Textile information carrier and method for producing a textile information carrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

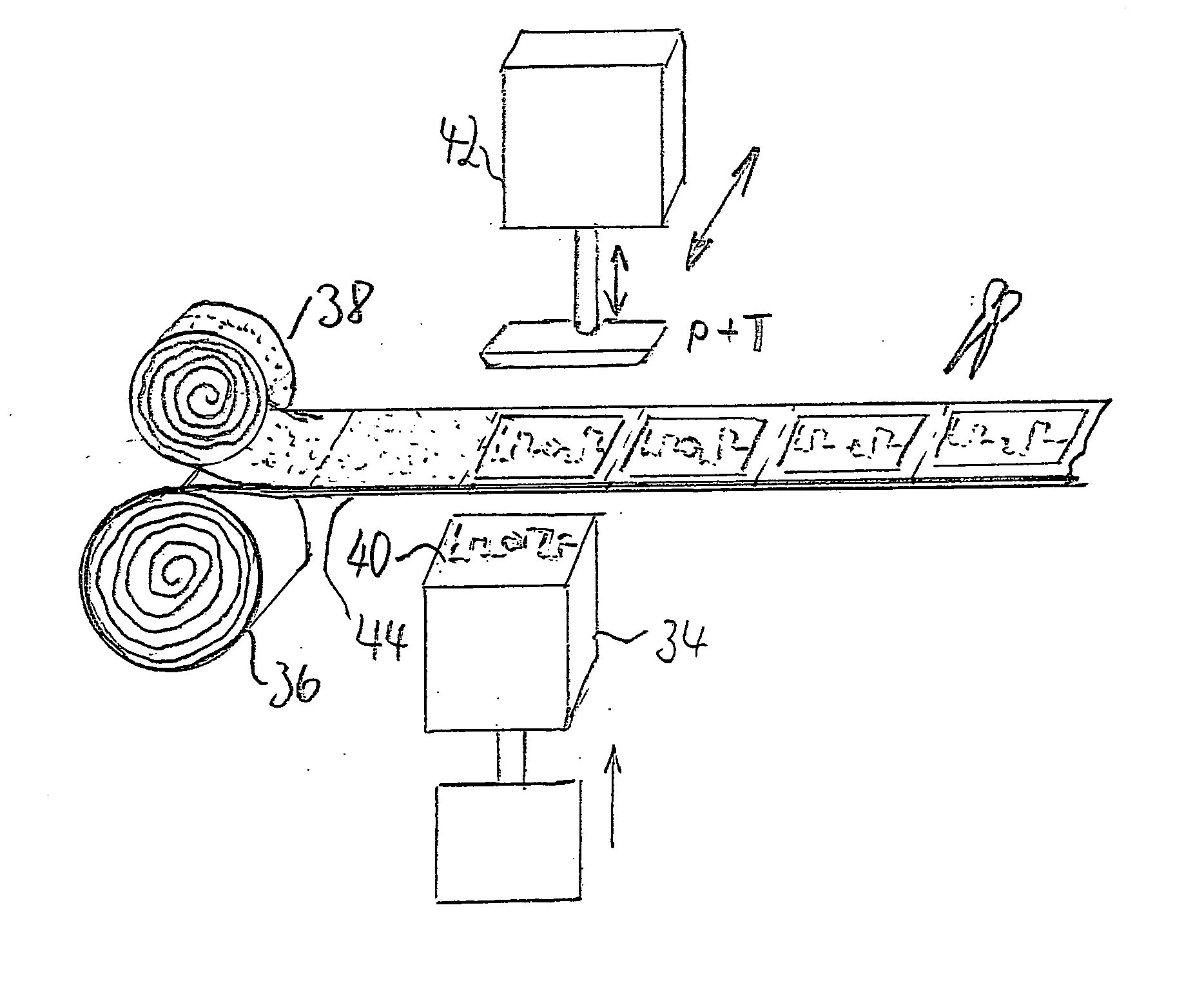

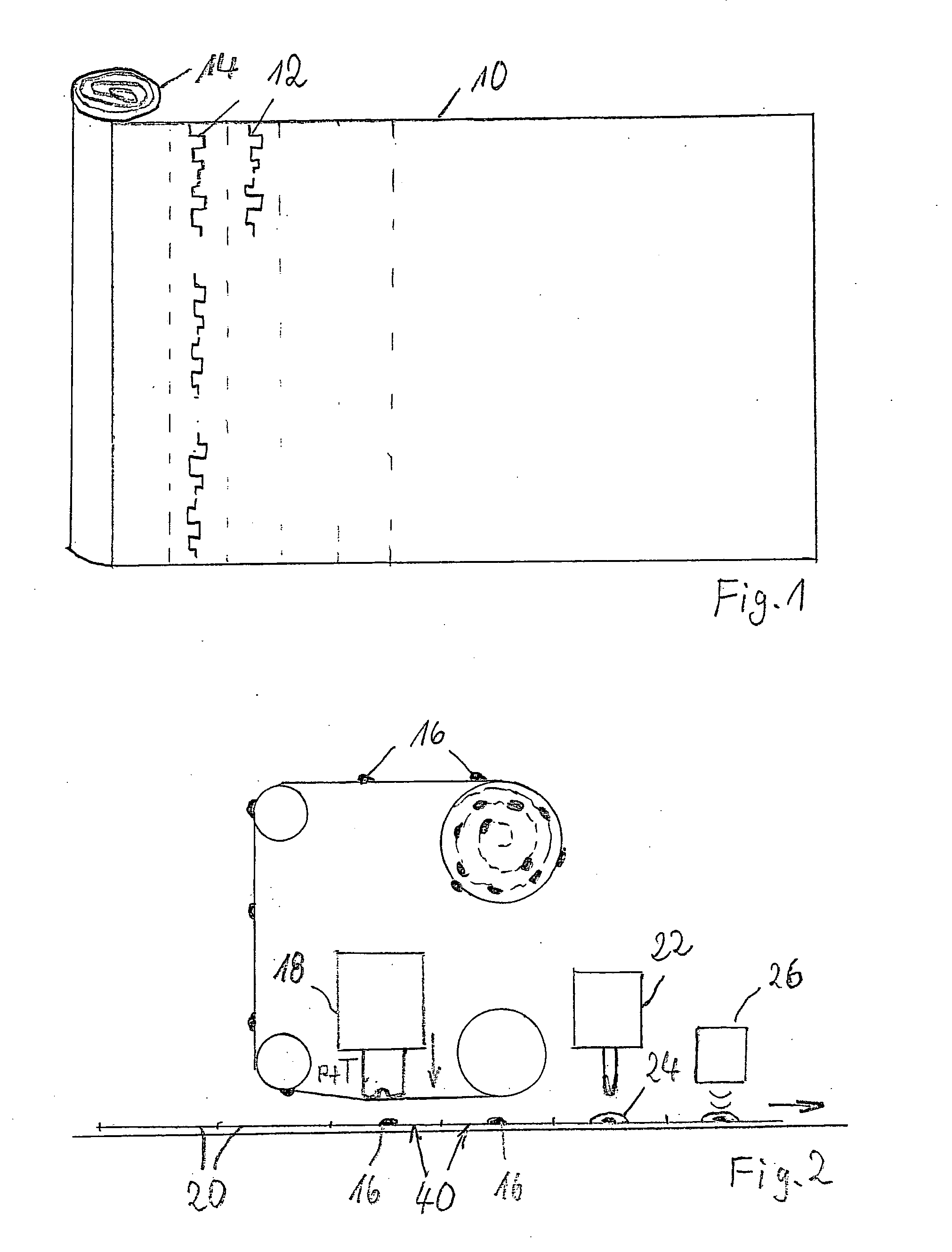

[0095]FIG. 1 shows an embroidery base 10, also designated as embroidery web, with embroidered structures of textile antennae 12. Fabrication takes place on an embroidery machine conventionally used in the textile industry. For this purpose a section of embroidery base 10 from a roll 14 is fixed as raw material in an embroidery frame of the embroidery machine over the height and width of the embroidery frame and the structures of textile antennae 12 are embroidered in the selected pattern repeat over the entire width of the embroidery frame of the knitting machine. The embroidery base 10 located on the roll 14 can be provided with an adhesive film.

[0096] The embroidery process is then repeated line by line over the height of the embroidery base. The embroidered section of the embroidery base 10 is then cut from the roll 14 and a new section from the roll 14 is clamped in the embroidery frame and embroidered in similar fashion. The individual textile detection wafers with the antenna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com