Copper strike plating method

a technology of copper strike and copper plate, which is applied in the direction of semiconductor devices, semiconductor element details, electrical apparatus, etc., can solve the problems of lead frame mechanical characteristics such as press working performance, lead frame damage, etc., and achieve the effect of shortening the pretreatment steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0064] The lead frame was obtained as the substrate by applying the press working to the stripe member made of the Cu—Ni—Si alloy (Corson alloy) that contains Mg at 0.15 wt %. Then, the heat treatment was applied to remove the machining distortion of the lead frame. Then, only the alkaline degreasing process and the electrolytic activating process were applied to this lead frame.

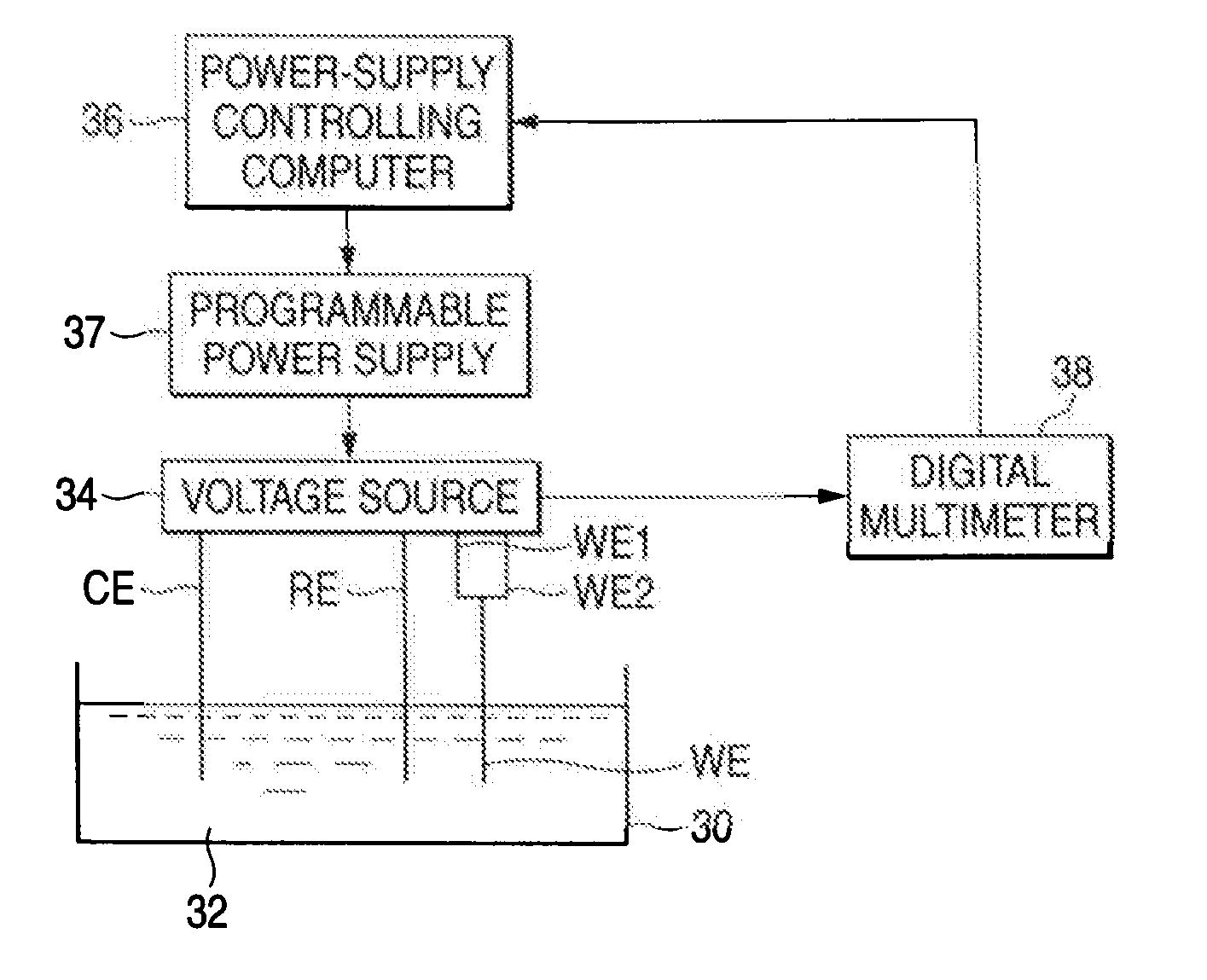

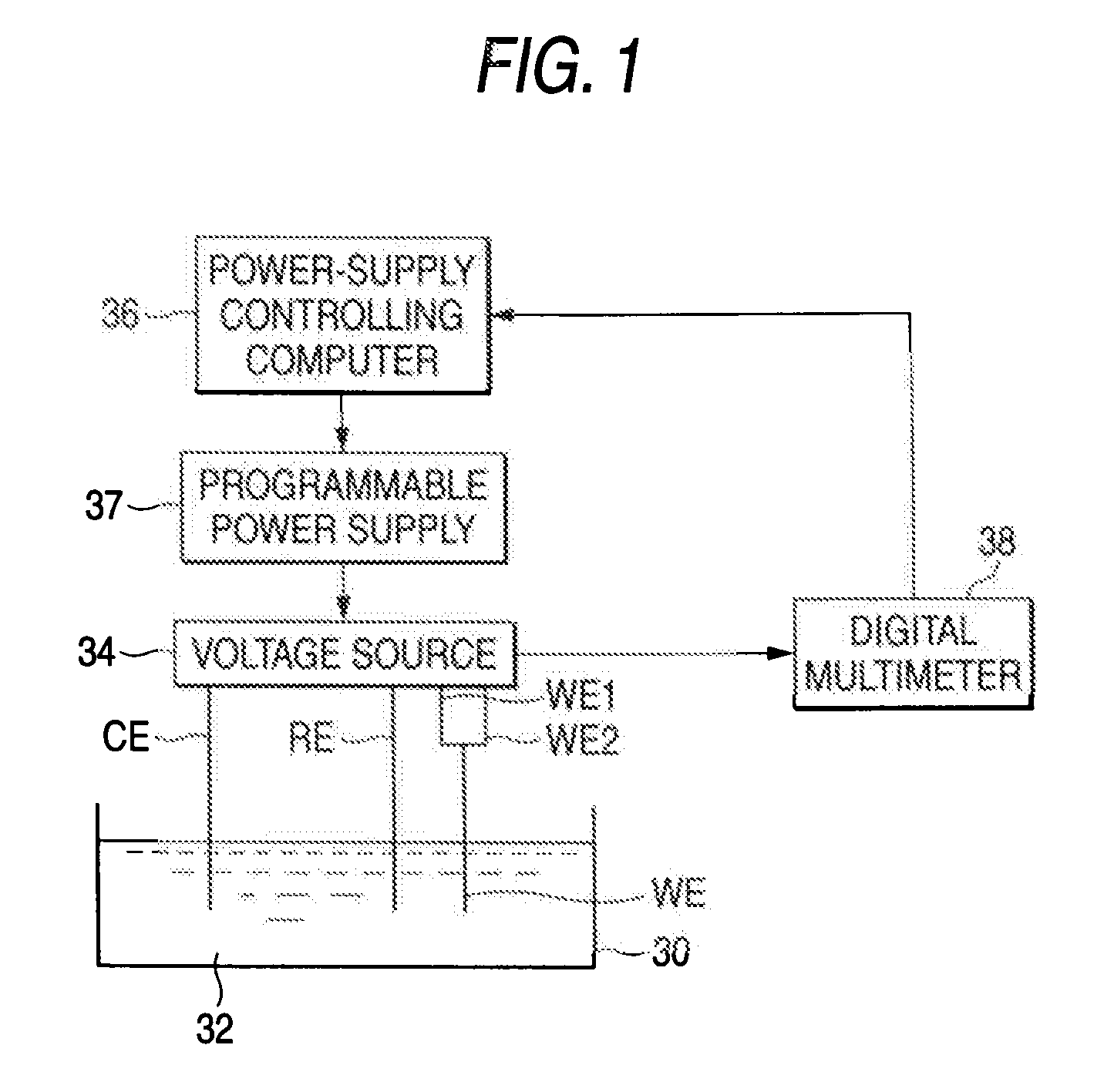

[0065] Then, while using the electrolytic copper plating equipment shown in FIG. 1, the lead frame was inserted as the substrate WE into the plating tab 30 in which an electrolytic copper plating solution is accumulated, and then the copper strike plating was applied to the surface of the lead frame by applying the pulse current.

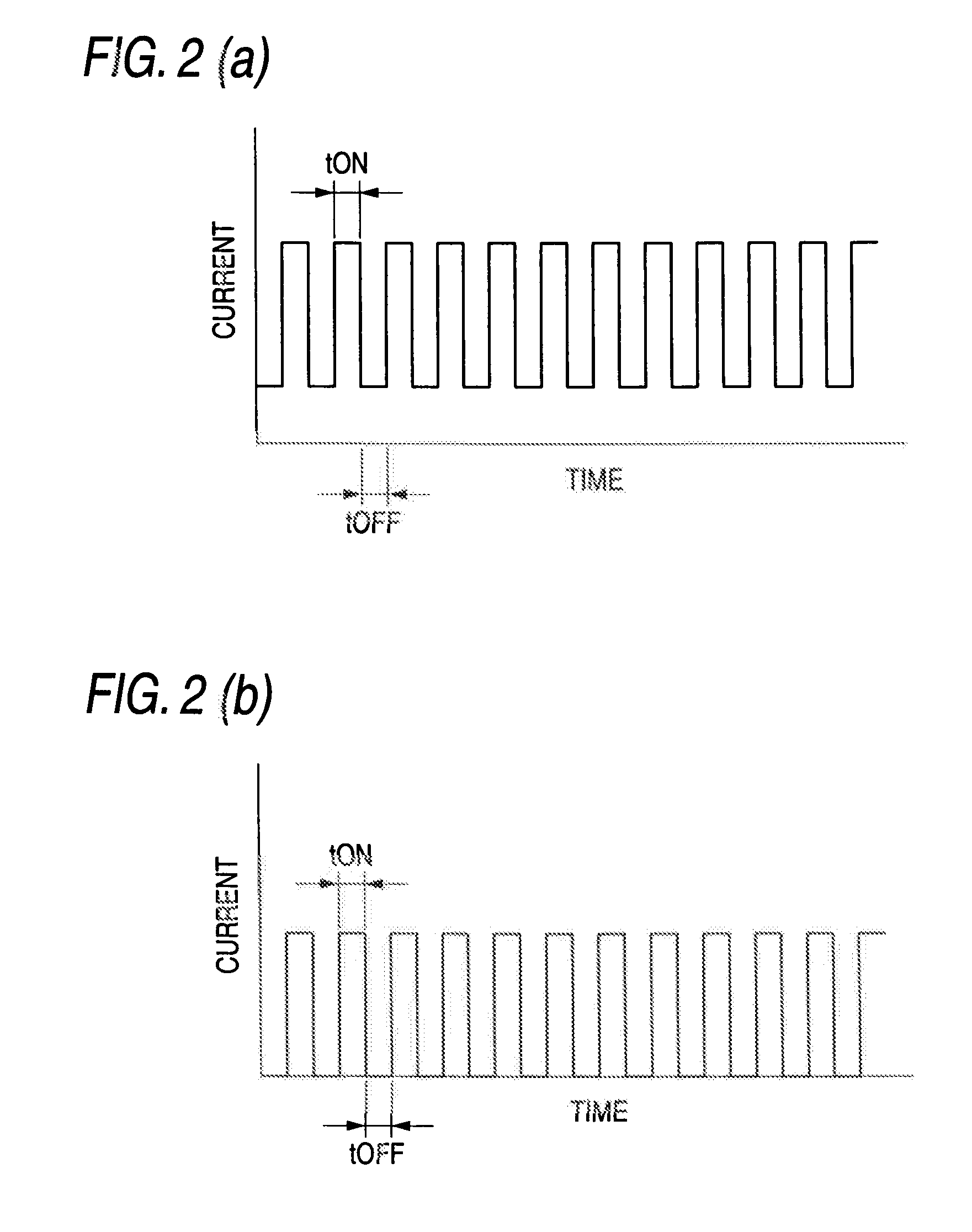

[0066] In the copper strike plating at this time, a pulse period of the pulse current was set to 100 Hz and also an average current density (C.D.) was set to 7 A / dm2. Then, the copper strike plating layer of 0.5 μm thickness was formed while changing the duty ratio from 0.2 to 1.0....

example 2

[0070] In Example 2, the copper strike plating and the electrolytic silver plating were applied in the similar manner to Example 1 except that the pulse period was changed as shown in Table 2 while keeping the duty ratio at 0.4. The results of the visual observation about the appearance of the copper strike plating layer and the appearance of the silver plating layer and occurring extents of nodule (surface roughness), level difference, and unevenness of gloss indicating the Ag anomalous deposition are also given in Table 2. In Table 2, ◯ denotes good, Δ denotes that the anomalous deposition was recognized slightly, and X denotes that the anomalous deposition was recognized.

TABLE 2Ag Anomalous DepositionPeriodAppearanceAppearanceUn-No.(Hz)of Cu layerof Ag layerNoduleL.D.evenness11◯◯◯◯◯210◯◯◯◯◯3100◯◯◯◯◯41000◯◯◯◯◯

[0071] As apparent from Table 2, even though the polishing was not applied to the lead frame that was subjected to the heat treatment, the good copper strike plating layer ...

example 3

[0074] In Example 3, the plating was applied to the lead frame by setting other conditions similarly to Example 1 except that the copper strike plating layer of 0.1 μm thickness was formed by applying the copper strike plating under conditions that the pulse period of the pulse current supplied to the lead frame was set to 100 Hz, the average current density (C.D.) was set to 7 A / dm2, and the duty ratio was set to 0.4 and that the silver plating layer of 3 to 5 μm thickness was formed on this copper strike plating layer by the electrolytic silver plating.

[0075] Then, a copper oxide film was formed on the lead frame that was subjected to the plating under the heating condition given in Table 3, and then a tape peeling test to check whether or not the plating layer is peeled off was executed by peeling off an adhesive tape stuck on the lead frame. In this manner, the adhesiveness of the copper strike plating layer to the oxide film was evaluated. The results of the evaluation are als...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| average current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com