Composite neural conduit

a neural conduit and composite technology, applied in the field of composite neural conduits, can solve the problems of mechanical defects, inflammatory responses, and much more difficult, and achieve the effects of improving biocompatibility, reducing the risk of infection, and improving the quality of li

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

rotocol

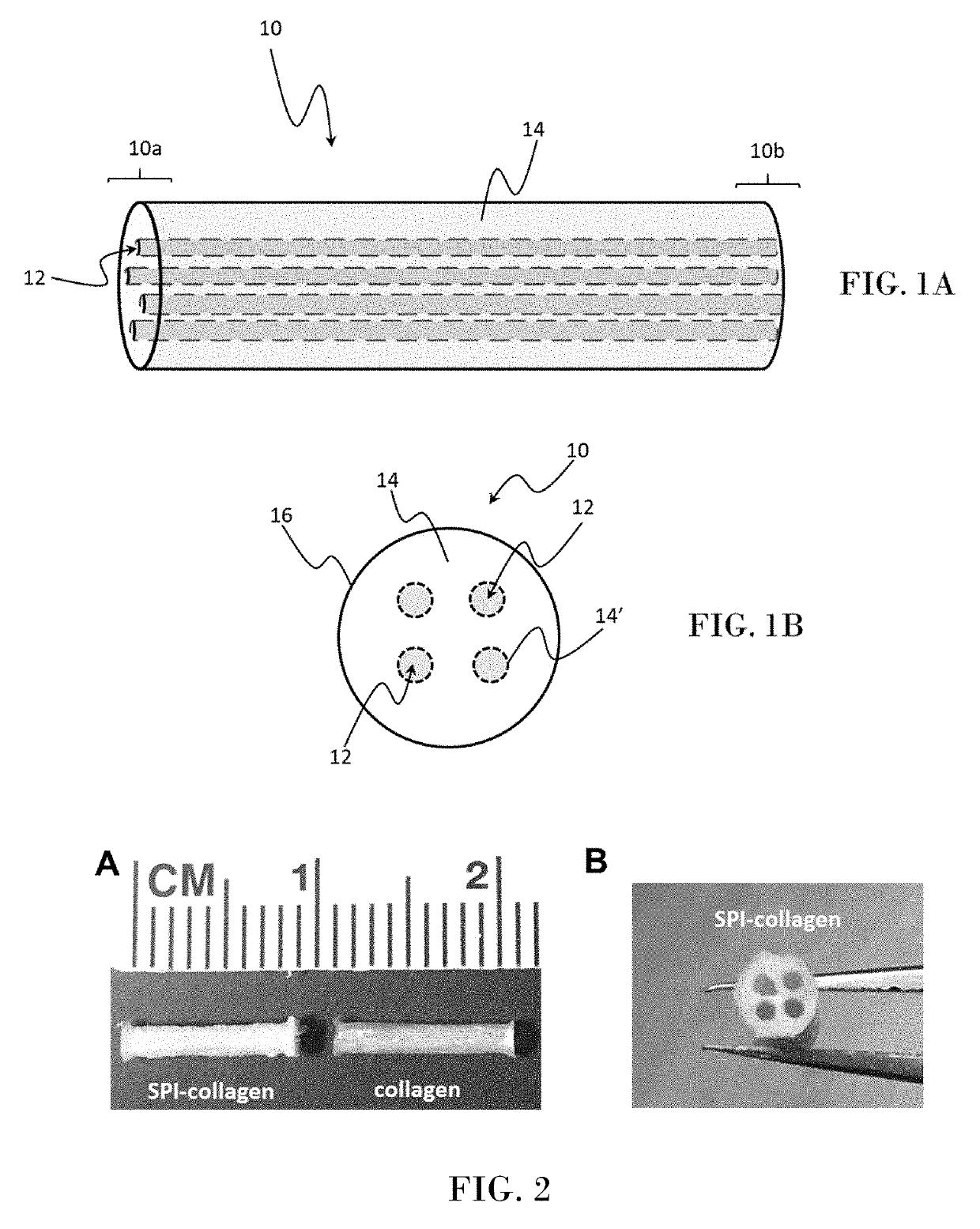

Fabrication of Multichannel Collagen-Soybean Neural Conduits

[0041]Soybean protein isolate (SPI) solutions will be prepared by slowly dissolving the SPI with constant stirring in distilled water with the concentration of 3-15% w / v. The pH may be adjusted to 7.2 with 1M sodium hydroxide or 1M HCl. Then glycerol, 50% w / w, (relative to SPI) will be added to the solution with constant stirring, which helps to stabilize the SPI in solution. The solution will be heated at a constant temperature of 55° C. for 30 min and cooled at room temperature. Then the soybean solution will be mixed with type I collagen solution (10 mg / ml, in acetic acid) as different SPI to collagen ratios (weight to weight) to fabricate neural conduits. The neural conduits are fabricated using the type I collagen-SPI composite according to fabrication methods described in U.S. Pat. No. 8,926,886, incorporated by reference in its entirety herein. Briefly, collagen-SPI solution sequentially self-assembles on the ...

example 2

Neural Conduit

1. Fabrication and Mechanical Properties

1.1 Fabrication of Multichannel Collagen-Soybean Neural Conduits.

[0042]Soybean protein isolate (SPI) solutions were prepared by slowly dissolving the SPI (Soy Protein Isolate, MP Biomedicals™) with constant stirring in distilled water with the concentration of 10% w / v. Then glycerol, 50% w / w, (relative to SPI) was added to the solution with constant stirring. The solution was heated at a constant temperature of 55° C. for 30 min and cooled at room temperature. Then the soybean solution was mixed with type I collagen solution (isolated in lab from bovine tendon; 10 mg / ml, in 50 mM acetic acid) as 1:1 protein weight ratio to fabricate neural conduits. Then 4-channel conduits were fabricated. The matrix was crosslinked with 30 m EDC and 20 mM NHS. After washing with NaH2PO4 (0.1 M) and distilled water, the collagen was freeze-dried on the wires. The resulting conduits are shown in FIG. 2.

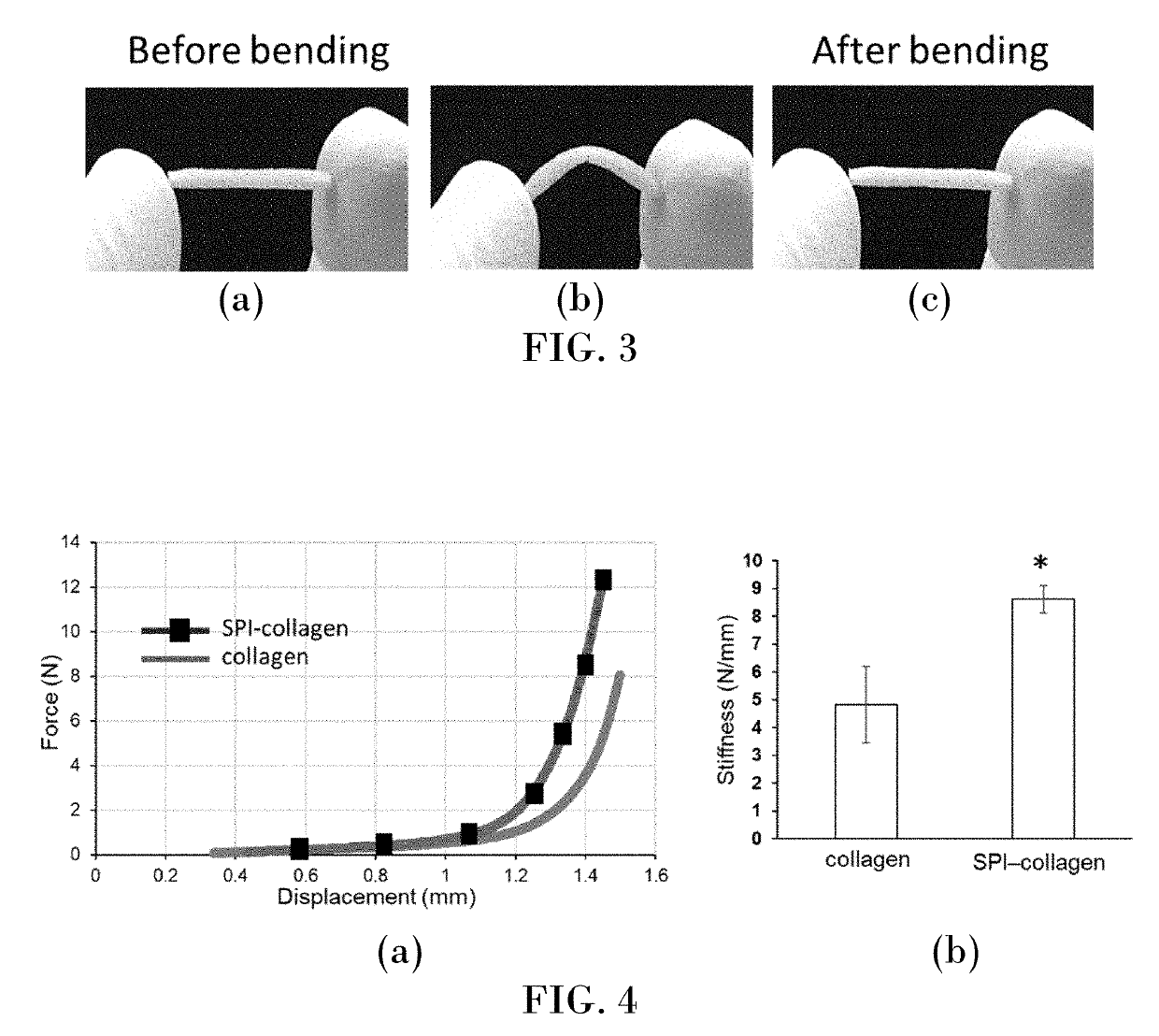

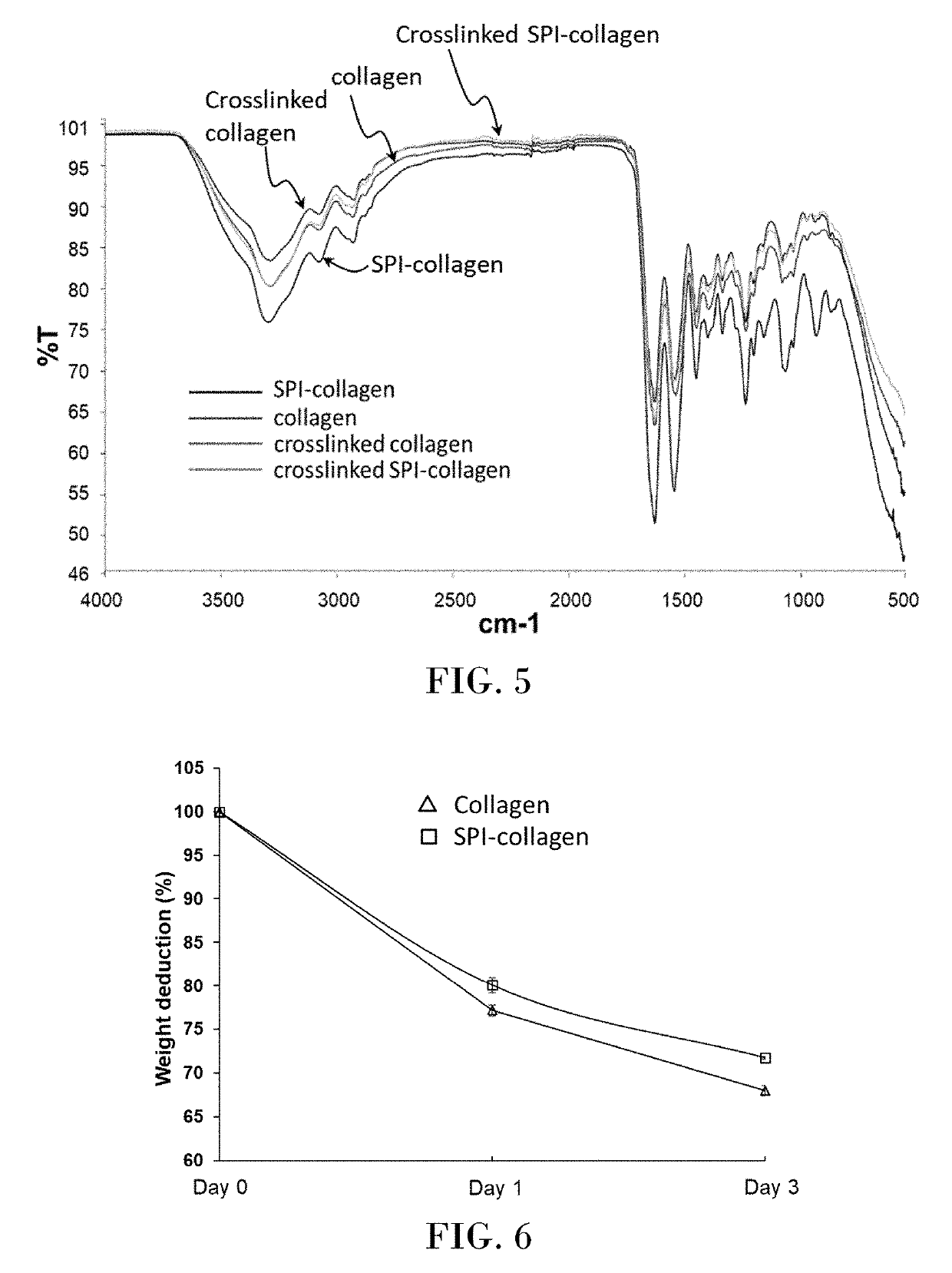

1.2 Mechanical Property of the Neural Conduit...

example 3

Neural Hydrogel

1. Fabrication and Mechanical Properties

1.1 Fabrication of a Composite Collagen-Soybean Hydrogels.

[0049]SPI solutions are prepared by adding SPI powder in distilled water with the concentration of 1-10% w / v. Then, glycerol is added to the SPI solution under mechanical stirring at a constant temperature of 55° C. for 30 min and cooled at room temperature.

[0050]The SPI solution is mixed with type I collagen solution (in acetic acid) at various weight ratios, respectively, to form an SPI / collagen solution. To form the hydrogel, the pH value of the SPI / collagen solution is adjusted to 7 by adding a NaOH aqueous solution (1M) and phosphate-buffered saline (PBS) solution (10λ). The gelation takes place by incubating the SPI / collagen solution in the 37° C. incubator.

[0051]The mixture of SPI-collagen solution is crosslinked with 4S-StarPEG at various concentrations. The final 4S-StarPEG concentrations in the SPI-collagen will range between 0.05 mM and 8 mM. A collagen hydroge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com