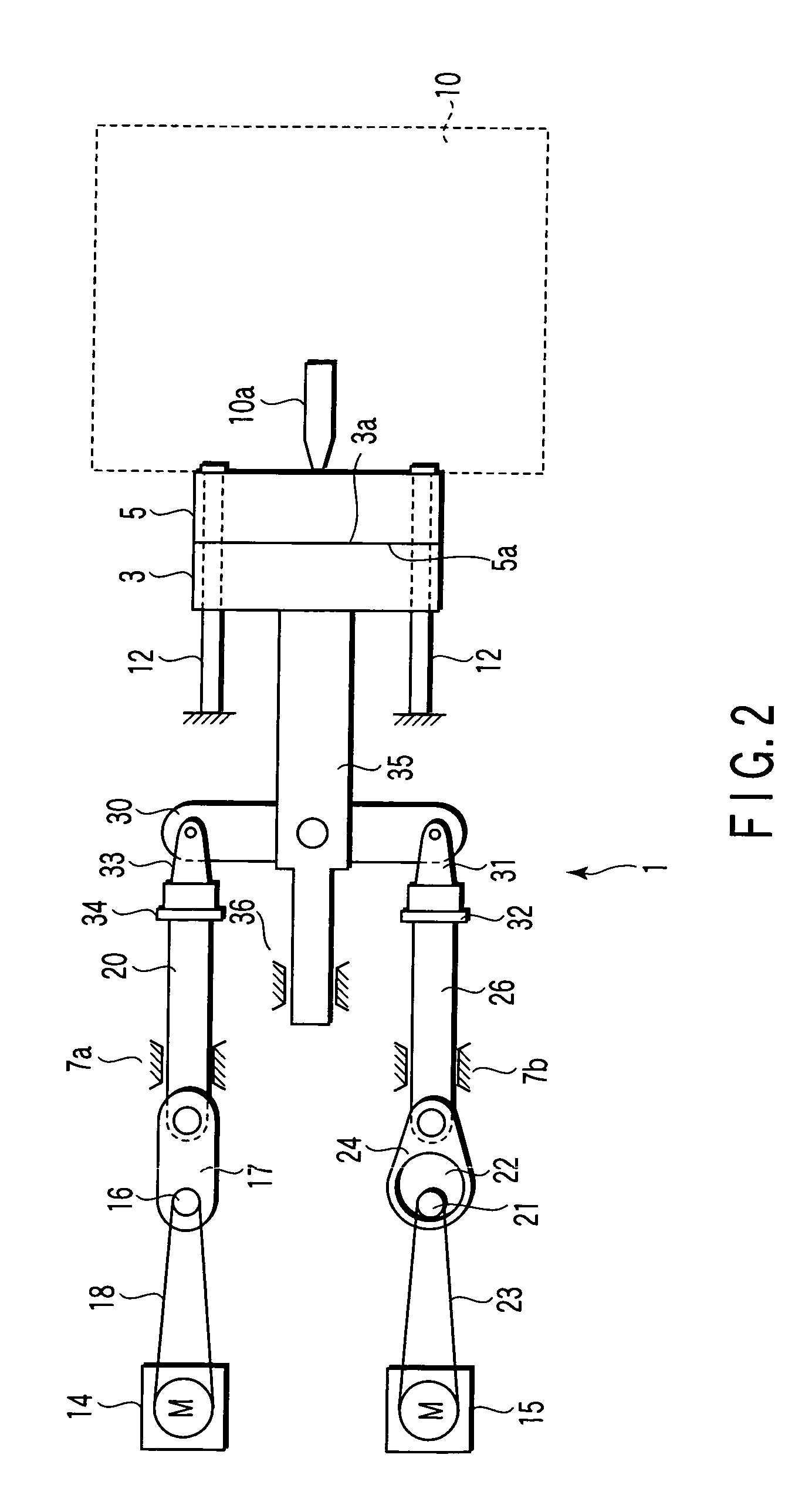

Press mechanism, clamp mechanism, and molding machine using this clamp mechanism

InactiveUS20050109229A1Highly accurate parallelismImprove accuracyControlling membersAddressographsMolding machineSupport point

A thermal pressing machine has a case in which a fixed-side press plate is fixedly provided, a main shaft to which a moving side press plate is attached, a lever arm pivotally attached to the main shaft, a first drive mechanism coupled to a force point at one end of the lever arm, and a second drive mechanism coupled to a supporting point at the other end of the lever arm. The first drive mechanism first causes the lever arm to pivot on the supporting point to greatly move the press plate, and the first drive mechanism is then stopped to operate the second drive mechanism, so that the lever arm pivots on the force point to press the press plate against the press plate.

Owner:ITRIX CORP

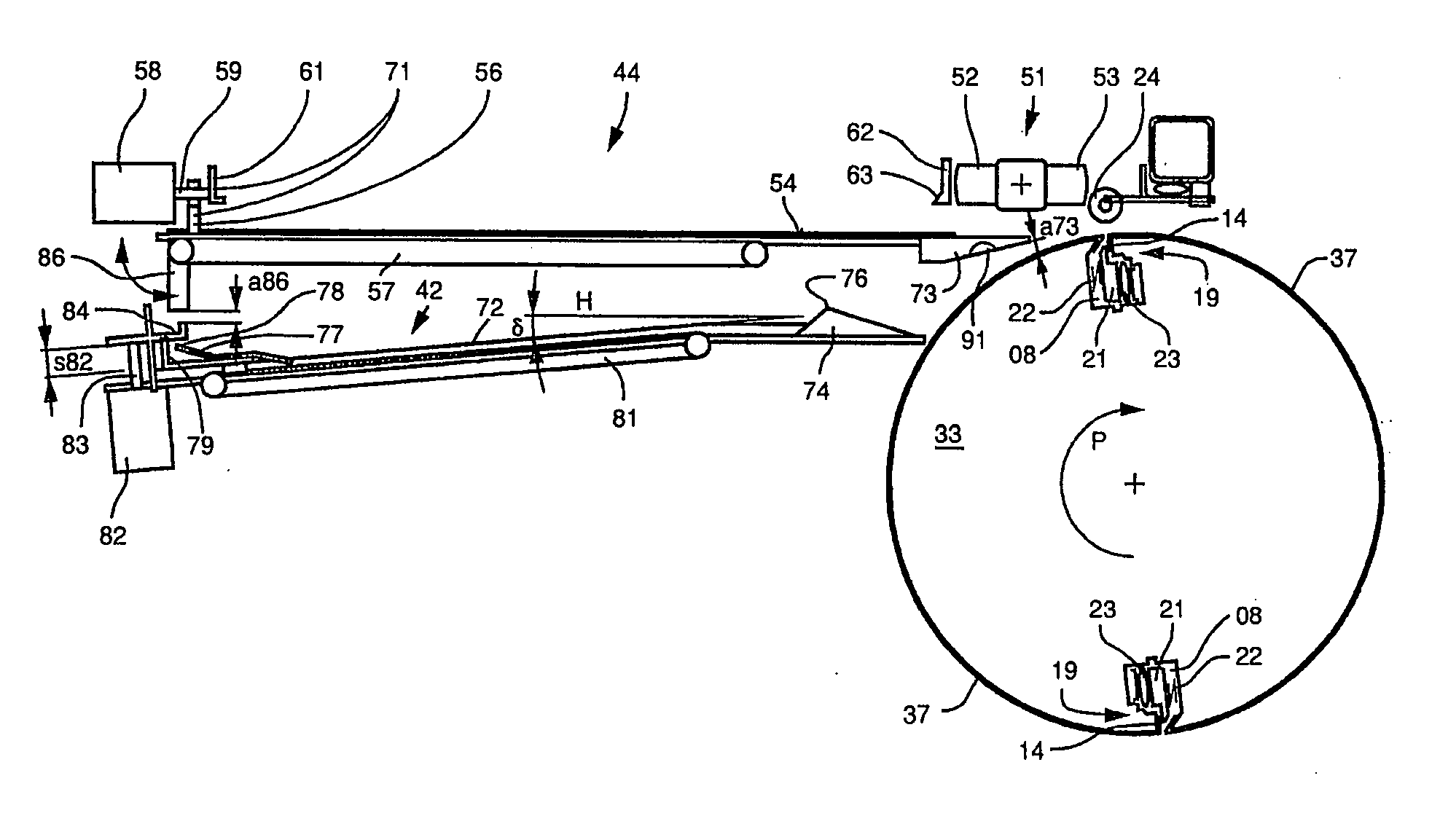

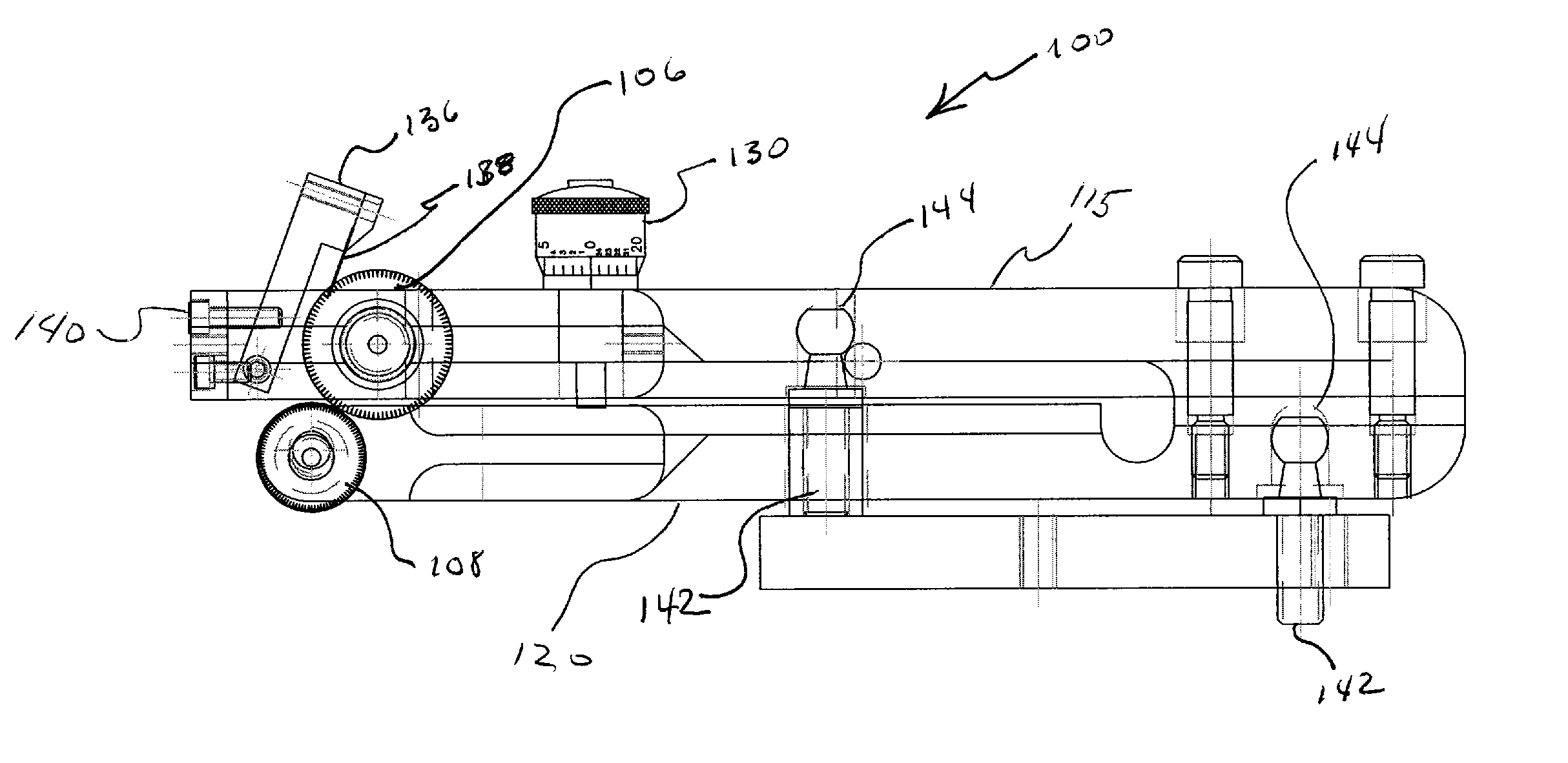

Machine for in-register mounting of flexographic printing plates

ActiveUS20060117973A1Easy and intuitive to useEasy to provideCylinder pressesAddressographsData processing systemGraphics

A machine for in-register mounting of flexographic printing plates with a virtual data-processing system, having a supporting footing for a printing plate cylinder, on which a respective flexographic printing plate is mounted, suitable for printing a predefined image, and at least one television camera, which is connected to a monitor, is trained onto the cylinder and can slide parallel to the cylinder to check correct positioning-mounting of the printing plate, the television camera being associated with position sensors and connected to a device for the real-time processing and display of at least one composite image, for allowing the operator to perform precise position comparisons for optimum plate mounting between a preprocessed graphical reproduction of the image to be printed, provided on a digital memory composed of graphical memory associated with position measurements, and the position of the printing plate.

Owner:BIEFFEBI SPA

Devices for storing a blanket to be supplied to a cylinder of a printing machine

InactiveUS20050172846A1The overall height of the structure becomes lowerLow structural requirementsCylinder pressesAddressographsEngineeringPrinting press

A device is used to store blankets or dressings which are to be supplied to a cylinder of a printing machine. A plurality of such blankets or dressings, which are to be applied to the cylinder adjacent each other and axially spaced, are stored next to each other. These blankets or dressings are stored vertically above a supporting surface, in at least two vertically offset planes. The offset planes form a first storage position and the supporting surface forms a second storage position once at least one of the blankets or dressings has been stored in the different planes.

Owner:KOENIG & BAUER AG

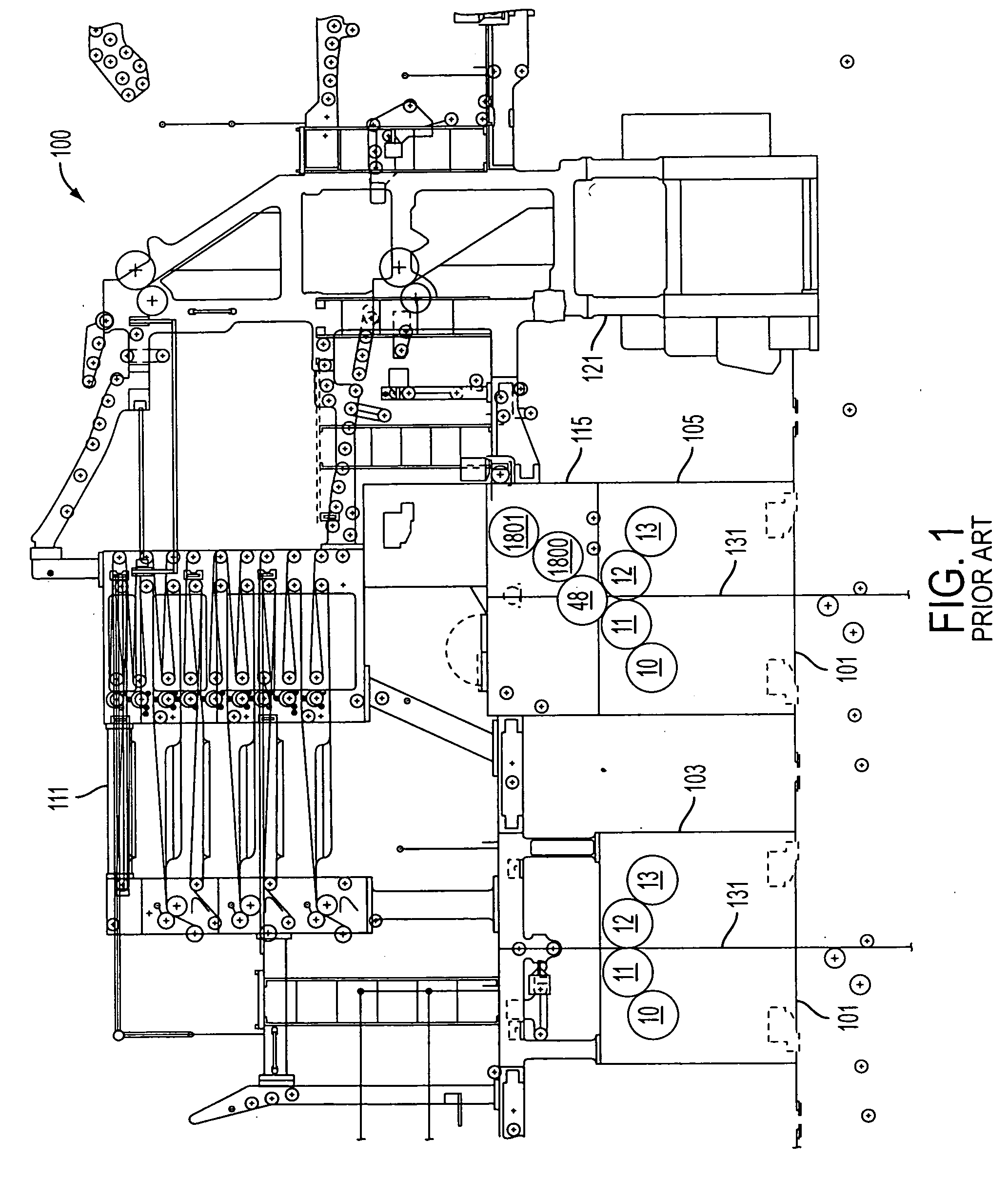

Rotary printing machine, having safety oriented access modules

InactiveUS6644192B2High degree of automationSufficient supplyAddressographsLetterpress printingEngineeringPrinting press

In a web-fed rotary offset printing machine, operating preferably with variable-format cylinders, both sides of the printing machine are covered, during the operation and resetting of the machine, so that no access, in particular no access to the printing units, is possible. For this purpose, an access module is used between the printing-units, which module is equipped laterally with covers which resemble window roller blinds and cannot be opened while the machine is in operation.

Owner:MANROLANAD AG

Ink bottle mounting apparatus and ink bottle for the apparatus

An ink bottle mounting apparatus comprising a bottle mounting apparatus body 11 having an ink bottle 1 and a bottle insertion chamber 12 into which the ink bottle 1 is inserted, wherein the ink bottle mounting apparatus further comprises a bottle lock member 15 which is engaged with a groove 5 formed on a side peripheral surface of the ink bottle 1 to prevent the ink bottle 1 from being pulled out when the ink bottle 1 is mounted to the bottle mounting apparatus body.

Owner:RISO KAGAKU CORP

Roll-forming apparatus

Roll-forming apparatus is provided together with a conveyor system utilized to transport raw dough rolls. A stop gate is movably positioned in the path of the rolls and, when placed in an interfering position, temporarily stops the rolls while the rolls maintain sliding contact with the conveyor. An imprinter is positioned above the conveyor and adjacent the stop gate. The stop gate is subsequently moved to a noninterfering position to permit the rolls to pass to the imprinting drums where the rolls are formed into a desired shape.

Owner:BRYAN WILLIAM ROY

Sheet feeding device and image forming apparatus

InactiveUS20060288893A1High positioning accuracyImprove reliabilityAddressographsLetterpress printingPaper sheetSheet material

Owner:CANON KK

Rotary printing machine, in particular web-fed rotary offset printing machine

InactiveUS20010017088A1High degree of automationSufficient supplyAddressographsLetterpress printingPrinting pressMechanical engineering

In a web-fed rotary offset printing machine, operating preferably with variable-format cylinders, both sides of the printing machine are covered, during the operation and resetting of the machine, so that no access, in particular no access to the printing units, is possible. For this purpose, an access module is used between the printing-units, which module is equipped laterally with covers which resemble window roller blinds and cannot be opened while the machine is in operation.

Owner:MANROLANAD AG

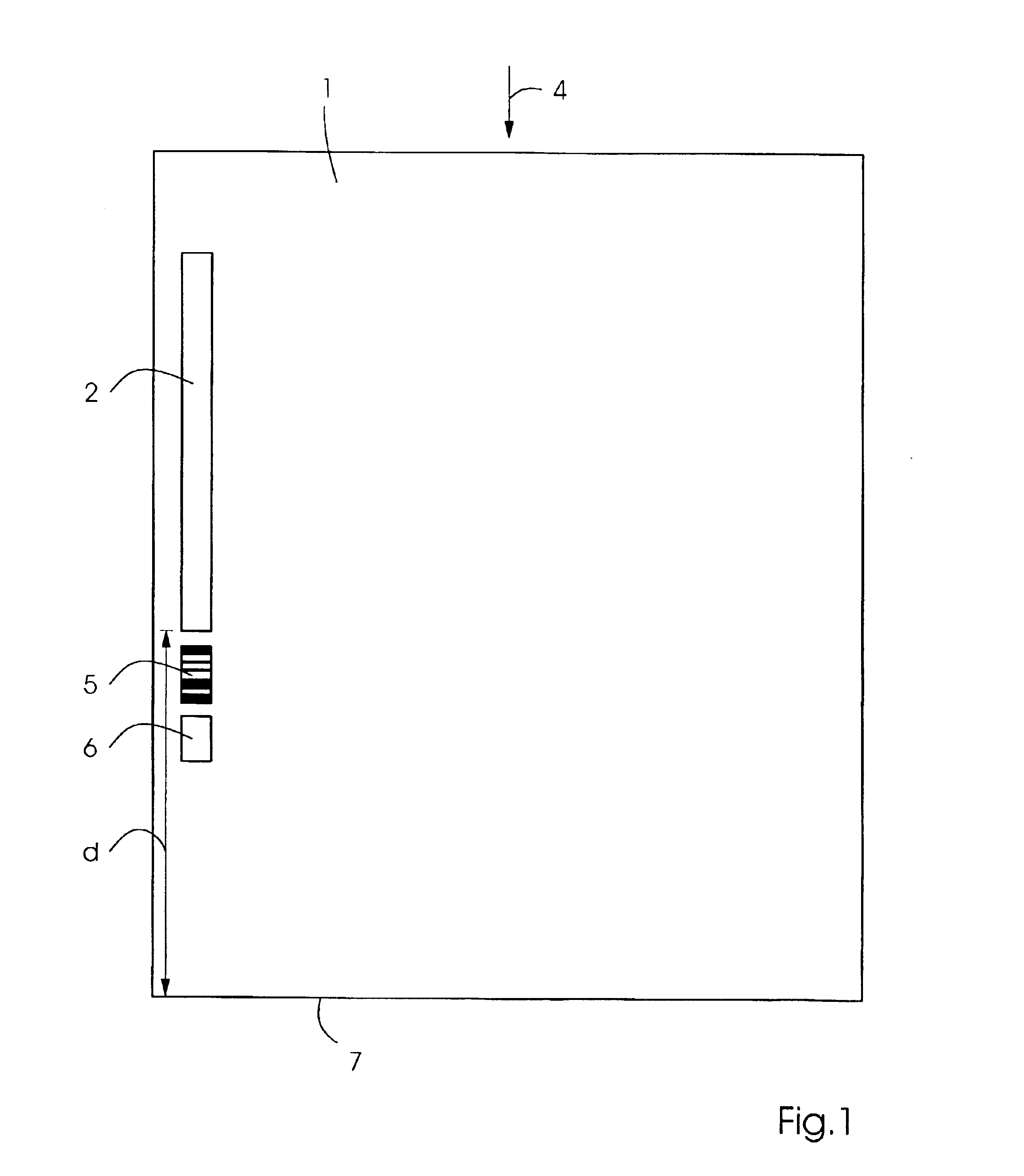

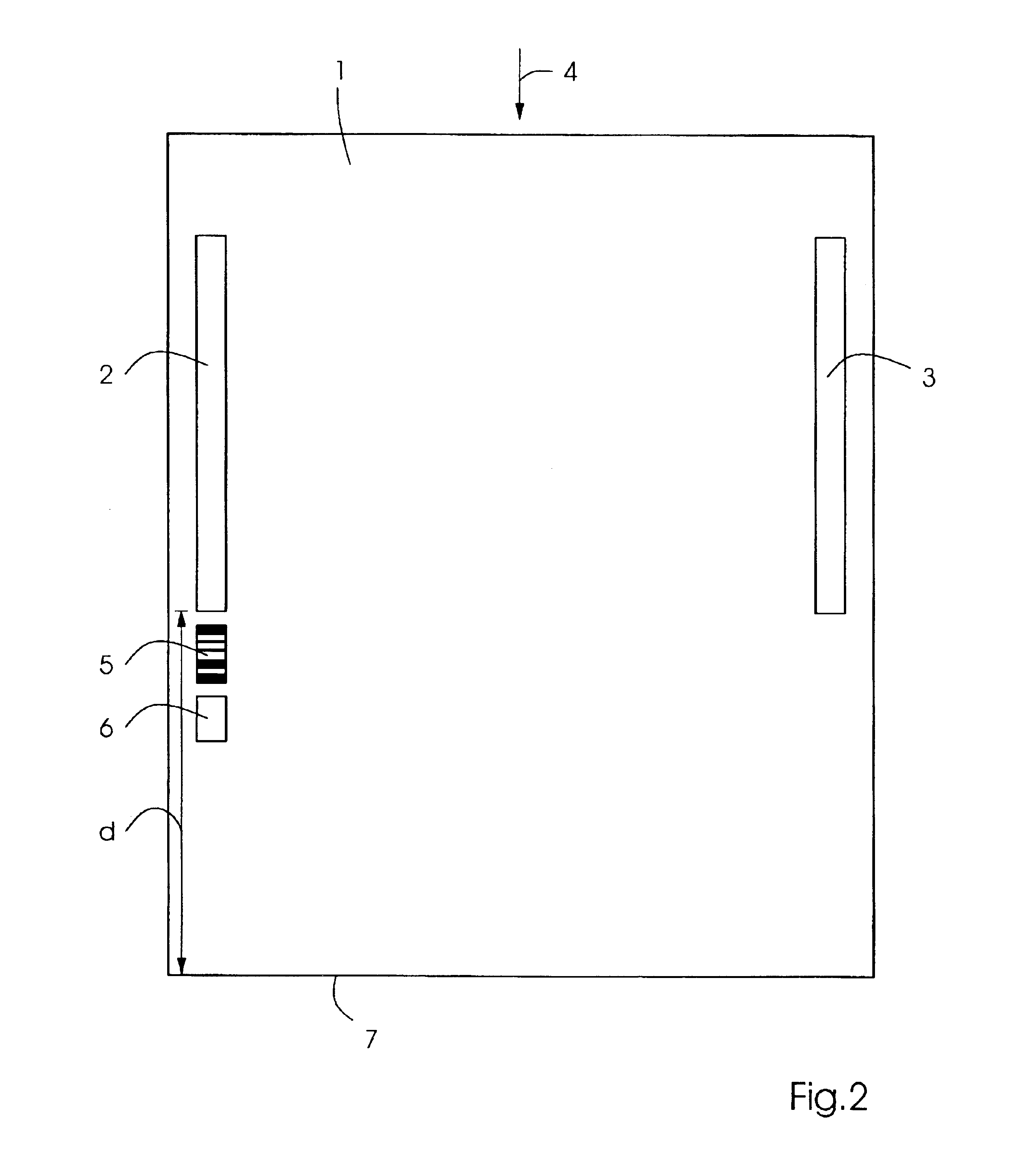

Automatic transmission of data from the pre-press stage to a printing press

InactiveUS6845712B2Quick controlAddressographsLetterpress printingSoftware engineeringPrinting press

A method and a device for automatically transmitting data from a pre-press stage (9) to a printing substrate processing machine (8) having at least one print unit (10) and one print form (11) for printing on a printing substrate (1). The method and the device are distinguished in that the data of the pre-press stage (9) to be transmitted to the printing substrate processing machine (8) are applied in an encoded form to the print form (11), and these data are able to be read out by the printing substrate processing machine (8). Also provided is a method and a device for automatically transmitting data from a first printing substrate processing machine (8) having at least one print unit (10) and one print form (11) for printing on a printing substrate (1), to a further printing substrate processing machine, in particular a folding machine. This method and this device are distinguished in that the data to be transmitted to the further printing substrate processing machine are applied in the first printing substrate processing machine (8), in a machine-readable form, to the print form (11), and these data are read out by the further printing substrate processing machine.

Owner:HEIDELBERGER DRUCKMASCHINEN AG

Ink bottle mounting apparatus and ink bottle for the apparatus

InactiveUS20020035940A1Easy to replaceReliable lockingAddressographsInking apparatusEngineeringBottle

An ink bottle mounting apparatus comprising a bottle mounting apparatus body 11 having an ink bottle 1 and a bottle insertion chamber 12 into which the ink bottle 1 is inserted, wherein the ink bottle mounting apparatus further comprises a bottle lock member 15 which is engaged with a groove 5 formed on a side peripheral surface of the ink bottle 1 to prevent the ink bottle 1 from being pulled out when the ink bottle 1 is mounted to the bottle mounting apparatus body.

Owner:RISO KAGAKU CORP

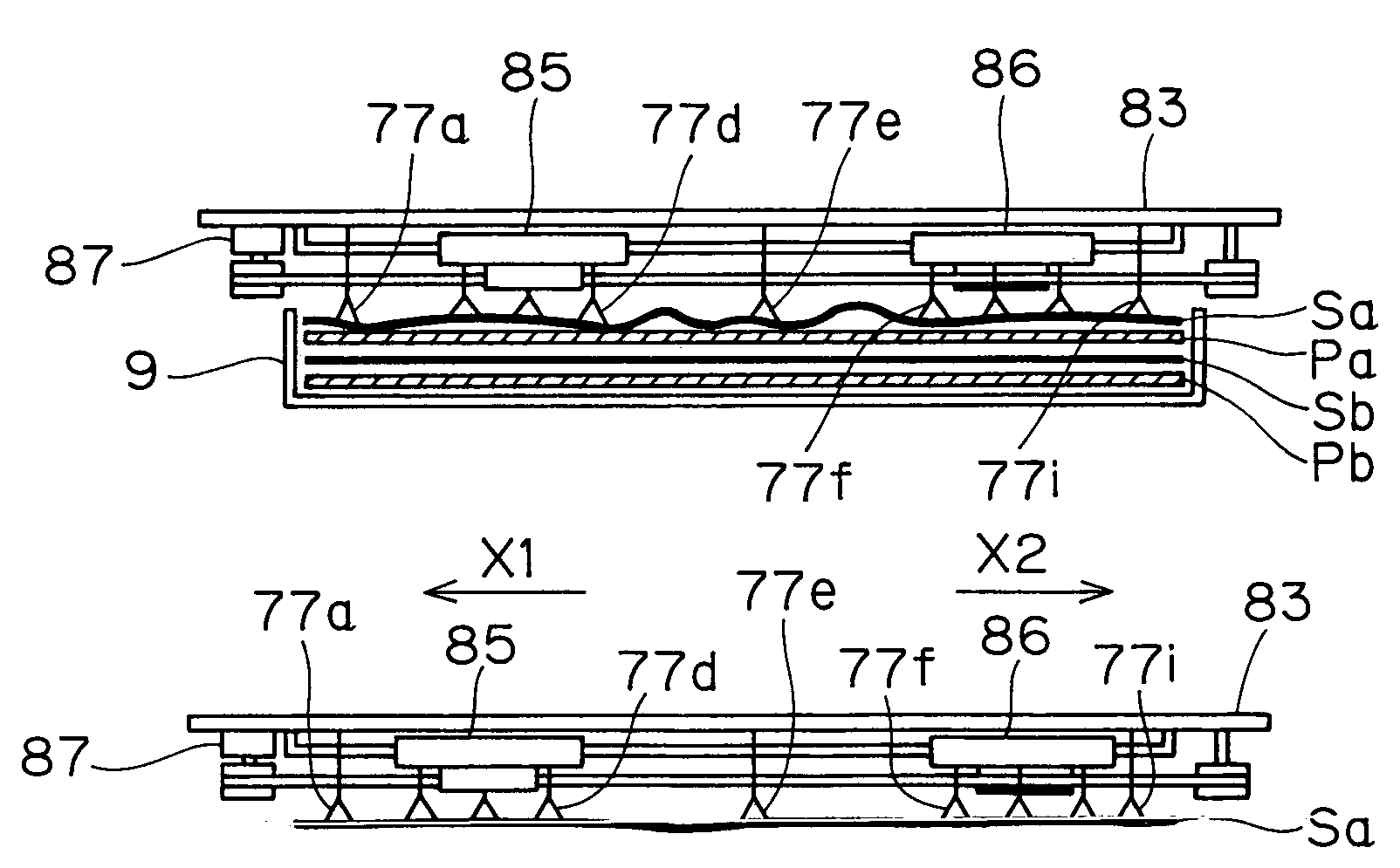

Interleaf removal apparatus, plate feed apparatus and image recording system

InactiveUS7152531B2Prevents a paper jam in the rotatable holding element more effectivelyEffective preventionAddressographsLetterpress printingImage recordingEngineering

An interleaf at the top position of a stack of plates and interleaves stored in a cassette is removed by attaching the interleaf to suction pads mounted to a vertically movable support. When the interleaf in the cassette is moved upwardly to a position opposed to a pair of nip rollers, movable suction pads move horizontally in such a direction as to stretch the interleaf to remove wrinkles in the interleaf. Then, a leading edge portion of the interleaf is held between the pair of nip rollers and removed outwardly.

Owner:DAINIPPON SCREEN MTG CO LTD

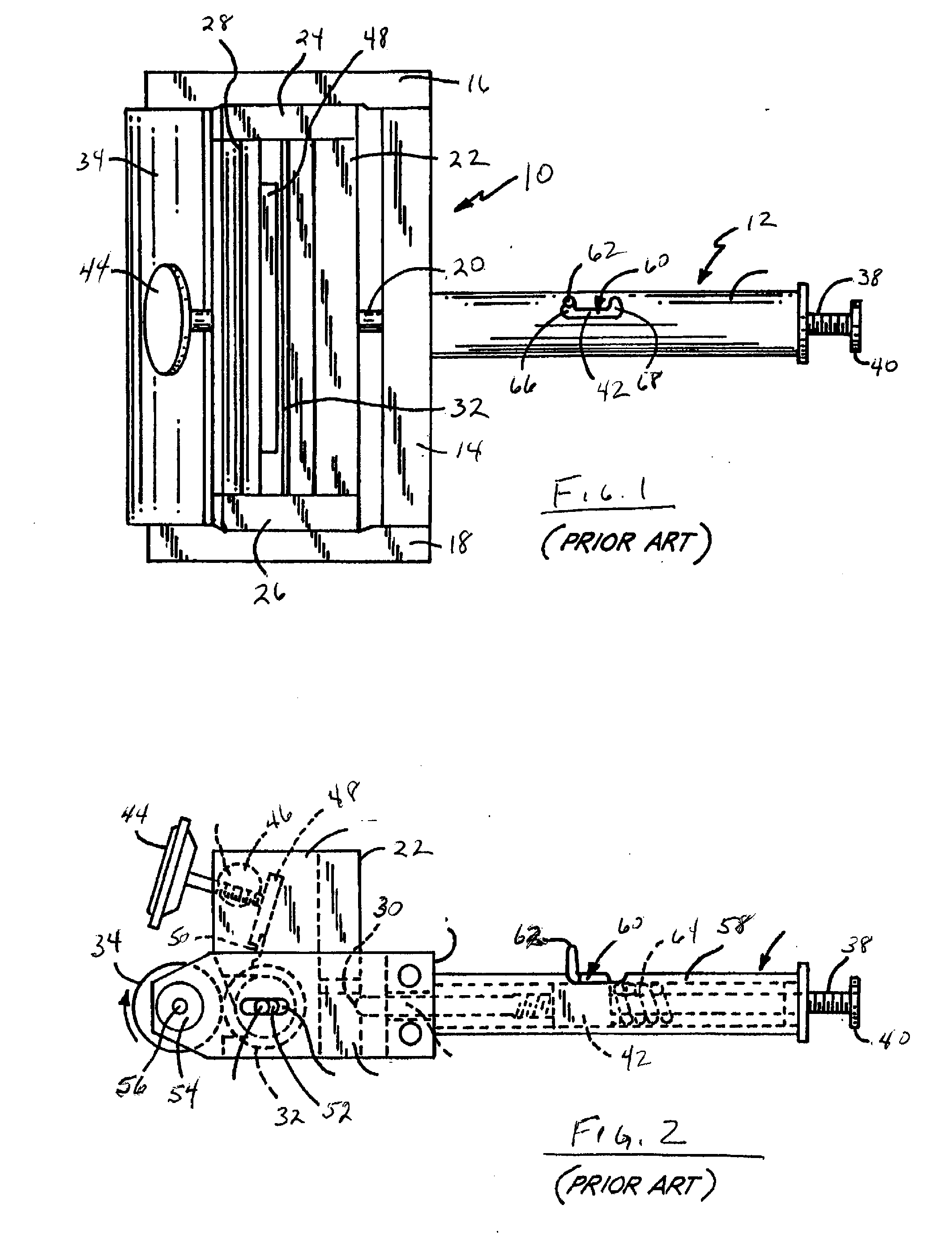

Hand proofer tool

InactiveUS20070006750A1Reliable and consistent proofDuplicates arrangementAddressographsLiquid surface applicatorsEngineeringMechanical engineering

A proofing tool including an anilox roll and an impression roll that are shiftable relative to each other between an engaged position and a disengaged position. The invention further includes a positive rotational linkage between the anilox roll and the impression roll whereby a pitch velocity of the anilox roll and a pitch velocity of the impression roll are substantially matched.

Owner:PROBITY ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com