Method of manufacturing nitride semiconductor light emitting diode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

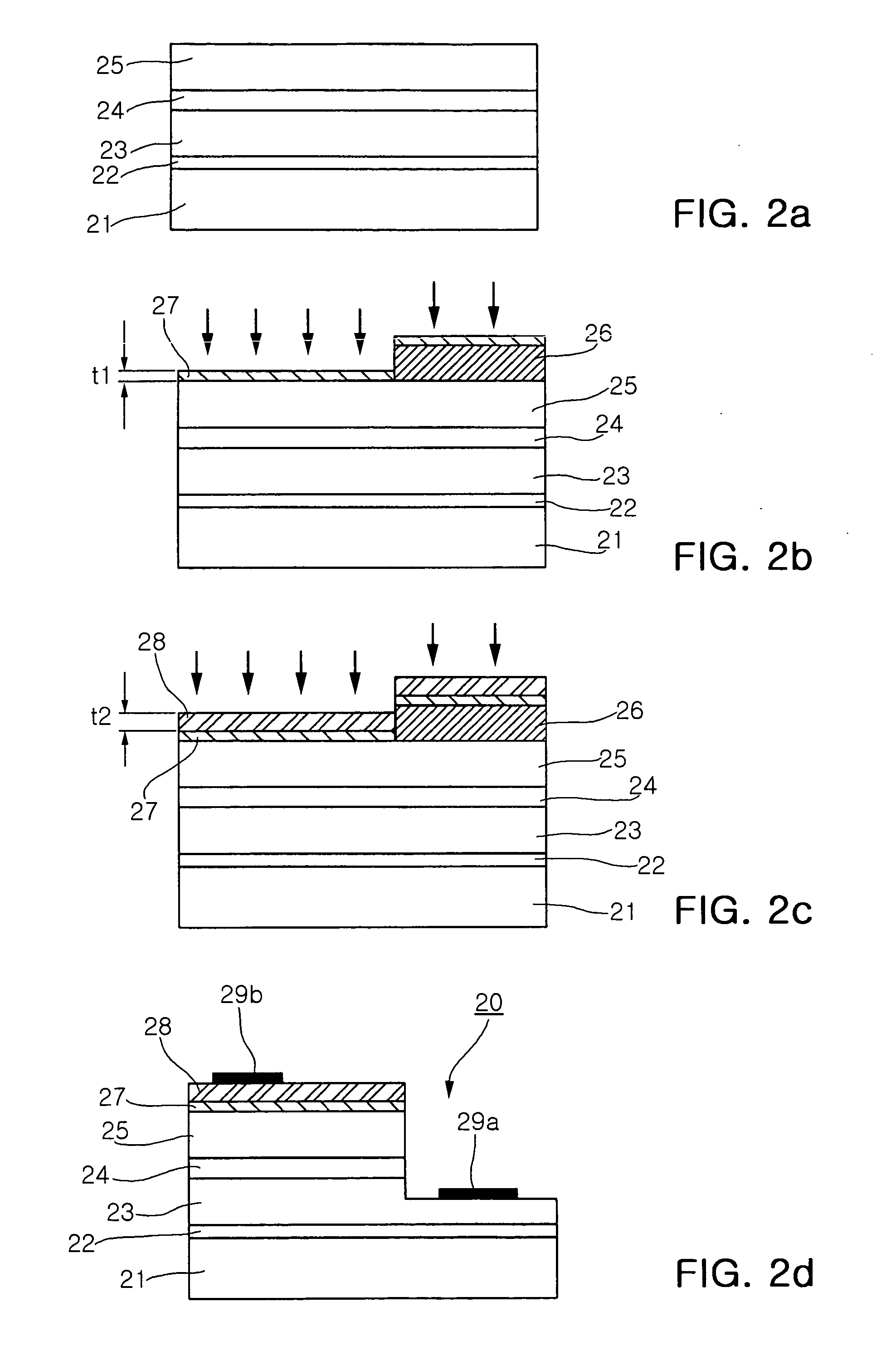

[0025] Preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

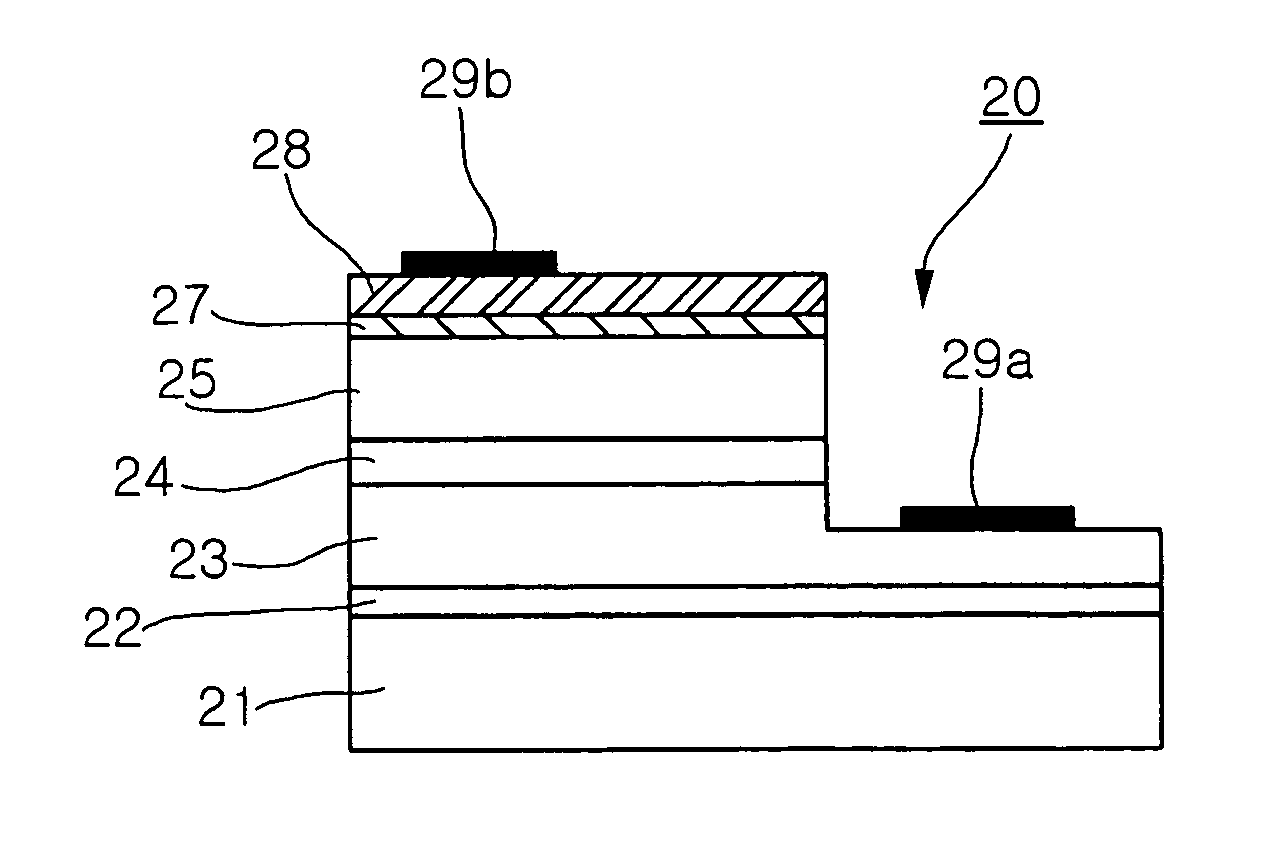

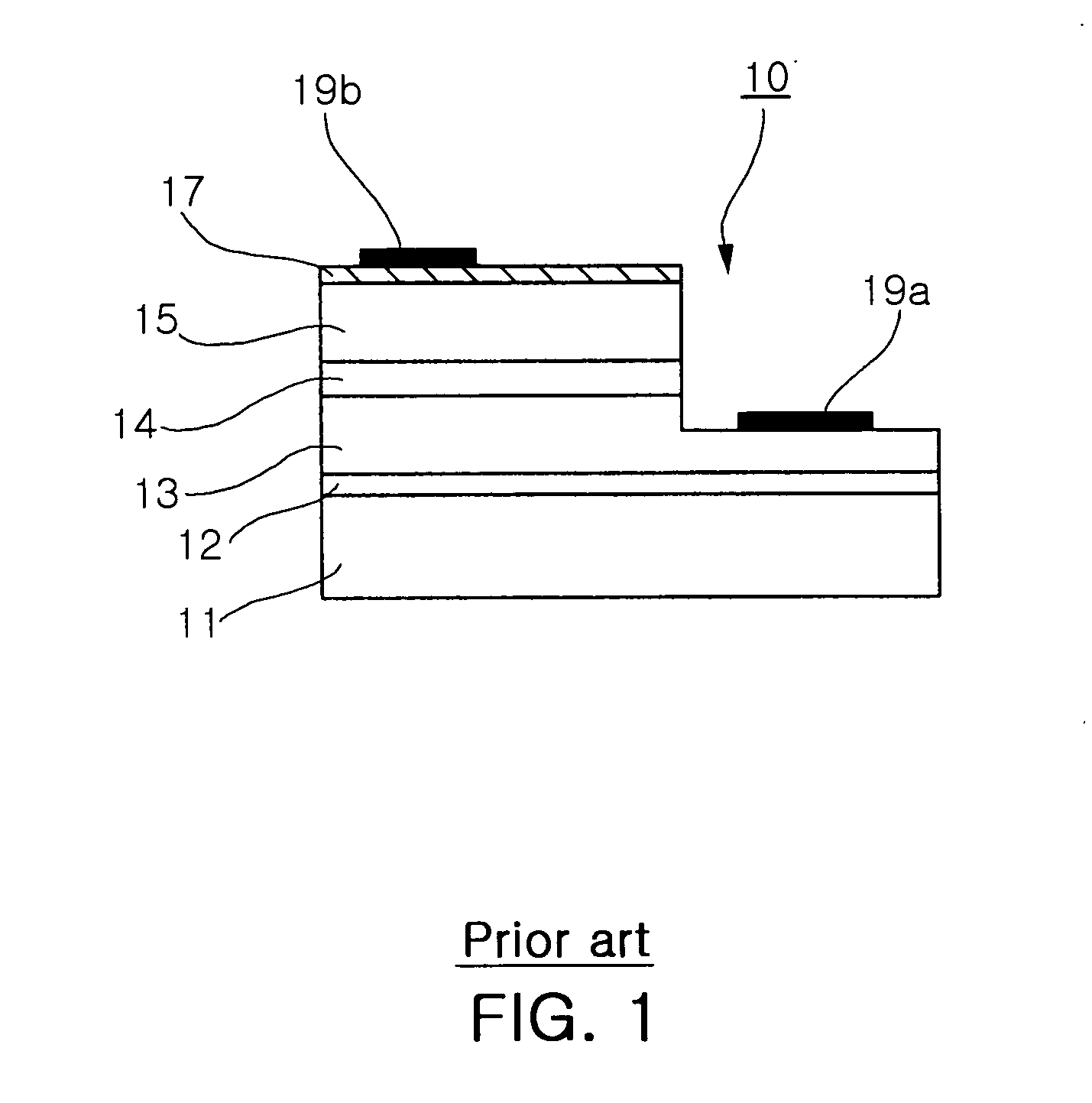

[0026]FIGS. 2a to 2d are sectional views illustrating a method of manufacturing a nitride semiconductor light emitting diode according to the invention.

[0027] The manufacturing method according to the invention, as shown in FIG. 2a, starts with forming an n-type nitride semiconductor layer 23, an active layer 24 and a p-type nitride semiconductor layer 25 sequentially on a substrate 21. The substrate 21 may be a sapphire substrate, a heterogeneous substrate made of e.g, SiC, or a homogenous substrate made of GaN. The substrate 21 may additionally include a buffer layer 22 made of e.g, AlN, GaN, or AlGaN grown at a low temperature. The nitride semiconductor layer (22,23,24 and 25) may be grown by metal-organic chemical vapor deposition (MOCVD), hydride vapor physe epitaxy (HVPE), and molecular beam epitaxy (MBE).

[0028] Thereafter, a photoresist is appli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com