Cr-Al-Steel for High-Temperature Application

a technology of cr-al-steel and high-temperature application, which is applied in the field of cr-al-steel for high-temperature application, can solve the problems of considerable deformation, mechanical weakness, and great disadvantage of conventional fe—cr-al-alloys, and achieve the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0057]Table 1 shows compositions of examined alloys. Example C and comparative example 1 were prepared in the conventional way by pyrometallurgy and hot working. From comparative example 1, 50 μm thick strips were also prepared via hot rolling and cold rolling. Comparative example 1 is an alloy that today is used as supporting material in catalytic converters. This material has sufficient oxidation resistance for this use. However, the mechanical strength thereof is low and is regarded to be the limiting factor of the service life of the entire device.

[0058]The very low ductility at room temperature (2% elongation at fracture) of the alloy according to example C entails that this alloy hardly can be manufactured in the form of thin strips. However, the same alloy has, as is seen in table 1, a very good high temperature strength, thus at 700° and 900° C. the ultimate strength, for instance, is approx. 100% higher than for comparative example 1. The oxidation resistance of example C a...

example 2

[0059]Table 1 shows compositions of examined alloys. Examples A and B and comparative examples 1 and 2 were prepared in the conventional way by pyrometallurgy and hot working. Then 50 μm thick strips of all alloys were also prepared via hot rolling and cold rolling. The alloys according to examples A and B are all sufficiently ductile at room temperature in order to be able to be cold-rolled to very thin strips of good productivity.

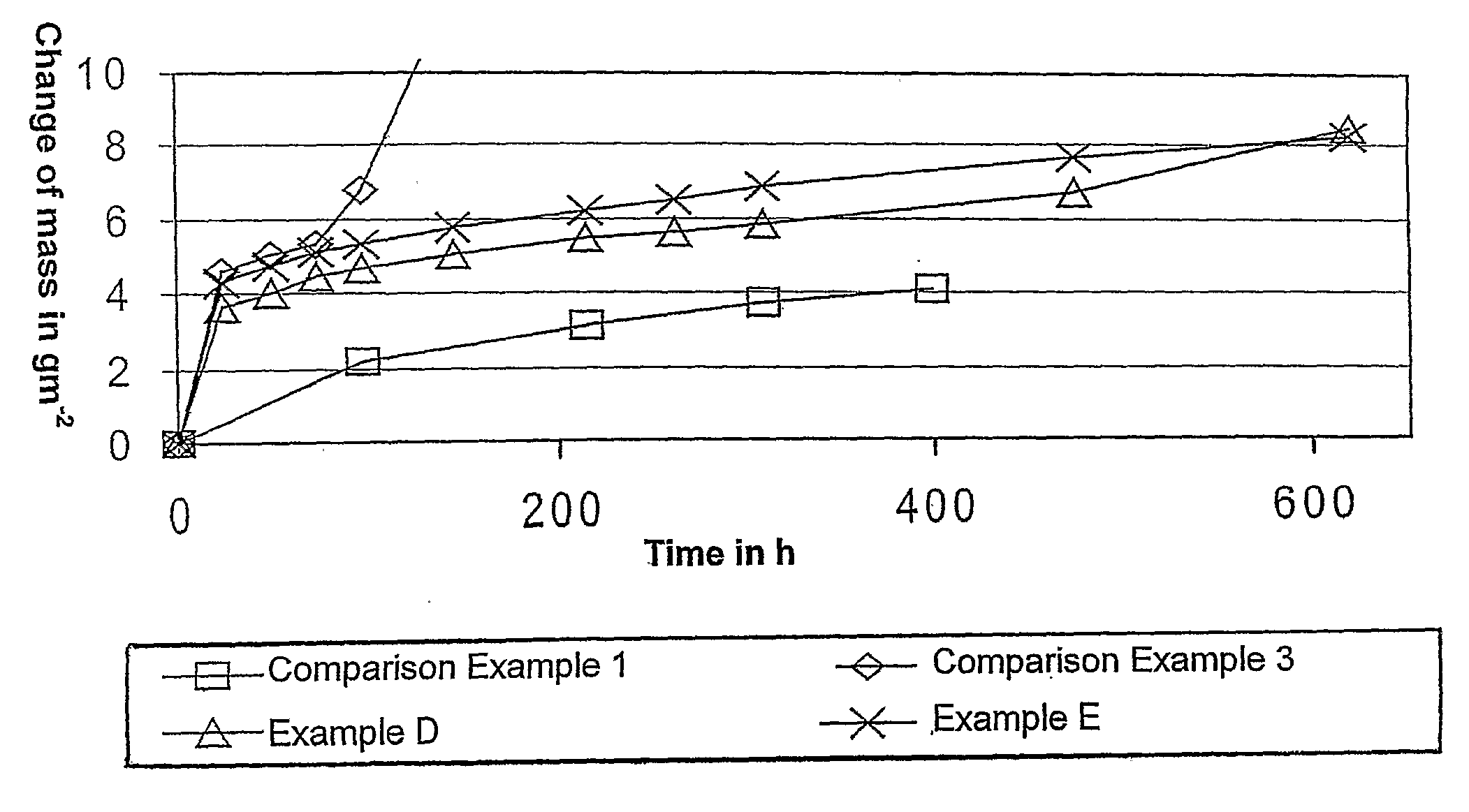

[0060]Examples D and E and comparative example 3 correspond to cold-rolled strips of alloy according to examples B and C and comparative example 2, respectively, which was coated by vaporization or sputtering with Al on both sides in such a quantity that the total content of Al corresponded to 5.5-6% (see table 3).

TABLE 3Thick-nessCoatedDesiredMeasuredSub-beforethickness oftotal con-coatingstratecoatingcoated Altent of AlthicknessExamplealloy[μm]alloy [μm][%][μm]DA5056EB50464.1ComparativeCf.50564.7example 3example2

[0061]The obtained thickness of Al was me...

example 3

[0062]Examples F and G and comparative example 4 have the same composition as the alloys according to examples D and E and comparative example 3 having been annealed at 1050° C. for 10 min with the purpose of providing an equalising of the content of Al in the material. The ductility of the material was determined by a bending test where the smallest bending radius that the material could be bent to without fracture was determined, see table 4.

TABLE 4SmallestResults ofDiffusion an-bendingtensile testingEx-nealing in H2radius withoutat 900° C.ampleComposition[min / 1050° C.]fracture [mm][Rm / MPa]FThe same as100.546example DGThe same as100.3881example ECom-The same as102.5could not beparativecomparativemeasured dueexampleexample 3to brittleness4

[0063]The smallest radius that the material was tested at was 0.38 mm. The alloys according to the invention have a ductility being superior to comparative example 4. The alloy according to comparative example 4 proved to be so brittle that this a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com