Coating and coating method for gas turbine engine component

a gas turbine engine and coating technology, applied in the direction of liquid fuel engine components, solid-state diffusion coatings, electrodialysis, etc., can solve the problems of ineffective masking in these processes and inability to apply in high-temperature processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

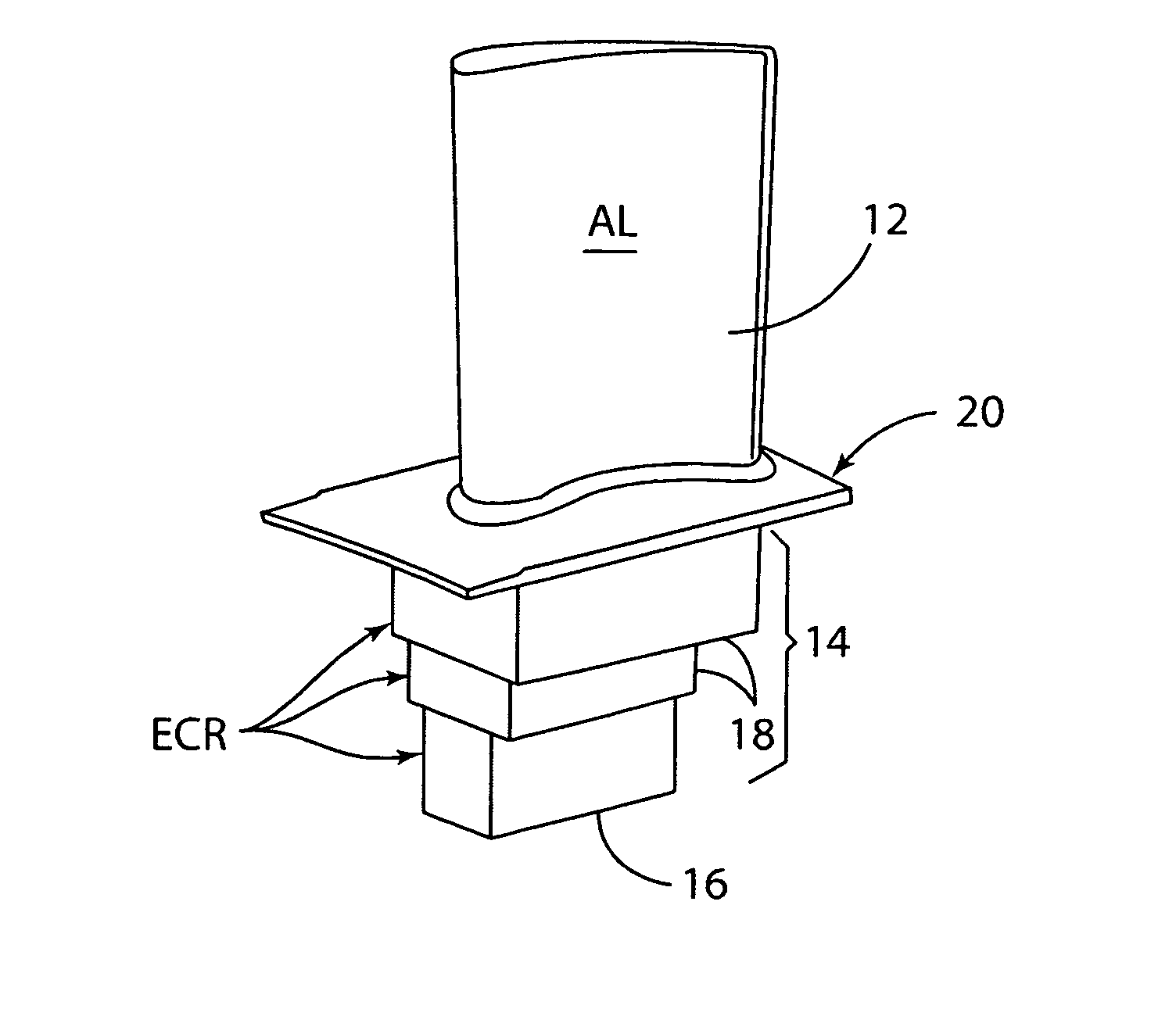

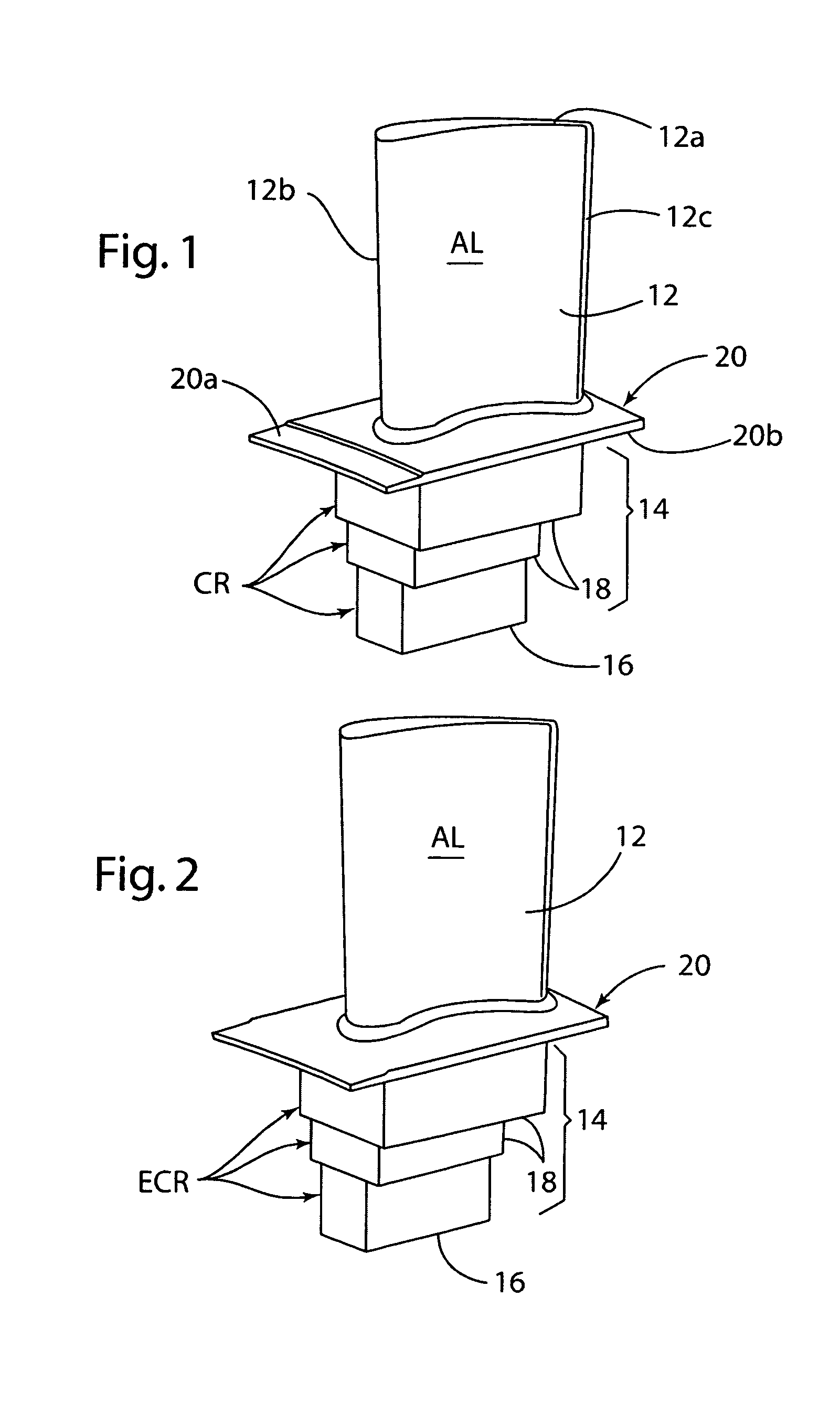

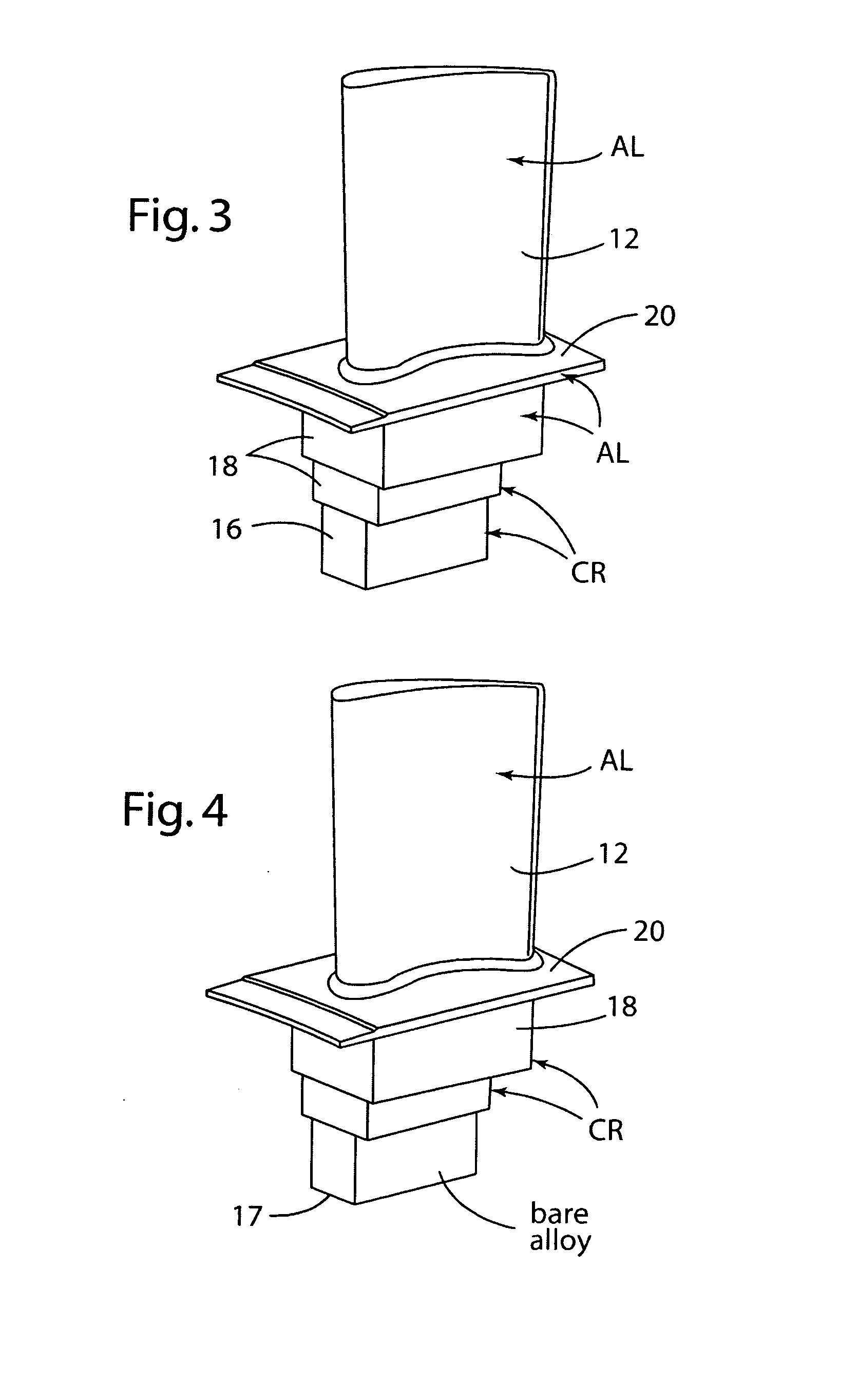

[0043]Pursuant to an illustrative embodiment of the present invention, the following processing steps are employed:

[0044]1. If a platinum-modified diffusion aluminide coating is to be formed on the gas path surfaces 12, 20a, then these surfaces are optionally electroplated with a layer of Pt pursuant to U.S. Pat. No. 5,788,832 which is already incorporated herein by reference. If a simple diffusion aluminde coating is to be formed, then this step is omitted.

[0045]2. Masking the second region of the turbine blade (i.e. root region 14 and platform surface 20b) with the M1 maskant powder mentioned above in a containment box. That is, the root region 14 and platform surface 20b are embedded in the maskant powder in the containment box.

[0046]3. Aluminize the first hotter region (i.e. airfoil 12 and platform surface 20a) to form a diffusion aluminide coating, such as a Pt-modified diffusion aluminide coating if step 1 is practiced, with the masking covering the second region.

[0047]4. Mask...

example 2

[0070]Pursuant to another illustrative embodiment of the present invention, the following processing steps are employed:

[0071]1. If a platinum-modified diffusion aluminide coating is to be formed on the gas path surfaces 12, 20a, then these surfaces are optionally electroplated with a layer of Pt pursuant to U.S. Pat. No. 5,788,832 which is already incorporated herein by reference. If a simple diffusion aluminide coating is to be formed, then this step is omitted.

[0072]2. Aluminize the first hotter region and the second region to form a diffusion aluminide coating, such as a Pt-modified diffusion aluminide coating. No masking covering the second region.

[0073]3. Removing the diffusion aluminide coating selectively from the second region by grit blasting, machining or other technique to expose the substrate alloy, while leaving the diffusion aluminide coating on the first region.

[0074]4. Masking the diffusion aluminide coating on the first region as described in Example 1.

[0075]5. Cr ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com