Control Electronics for Brushless Motors

a technology of control electronics and motors, applied in the direction of motor/generator/converter stoppers, software algorithm control, dynamo-electric converter control, etc., can solve the disadvantage of controlling methods of fitting hall sensors, including components and assembly costs, and achieve the effect of improving electric efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

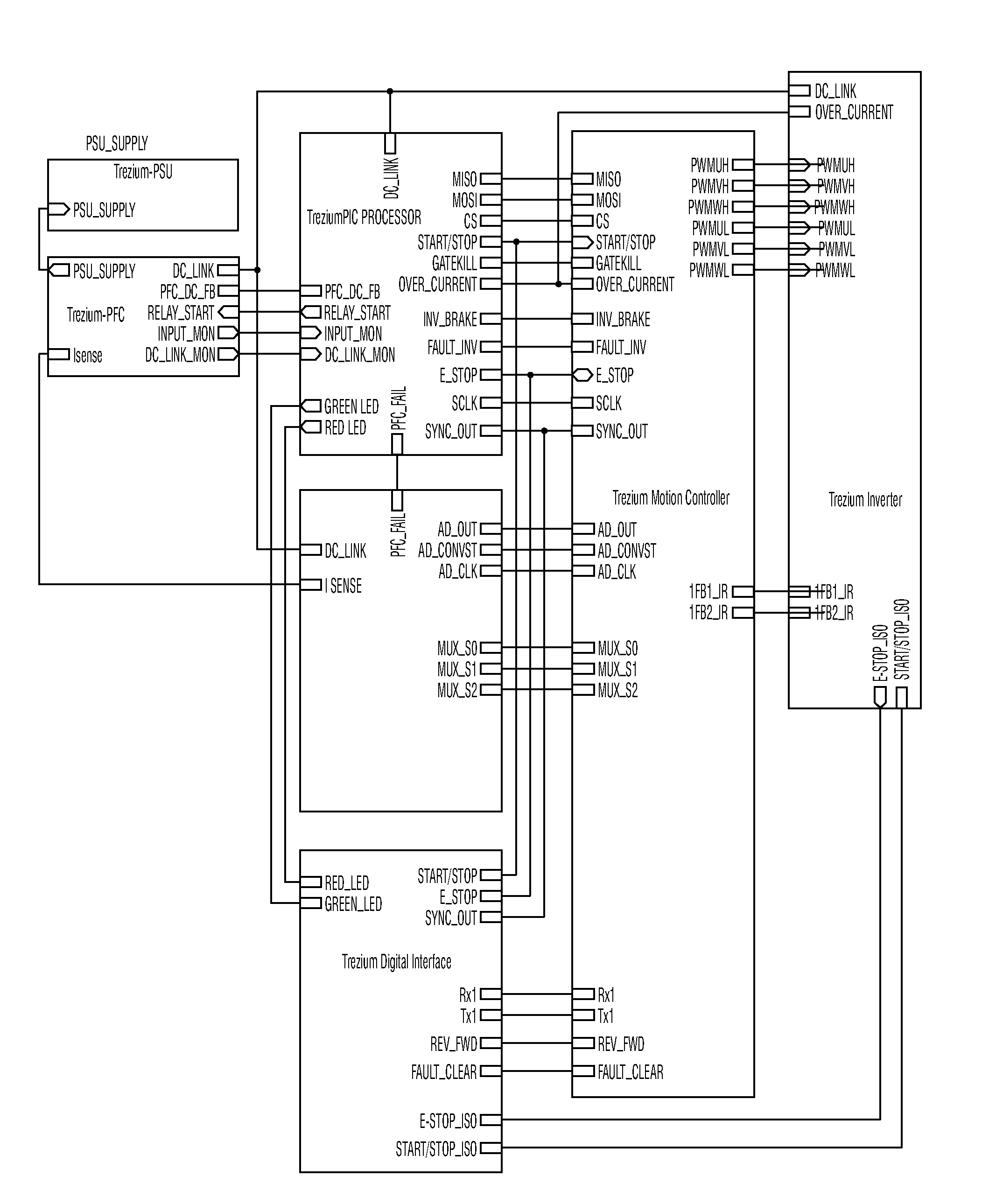

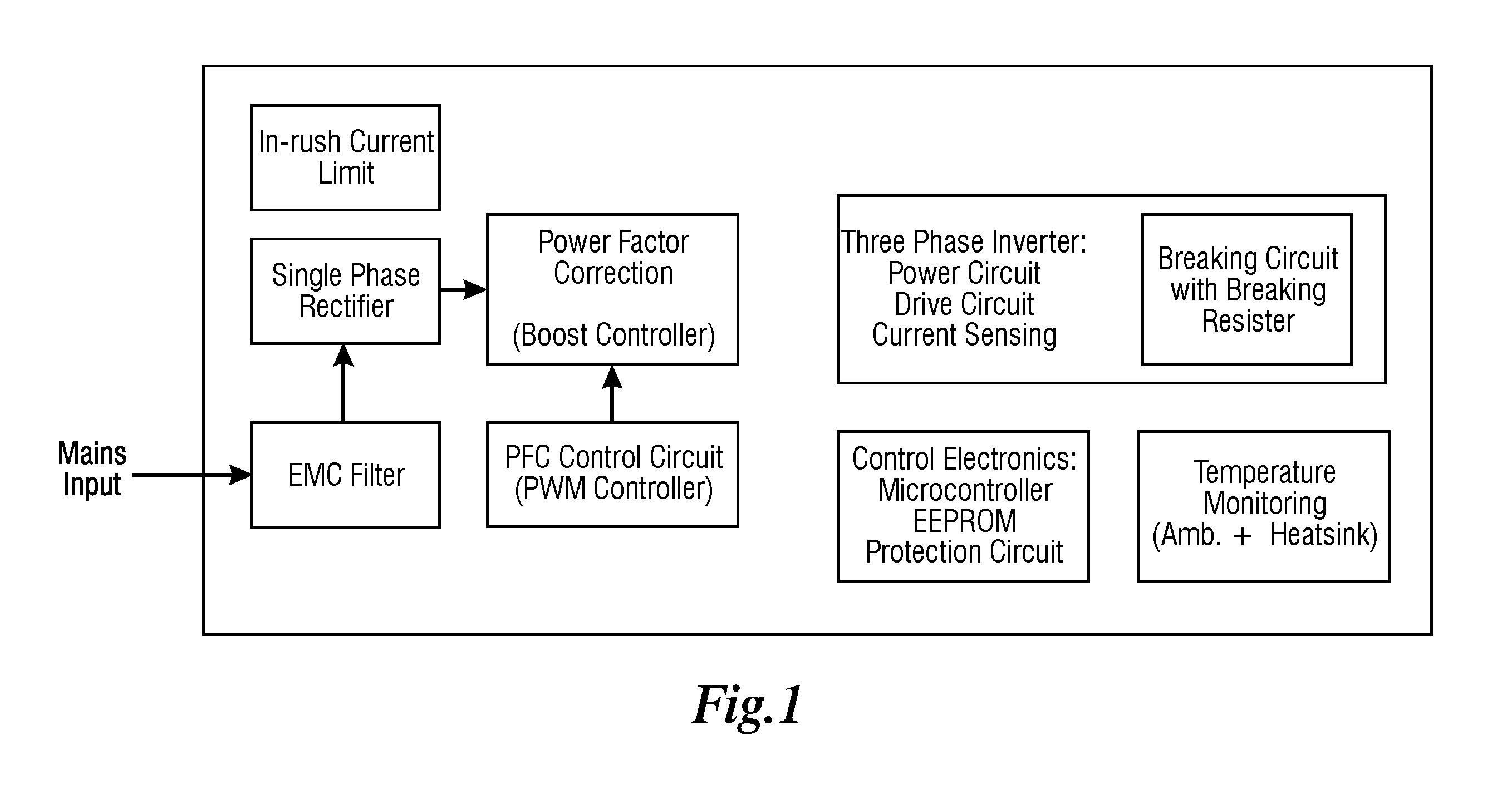

[0021]The invention encompasses several preferred embodiments of control electronics for brushless motors. The major building blocks of one preferred embodiment of the control electronics are shown in FIG. 1 and described below and in the parent patent applications that are incorporated herein by reference in their entirety.

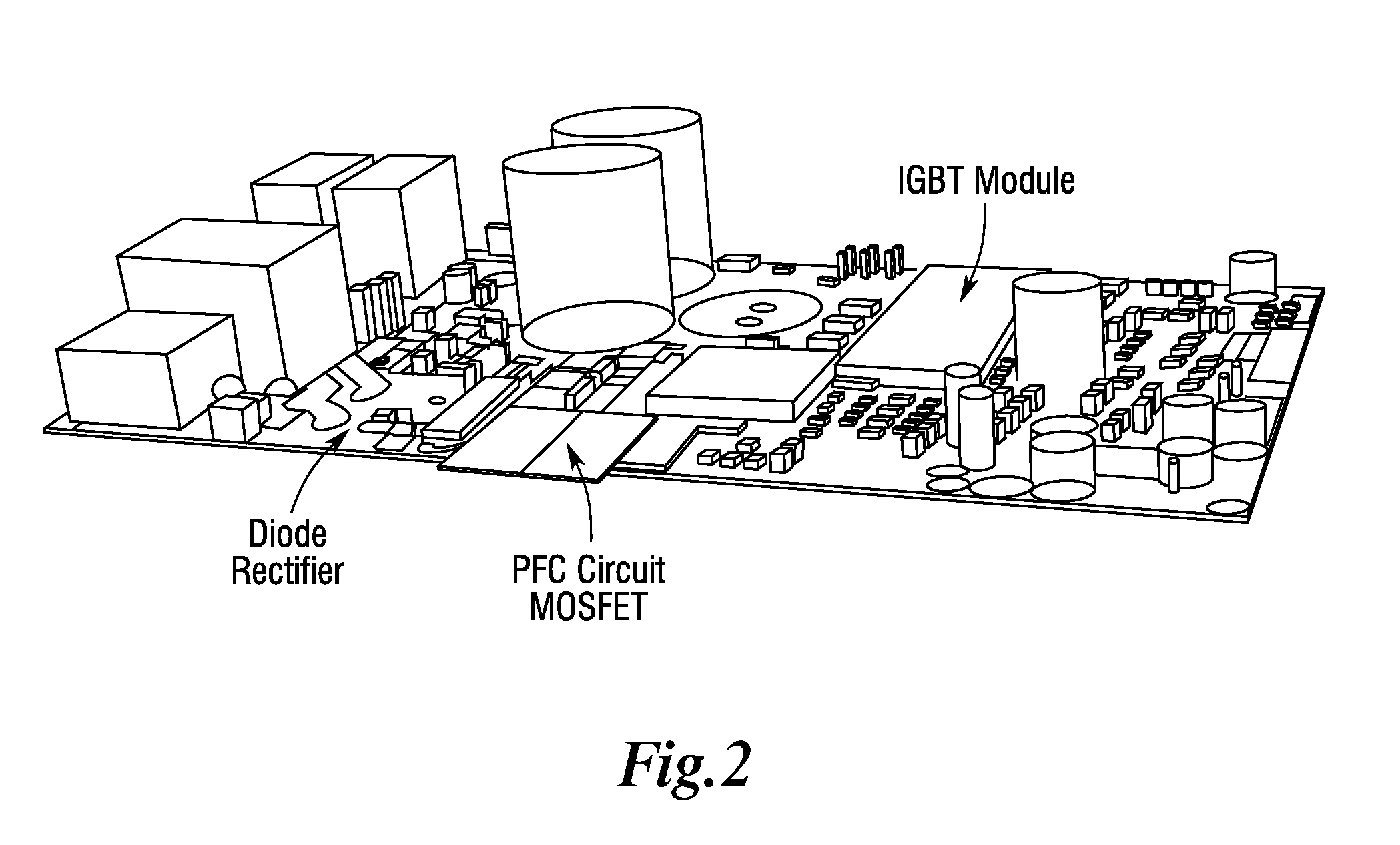

[0022]A very high power density is achieved by configuring all of the control electronics on a single printed circuit board. Optimally, the electronics are separated and divided into two parts. On the left side, there is input power control circuitry connected by a DC link to control circuitry and power output circuitry on the right side. A perspective view of an example layout implementation is shown in FIG. 2. The diode rectifier module, PFC Circuit MOSFET elements, and IGBT module dissipate the most amount of heat and the approximate location of these parts are shown in FIGS. 2 and 3. These parts are preferably located on the bottom side of the printed circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com