Film formation method and apparatus for semiconductor process

a film and semiconductor technology, applied in the direction of wing accessories, door/window fittings, coatings, etc., can solve the problems of increasing parasitic capacitance, increasing background level, and deteriorating inter-substrat uniformity in the composition of deposited films, so as to improve the uniformity of inter-substrat composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

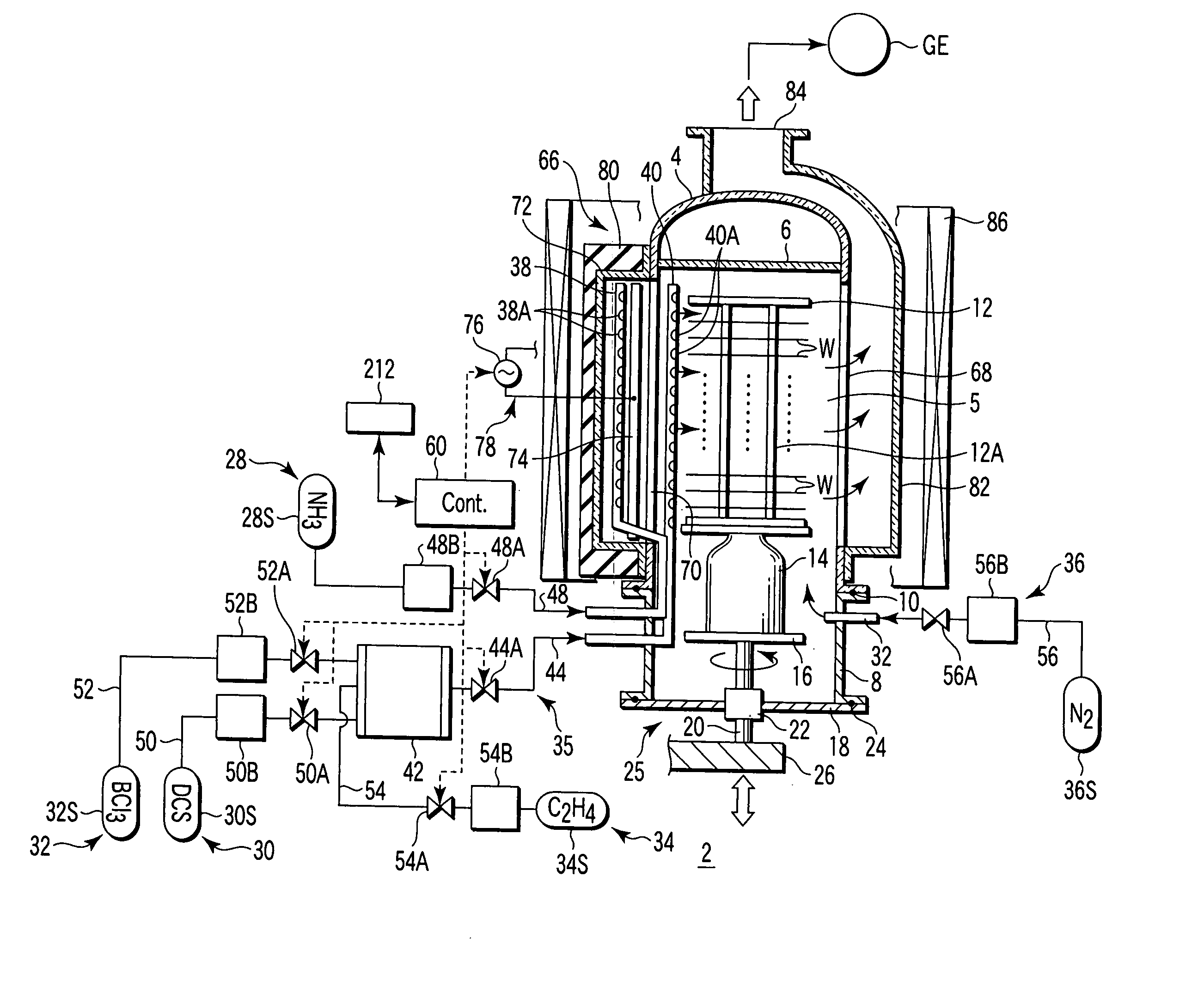

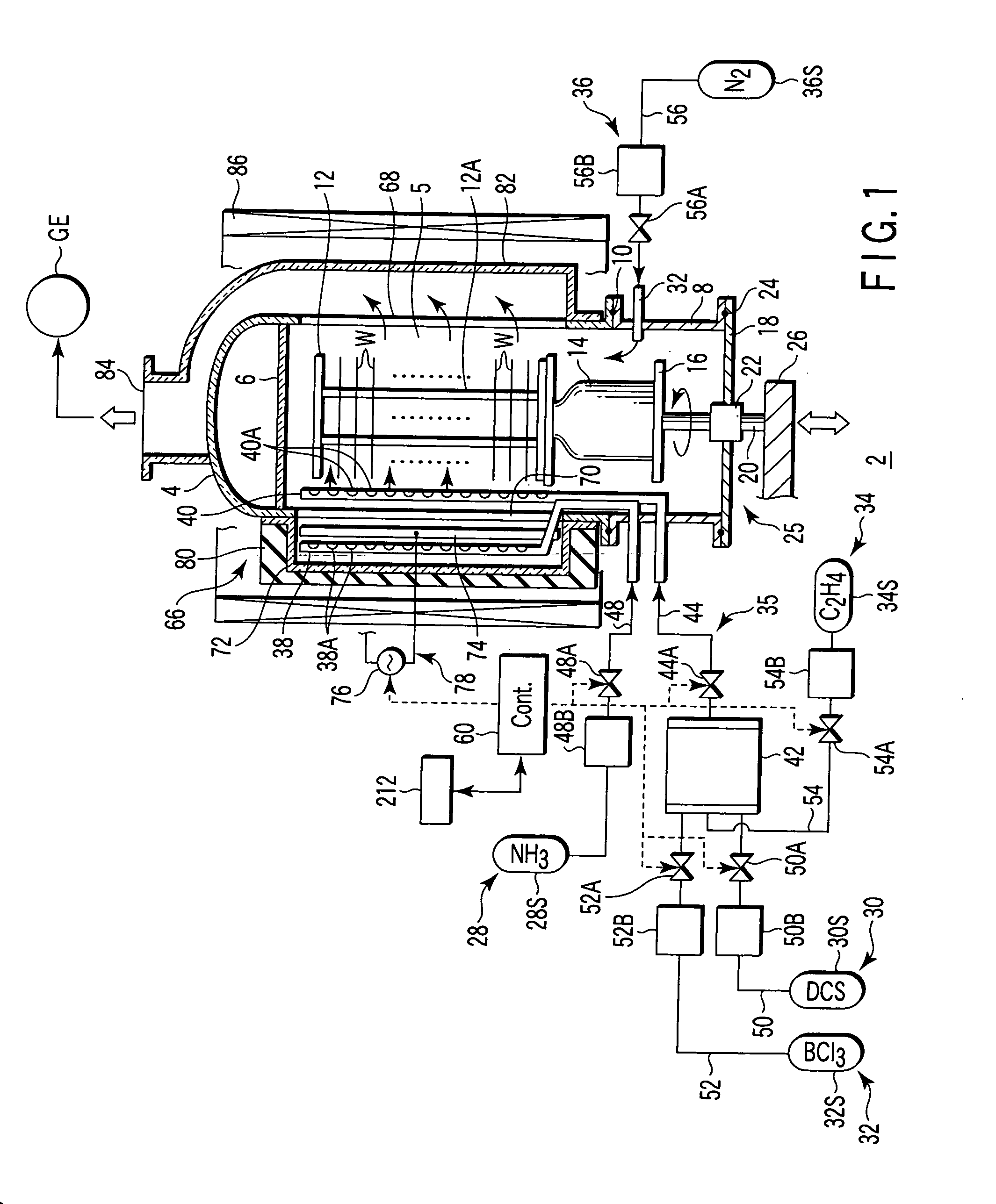

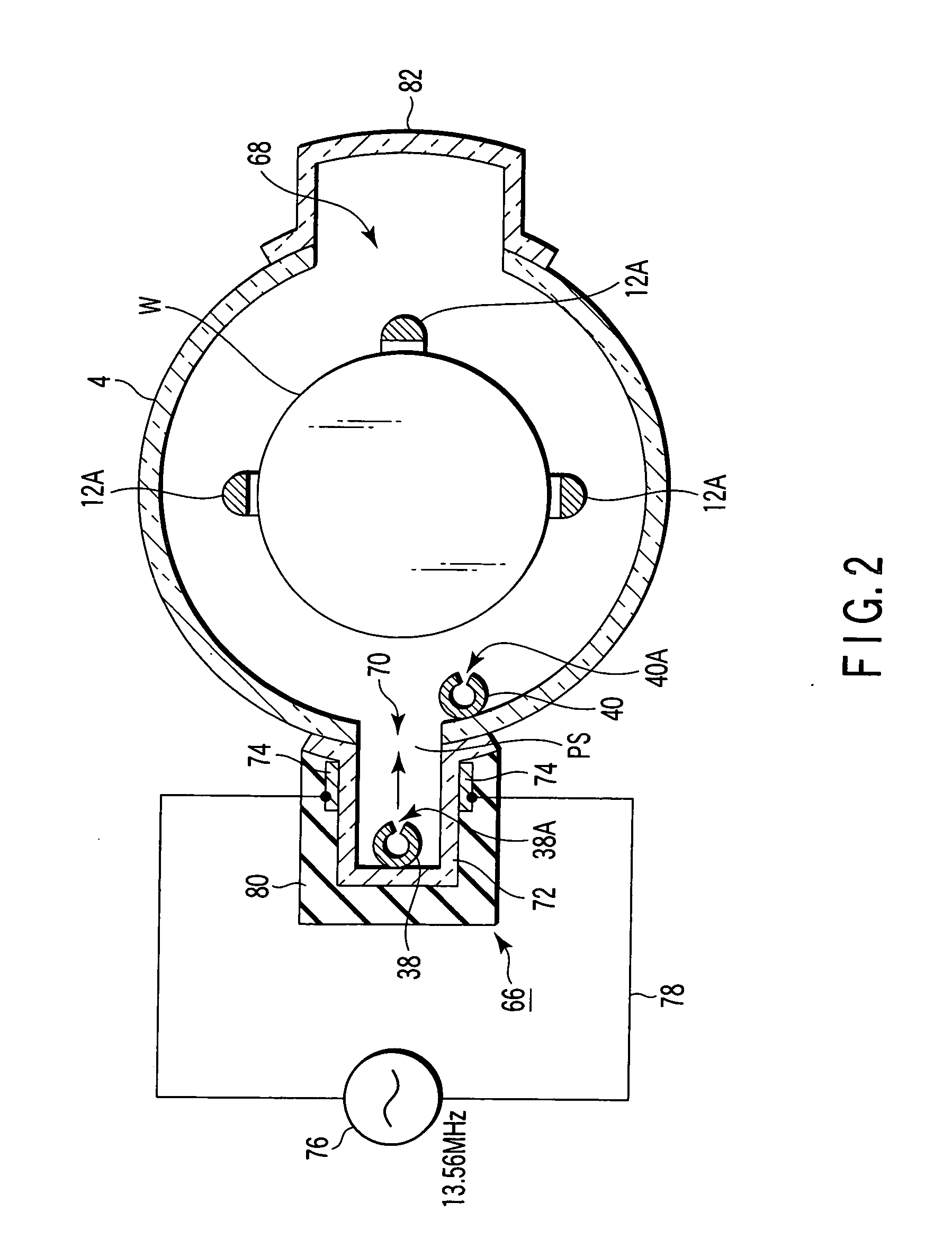

[0084]FIG. 1 is a sectional view showing a film formation apparatus (vertical CVD apparatus) according to the present invention. FIG. 2 is a sectional plan view showing part of the apparatus shown in FIG. 1. The film formation apparatus 2 has a process field configured to be selectively supplied with a first process gas containing dichlorosilane (DCS) gas as a silane family gas, a second process gas containing ammonia (NH3) gas as a nitriding gas, and a third process gas containing BCl3 gas as a boron-containing gas. The film formation apparatus 2 is configured to form an SIBN (boron doped silicon nitride) film on target substrates by CVD in the process field. Accordingly, the boron-containing gas is used as a doping gas. The process field is further configured to be selectively supplied with a fourth process gas containing C2H4 gas (ethylene gas) as a carbon hydride gas, as needed.

[0085] The apparatus 2 includes a process container 4 shaped as a cylindrical column with a ceiling an...

second embodiment

[0125]FIG. 4 is a sectional view showing a film formation apparatus (vertical CVD apparatus) according to the present invention. This film formation apparatus 2X has the same structure as the film formation apparatus 2 shown in FIG. 1 except for the first, third, and fourth process gas supply circuits 30, 32, and 34 and the mixture gas supply circuit 35. Accordingly, an explanation will be give of the film formation apparatus 2X, focusing on the difference from the film formation apparatus 2.

[0126] In the film formation apparatus 2X, the first, third, and fourth process gas supply circuits 30, 32, and 34 are connected to a common mixture gas supply circuit 35X. The mixture gas supply circuit 35X includes a mixture gas supply pipe 40X configured to mix the first and third process gases, and further the fourth process gas in addition thereto, as needed. The mixture gas supply pipe 40X is formed of a quartz pipe, which is a proximal end portion of a gas distribution nozzle 40.

[0127] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com