Bacteriostatic and fungistatic additive in masterbatch for application in plastics, and method for producing same

a technology of additives and fungi, applied in the field of additives, can solve the problems of inferior dispersibility, undesirable effects, and inability to prevent microorganisms from settling back, and achieve the effect of improving the integration properties and preventing degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

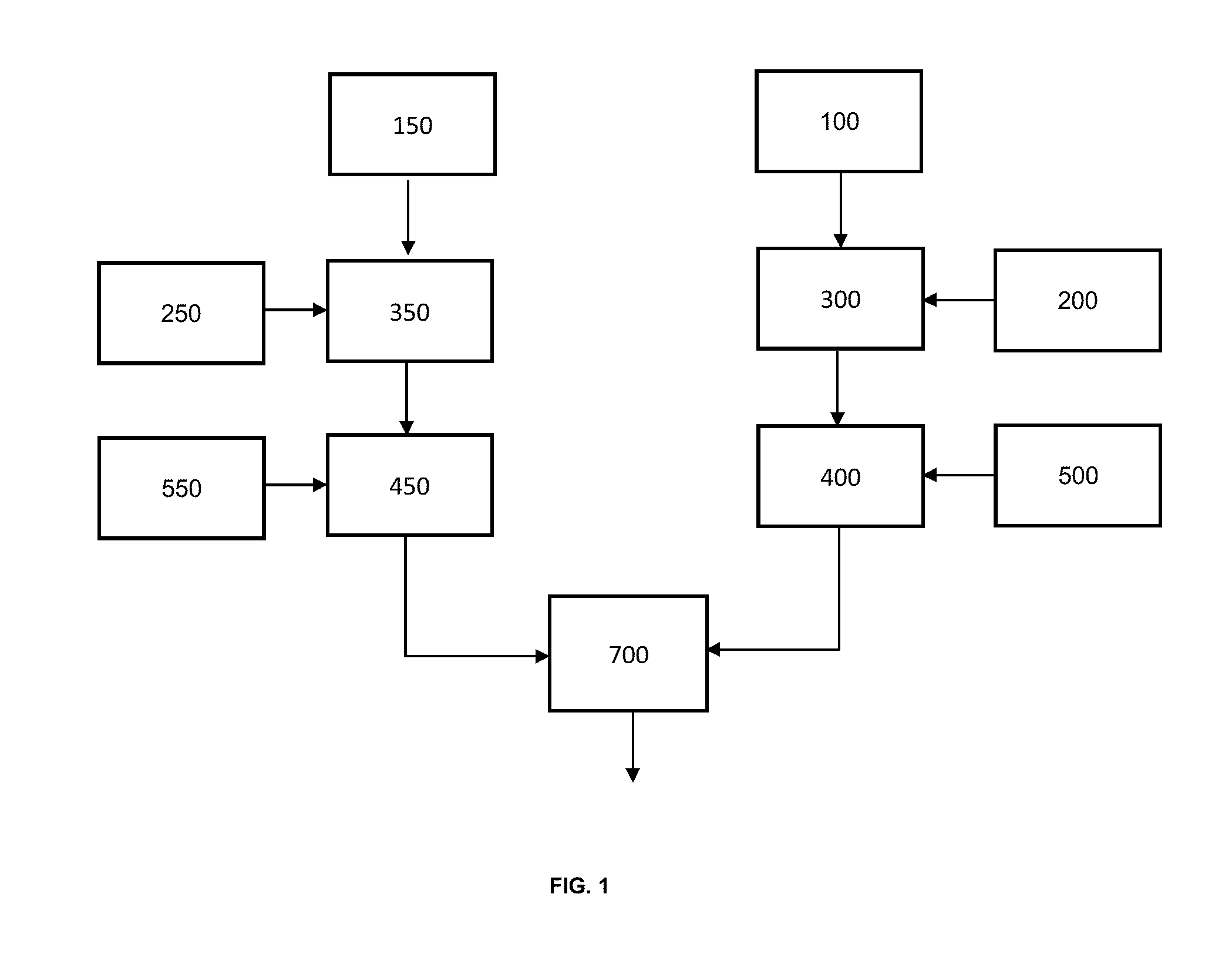

Method used

Image

Examples

example 1

Preparation of Raw Material Concentrates

[0063]A. Preparation of the silver concentrate in low density polyethylene (LDPE).

[0064]To prepare the silver concentrate an intensive mixing equipment for polymers is used.[0065]Step 1. Enter into the equipment 167 g of silver paste with 80% by weight of solids,[0066]Step 2. Add 1200 g of virgin LDPE resin to obtain a concentrate of about 10% by weight of silver,[0067]Step 3. Mix for 8 minutes ensuring the complete integration into the molten polymer,[0068]Step 4. Homogenize the material obtained by means of a twin screw extruder,[0069]Step 5. Check final concentration, which should be about 10% by weight.

[0070]B. Preparation of the ZnO Concentrate in Low Density Polyethylene (LDPE)

[0071]It is started from a paste of zinc oxide at 50% by weight solids with the above described specifications.

[0072]Once the dough is obtained its integration into the polymer is carried out in an equipment for intensive mixing of polymers, performing the followin...

example 2

Preparation of 5 kg of the Concentrate of ZnO / Ag° LDPE at 5% for a ZnO / Ag Ratio of 90:10.

[0077]a. Mix 225 g of zinc oxide concentrate with 25 g of silver concentrate, prepared according to Example 1,[0078]b. For a final application of 1 kg of LDPE, 40 g of the mixture from the previous step will be added, diluting with 960 g of LDPE for final application in a twin screw extruder for the additive ZnO / Ag° to be 0.2% by weight of the final mixture.

example 3

Preparation of 5 kg of the Concentrate of ZnO / Aq° LDPE at 1% for a ZnO / Aq Ratio of 90:10.

[0079]a. Mix 45 g of the zinc oxide concentrate with 5 g of silver concentrate, prepared according to Example 1,[0080]b. For a final application of 1 kg at 0.05%, 50 g of concentrate will be added, diluting 950 g of the final compound for a final application in a twin screw extruder for the additive ZnO / Ag° to be at 0.05%.

[0081]It is to be noted that the above examples produce an additive in a ZnO / Ag° ratio of 90:10, which is the recommended ratio for best results in typical applications, however combinations up to 10:90 ZnO / Ag can be used passing through the intermediate ranges for different performances and applications.

[0082]Results

[0083]The additive obtained according to the described method was tested on several polymers, in accordance with Examples 2 and 3, which were exposed to three bacterial strains and four fungal strains with the results shown below.

[0084]In Table 3 are shown in summa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com