High strength aluminum alloys and process for making the same

a technology of aluminum alloy and high strength, applied in the field of high strength aluminum alloy, can solve problems such as reducing toughness, and achieve the effects of reducing the amount of low melting point eutectic phases, and maximizing alloying effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

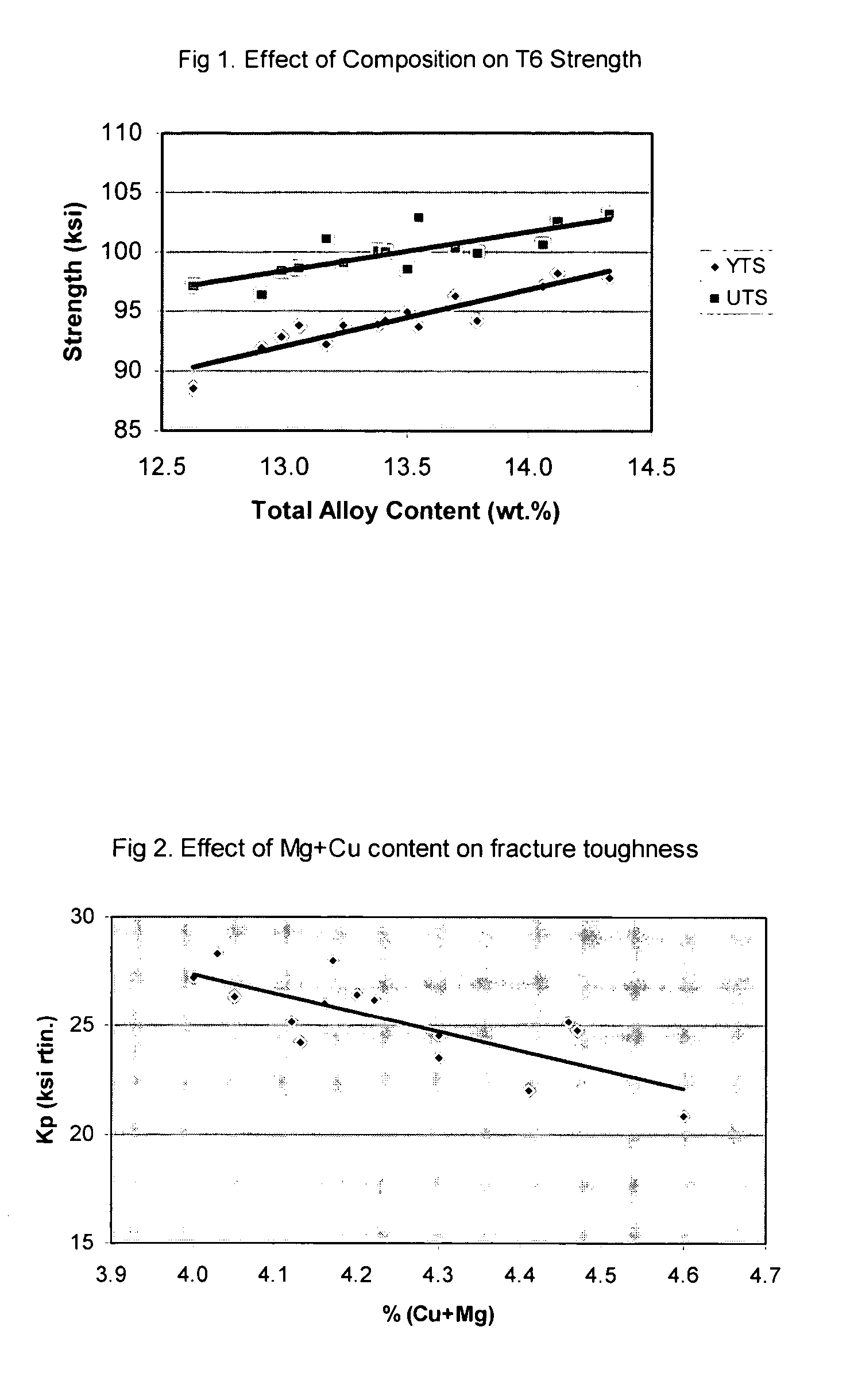

example 1

[0019] A heretofore unexplored region of the Al—Zn—Mg—Cu alloy system consists of compositions comprising about 9% to 10% zinc, 2.2% to 2.8% copper, and 1.6% to 2.0% magnesium. The alloy compositions listed in Table 1 were cast as 9-in. diameter billets: note that all these alloys contain about 0.05% scandium, an element which in combination with zirconium is effective in preventing recrystallization.

TABLE 1Alloy compositionsPercent by WeightAlloySiFeCuMgZnZrSc1790.040.072.471.838.870.140.061800.040.092.711.898.950.130.061890.040.082.141.898.600.120.051900.030.092.311.869.210.130.051910.030.112.351.819.630.130.051920.040.102.331.8710.130.120.052000.040.092.581.648.840.120.052020.040.122.461.668.870.130.052030.040.102.691.788.940.130.052040.030.102.881.588.780.120.052090.040.082.641.498.780.140.052130.030.072.421.639.650.130.052140.030.092.561.449.500.140.052150.040.092.571.739.820.120.052160.030.102.811.609.650.130.05

[0020] The billets were homogenized at 880 F. (F means degrees F...

example 2

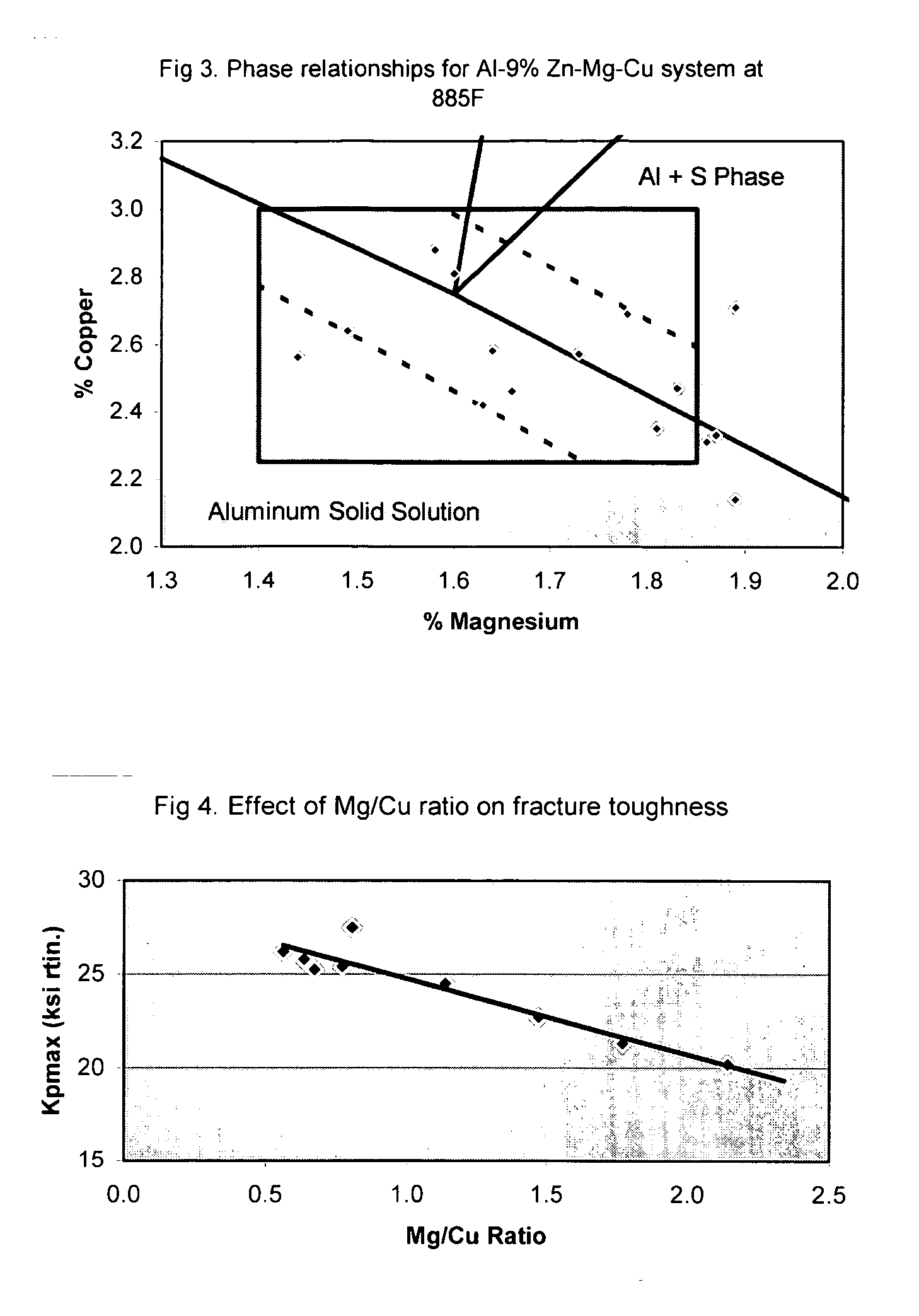

[0023] To compare the invention alloy with other commercial high-zinc alloys such as AA7036, AA7056 and AA7449, which have higher Mg / Cu ratios in the range 1.0 to 1.4, the following alloys were prepared as described in Example 1.

TABLE 3Compositions of Comparative AlloysPercent by WeightAlloy No.SiFeCuMgZnZrSc360.030.061.912.179.020.150.05390.040.051.282.749.020.130.06430.030.031.442.629.040.130.05470.040.061.592.348.950.140.06

[0024] The yield strengths and toughness values for these alloys are listed in the following table.

TABLE 4Mechanical Properties of Comparative AlloysMg / CuYieldKpmaxAlloyRatio%(Mg + Cu)Strength (ksi)(ksi rtin.)361.144.0894.924.5471.473.9393.922.7431.773.9993.921.3392.144.0292.720.2

[0025]FIG. 4 compares the toughness levels of these alloys on the basis of Mg / Cu ratio with the invention alloys, using those compositions that have similar strength levels (93-95 ksi) and total Mg+Cu contents (4.0-4.2%).

example 3

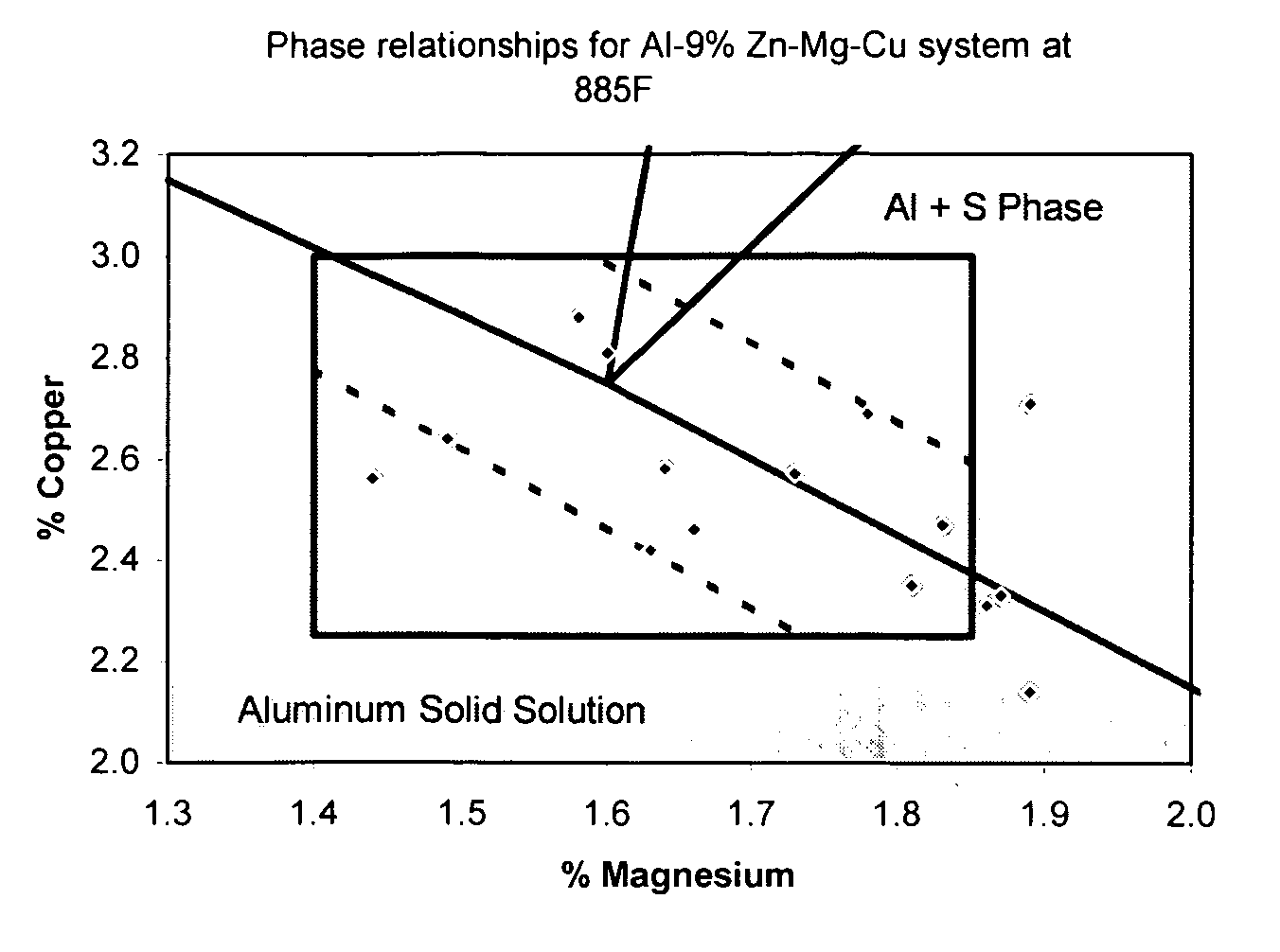

[0026] As noted earlier it is important that undissolved second phases do not remain after processing so that fracture toughness can be maximized. This is especially important in alloys that are rich in alloy content, and lie near an equilibrium solvus phase boundary. To illustrate how homogenizing practice can affect the amount of such undissolved phase(s), samples of as-cast AA7068 alloy billet were heated from 850 F. at various rates in a differential scanning calorimeter (DSC), and the energy associated with eutectic melting, which started at about 885 F. was measured. This energy measurement is directly proportional to the amount of undissolved second phase remaining at the incipient melting point, and the relationship between these factors has been determined by quantitative microscopy. FIG. 5 shows how heating rate affects the amount of this phase as determined from the DSC data.

[0027] Note that a slow heating rate of about 10 F. / hr reduces the amount of second phase to a le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com