Spinal Intervertebral Disk Replacement Material for Nucleus Pulposus and Production Method Thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

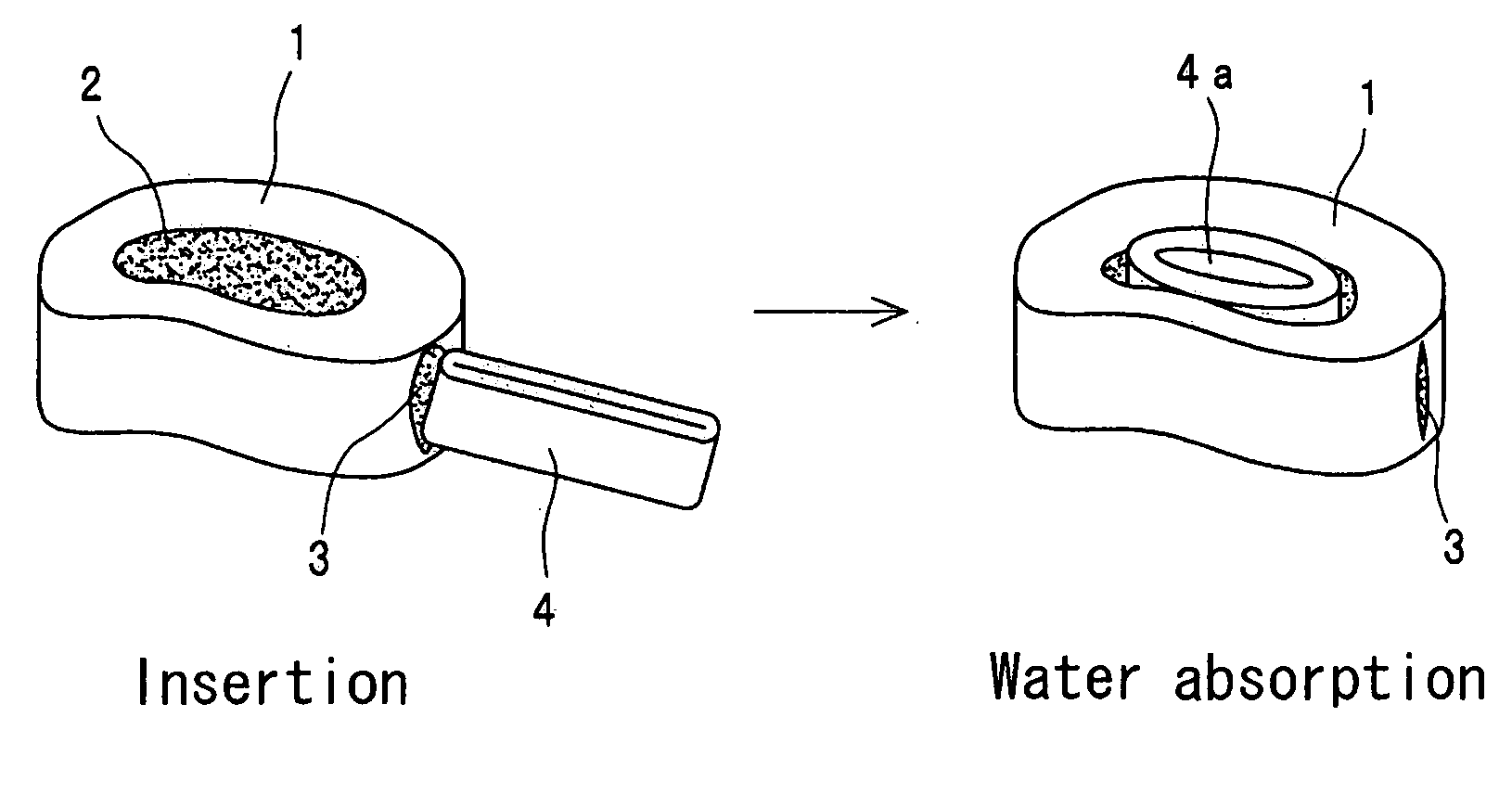

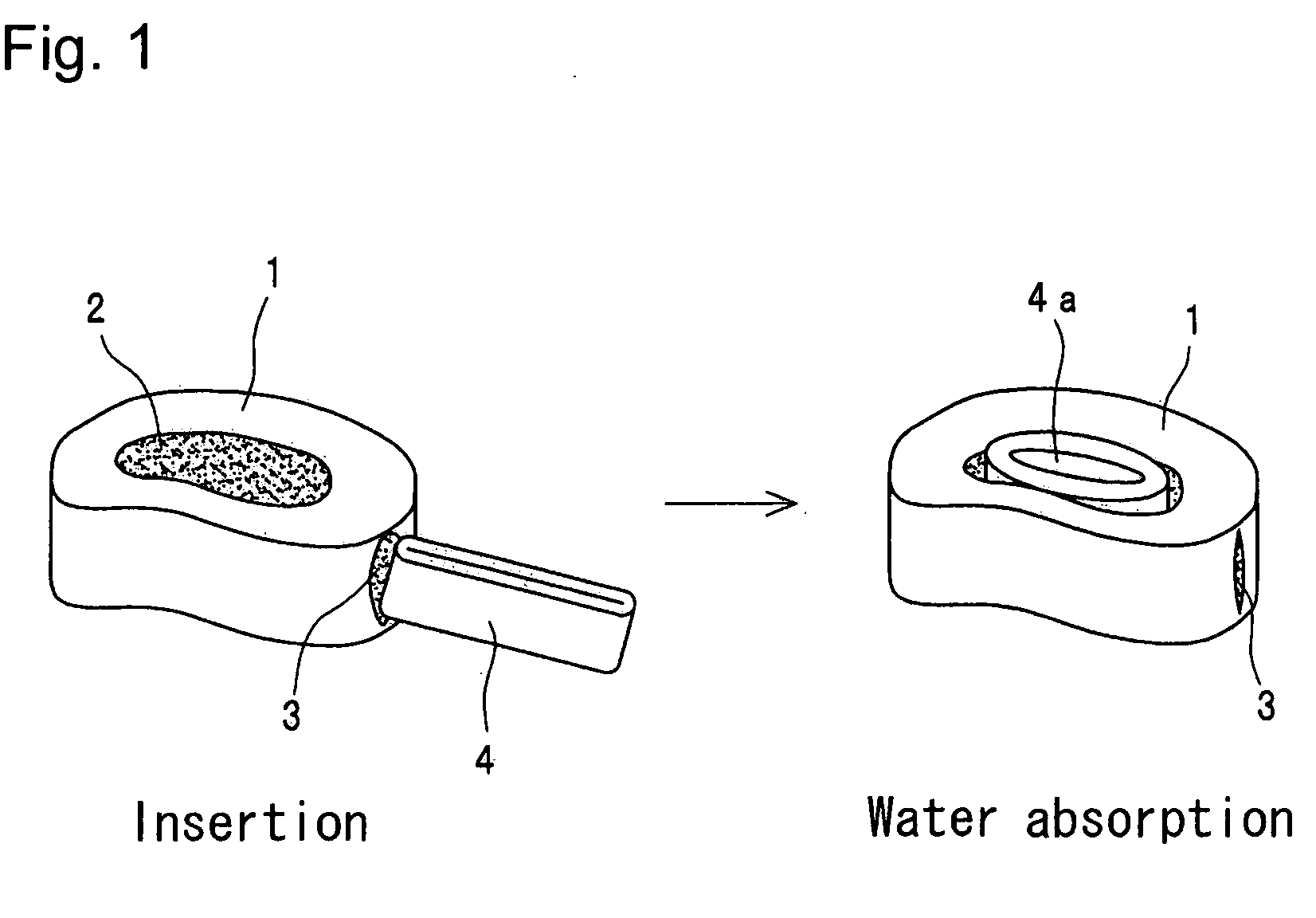

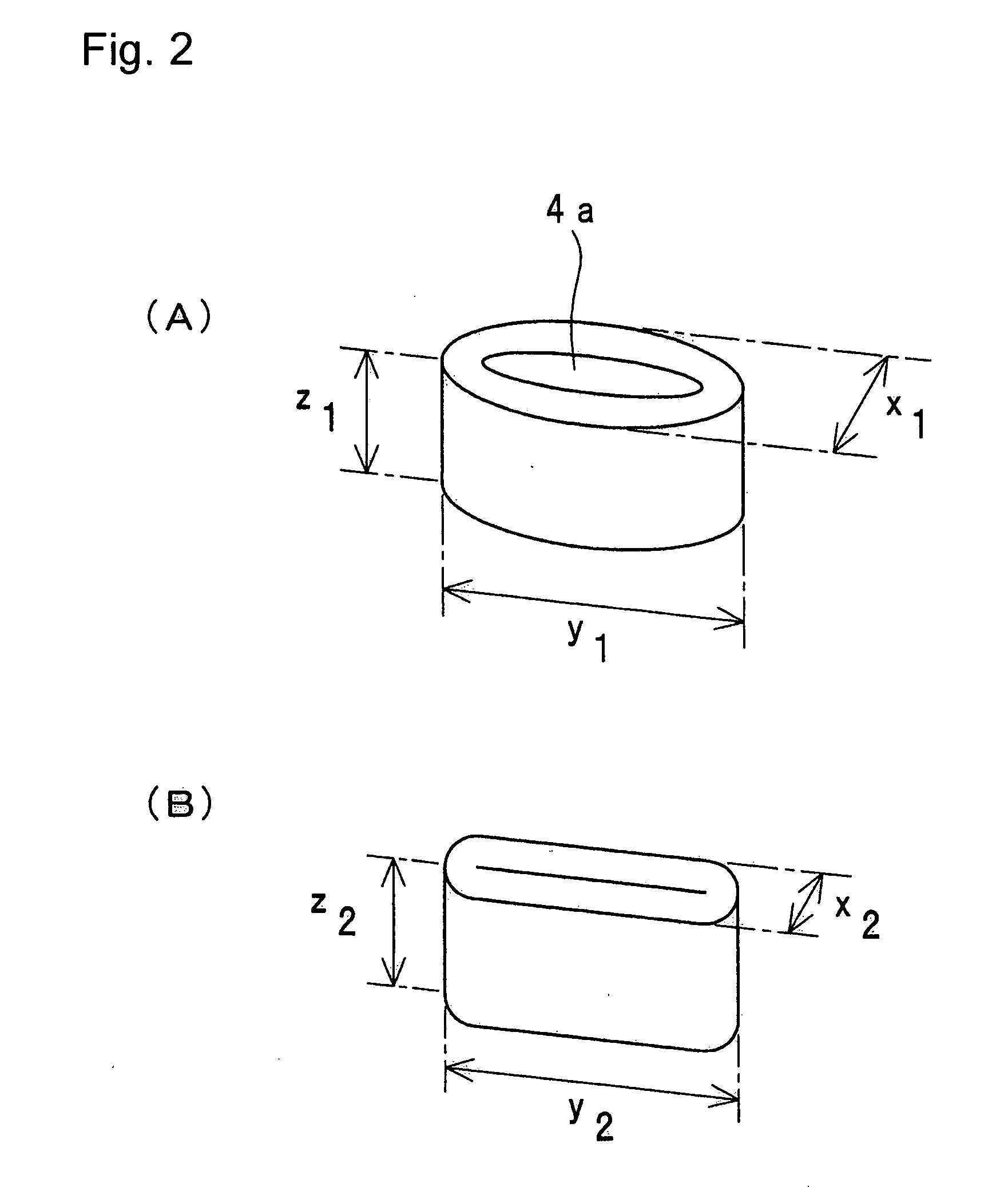

[0074]PVA (polymerization degree: 8800) (10 wt parts) was added to a mixture (90 wt parts) of dimethylsulfoxide (DMSO) and water at a weight ratio of 80:20, and the mixture was dissolved at 120 to 140° C., to give a PVA solution. The PVA solution was poured into a form giving a formed product in the hollow disk shape shown in FIG. 2(A), and then, the mold was rapidly cooled at −15° C. After rapid cooling, the PVA gel was removed from the mold and washed with ethanol for replacing DMSO and water with ethanol in the PVA gel. The PVA gel was then subjected to a vacuum heat treatment under a reduced pressure of 1 Torr at 140° C. for 3 hours. The PVA gel was immersed in nitrogen-substituted water for 48 hours or more for hydrogelation. The percentage of saturated water content of the PVA hydrogel was 35 wt %. The PVA hydrogel with the shape shown in FIG. 2(A) was obtained by γ-ray irradiation to the PVA hydrogel in nitrogen-substituted water of low oxygen concentration at an irradiation ...

example 2

[0081]PVA (polymerization degree: 8800) (10 wt parts) was added to a mixture (90 wt parts) of dimethylsulfoxide (DMSO) and water at a weight ratio of 80:20, and the mixture was dissolved at 120 to 140° C., to give a PVA solution. The PVA solution was rapidly cooled at −15° C. Then, the PVA gel was washed with ethanol, replacing DMSO and water with ethanol in the PVA gel, and the resulting gel was subjected to a vacuum heat treatment under a reduced pressure of 1 Torr at 60 to 140° C. The PVA gel was soaked in nitrogen-substituted water for 48 hours or more for hydrogelation. In this way, PVA hydrogels having a percentage of saturated water content of 20, 25, 30, 35, 50 and 60 wt % were prepared. PVA hydrogel having a percentage of saturated water content of 15 wt % was prepared only unsuccessfully, because of low reactivity in thermal condensation polymerization, and it was difficult to prepare a hydrogel with a desired water content. The PVA hydrogel obtained was molded into a cyli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Irradiation dose | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com