Grease composition and process for production thereof

a technology of grease composition and process, applied in the field of grease composition, can solve the problems of affecting the quality of grease application, and difficulty in removing the operation of grease, and achieve the effects of preventing the scattering of grease composition, and excellent rust prevention capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

First, a description will be given of a grease composition and a process for production thereof in accordance with the invention.

The grease composition in accordance with the first embodiment is characterized in that, in particular, a grease produced by compounding at least one kind of base oil selected from a mineral oil-type lubricant base oil, a synthetic lubricant base oil, and a biodegradable lubricant base oil with a thickener is compounded with a wax and water.

In this case, as a mineral oil-type lubricant base oil, it is possible to cite, for example, “Diana Fresia” (tradename) made by Idemitsu Kosan Co., Ltd., as a lubricant base oil. As a synthetic lubricant base oil, it is possible to cite, for example, “MORESCO” (tradename) made by Matsumura Oil Co., Ltd., as a lubricant base oil. Further, as biodegradable lubricant base oils, it is possible to cite a general-purpose product base oil called “PAO” (polyalphaolein) or “XHVI” (tradename), which are made by SHOWA SHELL SEKIYU...

examples 1 to 8

In Examples 1 to 8 shown in Table 1 below, a grease obtained by compounding a base oil with a calcium sulfonate complex which is a thickener (namely, a calcium sulfonate complex grease) was mixed with a wax component (e.g., carnauba wax) and the water, and various additives were compounded therewith in some cases. On the other hand, Table 2 shows Comparative Examples 1 to 4 with respect to Examples 1 to 8.

In this case, in Examples 2 to 8 and Comparative Examples 2 to 4, sodium alkyl sulfonate was added as a surfactant. In Examples 5 to 8, a silicone oil was added as a defoamer. Further, in Tables 1 and 2 below, results are shown in which a salt spray test was conducted on Examples 1 to 8 and Comparative Examples 1 to 4.

In Tables 1 and 2, concerning the results in which the grease compositions of the respective specimens (Examples 1 to 8 and Comparative Examples 1 to 4) were applied to steel plates by brush coating, those in which coating could be effected very easily are represented...

second embodiment

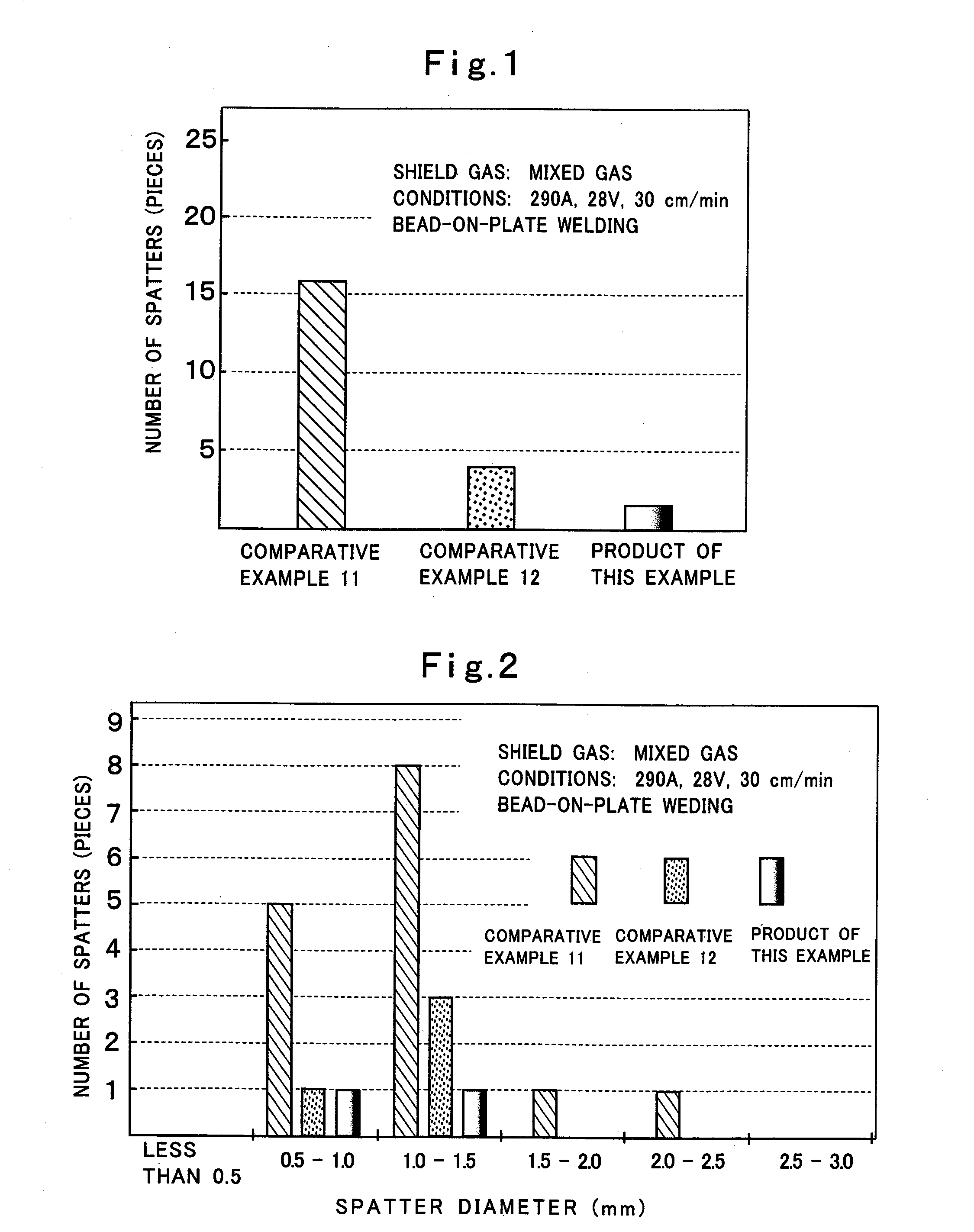

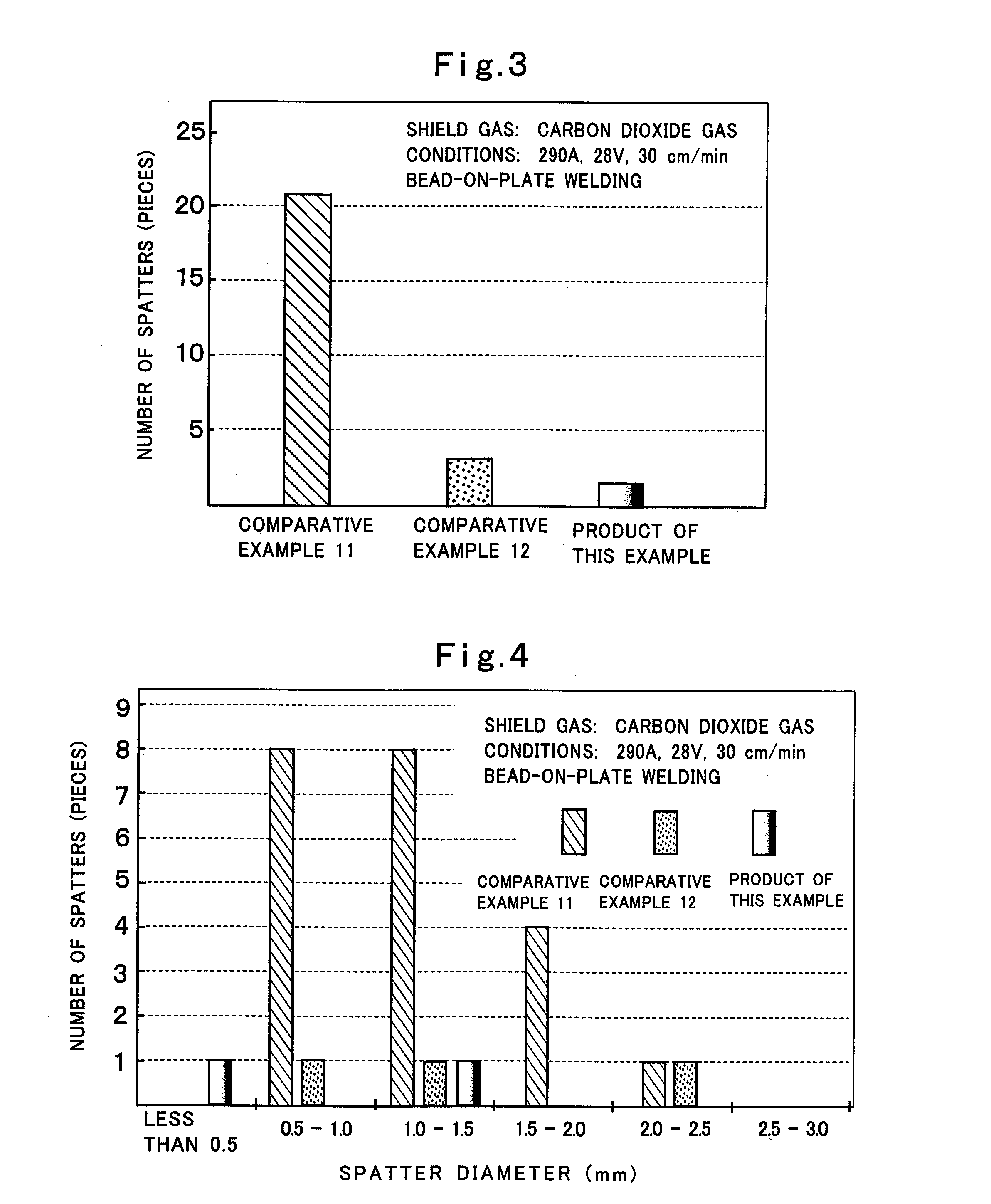

Next, a detailed description will be given of a welding spatter adhesion preventing grease (hereafter referred to as the welding spatter adhesion preventing agent) which is adopted in the invention.

The welding spatter adhesion preventing agent in accordance with the second embodiment has a substantially similar constitution to that of the grease composition in accordance with the above-described first embodiment, and is characterized in that a grease produced by compounding at least one kind of base oil selected from a mineral oil-type lubricant base oil, a synthetic lubricant base oil, and a biodegradable lubricant base oil with a thickener is compounded with a wax and water by being mixed and stirred.

As for the welding spatter adhesion preventing agent in accordance with the second embodiment, a grease in which a calcium sulfonate serving as a base is used as a thickener is first produced. The main function of this grease is the performance of prevention of adhesion of welding spa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wt. % | aaaaa | aaaaa |

| wt. % | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com