Scaffolded Nucleic Acid Polymer Particles and Methods of Making and Using

a nucleic acid polymer and polymer technology, applied in the field of scaffolded nucleic acid polymer particles and methods of making and using, can solve the problems of limited ease of manipulation and/or reagent access, lack of fragment density or concentration for adequate signal-to-noise ratio, and labor-intensive emulsion reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

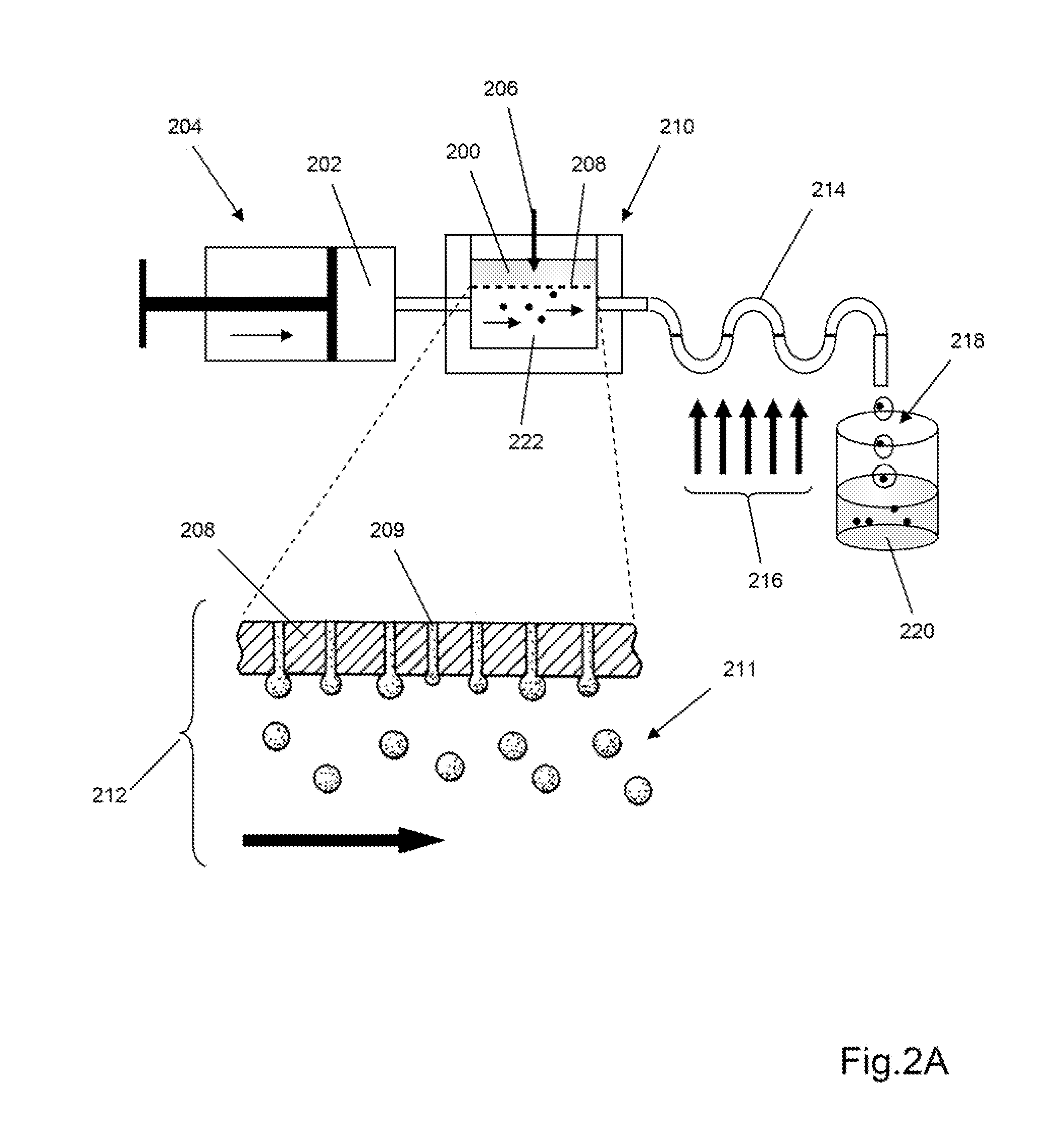

Making Polyacrylamide Nucleic Acid Polymer Particles By Membrane Emulsification

This example describes the method and apparatus for production of uniformly sized droplets of aqueous solution in non-miscible continuous phase by extrusion through a micro fabricated plate with multiple through holes (nozzles, orifices) and the subsequent transformation of the emulsion into polymer particles by radical polymerization. The fabrication of the plate with multiple through holes is described in the above references.

A solution of specific amounts of acrylamide and methylene-N,N-bisacrylamide containing a specified concentration of acrodyte oligonucleotides (primers for PCR) is degassed by bubbling an inert atmosphere (Argon, Nitrogen, Helium) through the solution for a minimum of 30 minutes. Just prior to emulsification, a radical initiator is added. The radical initiator can be a combination of ammonium persulfate (APS) and N,N,N′,N′-tetramethylethylenediamine (TMED) which catalyses the radic...

example 2

Making Polyacrylamide Nucleic Acid Polymer Particles By Membrane Emulsification with Batch Mode Initiation

This example describes membrane emulsification and the subsequent transformation of the aqueous micelles of the emulsion into polyacrylamide particles by radical polymerization in batch mode using an initiator-saturated oil phase. The steps of the process comprise (a) formation of a gel reaction mixture-in-oil emulsion using a membrane, (b) particle polymerization, and (c) particle extraction and washing.

The following reagents are employed in the process: (a) SNAPP Oil comprises the following mixture: Tegosoft™ DEC oil (730 mL), ABIL WE09 (70 gm), and mineral oil (200 mL) (SNAPP oil is stored under argon); (b) SNAPP Buffer: 1× TE, 0.1% Triton X-100, 02% sodium azide; (c) Acrylamide Solution: 50 mg N,N-methylene bisacrylamidc, 450 mg acrylamide, 550 uL double distilled H2O kept under argon; (d) DNA Mix: 10 umol 30-mer acryditc oligonucleotide with 18C spacer in 2.5 mL H2O. Gel Re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| average nearest neighbor distance | aaaaa | aaaaa |

| average nearest neighbor distance | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com