Metal carboxylate additives for thermoplastics

a technology of metal carboxylate and additives, applied in the field of thermoplastics, can solve the problems of deterioration of other beneficial properties, deficiency in heat distortion temperature, modulus or tensile strength, and formulated thermoplastic compositions that require a balance of cost and performance, so as to improve mechanical properties, improve heat distortion temperature, modulus and tensile strength. , the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

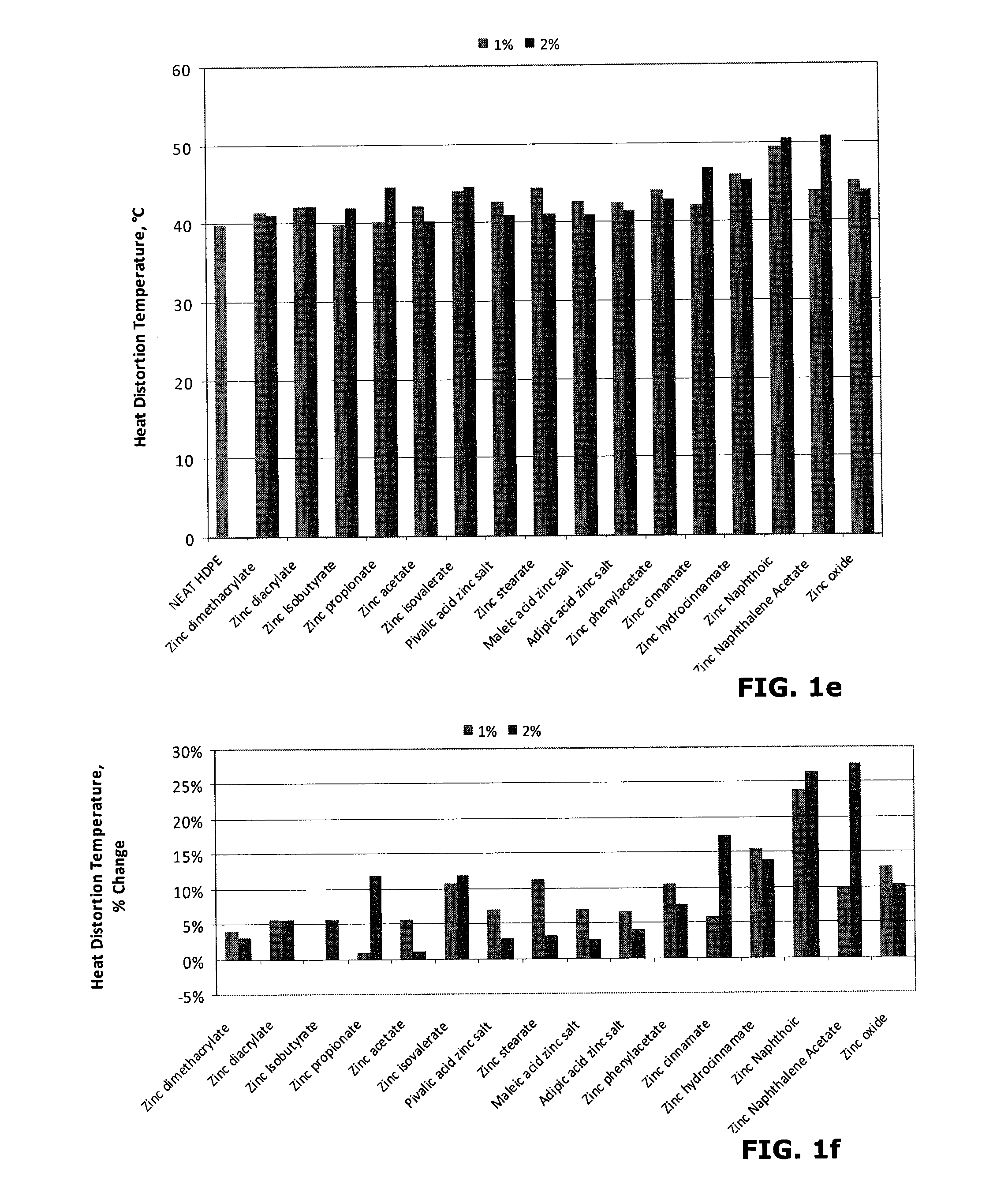

example 1

[0042]As a first example, a simple test was performed using two zinc-centered carboxylate salt additives to impart improved mechanical properties to a high-density polyethylene. The loading amounts of zinc 1-naphthoate and zinc 1-napththalene acetate were varied from about 1% to about 2% to measure the impact on the heat distortion temperature of the high-density polyethylene. Repetitive samples were tested for reproducibility. As known by one having ordinary skill in the art, the ingredients may be adjusted to achieve specifically desired properties. For example, the amount of the additive may be varied to achieve a thermoplastic having the desired mechanical properties and intrinsically beneficial characteristics.

TABLE 1Heat Distortion Temperature (° C.) - HDPELoadingHeat Distortion Temperature (° C.) individual resultsSampleLevel123456AverageStd DevHDPE40.0939.6939.75———39.840.21Zinc1%50.0149.8249.4749.7847.3349.8149.371.011-2%51.0352.2549.0849.9048.0751.9550.381.65naphthoateZinc...

example 2

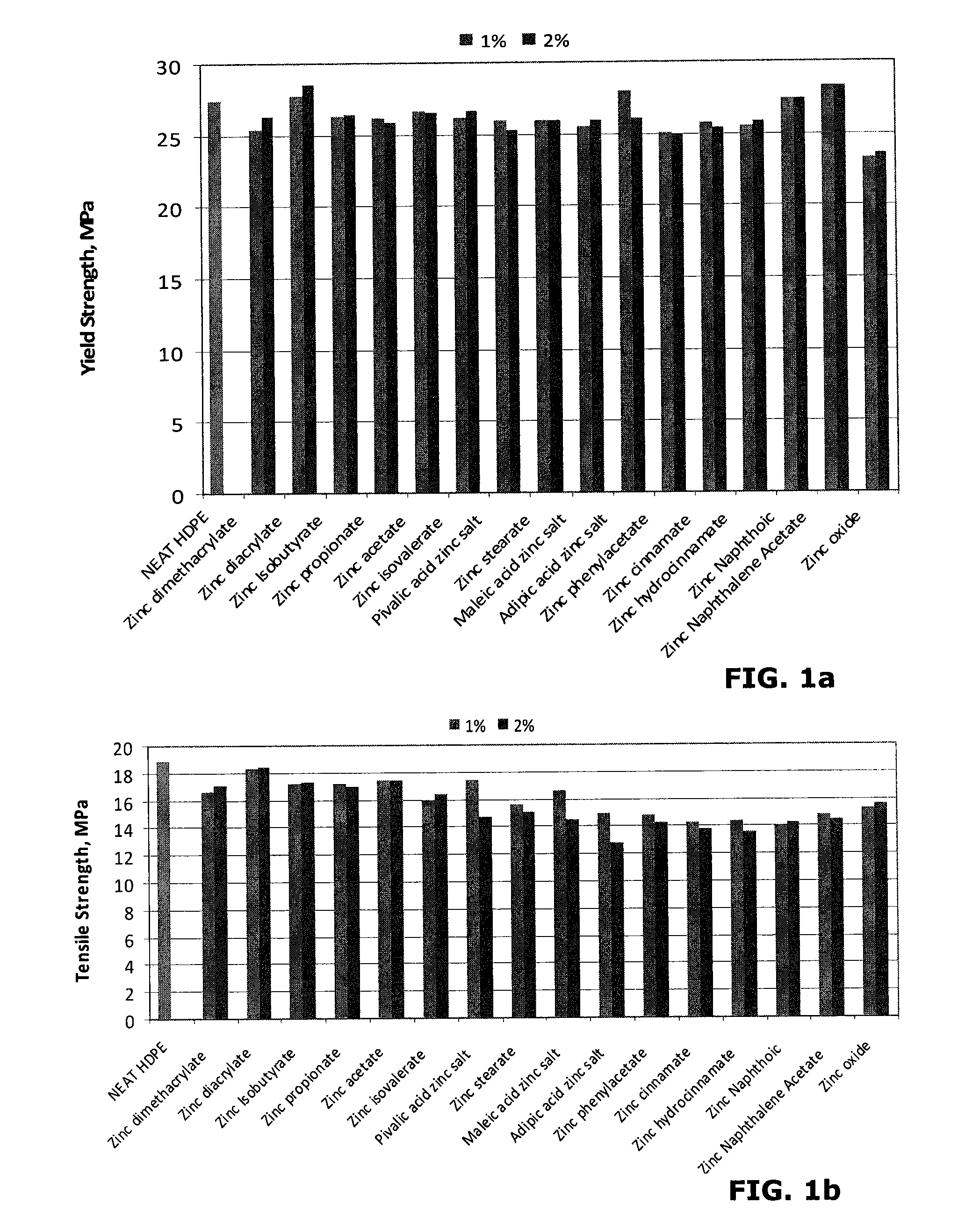

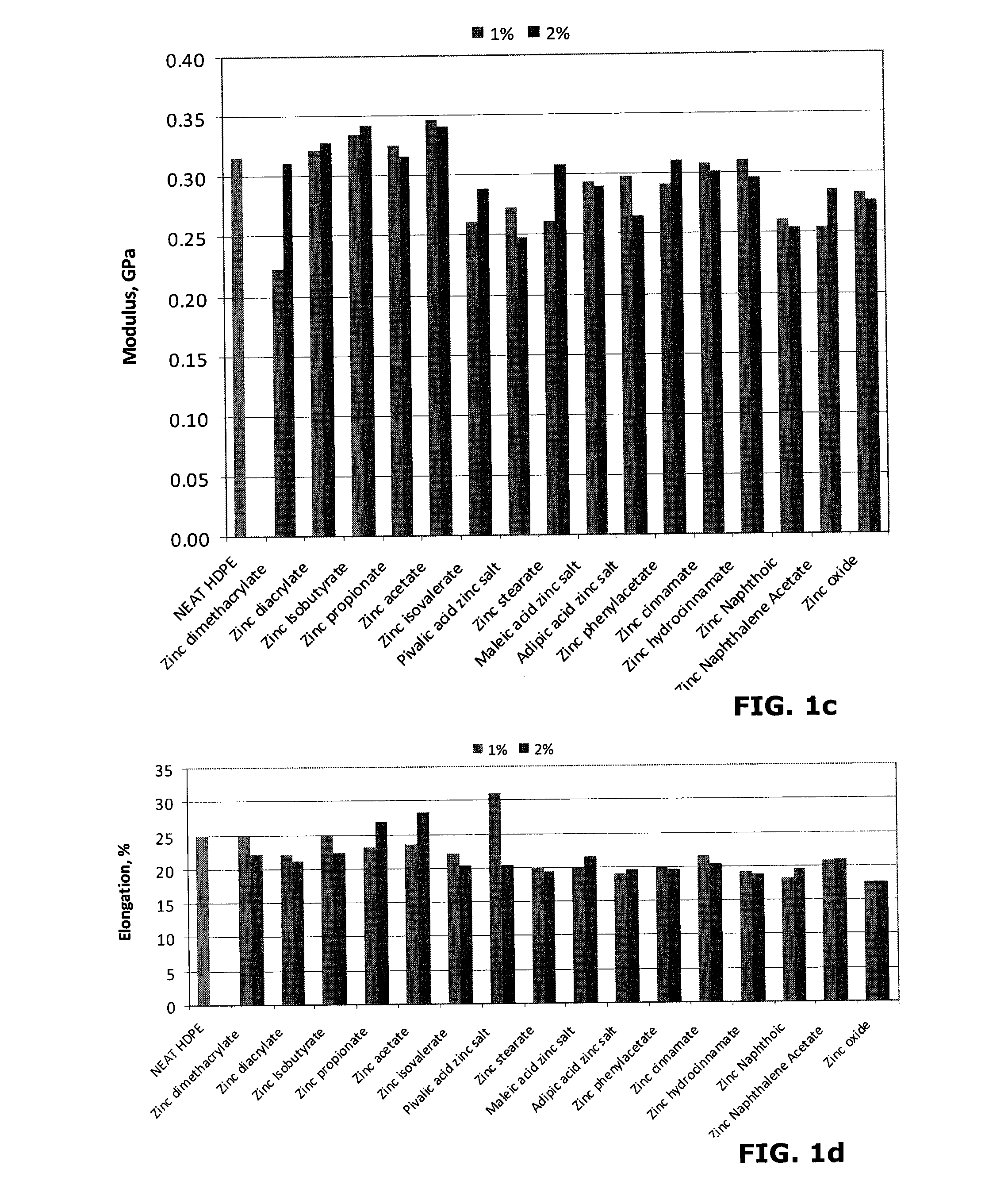

[0044]As a further example, a number of zinc-centered carboxylate salt additives were tested to impart improved mechanical properties to a high-density polyethylene. The loading amounts of these additives were again varied from about 1% to about 2% to measure the impact on the mechanical properties of the high-density polyethylene. A native high-density polyethylene sample containing zero amount of additive was used as a control sample. Additionally, a sample having zinc oxide as the additive was tested, for comparative purposes. As known by one having ordinary skilled in the art, the ingredients may be adjusted to achieve specifically desired properties. For example, the amount of the additive may be varied to achieve a thermoplastic having the desired mechanical properties and intrinsically beneficial characteristics.

TABLE 2Effect of zinc-centered carboxylate additives on the mechanical propertiesof HDPE.%YS,%TS,%SampleAdditiveMPaChangeMPaChangeControl HDPE0%27.476—18.892—Zinc1%25...

example 3

[0047]As discussed above, a number of zinc-centered carboxylate salt additives were tested to impart improved mechanical properties to a high-density polyethylene. Some of these additives were found to impart greater mechanical properties to the thermoplastic polymer than others. For example, zinc 1-naphthoate and zinc 1-naphthalene acetate were found to impart greater mechanical properties to the HDPE than other zinc-centered carboxylate salt additives. For comparison, a test was performed to substitute the metal at the center of the carboxylate salt additives. In various samples, zinc was substituted with magnesium or calcium to form magnesium naphthoate (or naphthoic) and magnesium naphthalene acetate, and calcium naphthoate (or naphthoic) and calcium naphthalene acetate, respectively. The loading amounts of these additives were again varied from about 1% to about 2% to measure the impact on the mechanical properties of the high-density polyethylene. A native high-density polyeth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com