Exterior coatings for golf balls

a golf ball and outer coating technology, applied in the field of golf balls, can solve the problems of insufficient surface area increase, uneven surface, and reducing desirable surface area, and achieve the effect of greatly reducing the cost of coating application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example one

[0084] Deposition of a Silicon Oxide Layer Having a Controlled Number of OH Reactive Sites Available on the Oxide Layer Surface

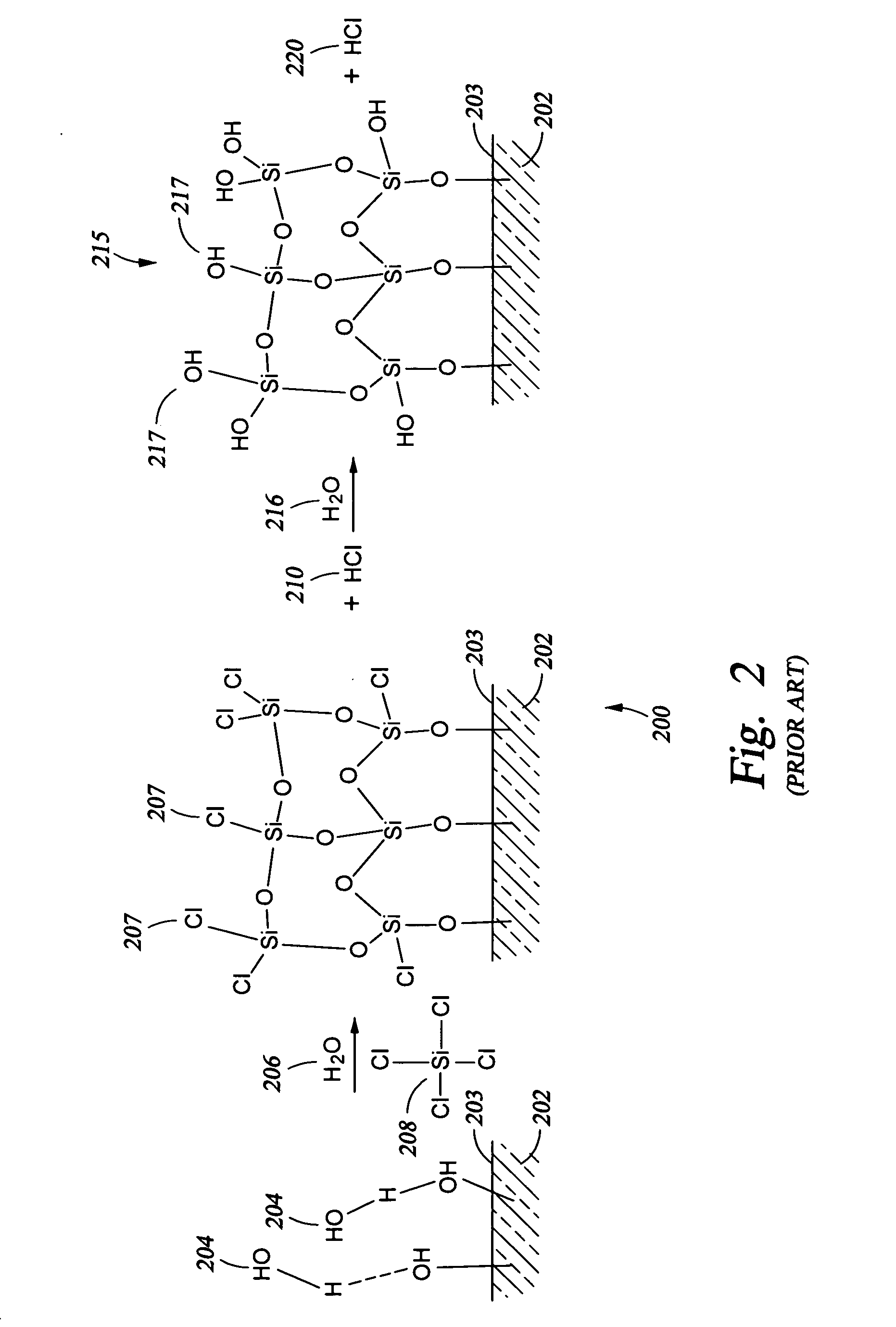

[0085]FIG. 2 shows a schematic 200 of the mechanism of bonding oxide layer formation. In particular, a substrate 202, plasma-cleaned golf ball layer surface, for example, may have some OH groups 204 present on the surface 203. A chlorosilane 208, such as the tetrachlorosilane shown, and water 206 are reacted with the OH groups 204, either simultaneously or in sequence, to produce the oxide layer 205 shown on surface 203 of substrate 202 and byproduct HCl 210. In addition to chlorosilane precursors, chlorosiloxanes, fluorosilanes, and fluorosiloxanes may be used to provide the oxide bonding layer.

[0086] Subsequently, the surface of the oxide layer 205 can be further reacted with water 216 to replace C1 atoms on the upper surface of oxide layer 205 with OH groups 217, to produce the hydroxylated layer 215 shown on surface 203 of substrate 202 and byproduct H...

example two

[0087] To evaluate process parameters useful in preparation of a silicon oxide bonding layer, silicon oxide layers were applied over a glass substrate. The glass substrate was treated with an oxygen plasma in the presence of residual moisture which was present in the process chamber (after pump down of the chamber to about 20 mTorr) to provide a clean surface (free from organic contaminants) and to provide the initial OH groups on the glass surface.

[0088] Various process conditions for the subsequent reaction of the OH groups on the glass surface with vaporous tetrachlorosilane and water are provided below in Table I, along with data related to the thickness and roughness of the oxide coating obtained and the contact angle (indicating hydrophobicity / hydrophilicity) obtained under the respective process conditions. A lower contact angle indicates increased hydrophilicity and an increase in the number of available OH groups on the silicon oxide surface.

TABLE IDeposition of a Silico...

example three

[0092] In the preferred embodiment discussed in detail below, the silicon oxide bonding layer was applied over golf ball having a polymeric cover layer of ionomer, which exhibited a contact angle coming out of the box which ranged between about 80° and about 90°. The golf ball was wiped with isopropyl alcohol to remove any grease or oils present on the golf ball surface. The golf ball surface was then treated with an oxygen plasma in the presence of residual moisture which was present in the process chamber (after pump down of the chamber to about 20 mTorr) to provide a clean surface (free from organic contaminants) and to provide the initial OH groups on the golf ball surface. In a process chamber of the kind described above, the flow rate of oxygen was about 400 sccm, and the RF power applied to create the plasma was about 200 W, with the exposure time of the golf ball being about 5 minutes at 35° C.

[0093] A silicon oxide coating of the kind described above was applied over the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com