Although excellent toner images can be obtained with multilayered belt photoreceptors, it has been found that as more advanced, higher speed electrophotographic copiers, duplicators and printers are developed, fatigue-induced

cracking of the charge

transport layer at the welded seam area is frequently encountered during photoreceptor belt

cycling.

Moreover, the onset of seam

cracking has also been found to rapidly lead to seam

delamination due to fatigue, shortening belt service life.

Dynamic fatigue seam

cracking can possibly happen in ionographic imaging member belts as well.

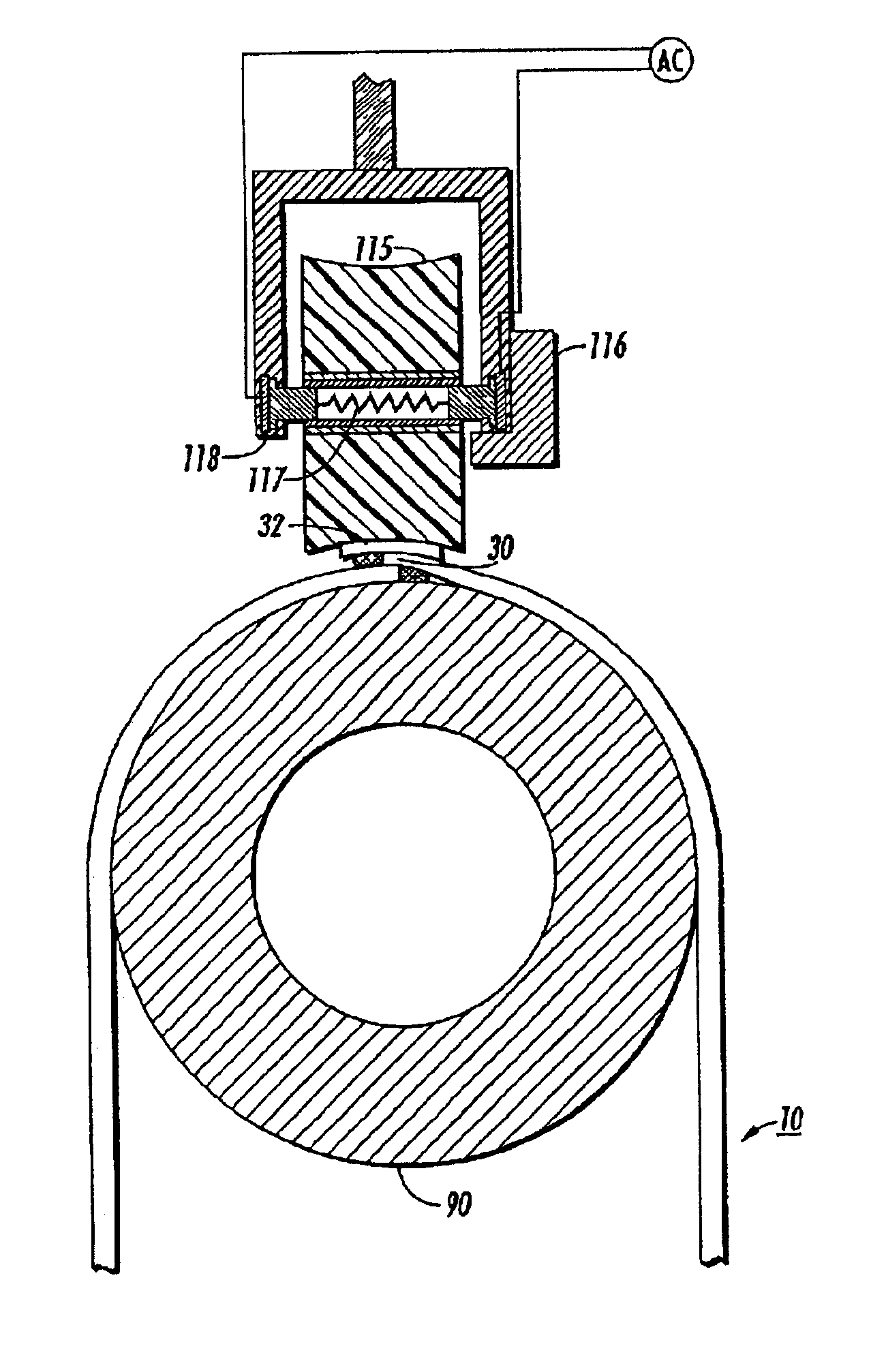

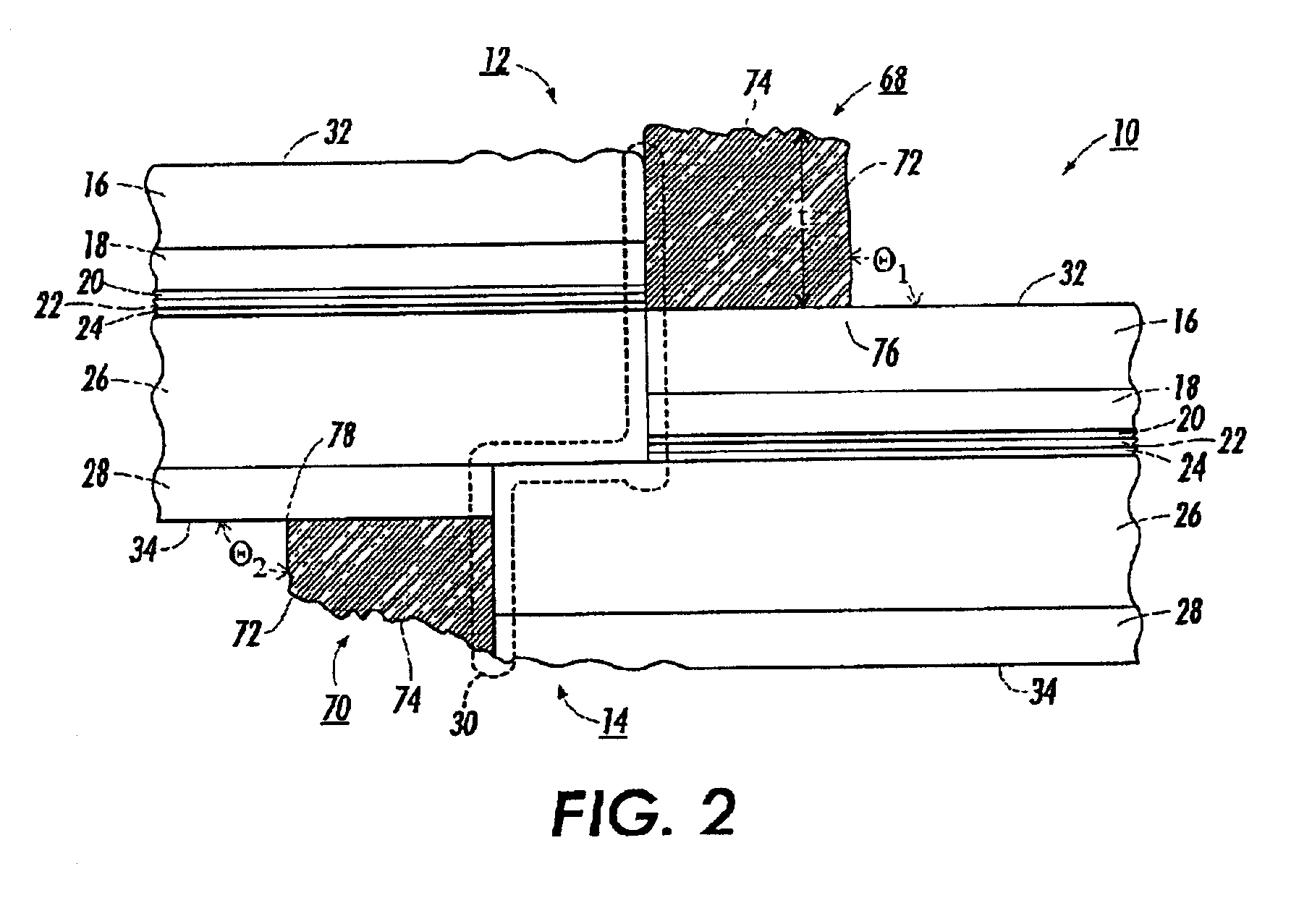

When ultrasonically welded into a belt, the seam of multilayered electrophotographic imaging flexible members can occasionally contain undesirable high protrusions such as peaks, ridges, spikes, and mounds.

These seam protrusions present problems during image

cycling of the

belt machine because they interact with cleaning blades to cause blade

wear and tear, which ultimately affects cleaning blade efficiency and service life.

Moreover, the protrusion high spots in the seam can also interfere with the operation of subsystems of copiers, printers and duplicators by damaging

electrode wires used in development subsystems that position the wires parallel to and closely spaced from the outer imaging surface of belt photoreceptors.

Another frequently observed

mechanical failure in the imaging belts during image

cycling is that, after being subjected to extended bending and flexing cycles over small

diameter belt support rollers, the ultrasonically welded seam of an electrophotographic imaging member can develop cracks that propagate and lead to

delamination of the belt.

Addtionally, such cracking and

delamination can result from lateral forces caused by mechanical

rubbing contact against stationary web edge guides of a belt support module during cycling.

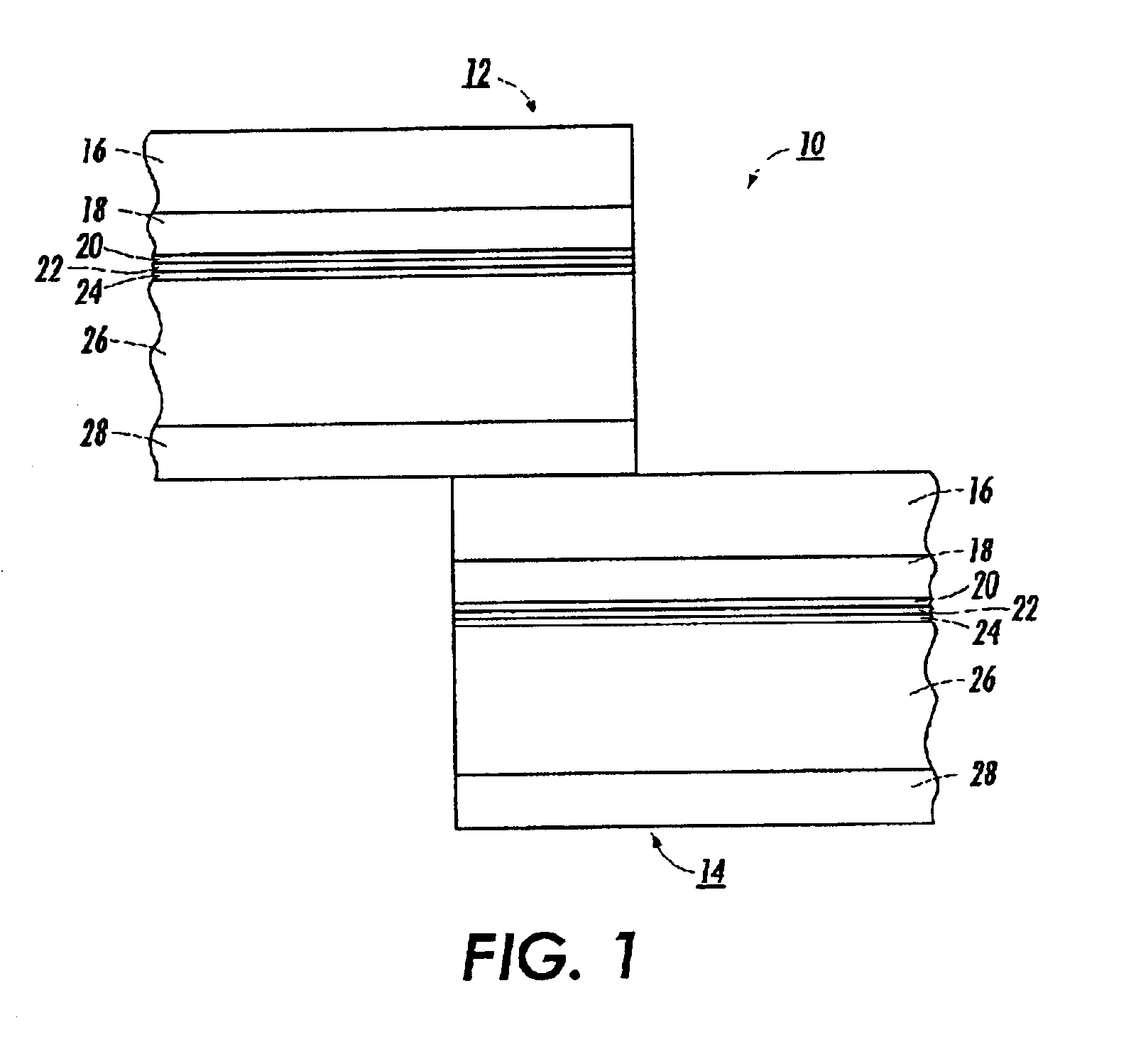

Alteration of materials in the various photoreceptor belt

layers such as the conductive layer, hole

blocking layer,

adhesive layer, charge generating layer, and / or charge

transport layer to suppress cracking and delamination problems is not easily accomplished.

The alteration of the materials can adversely

impact the overall physical, electrical, mechanical, and other properties of the belt such as well as

coating layer uniformity,

residual voltage, background, dark decay, flexibility, and the like.

The ultrasonic welded seam of a multilayered photoreceptor belt is relatively brittle and low in strength and

toughness.

The joining techniques, particularly the

welding process, can result in the formation of a splashing that projects out from either side of the seam in the overlap region of the belt.

The excessive thickness of the photoreceptor belt in the seam region due to the presence of the splashing results in a large induced

bending strain as the seam travels over each roller.

Unfortunately, small

diameter rollers, e.g., less than about 0.75 inch (19 millimeters) in

diameter, raise the threshold of mechanical performance criteria to such a high level that photoreceptor belt seam failure can become unacceptable for multilayered belt photoreceptors.

Thus, the splashing tends to shorten the mechanical life of the seam and service life of the flexible member belts used in copiers, duplicators, and printers.

Although a solution to suppress the seam cracking / delamination problems has been successfully demonstrated, as described in a prior art, by a

specific heat treatment process of a flexible electrophotographic imaging member belt with its seam parked directly on top of a 19 mm diameter

back support rod for stress-releasing releasing treatment at a temperature slightly above the

glass transition temperature (T.sub.g) of the charge

transport layer of the imaging member, nevertheless this seam stress release process was also found to produce various undesirable effects such as causing seam area imaging member set and development of belt ripples in the active electrophotographic imaging zones of the belt (e.g., the region beyond about 25.2 millimeters from either side from the midpoint of the seam).

Moreover, the heat treatment can induce undesirable circumferential shrinkage of the imaging belt.

The set in the seam area of an imaging member mechanically adversely interacts with the cleaning blade and impacts cleaning efficiency.

The ripples in the imaging member belt manifest themselves as copy printout defects.

Further, the

heat induced imaging belt dimensional shrinkage alters the precise dimensional specifications required for the belt.

Since the belt must be cooled to below the

glass transition temperature of the thermoplastic material in the belt prior to removal from the support rod to produce the desired degree of seam stress release in each belt, the heat treatment and

cooling cycle time is unduly long and leads to very high belt production costs.

Both the

time consuming procedure of manual inspection and the number of seamed belts rejected due to the presence of high seam protrusions constitute a substantial financial burden on the production cost of imaging members.

While these and other innovative prior art approaches provided improved flexible belt seam morphology, nevertheless it has been found that solution of one problem has also created new undesirable issues.

For example, overcoating the seam of a photoreceptor belt with

metallic foil can cause electrical seam arcing as the belt cycles beneath a charging device during electrophotographic imaging processes.

Additionally, application of liquid overcoating layer over the seam induced charge transport molecule

crystallization in the vicinity of the seam overcoat, not to mention that liquid overcoating layer can produce poor adhesion

bond strength to the seam after solidification into a dried coat.

The amount of the debris, however, is beyond the removal capacity of the cleaning instrument, and portions of the highly concentrated debris are deposited onto the surface of the flexible electrophotographic imaging member 10.

The upward movement of the flap presents an additional problem during the cleaning operation.

As the cleaning instrument strikes the flap, great force is exerted on the cleaning instrument which can lead to damage thereof, e.g., excessive wear and tearing of the cleaning blade.

In addition to damaging the cleaning blade, the striking of the flap by the cleaning instrument causes unwanted vibration in the flexible electrophotographic imaging member 10.

This unwanted vibration adversely affects the copy / print quality produced by the flexible electrophotographic imaging member 10.

However, the

radius at the

waist of the wheel should not be so small that rigidity of the compression wheel is compromised.

Login to View More

Login to View More