Preparation method of pimaric acid type resin acid

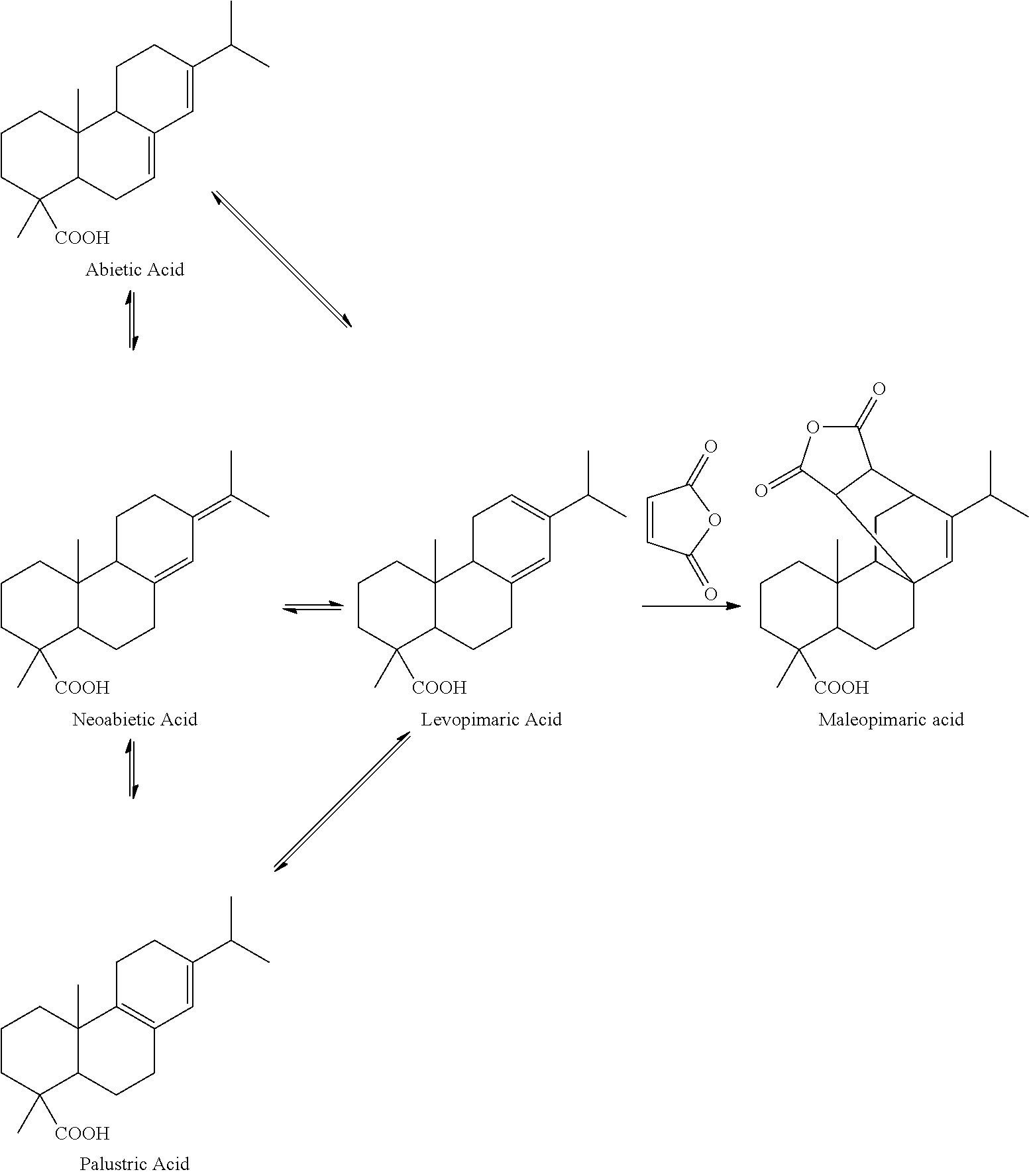

a technology of resin acid and pimaric acid, which is applied in the preparation of carboxylic compounds, organic chemistry, chemistry apparatus and processes, etc., can solve the problems of severe loss, low yield of pimaric acid, and yield of this pimaric acid type resin acid, and achieves low cost, high yield, and low yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Refined Resin Acids

[0031]Add 1 part by weight (pbw) of Pinus elliottii pine oleoresin into a three-neck flask with agitator and reflux condenser; add 2.5 pbw of petroleum ether with 60° C.-90° C. boiling range into the flask; agitate the solution at 40° C. until the Pinus elliottii pine oleoresin is dissolved completely; remove insoluble solid impurities by filtering before the solution cools down; remove water contained in the pine oleoresin from the filtrate with a separatory funnel; add the filtrate into a four-neck flask with agitator and reflux condenser; slowly add drops of cyclohexylamine solution while agitating to produce a large quantity of white precipitate of ammonium salt of resin acid, wherein the cyclohexylamine solution is prepared by dissolving cyclohexylamine, in a quantity equal to the molar quantities of the resin acids contained in the pine oleoresin, into 0.4 pbw of petroleum ether; agitate at 40° C. for 1 hour; cool down to room temperature; fur...

example 2

Preparation of Refined Resin Acids

[0034]The Pinus elliottii pine oleoresin used in example 1 is replaced with Pinus massoniana pine oleoresin, while the rest of the operations are the same as those in example 1. The result of the analysis indicates that the total mass fraction of pimaric type resin acids in the Pinus massoniana pine resin acids is 7.76 wt %.

example 3

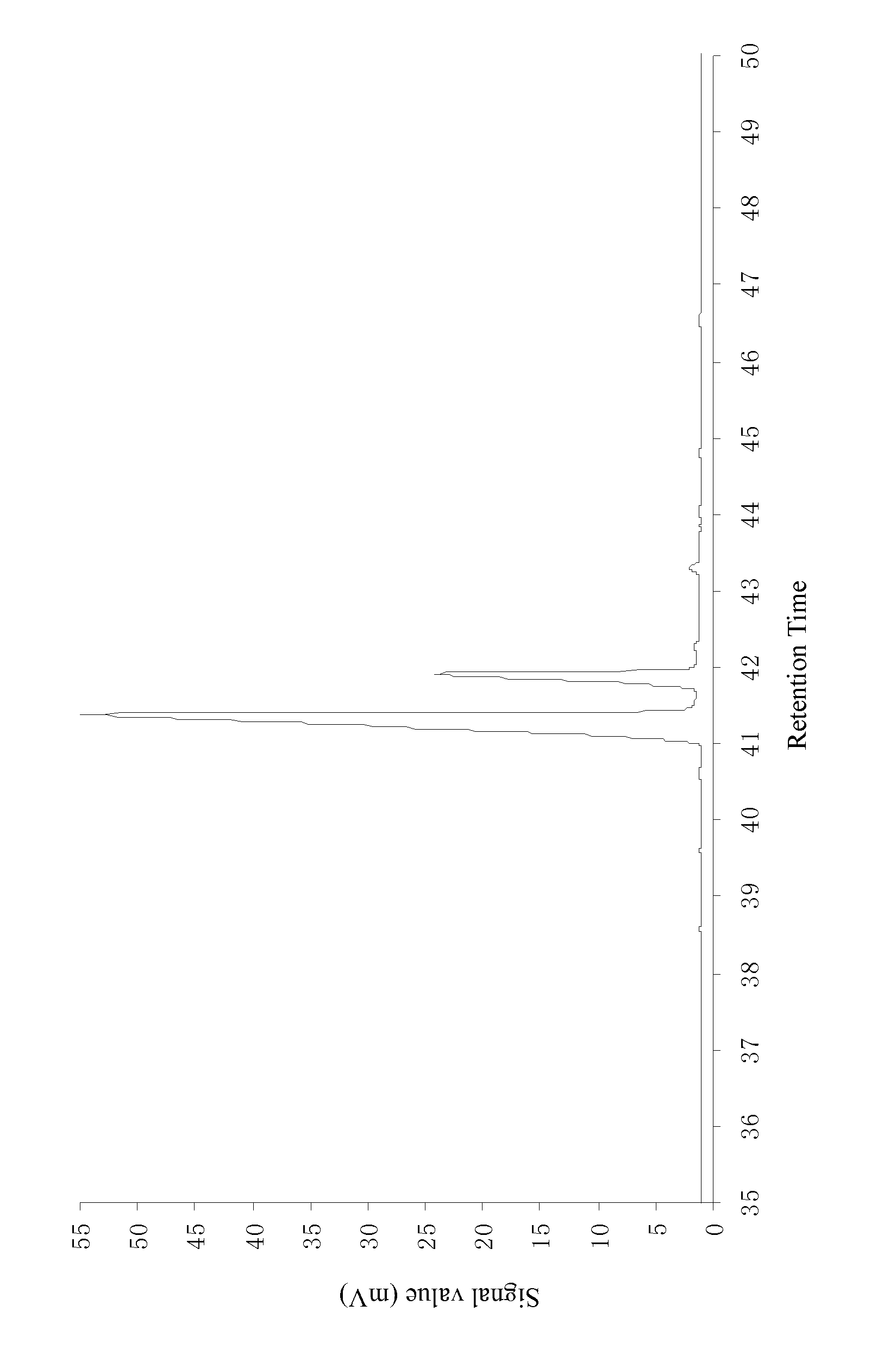

[0035]Add 20.1 g of refined resin acids, prepared according to example 1, into a special microwave reaction bulb; add 8.1 g of maleic anhydride and 8.2 g of glacial acetic acid; agitate until the added substances are dissolved completely; arrange the microwave reaction bulb containing the material in a microwave reactor with a reflux condenser; adjust the microwave power to 120 W; after reacting for 28 minutes, take out the reaction bulb from the microwave reactor; add 47.2 g of glacial acetic acid into the reaction bulb; cool down the solution and let it crystallize; filter the solution; wash the precipitate with 5 g of glacial acetic acid; combine the filtrate; distil the solvent at reduced pressure, and then dissolve it in 28 wt % of sodium hydroxide solution; add water to dilute the solution to 1000 mL; slowly add drops of hydrochloric acid while agitating until the pH reaches 7.5; filter the precipitate and wash it with water; add 17 g of ether to dissolve the precipitate; wash...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com