Gas injection system for etching profile control

a technology of etching profile and injection system, which is applied in the direction of electrical equipment, basic electric elements, electric discharge tubes, etc., can solve the problems of difficult precise control, unsatisfactory cd control effect of temperature control, and remarkable degradation of chip yield of edge parts, etc., to achieve the effect of effectively controlling the cd uniformity or profile of edge parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]Exemplary embodiments of the present invention will now be described in detail with reference to the annexed drawings. In the following description, a detailed description of known functions and configurations incorporated herein has been omitted for conciseness.

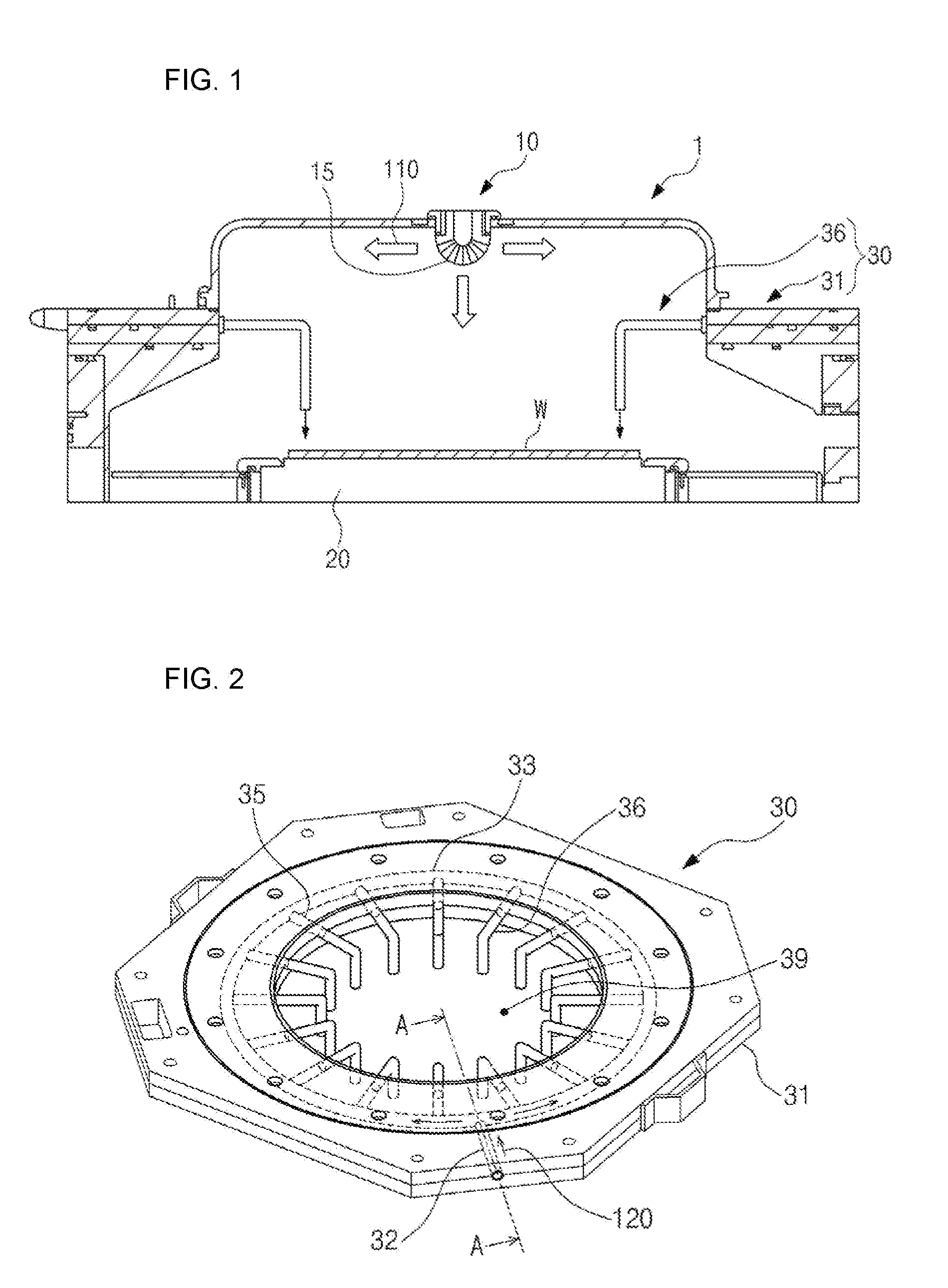

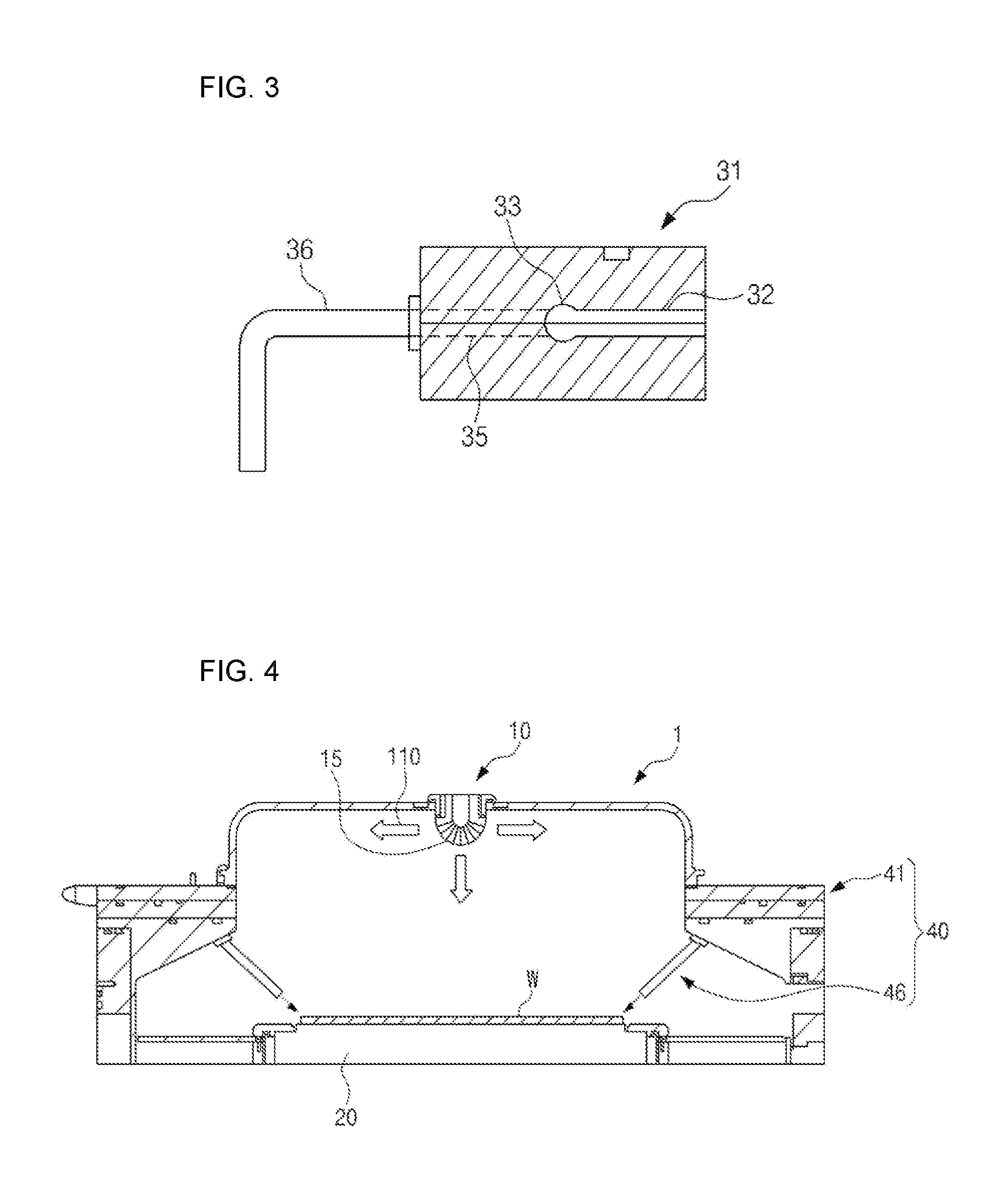

[0041]FIG. 1 is a schematic diagram illustrating a construction of an exemplary embodiment of the present invention. FIG. 2 is a perspective diagram illustrating a side gas injector according to an exemplary embodiment of the present invention. FIG. 3 is a cross section taken along line A-A of FIG. 2.

[0042]As illustrated in FIG. 1, the gas injection system of the present invention includes a top gas injector 10 and a side gas injector 30.

[0043]The top gas injector 10 is installed on a top surface inside a chamber 1, and the side gas injector 30 is installed along a side surface of the chamber 1.

[0044]The chamber 1 is to provide a plasma reaction space isolated from the external in an etching process. The chamber 1 form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com