Aluminum alloy conductor and method of producing the same

a technology of aluminum alloy and conductor, which is applied in the direction of metal/alloy conductor, reduction of cable/conductors, and conductors, etc., can solve the problems of reducing the contact pressure at the connection unit, lack of durability and reliability, and bending fatigue, and achieve excellent mechanical strength, flexibility and electrical conductivity. , the effect of excellent workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

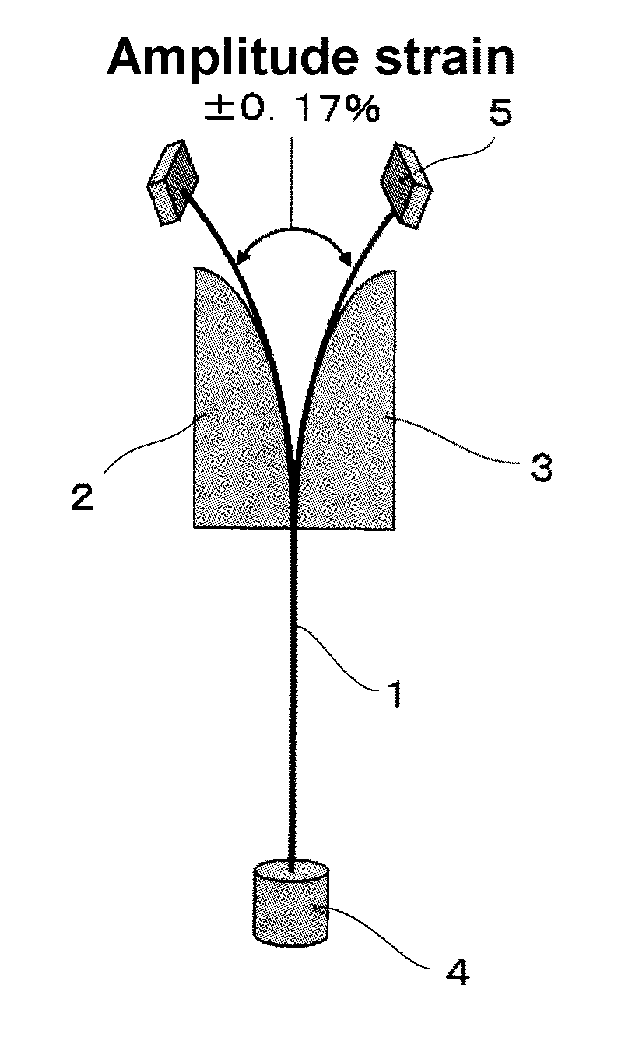

Image

Examples

first embodiment

(Alloy Composition)

[0025]A preferable first embodiment of the present invention has an alloy composition (i.e. a structure of alloying elements), which contains 0.01 to 0.4 mass % of Fe, 0.1 to 0.5 mass % of Cu, 0.04 to 0.3 mass % of Mg, and 0.02 to 0.3 mass % of Si, and further contains 0.001 to 0.01 mass % of Ti and V in total, with the balance being Al and inevitable impurities (herein, % in mass is represented by mass %).

[0026]Fe

[0027]In this embodiment, the reason why the content of Fe is set to 0.01 to 0.4 mass %, is to utilize various effects by mainly Al—Fe-based intermetallic compound. Fe is made into a solid solution in aluminum in an amount of only 0.05 mass % at 655° C., and is made into a solid solution lesser at room temperature. The remainder of Fe is crystallized or precipitated as intermetallic compounds, such as Al—Fe, Al—Fe—Si, Al—Fe—Si—Mg, and Al—Fe—Cu—Si. The crystallized or precipitated product acts as a refiner for grains to make the grain size fine, and enhan...

second embodiment

(Alloy Composition)

[0036]A preferable second embodiment of the present invention has an alloy composition, which contains 0.4 to 1.2 mass % of Fe, 0.02 to 0.5 mass % of at least one additive element selected from Cu, Mg, and Si in total, and further contains 0.001 to 0.01 mass % of Ti and V in total, with the balance being Al and inevitable impurities.

[0037]Fe In this embodiment, the reason why the content of Fe is set to 0.4 to 1.2 mass %, is to utilize the various effects by mainly Al—Fe-based intermetallic compound, similarly to the first embodiment. This is set such that the mechanical strength and the resistance to bending fatigue are enhanced largely, by containing the amount of Fe larger than that of the first embodiment. Accordingly, in regard to Cu, Mg, and Si that will be described below, the composition is set within the range appropriately. When the content of Fe is equal to or more than the lower limit, those effects are sufficiently obtained, and when the content is eq...

examples

[0058]The present invention will be described in more detail based on examples given below, but the invention is not meant to be limited by these.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com