Terminally modified acrylic polymer and method for producing terminallly modified acrylic polymer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

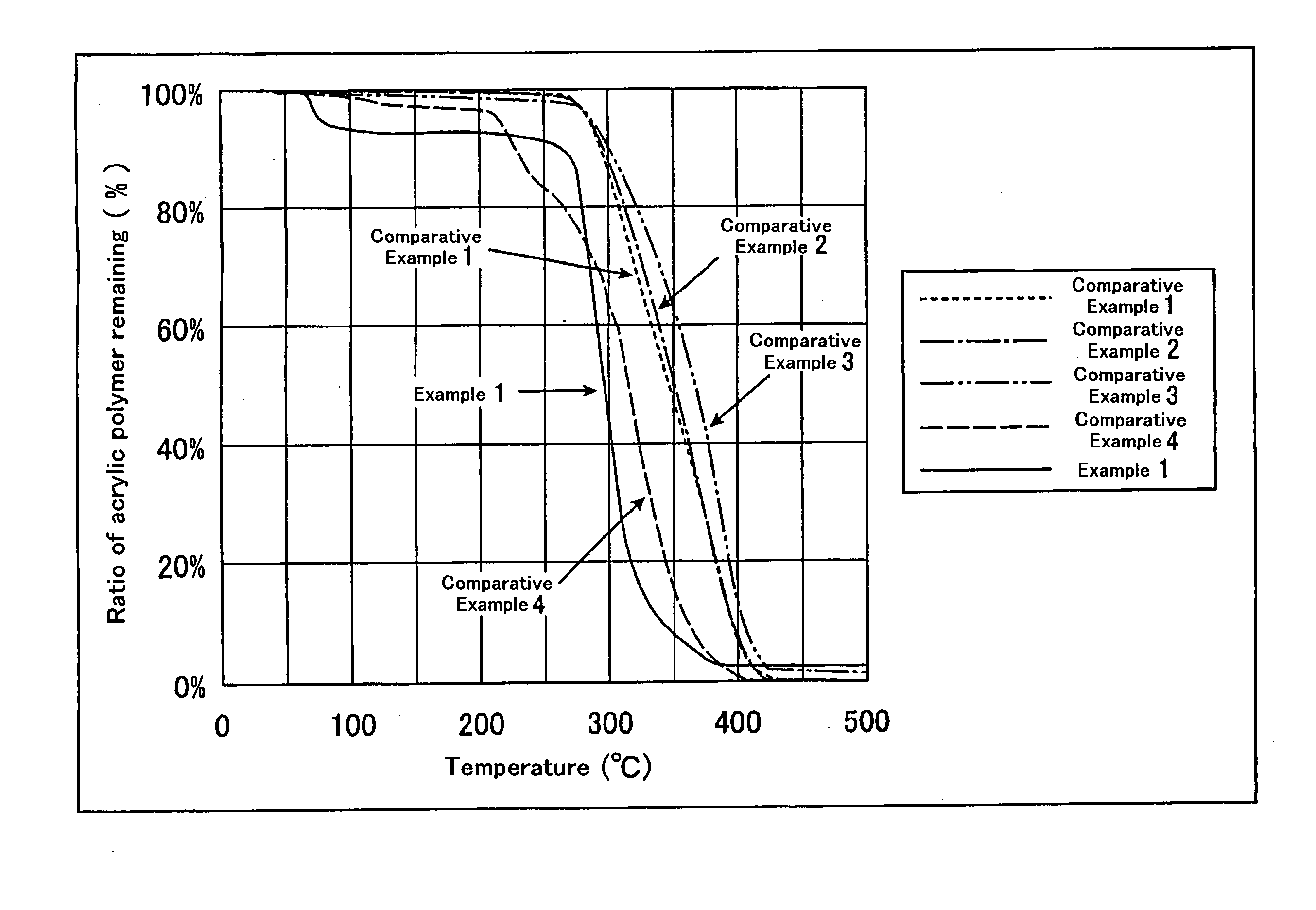

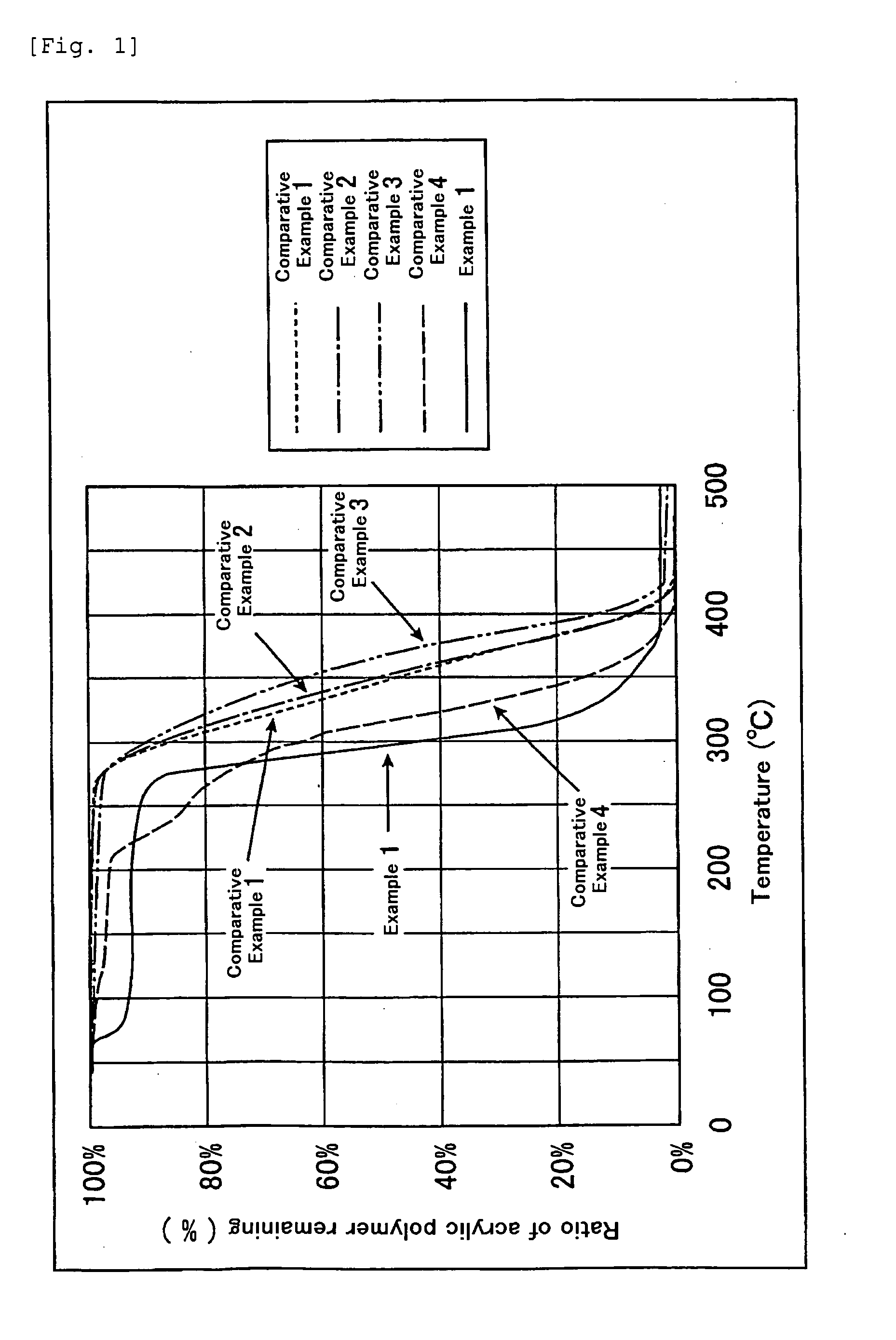

Image

Examples

example 1

(Production of Acrylic Polymer)

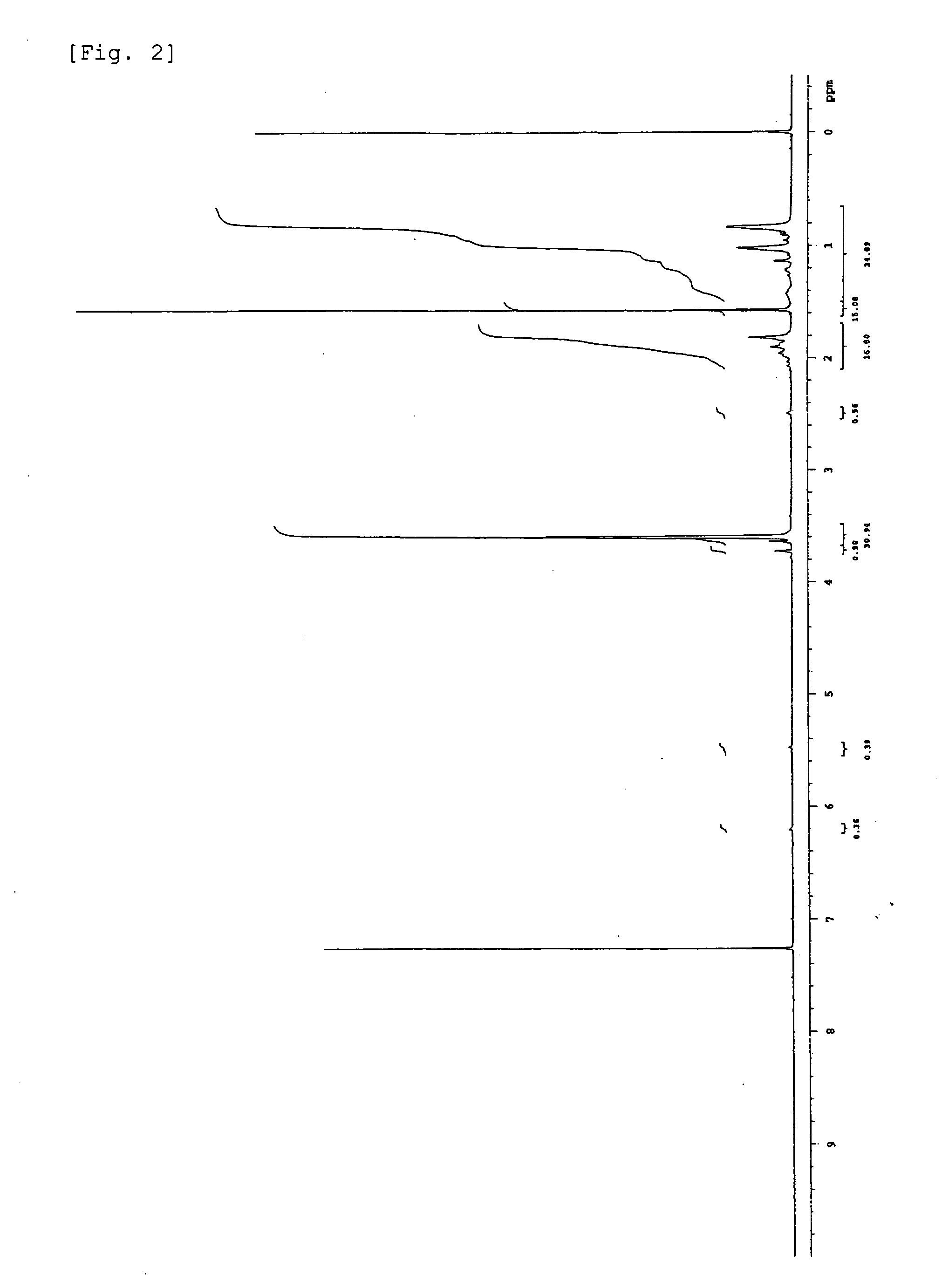

[0052]30 mol of methyl methacrylate (manufactured by Wako Pure Chemical Industries, Ltd.) as a monomer was added to 1 mol of an organic bismuth compound CH3C(CH3)(Bi(CH3)2)COOCH3 as a living radical polymerization initiator, and then, the resulting mixture was heated to 100° C. while stirring the mixture with a stirrer and maintained at this temperature for 3 hours. After the completion of a reaction, the reaction solution was dissolved in 15 mL of α,α,α-trifluorotoluene. To the resulting solution, 0.2 g of 2,2,6,6-tetramethylpiperidine 1-oxyl (TEMPO manufactured by Aldrich Chemical Co.) was further added and the resulting mixture was reacted at 80° C. for 1 hour. After the completion of a reaction, the resulting solution was charged into 250 mL of hexane (manufactured by Wako Pure Chemical Industries, Ltd.) being stirred. Thereafter, a precipitated polymer was filtered under suction and dried to obtain a terminally modified acrylic polymer (conversion...

example 2

(Production of Acrylic Polymer)

[0056]30 mol of isobutyl methacrylate (manufactured by Wako Pure Chemical Industries, Ltd.) as a monomer was added to 1 mol of an organic bismuth compound CH3C(CH3)(Bi(CH3)2)COOCH3 as a living radical polymerization initiator, and then, the resulting mixture was heated to 100° C. while stirring the mixture with a stirrer and maintained at this temperature for 3 hours. After the completion of a reaction, the reaction solution was dissolved in 15 mL of α,α,α-trifluorotoluene. To the resulting solution, 0.2 g of 2,2,6,6-tetramethylpiperidine 1-oxyl (TEMPO manufactured by Aldrich Chemical Co.) was further added and the resulting mixture was reacted at 80° C. for 1 hour. After the completion of a reaction, the resulting solution was charged into 250 mL of hexane (manufactured by Wako Pure Chemical Industries, Ltd.) being stirred. Thereafter, a precipitated polymer was filtered under suction and dried to obtain a terminally modified acrylic polymer (conversi...

example 3

(Production of Acrylic Polymer)

[0059]A mixture solution of 15 mol of isobutyl methacrylate (manufactured by Wako Pure Chemical Industries, Ltd.) and 15 mol of isobutyl methacrylate (manufactured by Wako Pure Chemical Industries, Ltd.) as a monomer was added to 1 mol of an organic bismuth compound CH3C(CH3)(Bi(CH3)2)COOCH3 as a living radical polymerization initiator, and then, the resulting mixture was heated to 100° C. while stirring the mixture with a stirrer and maintained at this temperature for 3 hours. After the completion of a reaction, the reaction solution was dissolved in 15 mL of α,α,α-trifluorotoluene. To the resulting solution, 0.2 g of 2,2,6,6-tetramethylpiperidine 1-oxyl (TEMPO manufactured by Aldrich Chemical Co.) was further added and the resulting mixture was reacted at 80° C. for 1 hour. After the completion of a reaction, the resulting solution was charged into 250 mL of hexane (manufactured by Wako Pure Chemical Industries, Ltd.) being stirred. Thereafter, a pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com