Boat control system

a control system and boat technology, applied in the field of boat control system, can solve the problems of severe damage, long operating hours, and the scope of the main engine of the boat to accomplish, and achieve the effects of low trolling speed, long operating hours, and fuel efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

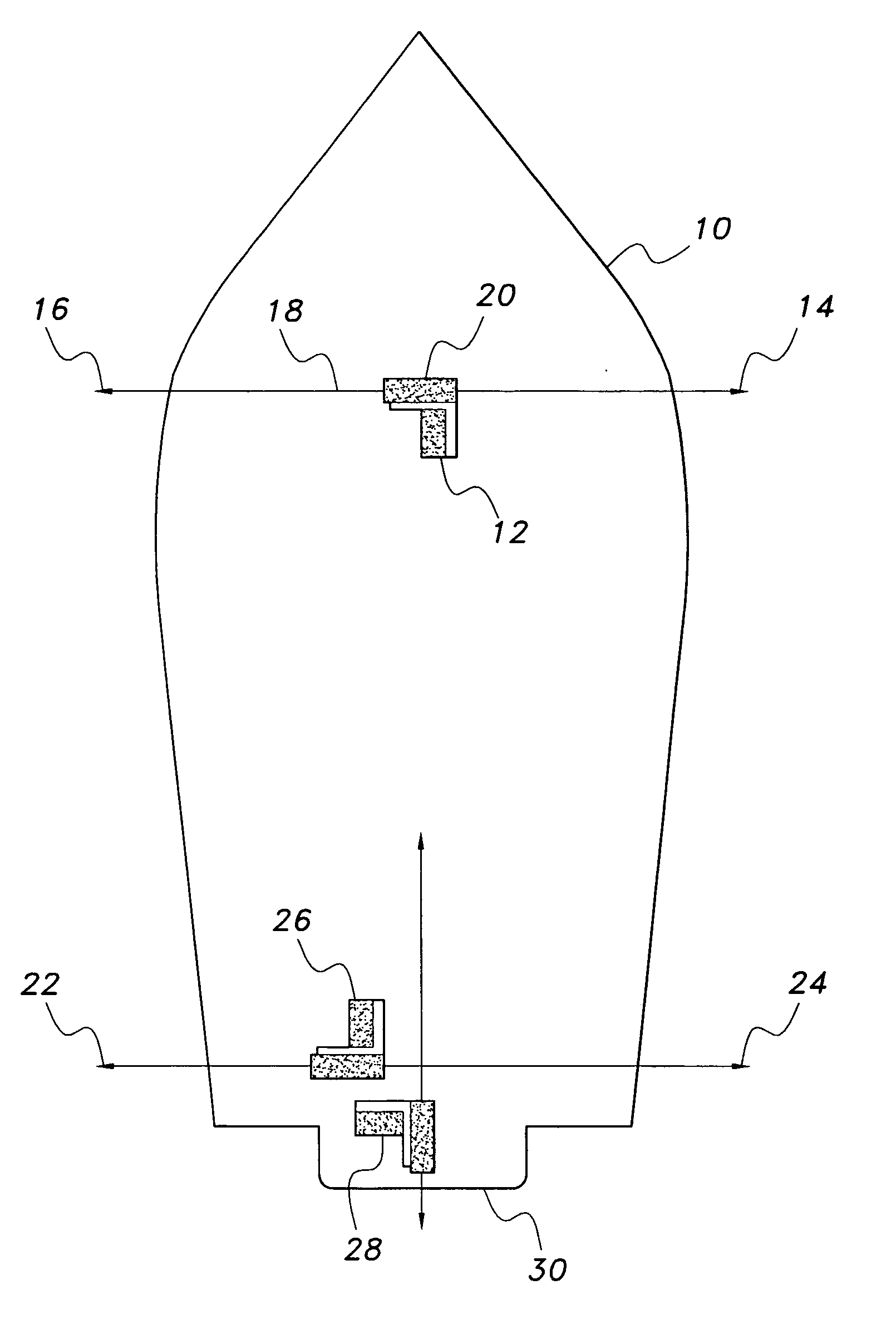

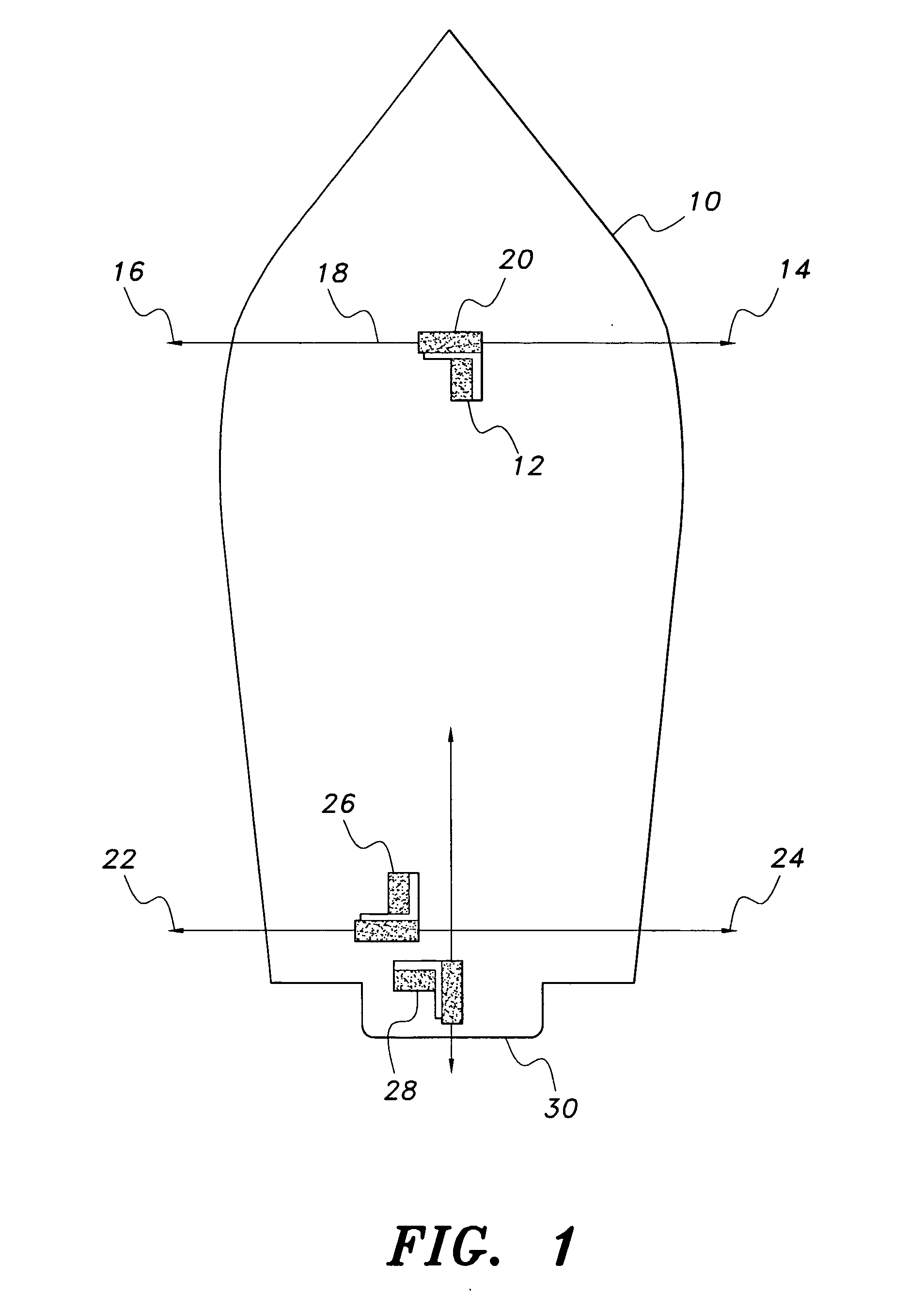

[0035] Referring to FIG. 1, a diagrammatic top view is presented showing the general shape of a boat 10. The bow thruster impeller pump 20 and reversible electric motor 12 are installed in the hull centered between the hull sides. The bow thruster nozzles 14 and 16 are connected to the pump 20 by flexible piping 18. The stern side lateral thrusters 22 and 24 and reversible electric motor and impeller pump 26 are installed in the hull close to the centerline of the hull. The forward and reverse unit, comprising the reversible electric motor and water impeller pump 28, is installed in the center line of the hull next to the transom 30, with one thruster nozzle installed on the stern and connected to the pump 28. The forward thruster nozzle is pointed obliquely down and to the rear into the seawater.

[0036] The system illustrated in FIG. 1 offers 360° thrust angles, including true straight lateral movement. The thruster units are controlled by one 3-axis joystick.

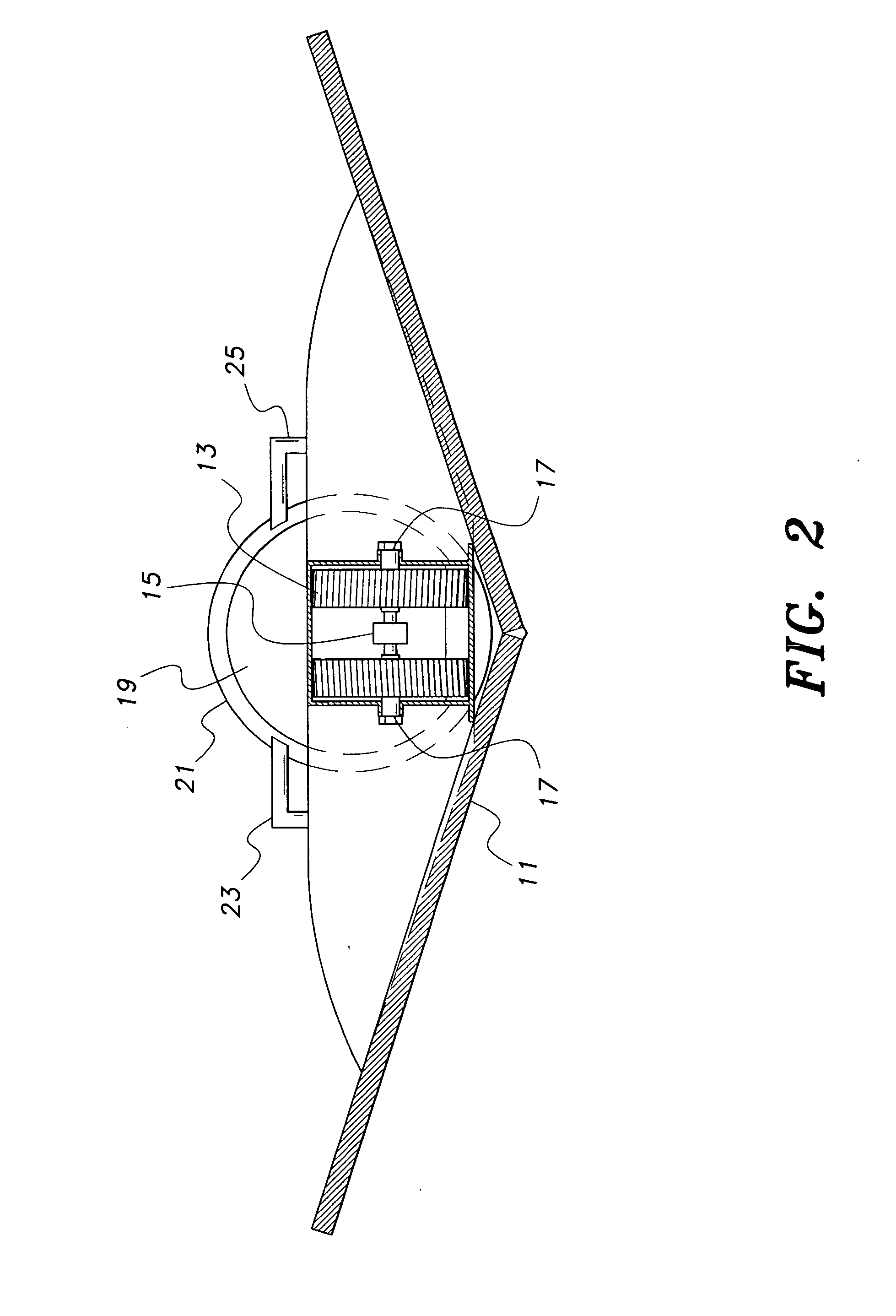

[0037] Referring to F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com