Phosphorus-sulfur FR additives and polymer systems containing same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

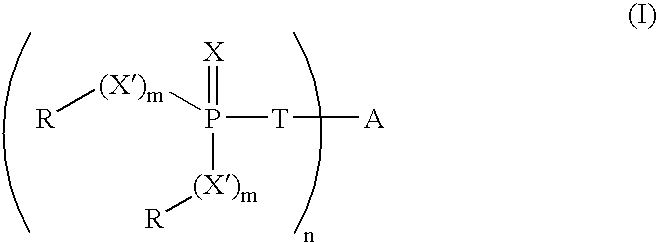

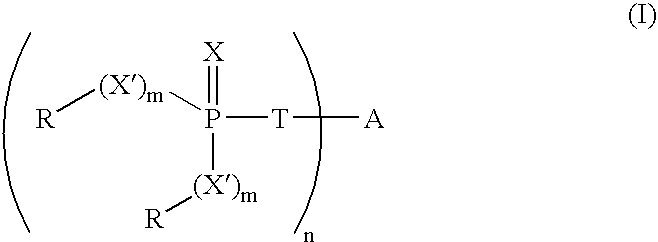

Method used

Image

Examples

example 1

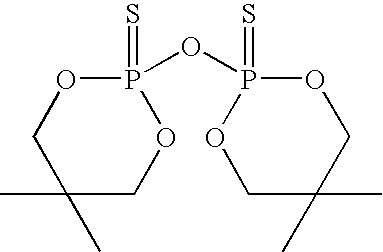

[0065]To a stirred solution of 5,5-dimethyl-2-thioxo-[1,3,2]dioxaphosphorinane-2-thiol (10.0 g, 50 mmol) in toluene (70 mL) is added triethylamine (5.0 g, 50 mmol), to form the trimethylammonium salt. The mixture is warmed to 45° C. To the resulting mixture is added 1,4-dibromobut-2-ene (5.34 g, 25 mmol) and the mixture is heated at reflux for 1 hour. The solution is then washed with saturated aqueous sodium bicarbonate solution (50 mL), dried over anhydrous magnesium sulfate and concentrated under reduced pressure to yield a white solid. The crude product is slurried in ethanol (40 mL) and filtered to yield 8.7 g (80%) of a white solid, 2,2′-[2-butene-1,4-diylbis(methylthio)]bis[5,5-dimethyl-1,3,2-dioxaphosphorinane]-2,2′-disulfide, having the structure:

[0066]The thermal stability of the 2,2′-[2-butene-1,4-diylbis(methylthio)]bis[5,5-dimethyl-1,3,2-dioxaphosphorinane]-2,2′-disulfide is evaluated by thermogravimetric analysis as described before. The sample exhibits a 5% WLT of 241°...

example 2

[0071]A mixture of N,N-diethylethanaminium, 5,5-dimethyl-1,3,2-dioxaphosphorinane-2-thiolate-2-oxide (7.5 g, 27 mmol) and 1,4-dibromobutene (2.84 g, 13.2 mmol) is slurried in 50 mL of ethanol and refluxed for 5 hours. The reaction mixture is cooled and concentrated under reduced pressure. The resulting residue is dissolved in methylene chloride (100 mL), washed with water (40 mL), dried and concentrated to yield 3.60 g (66%) of white solid, 2,2′-[2-butene-1,4-diylbis(methylthio)]bis[5,5-dimethyl-1,3,2-dioxaphosphorinane]-2,2′-dioxide, having the structure:

[0072]The 5% WLT for this material is 255° C. Plaques made from a blend of 4% of the product in 96% polystyrene have an LOI of 22% and an FP-7 value of 5.7 s.

example 3

[0073]To a stirred solution of the ammonium salt of dithiophosphoric acid O,O-diethyl ester (15.8 g, 78 mmol) in ethanol (130 mL) at 80° C. is added 1,4-dibromo-2-butene (7.55 g, 35 mmol) in portions. The resulting mixture is cooled, diluted with water (150 mL) and extracted with methylene chloride (3×100 mL). The organic layer is dried over anhydrous magnesium sulfate, filtered and concentrated under reduced pressure to yield 15 g (99%) of S-[4-(diethoxy-thiophosphorylsulfanyl)-but-2-enyl]dithiophosphoric acid O,O′-diethyl ester, having the structure:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Structure | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com