Explosive mixtures containing readily gasified additives

a technology of additives and explosive materials, which is applied in the direction of explosives, textiles and papermaking, looms, etc., can solve the problems of periodic generation of toxic gases, limited control of detonation velocity (vod), and significant operating expenses of explosive materials, so as to reduce nox formation, reduce the velocity of detonation, and reduce the effect of cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0065]Explosive mixtures containing varying concentrations of ammonium nitrate, fuel oil, emulsion, and the previously described carbonaceous additive have been successfully tested. As an illustrative example, an independent engineering firm was commissioned to complete a comprehensive study examining the effects of this additive in ANFO relative to standard ANFO (94% ammonium nitrate prill and 6% fuel oil). The field assessment program included six production blasts—three trials with approximately 25% (24%, 28%, & 33%) of the carbonaceous additive and three shots using standard ANFO. The shots alternated between the claimed mixture and standard ANFO to produce pairs of blasts in an attempt to compare similar geologic conditions (strata, depth, etc.) within each pairing. Among other metrics, the claimed mixture and ANFO shots were compared based on the following:[0066]Velocity of Detonation (VOD, described in more detail below).[0067]Seismic output in the far field (ground vibration...

PUM

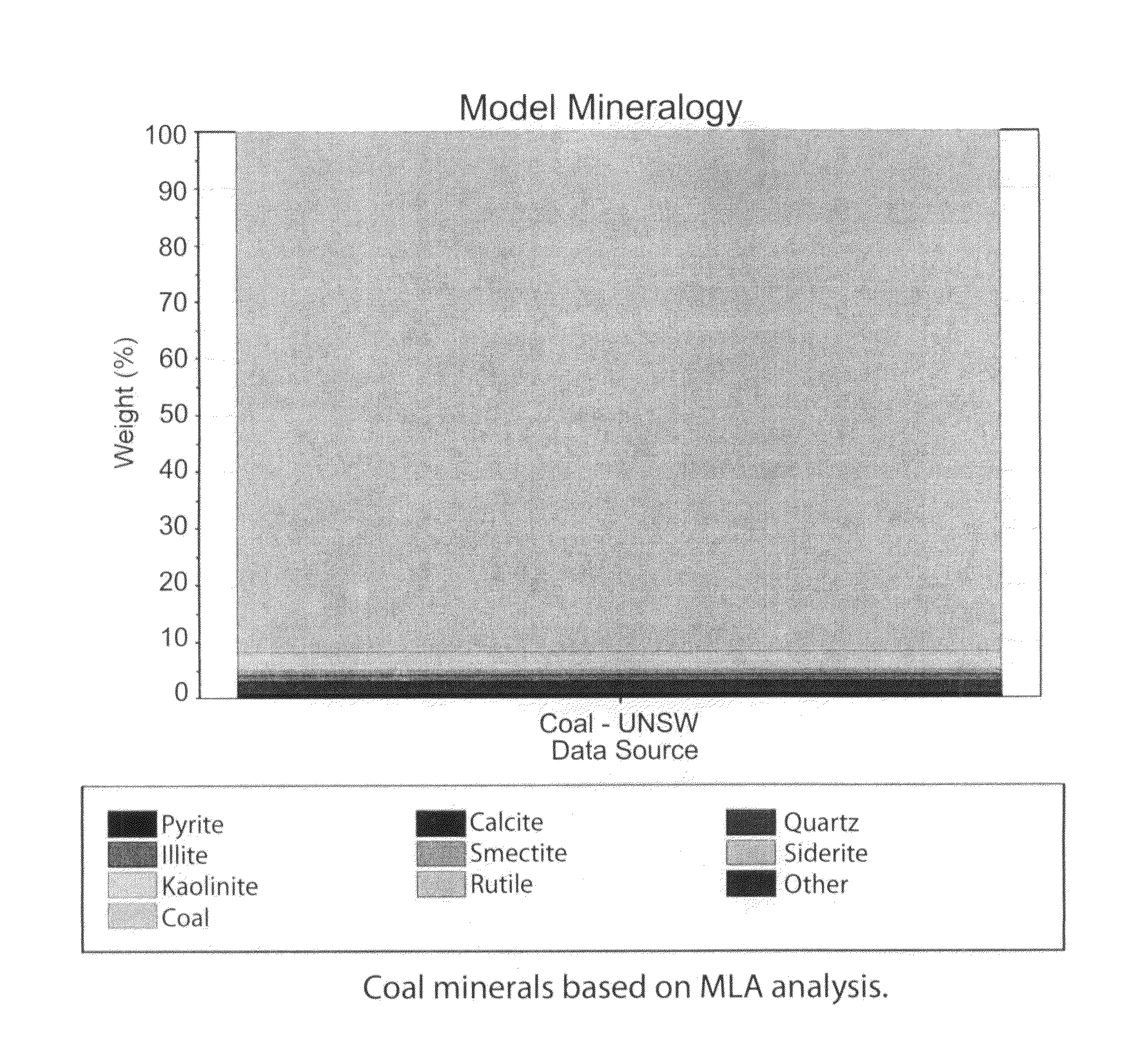

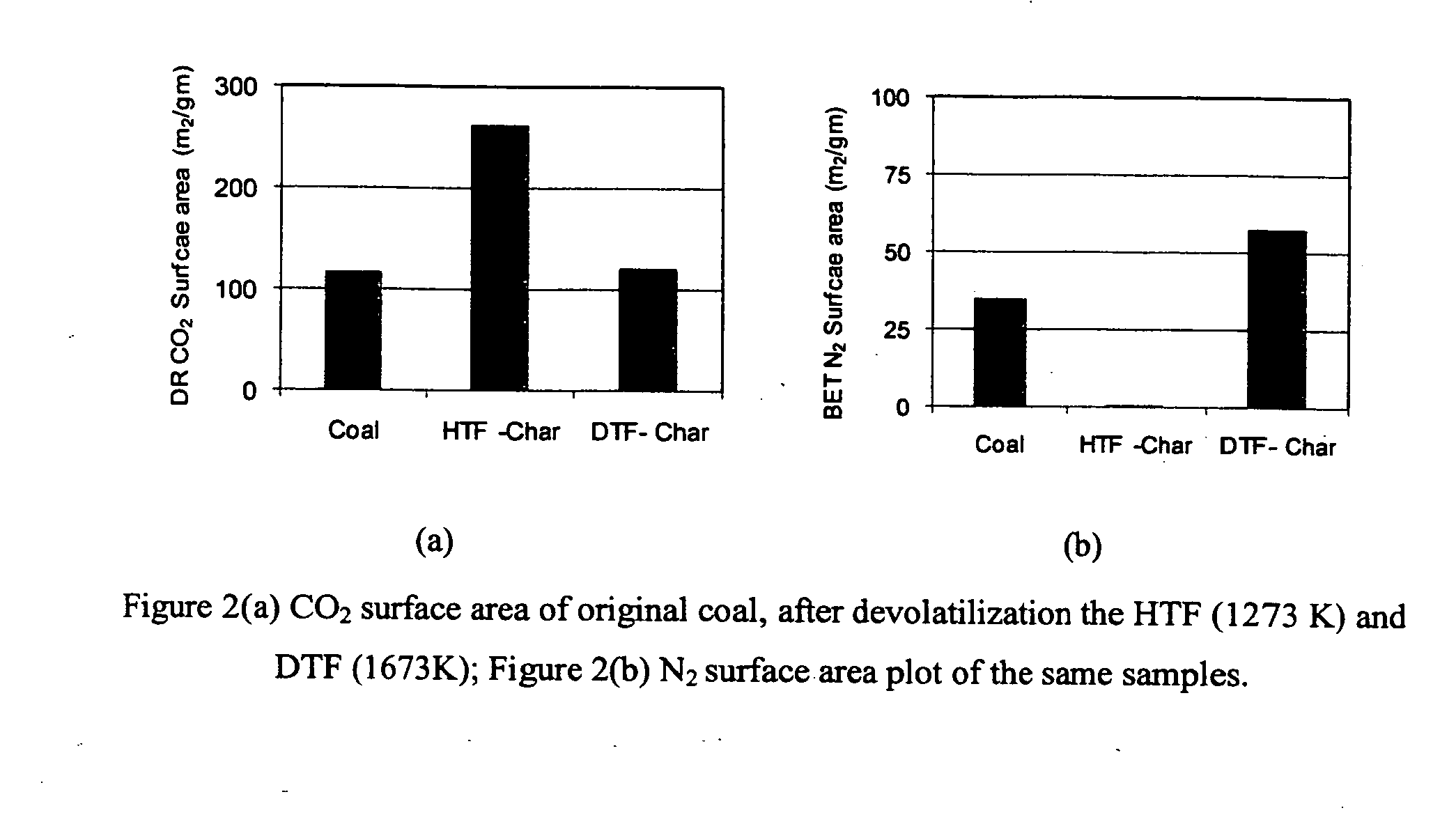

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com