Methods To Control Organic Contaminants In Fibers Using Zeolites

a technology of organic contaminants and fibers, applied in the field of papermaking processes, can solve the problems of inefficiency, maintenance problems and production inefficiencies, need to bleach fibers, and difficulty in controlling or removing them,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Testing Procedure for Detackification Testing

[0107]Take 500 ml of tap water in 1000 ml beaker and place beaker on a hot plate with temperature control and magnetic agitation. Use Ethylene-vinyl acetate (EVA) as a model of tack stickies. Warm up water to designed temperature and add EVA into water at designed concentration. Start agitation at designed speed for certain period of time. Dilute the test samples and add in stickies solution under agitation, continue to agitate the mixture for designed time and remove samples from the hot plate. Place a black filter paper on a funnel filter. Carefully filter the mixture of solution through the filter paper. Remove the filter paper and dry it on a hot plate. Use a coated paper to cover on the filter paper and place them in a heated carver press at 220° F. and 5000 psi for 2 minutes. Remove coated paper from the filter paper and use the filter paper for testing.

[0108]Stickies Counting:

[0109]Use a scanner to scan the filter paper and use Use...

example 2

Pulmac Testing (Using Recycled Pulp)

[0133]Testing procedure for pulp stickies testing:[0134]Pulmac Master Screen was used for stickies test for recycled pulp.[0135]Testing conditions: OCC pulp obtained from paper mill.[0136]After screening, use coated paper to cover on black filter paper and place them in a heated carver press at 220° F. and 5000 psi for 3 minutes. Remove coated paper after heating press and use the same stickies counting method as mentioned above for stickies analysis.

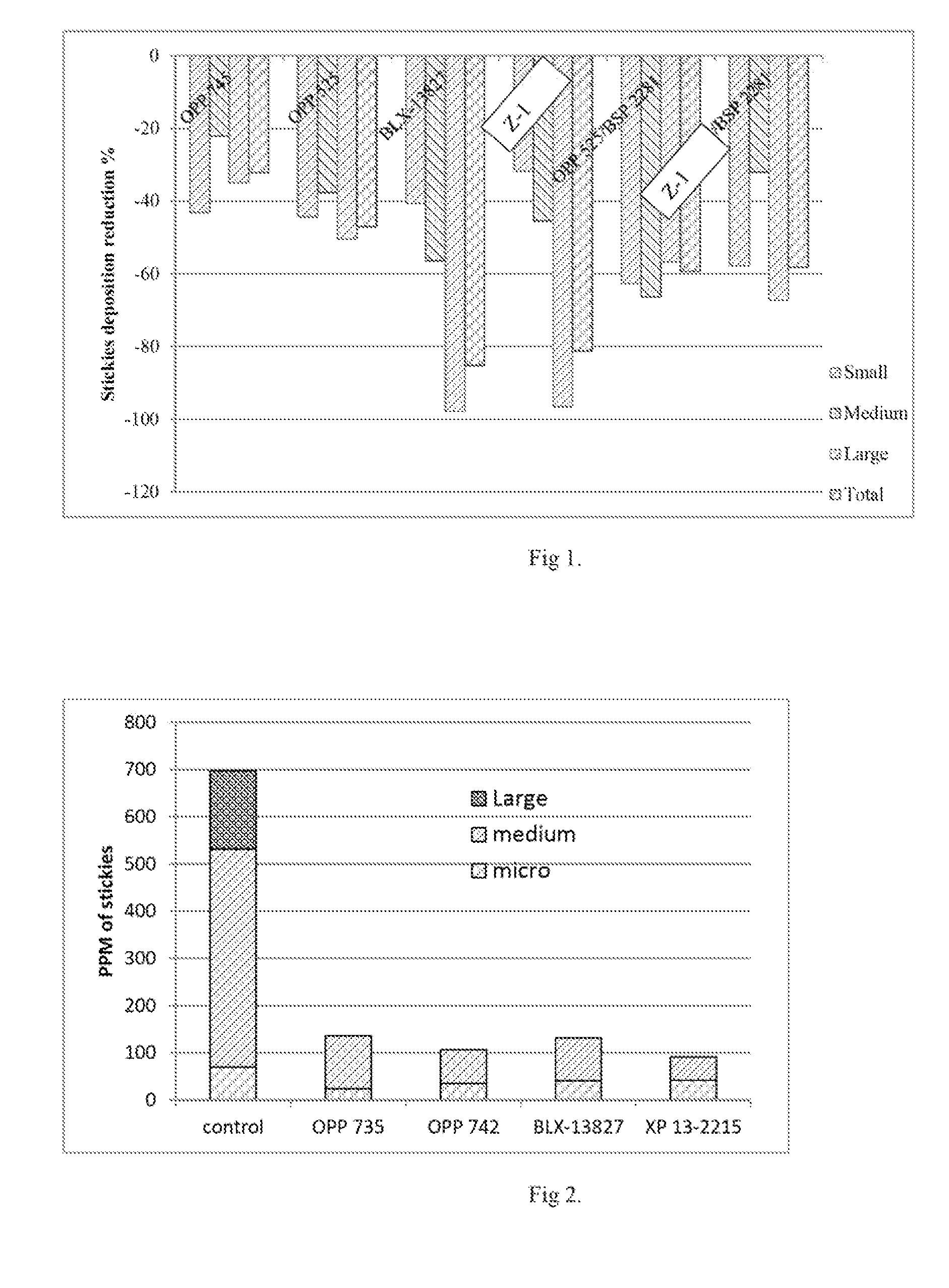

[0137]Table 4 and FIG. 2 show the comparison of zeolite formulation with some existing commercial non-zeolite containing products in stickies reduction in pulp by using Pulmac testing. Zeolite formulation (Z-1) provided better efficiency on stickies reduction.

[0138]As can be seen in Table 4 and FIG. 4, the zeolite formulation (Z-1) had almost comparable reduction in “count” but more importantly was able to reduce the size of the stickies better than the enzymes alone or with Diatomaceous earth.

TABLE 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com