Laminate body, laminate plate, multilayer laminate plate, printed wiring board, and method for manufacture of laminate plate

a technology of laminate body and printed wiring board, which is applied in the direction of film/foil adhesives, transportation and packaging, synthetic resin layered products, etc., can solve the problems of reducing resin strength, increasing the content of filler, and reducing insulation reliability, so as to prevent warping, reduce thermal expansion coefficient, and reduce the effect of filler conten

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

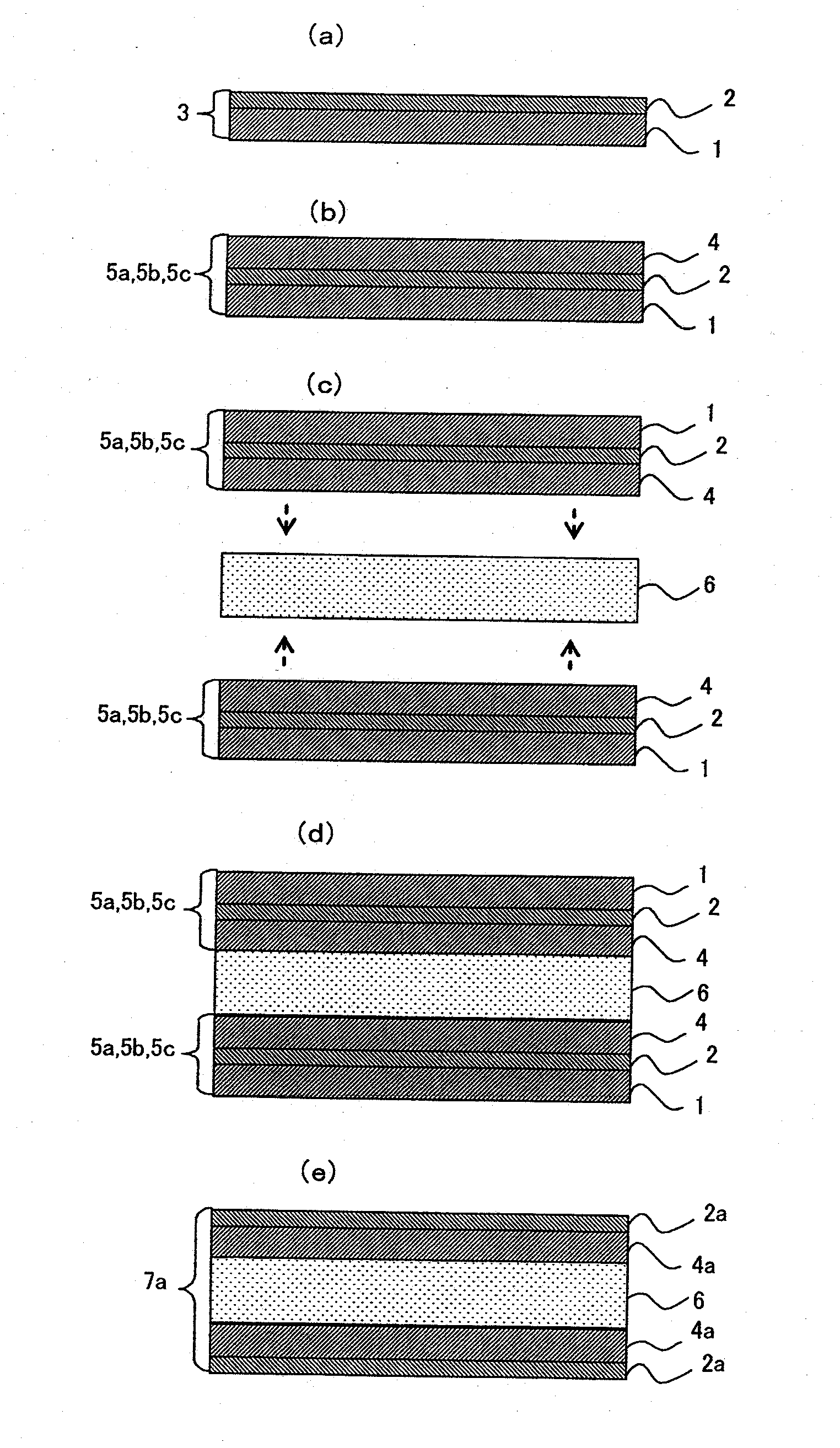

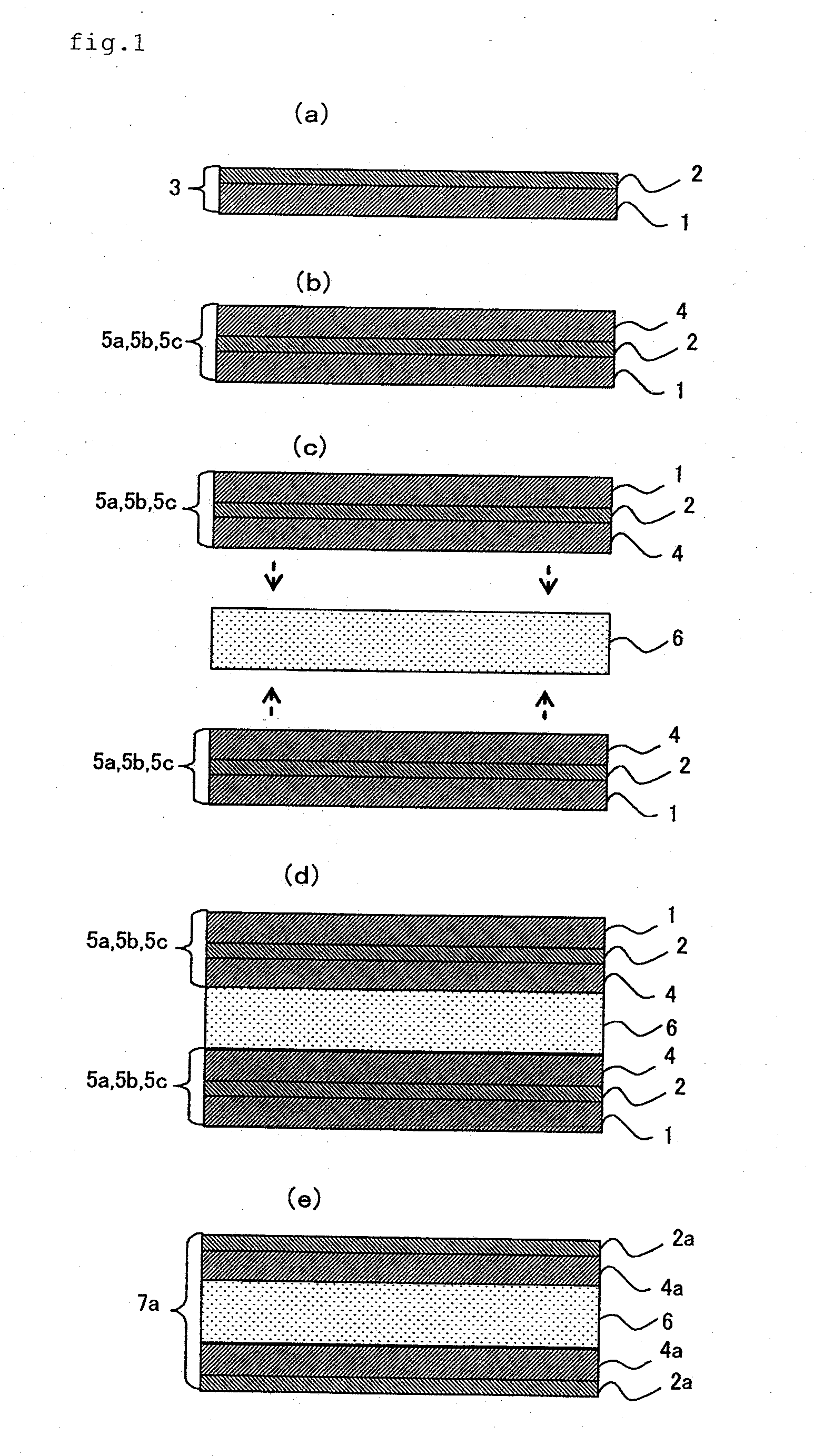

Production of Resin Film 3 (Laminate of Interlaminar Insulation Composition Layer 2 and Support Film 1)

[0154]To 135.4 parts of a polyamide resin, Nippon Kayaku's “BPAM-155” (product name) dissolved in a dimethylacetamide solvent to have a concentration of 10%, added were 62.0 parts of an epoxy resin, Nippon Kayaku's “NC3000-H” (product name, concentration 100%) as a thermosetting resin, 23.5 parts of a triazine-containing phenolic novolak resin, DIC's “LA-1356-60P” (product name, concentration 60%) as a curing agent, 0.6 parts of 2-phenylimidazole, Shikoku Chemical Industry's “2PZ” (product name, concentration 100%) as a curing promoter, 8.8 parts of fumed silica, Nippon Aerosil's “AEROSIL R972” (product name, concentration 100%; mean particle diameter of primary particles, 16 nm; specific surface area according to BET method, 110±20 m2 / g) as an inorganic filler, and 3.6 parts of a polyester-modified polydimethylsiloxane, BYK Chemie Japan's “BYK-310” (product name, concentration 25%...

example 2

Production of Adhesive Film 5b (Support Film / Interlaminar Insulation Composition Layer / Resin Composition Layer)

[0161]An adhesive film 5b of 250 mm×250 mm was produced according to the same process as that for the adhesive film 5a in Example 1, except that the coating thickness of the varnish was changed from 20 μm to 40 μm (as so defined that the interlaminar insulation composition layer 2 could be 5 μm, and the resin composition layer 4 could be 35 μm).

[0162]A five-layered laminate plate (interlaminar insulation layer / cured resin layer / glass substrate layer / cured resin layer / interlaminar insulation layer) was produced according to the same process as in Example 1 except that the above-mentioned adhesive film 5b was used in place of the adhesive film 5a.

example 3

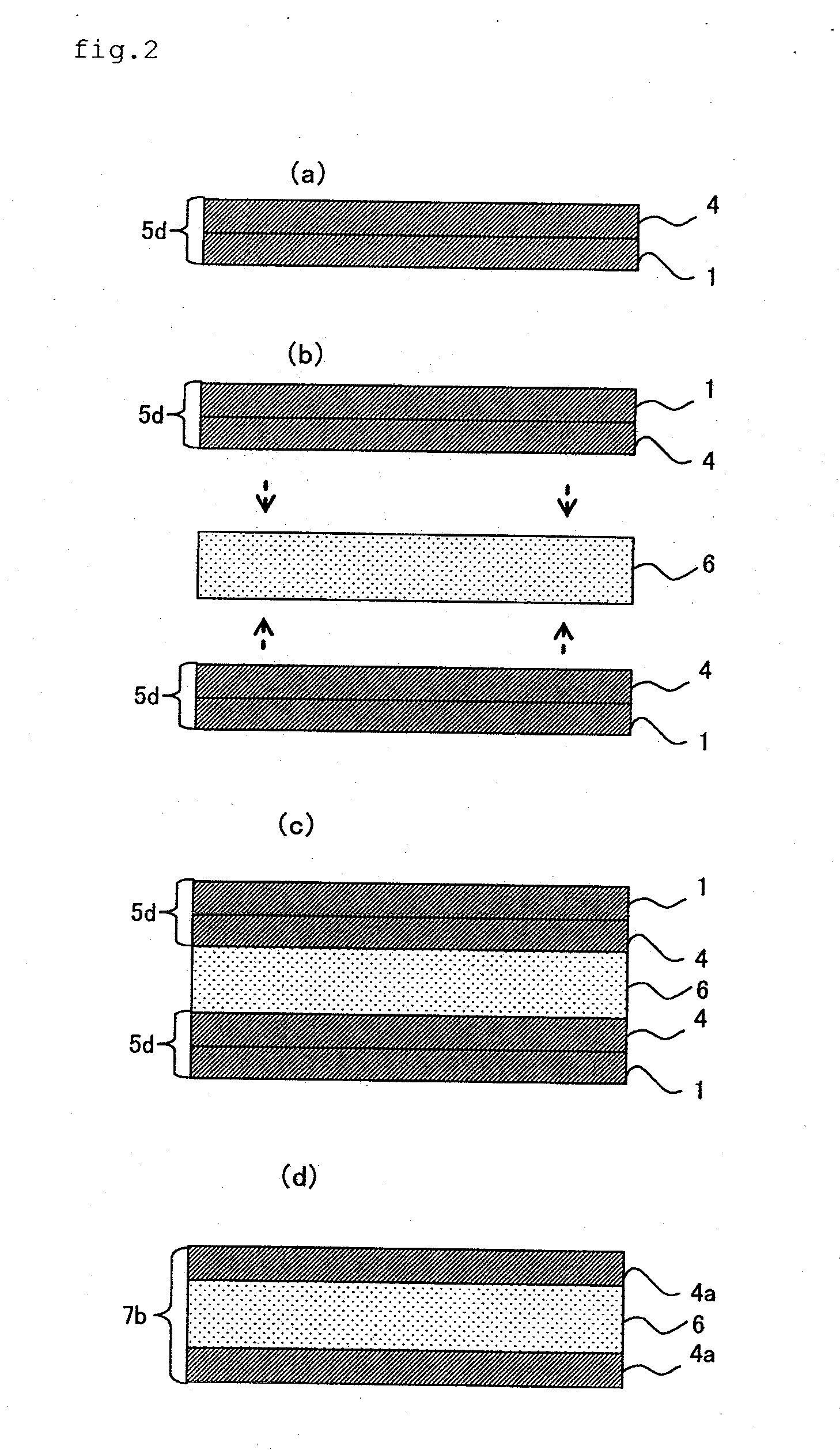

Production of Laminate Plate (Interlaminar Insulation Layer / Cured Resin Layer / Interlaminar Insulation Layer / Cured Resin Layer / Glass Substrate Layer / Cured Resin Layer / Interlaminar Insulation Layer / Cured Resin Layer / Interlaminar Insulation Layer)

[0163]As the glass substrate layer, used here was an ultrathin glass film, Nippon Electric Glass's “OA-10G” (product name, thickness 100 μm; 250×250 mm). On both surfaces of the glass substrate, the adhesive film 5b was so arranged that its cured resin layer could face the glass substrate, and laminated using a batch-type vacuum pressure laminator “MVLP-500” (Meiki's product name). In this stage, the vacuum degree was at most 30 mmHg, the temperature was 90° C., and the pressure was 0.5 MPa. After cooled to room temperature, the support film was peeled off.

[0164]On the interlaminar insulation composition layer which was exposed as a result of the peeling off of the support film, the above-mentioned adhesive film 5b was so arranged that its cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| storage elastic modulus | aaaaa | aaaaa |

| dynamic storage elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com